Heat radiation hole punching device of cast aluminum end cover

A technology of punching device and heat dissipation hole, which is applied in the field of casting stamping, can solve the problems of difficult mold adjustment of cast aluminum end caps, inability to fix the end caps, and easy deviations, so as to avoid secondary rework, improve versatility, and improve The effect of punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

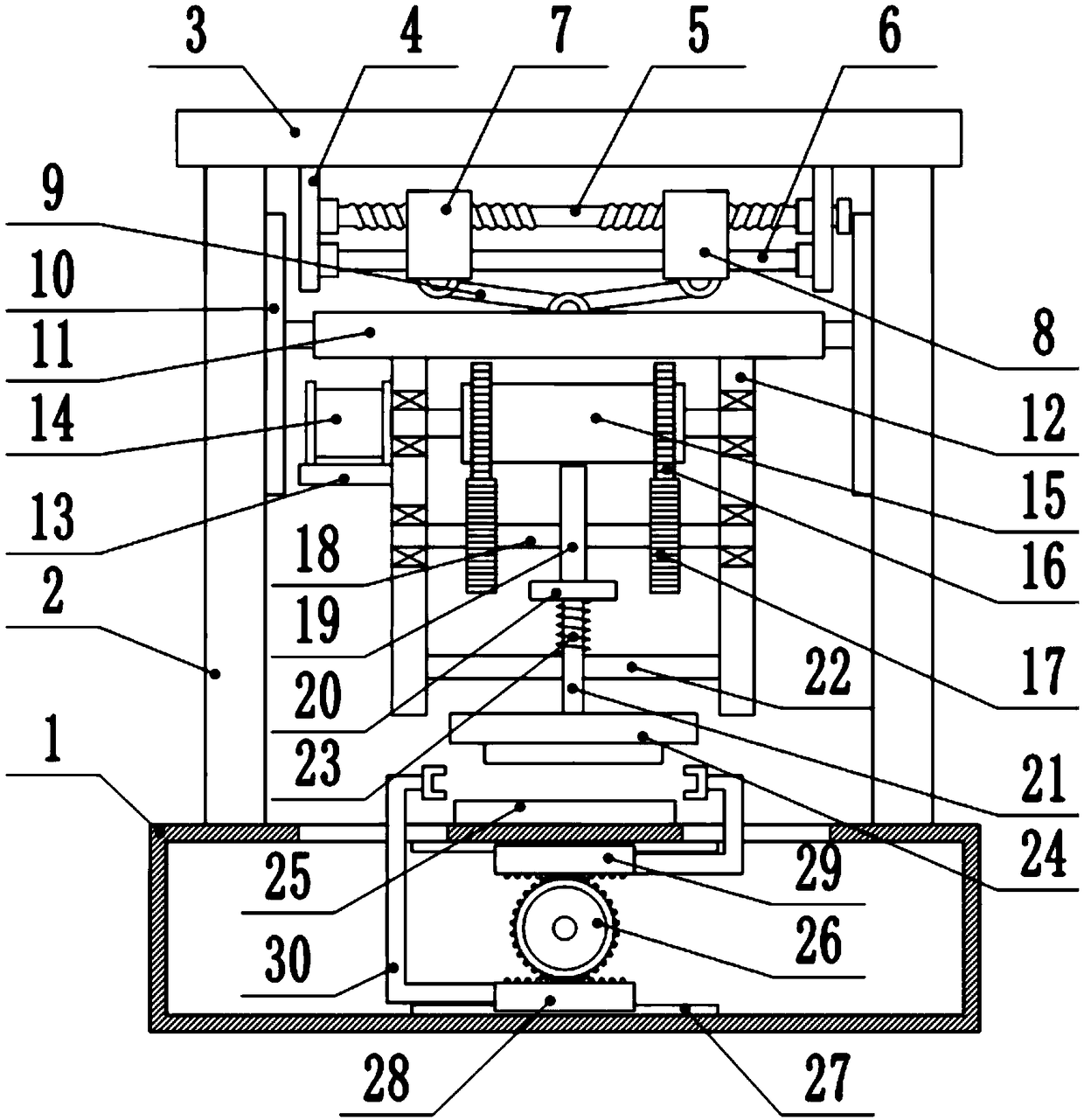

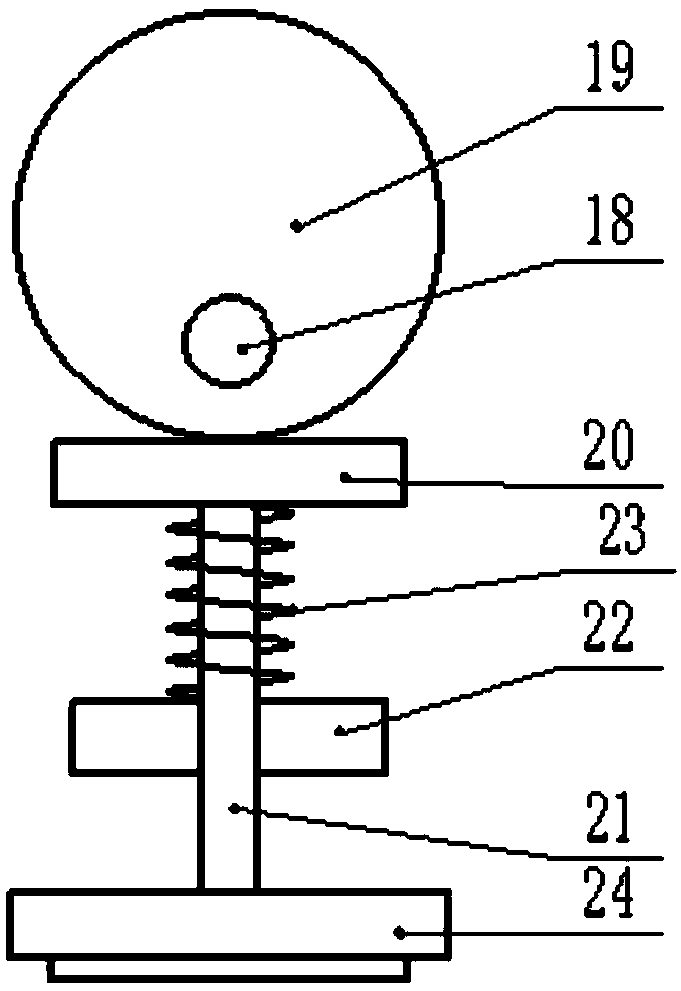

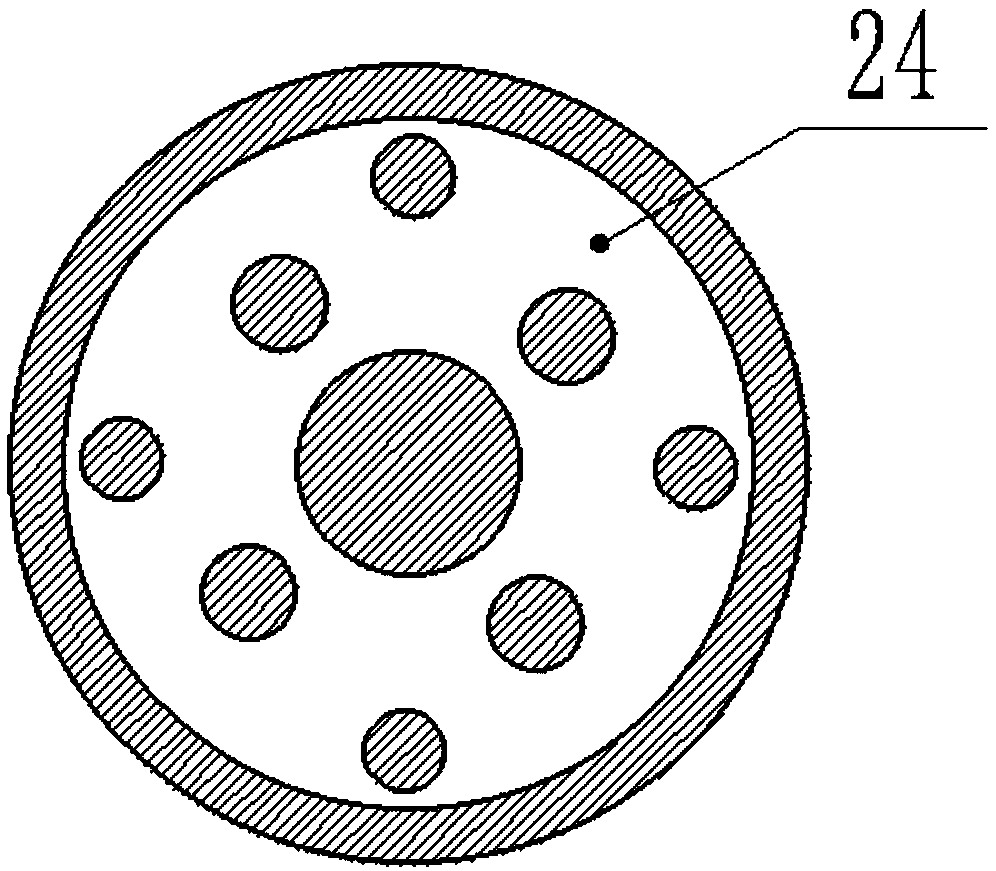

[0022] see Figure 1-3 , a cooling hole punching device for a cast aluminum end cover, comprising a base 1, a lifting plate 11, a punching head 24, a placement table 25 and a clamping arm 30, the left and right sides of the upper surface of the base 1 are symmetrically provided with columns 2, and the columns 2 is provided with a top plate 3, and the top plate 3 is welded to the column 2. The lower side of the top plate 3 is symmetrically provided with a mounting plate 4, and the mounting plate 4 and the top plate 3 are fixedly connected by self-tapping screws. Between the mounting plates 4 on both sides, a threaded screw 5 is installed through bearing rotation. The right end of the threaded screw 5 passes through the mounting plate 4 and is fixedly connected with a rocking wheel. The left and right parts of the threaded screw 5 are threaded and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com