Structural composition and method

A composite material and chemical combination technology, applied in the field of reinforced polymer composite materials, can solve problems such as complexity, increased material and labor costs, and achieve low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

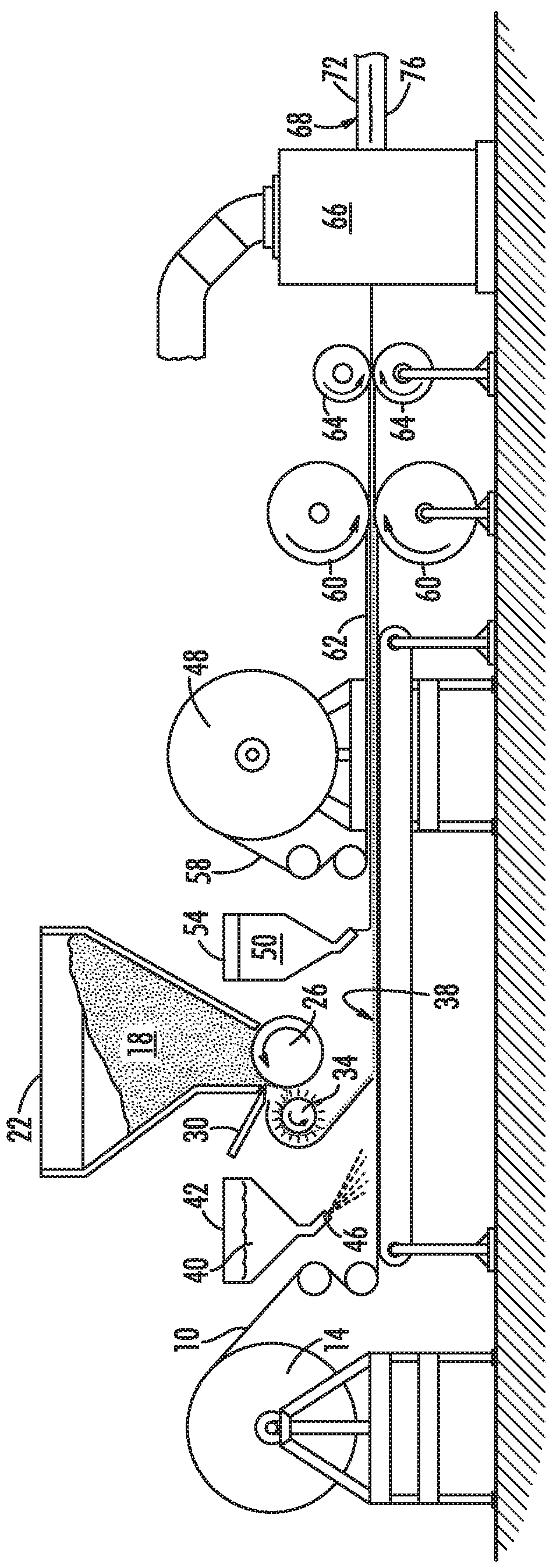

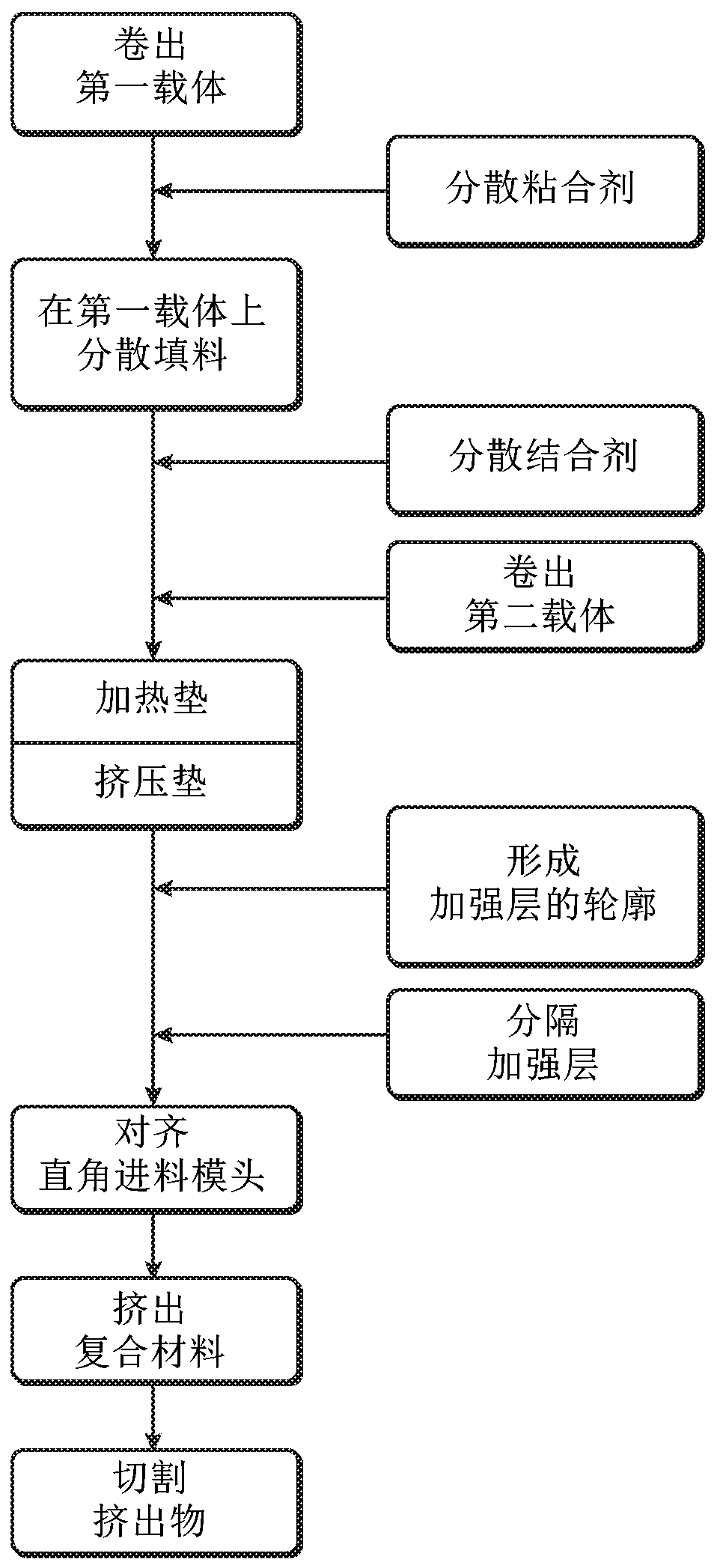

Method used

Image

Examples

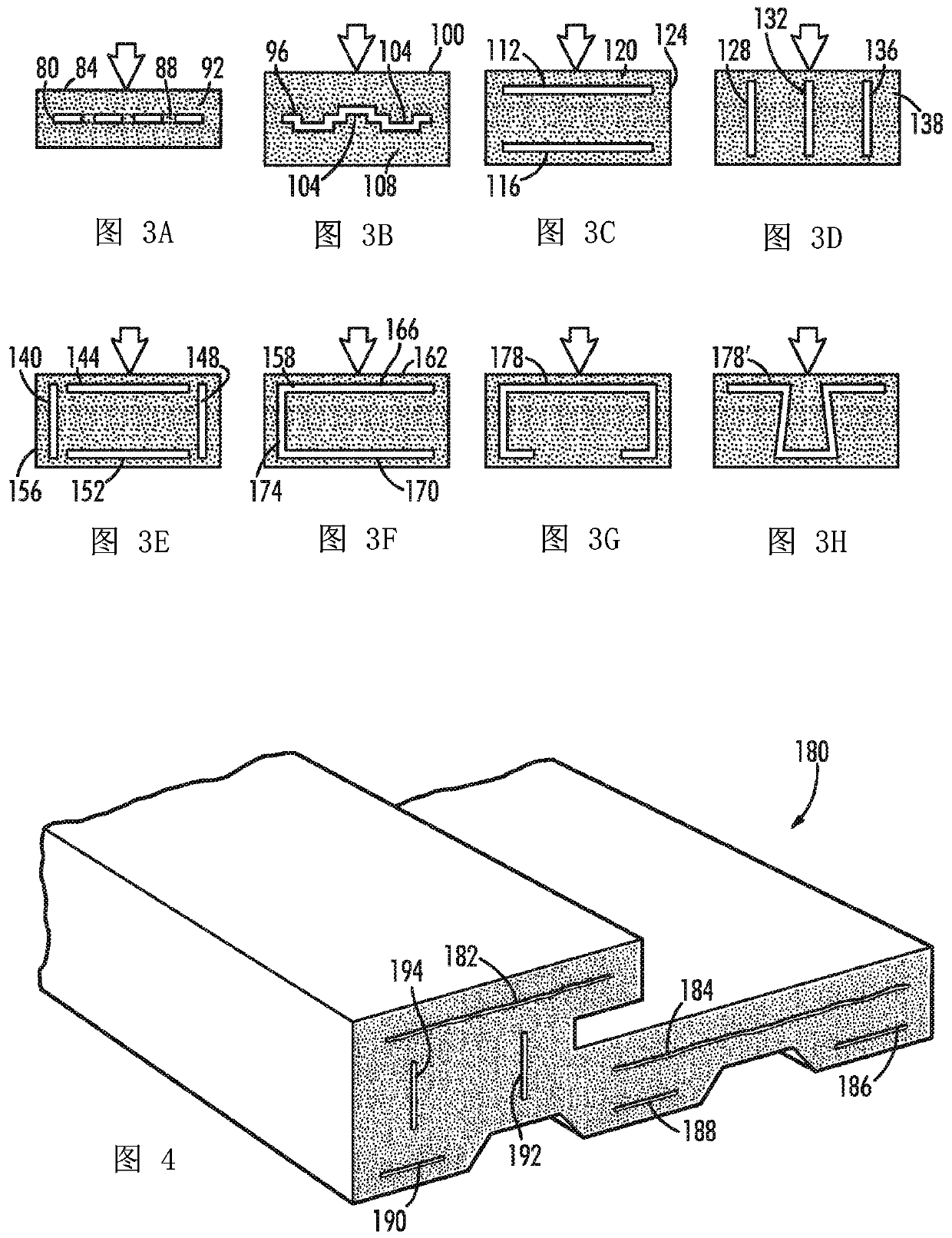

Embodiment Construction

[0032] The structural composites described herein are heterogeneous compositions that possess compressive strength and stiffness, enabling their use as wood substitutes in a wide variety of applications, including those where applicable building code requirements. Additionally, the structural composites of the present invention can replace other materials, such as aluminum, that have a higher modulus of strength than wood. The term heterogeneous means that at least some of its constituents are concentrated within the structural composite rather than uniformly dispersed. The present composite material can be engineered, meaning that its external shape and its components and their position and shape can be chosen to meet the strength and stiffness required for the particular task the composite material will be placed into. As a simple example, the present structural composite can be designed with stiffeners spaced from the neutral axis, similar to the flanges of an I-beam, provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com