Patents

Literature

40results about How to "Avoid secondary rework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

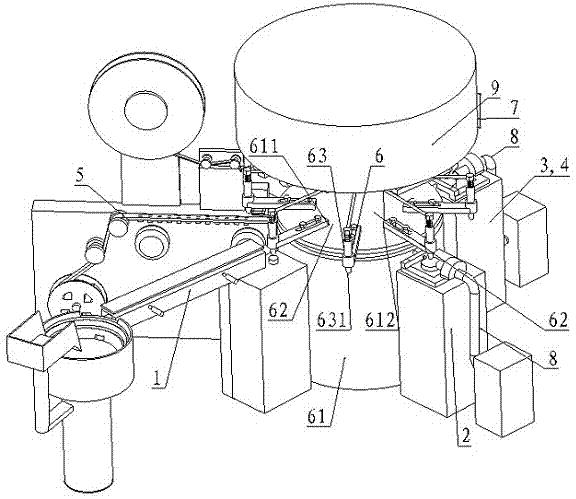

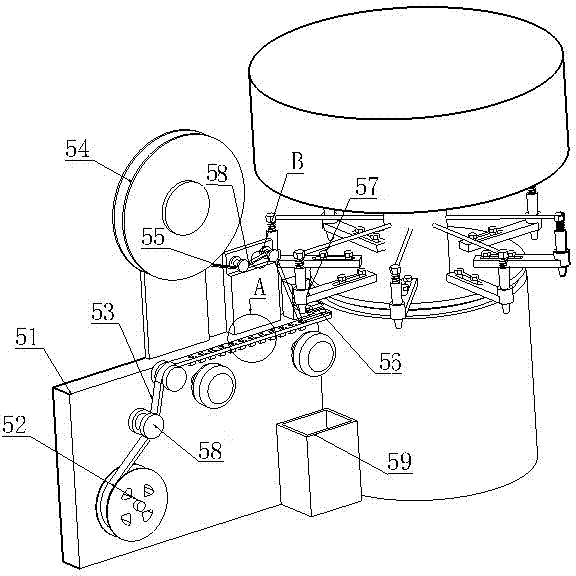

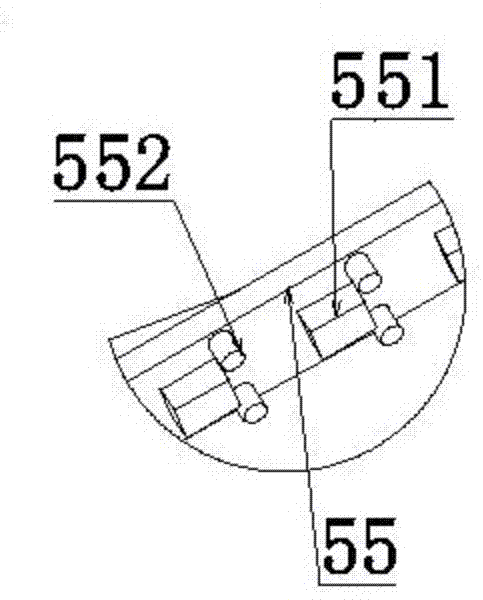

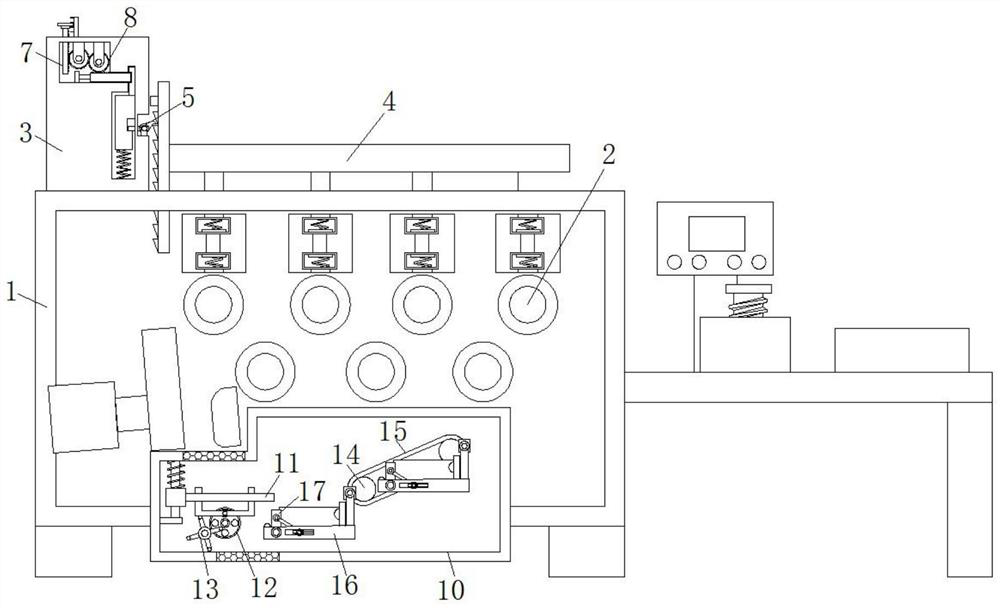

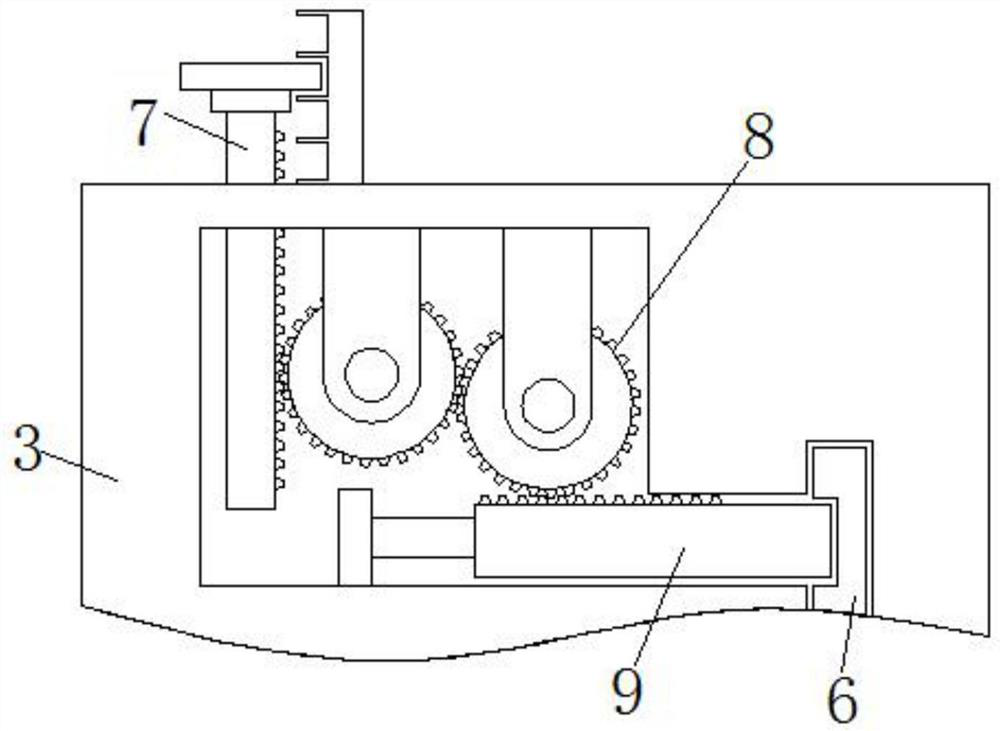

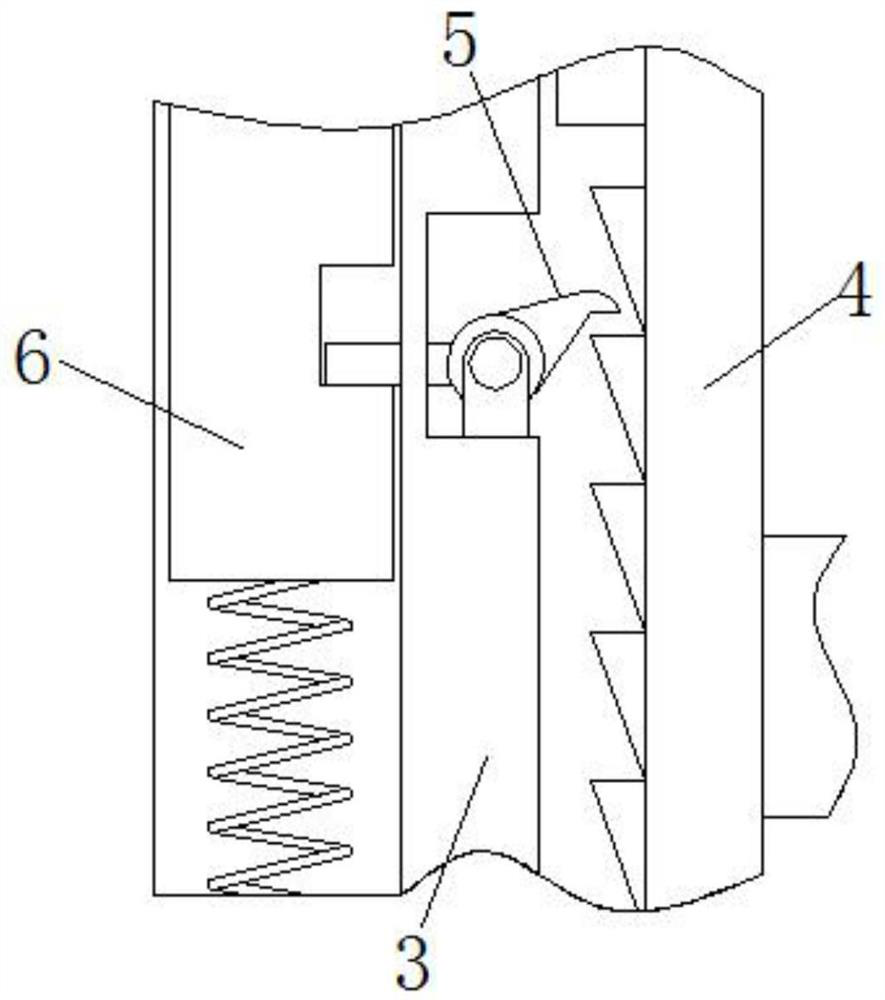

Automatic chip detection and packaging production line

InactiveCN104733340ARealize one by one detectionImprove detection accuracySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProduction lineCapacitance

The invention discloses an automatic chip detection and packaging production line which comprises a chip transmission device, a suction pump and a rotary disc. The rotary disc moves circumferentially in the vertical axial direction of the suction pump, an annular groove is further formed in the portion, connected with the rotary disc, on the suction pump, and the portion, located on the annular groove, of the rotary disc is further connected with multiple suction devices. Each suction device is provided with a nozzle, the rotary disc is further connected with a power source, and the power source drives the rotary disc to drive the suction devices to rotate. An automatic feeding station, a structural size detection station, a current detection station, a capacitance detection station and a packaging station are sequentially connected to the periphery of the chip transmission device and all the stations and the transmission device are connected with a microcomputer control device. Automatic detection conducted on assembly line production after chips are manufactured and automatic packaging conducted after detection can be achieved, the accuracy degree of automatic detection of the production line and the quality of the chips are improved, secondary rework is avoided, and labor cost is saved.

Owner:兴化市华宇电子有限公司

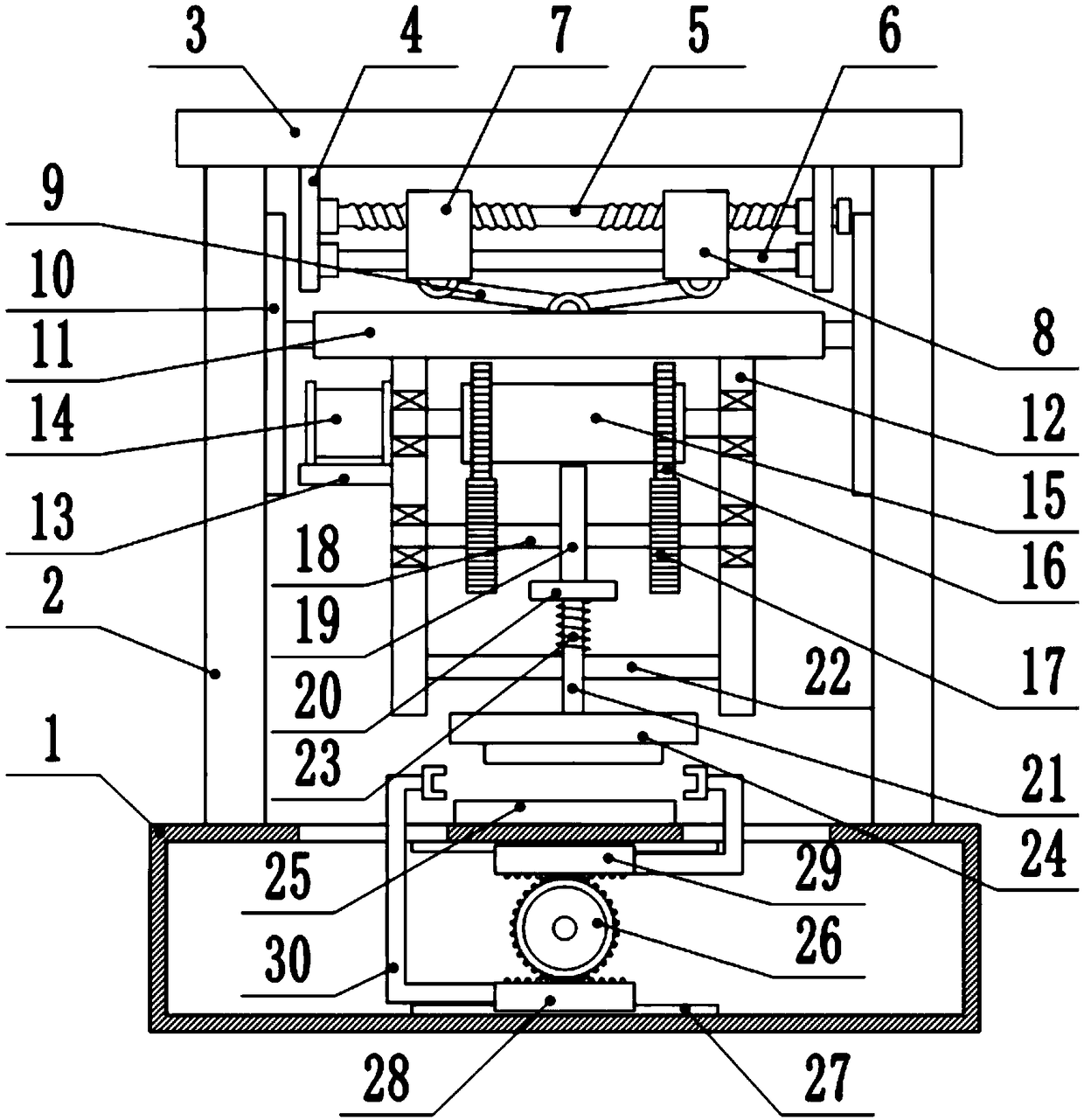

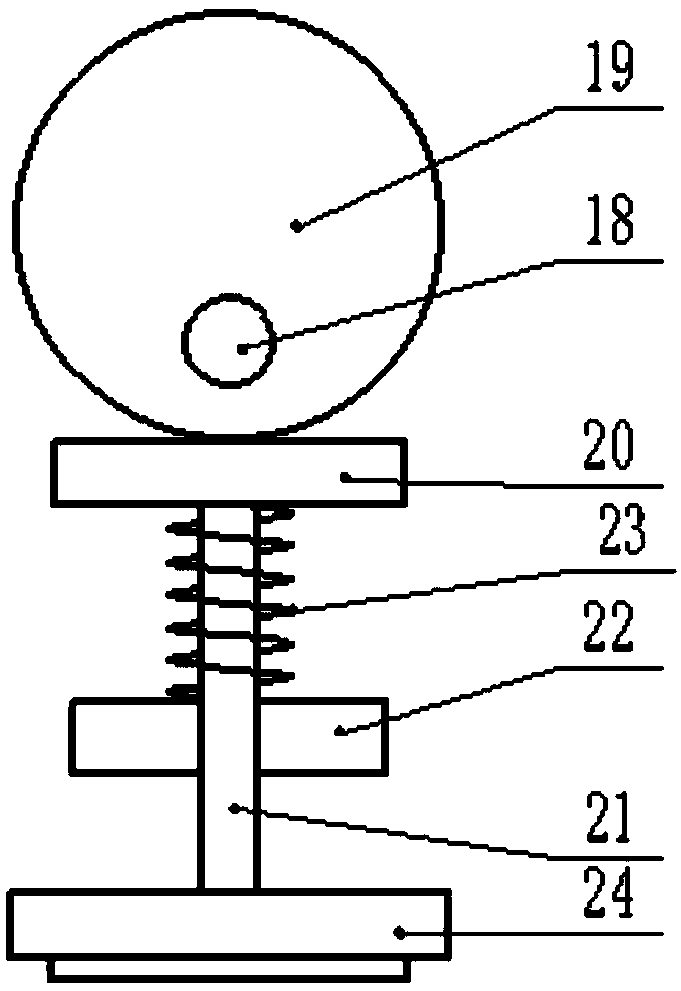

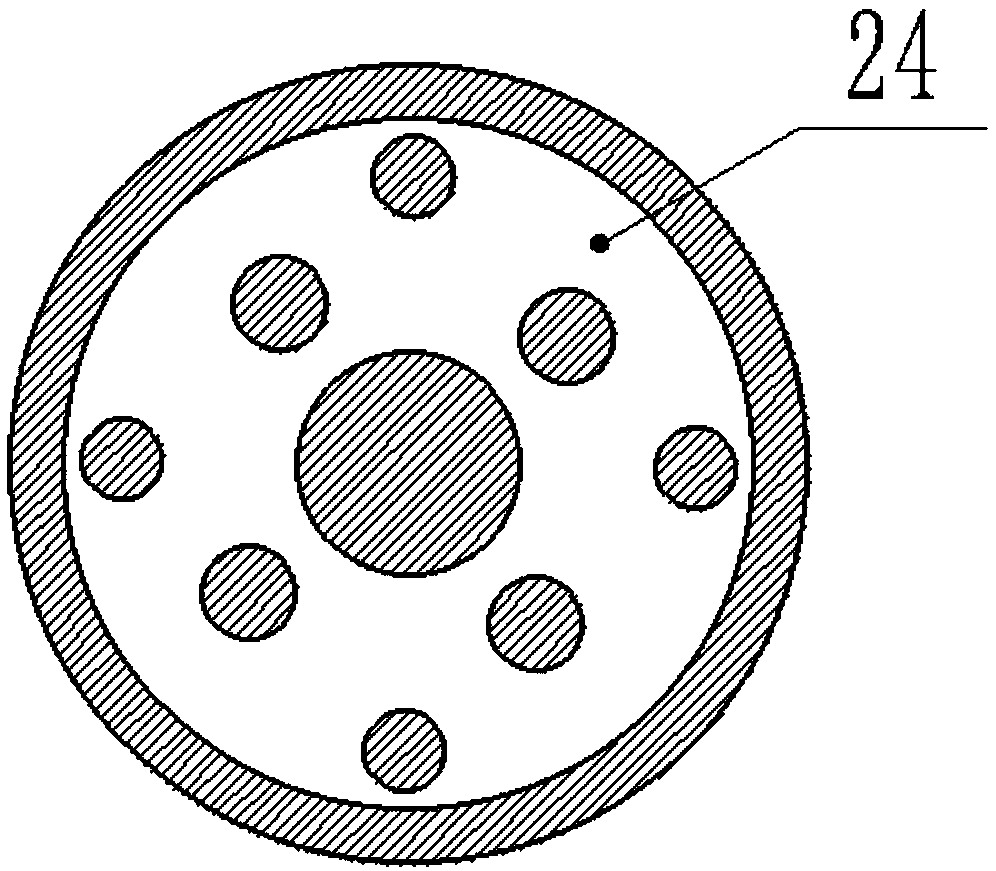

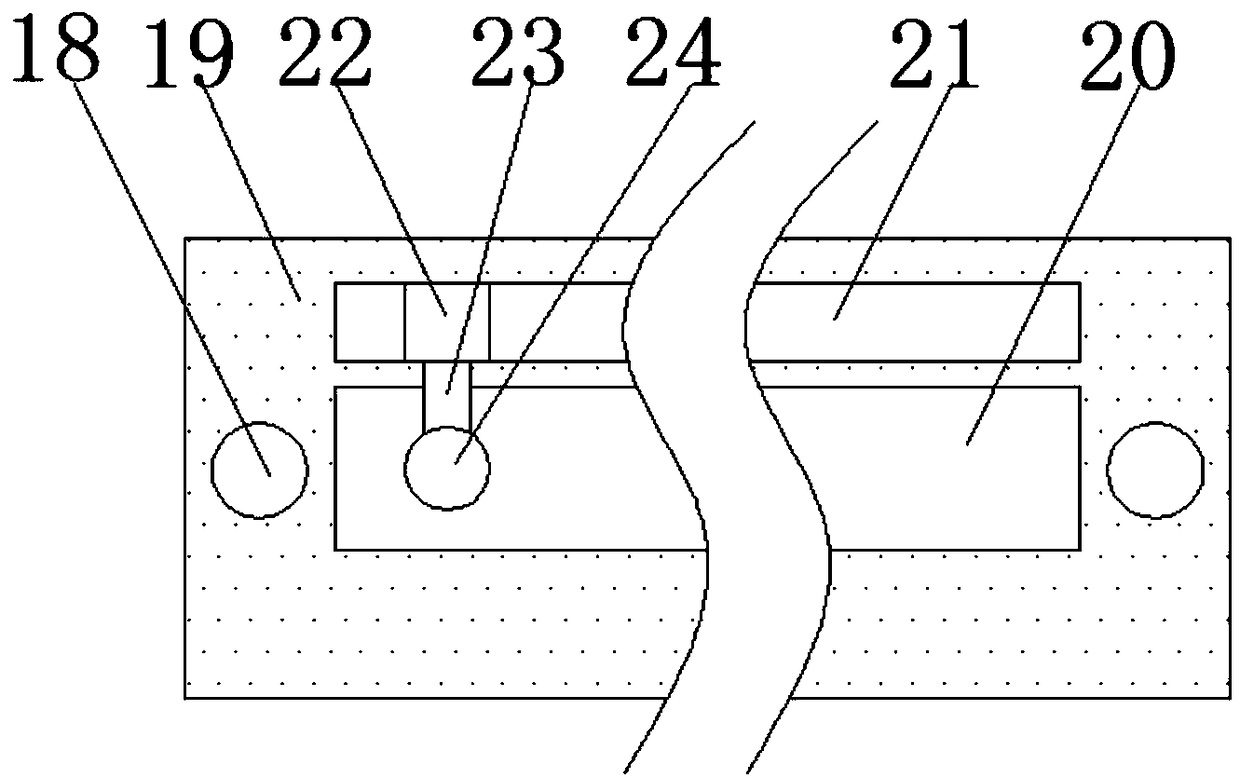

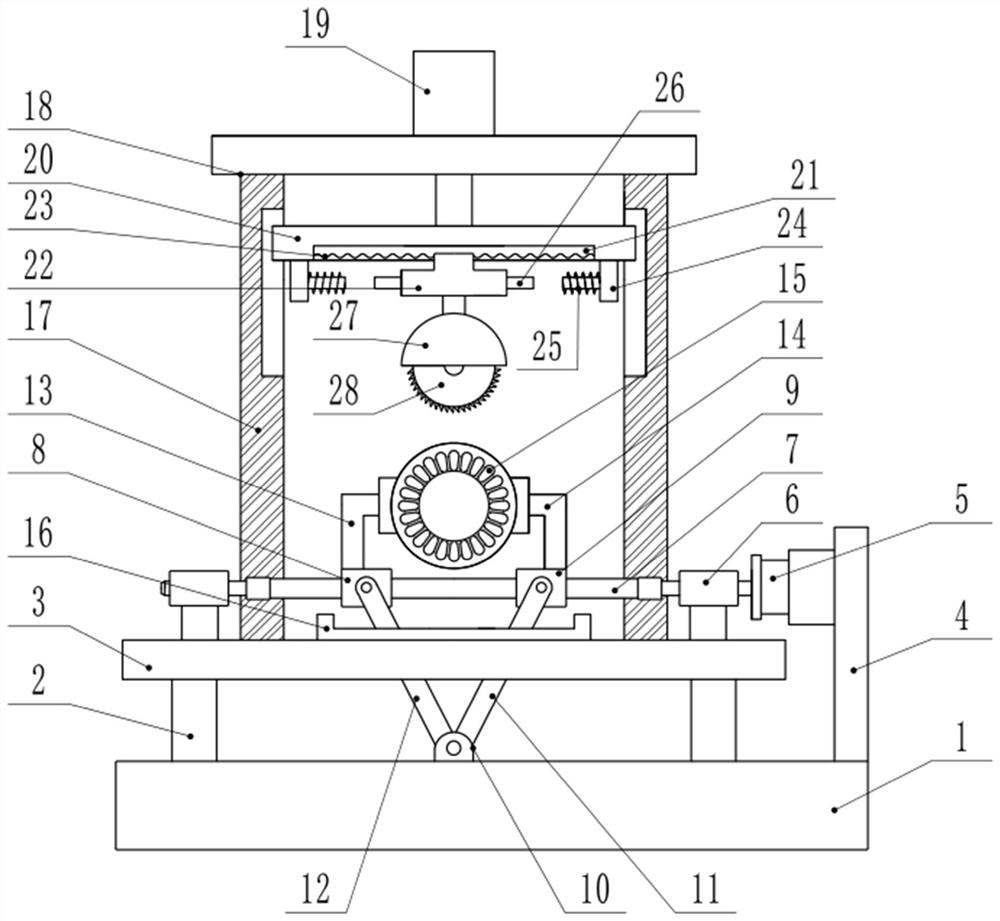

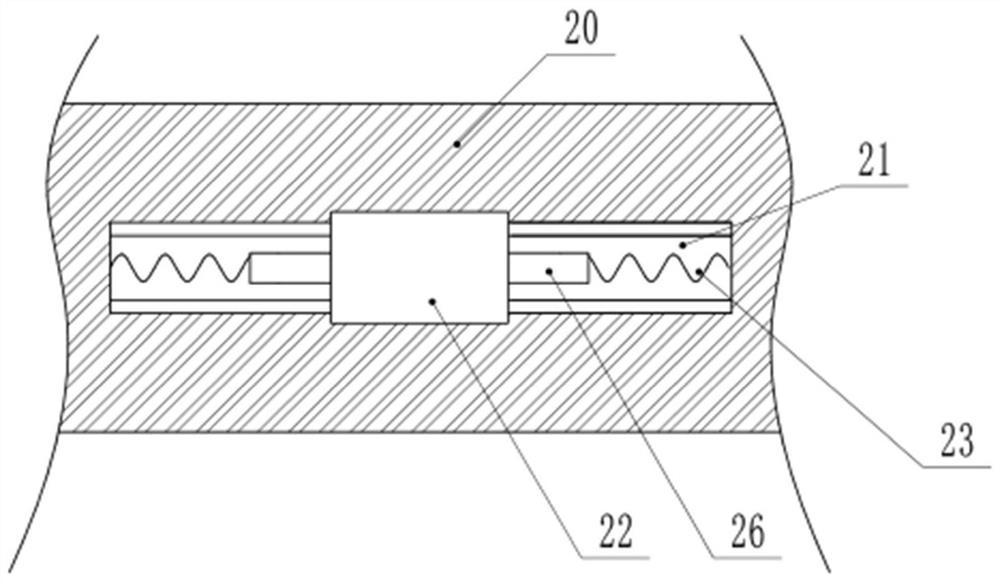

Heat radiation hole punching device of cast aluminum end cover

The invention discloses a heat radiation hole punching device of a cast aluminum end cover. The heat radiation hole punching device comprises a base, a lifting plate, a punching head, a containing table and clamp arms. A cam is fixedly mounted on a connecting shaft. A connecting plate is fixedly mounted between fixed plates located on the left side and the right side. An ejection rod is mounted atthe center position of the connecting plate in a sliding manner, and the punching head is fixedly mounted at the lower end of the ejection rod. The interior of the base is of a hollow structure, anda gear is rotationally mounted at the center position in the base through a rotating shaft. The right side of an upper rack and the left side of a lower rack are fixedly connected with the clamp armscorrespondingly. The position of the punching head is changed, and therefore punching work is carried out on cast aluminum end covers of different end face heights, and universality of the device is greatly improved; a drive motor rotates constantly, and therefore the punching head moves up and down to achieve continuous punching on the cast aluminum end cover; and compared with an existing primary punching device, the situation that primary punching is not achieved in place to cause secondary reworking can be effectively avoided, the punching efficiency is greatly improved, and the situationof secondary reworking is avoided.

Owner:盐城市顺天铸造有限公司

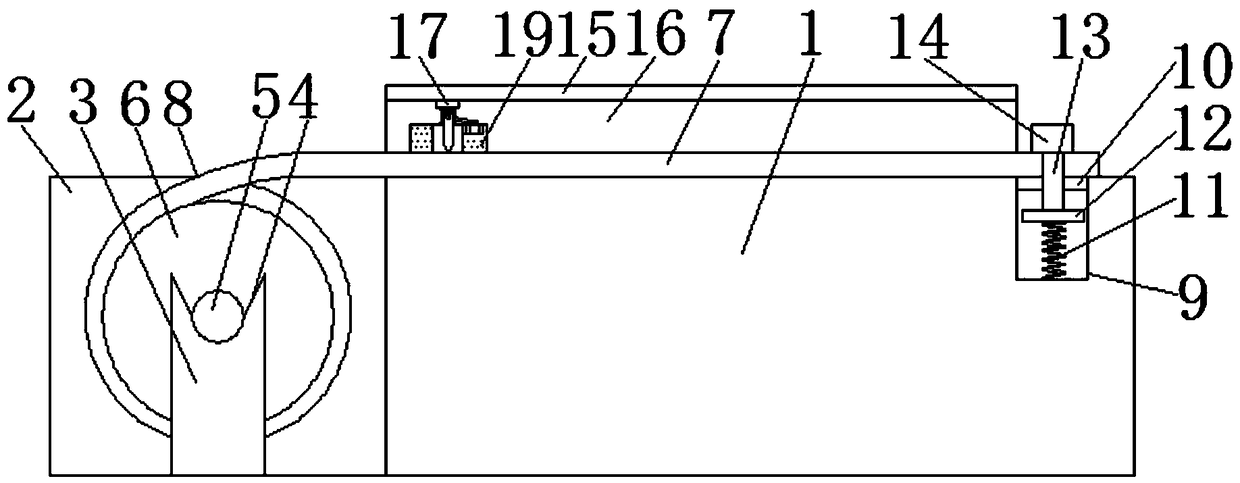

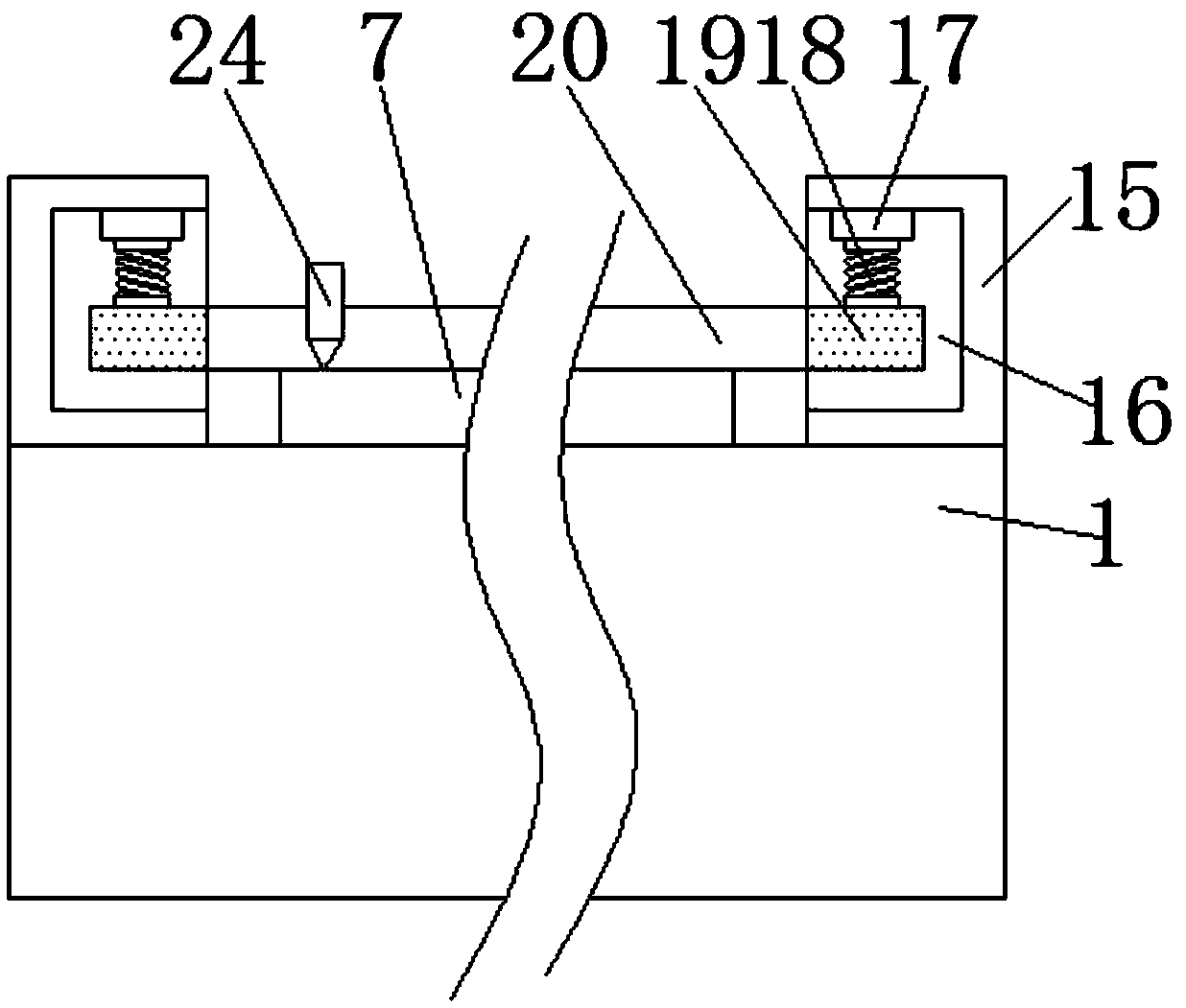

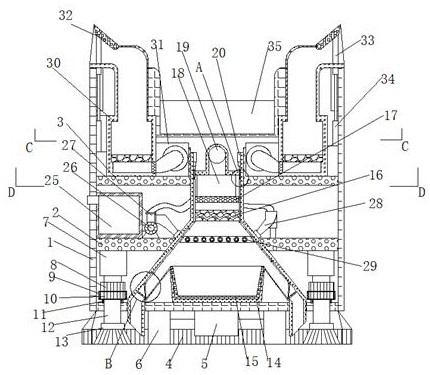

Device for cutting textiles

ActiveCN108823951AEffective finishing and levelingEffectively fixedSevering textilesEconomic benefitsEngineering

The invention discloses a device for cutting textiles. The device comprises a workbench, a rolling box is fixedly connected to the right side face of the workbench, supporting blocks are fixedly connected to the bottom of the inner wall of the rolling box, and placement grooves are formed in the upper surfaces of the supporting blocks; rotary shafts are movably connected to the interiors of the placement grooves, rolling shafts are fixedly connected to the outer walls of the rotary shafts, the textiles are fixedly connected to the outer walls of the rolling shafts, and a discharging opening isformed in the upper surface of the rolling box. By means of the device for cutting the textiles, pressing blocks are arranged at the ends, away from sliding blocks, of limiting springs, the textilescan be effectively finished to be flat when cut, and the situation is avoided that the flatness of notches is influenced during cutting due to the existence of wrinkles; meanwhile, the pressing blockscan effectively fix the textiles, the situation is avoided that the flatness of the notches is influenced when the textiles are not stably fixed during cutting, the qualified rate of the notches canbe effectively increased after the textiles are cut, the situation of rework is avoided, and greater economic benefits are created for enterprises.

Owner:江苏盛斯达纺织科技有限公司

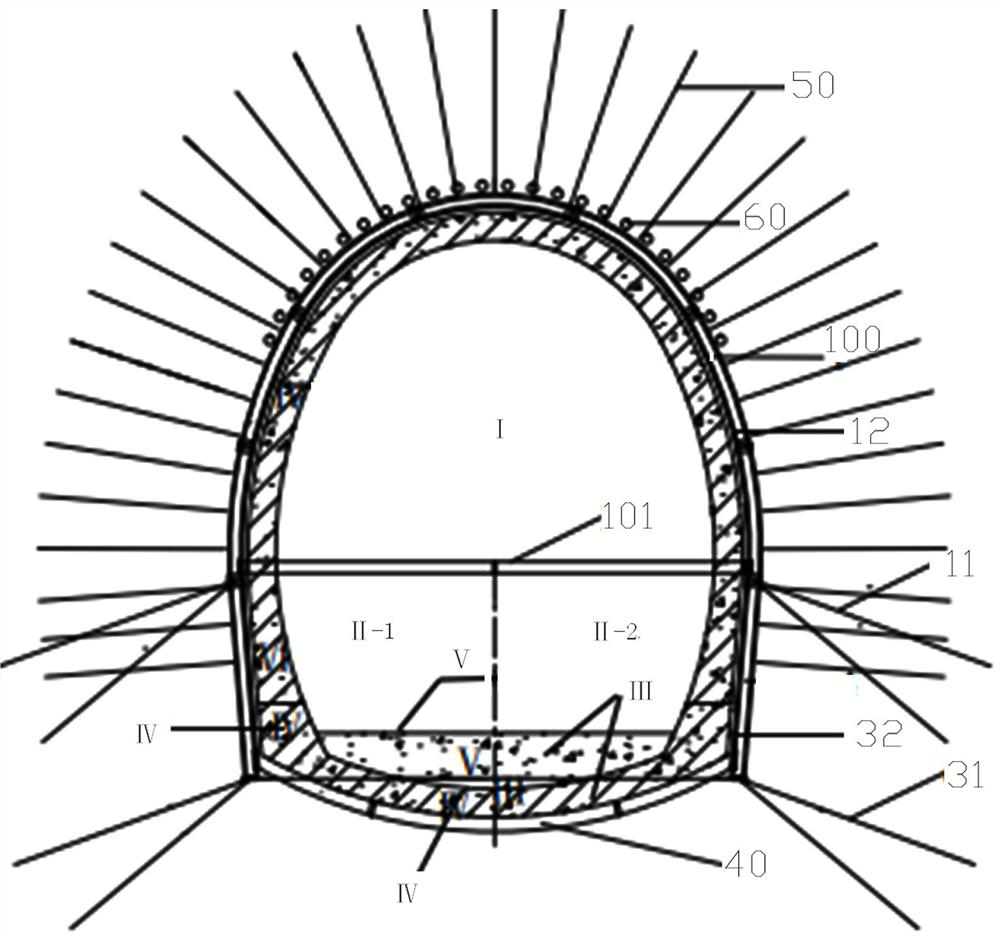

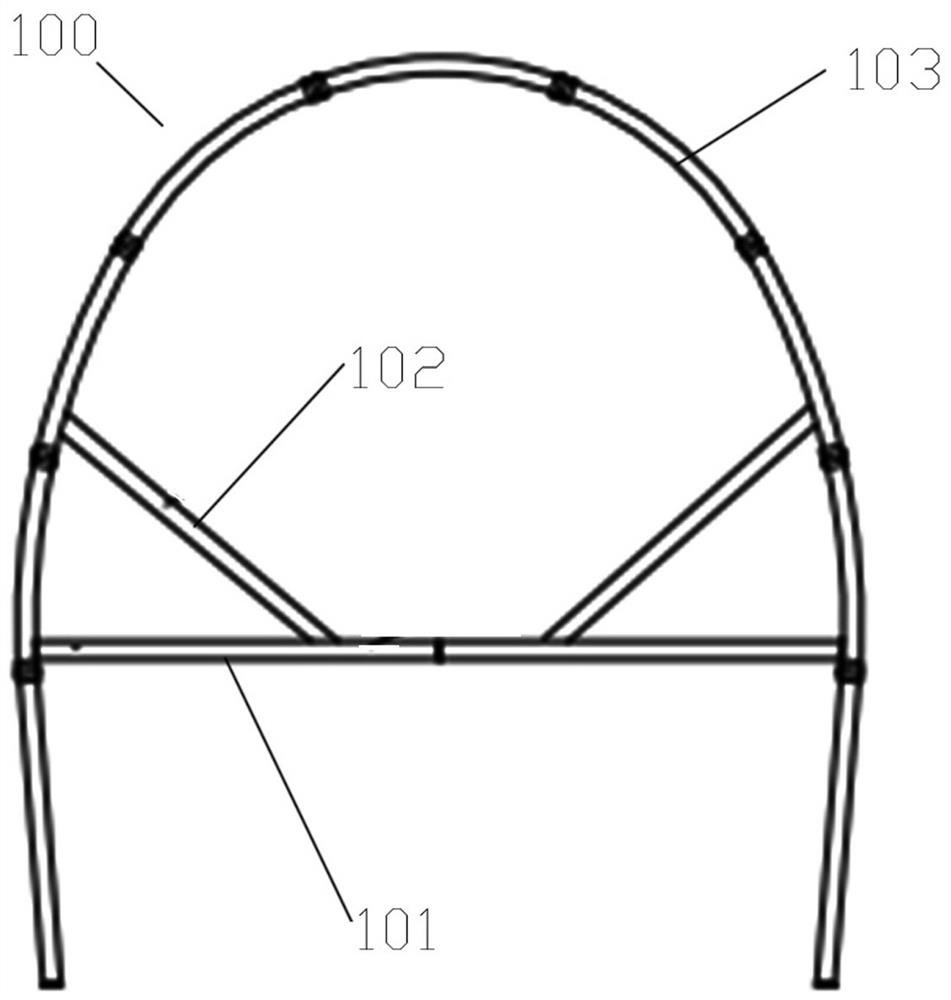

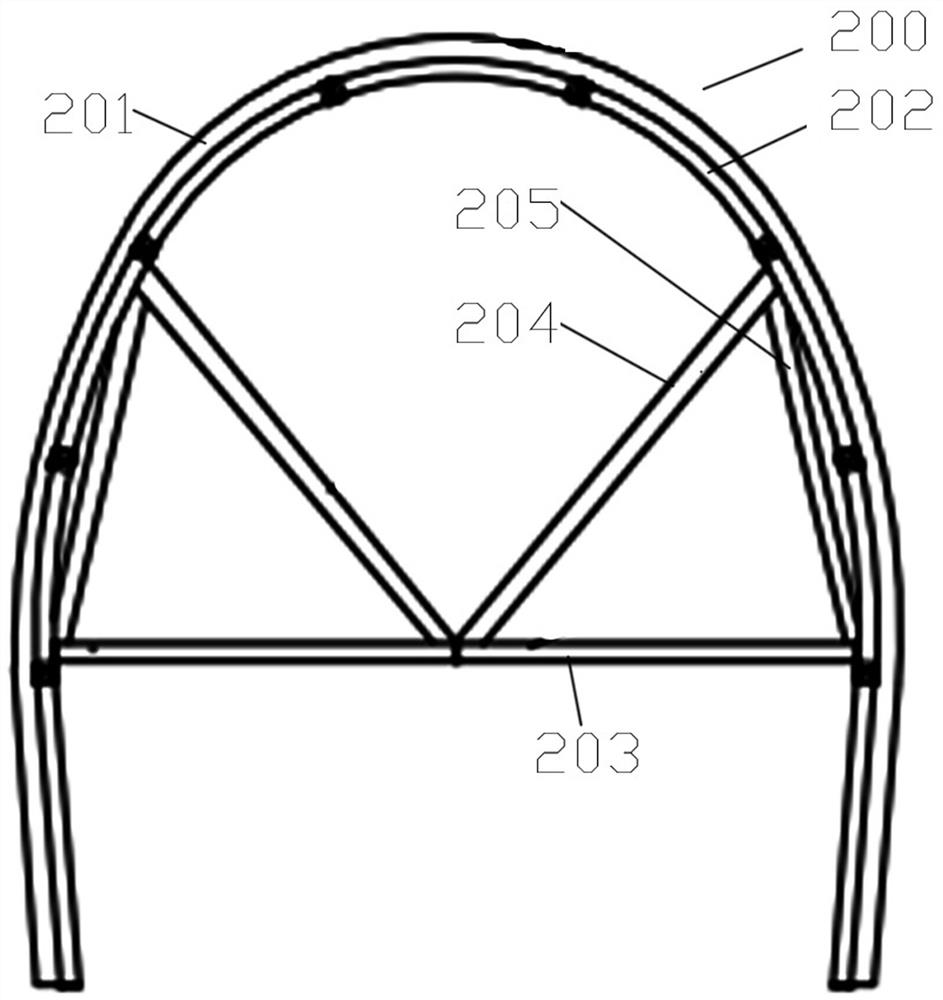

Supporting method suitable for large deformation of mudstone tunnel

PendingCN114412509AImprove stability and securitySolve the unstable situationUnderground chambersTunnel liningArchitectural engineeringMesh reinforcement

The invention discloses a construction supporting method suitable for large deformation of a mudstone tunnel. The construction supporting method comprises the following specific steps that firstly, a corresponding reinforcing supporting structure is selected according to tunnel investigation data and the deformation condition after primary supporting; secondly, a tunnel is excavated through a bench method, and then primary concrete spraying, reinforcing mesh laying, arch frame erecting, foot-lock anchor rod arranging and radial anchor rod drilling are sequentially conducted, and then concrete is re-sprayed to the designed thickness; the upper step part, the left side part of the lower step and the right side part of the lower step are sequentially constructed; thirdly, according to different surrounding rock deformation conditions, different arch frame supporting structures are arranged in an arch frame of the primary supporting structure; fourthly, an inverted arch part is excavated; and fifthly, after the tunnel is subjected to different pretreatments according to different invasion and limit degrees, secondary lining pouring is completed. According to the scheme, the capacity of resisting surrounding rock deformation of the primary support is improved, and the problem can be safely and rapidly solved to ensure the lining thickness.

Owner:中铁十五局集团第三工程有限公司 +1

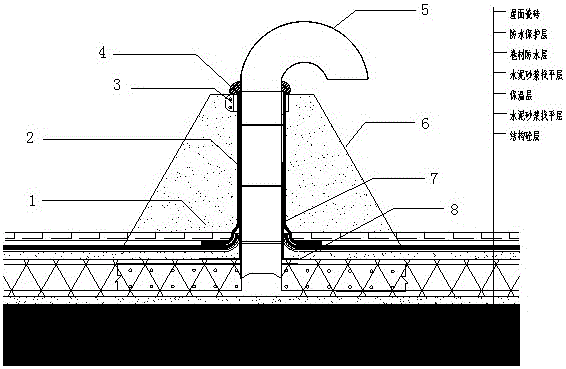

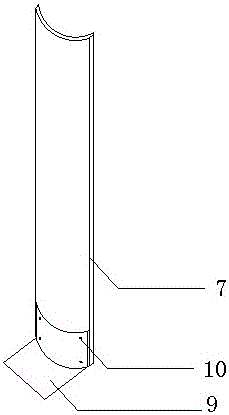

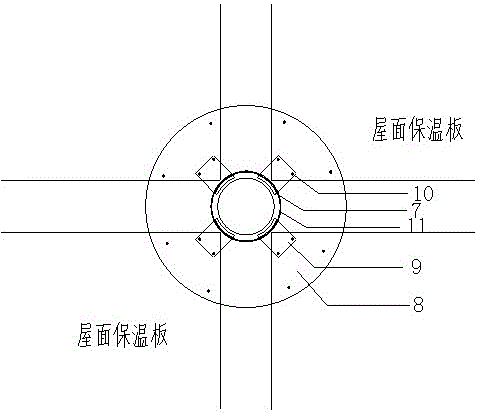

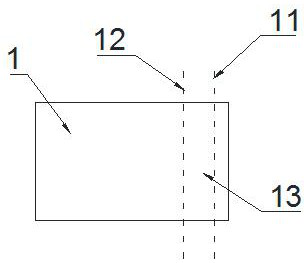

Roof exhaust pipe fixing device and manufacturing method thereof

ActiveCN105756298BSimple structureEasy to manufactureLighting and heating apparatusRoof covering ventilationsRound tableArchitectural engineering

A roof exhaust pipe fixing device, including a fixing bracket and a protective cover, characterized in that: the fixing bracket is provided with a base (8) and a set of upright pieces (7), the base is a ring-shaped steel plate, and the ring-shaped steel plate is made of several The nails (10) are fixed to the roof insulation board; the set of uprights is provided with four PVC pipe arcs; the protective cover (6) is a round table made of a steel plate, and its lower bottom is set on the exhaust pipe. The decorative surface layer and the protective layer are reserved at the bottom, the upper bottom surrounds the upper part of the exhaust pipe, the inside of the round table is poured with concrete (1), and the top of the round table is coated with sealing paste (4) around the exhaust pipe on the roof. The roof exhaust pipe fixing device of the present invention has the advantages of simple structure, convenient manufacture, good verticality control of roof exhaust holes, beautiful and uniform appearance, preventing damage to PVC pipes, avoiding secondary rework and facilitating follow-up process construction, improving work efficiency, Advantages of saving time.

Owner:MCC5 GROUP CORP SHANGHAI

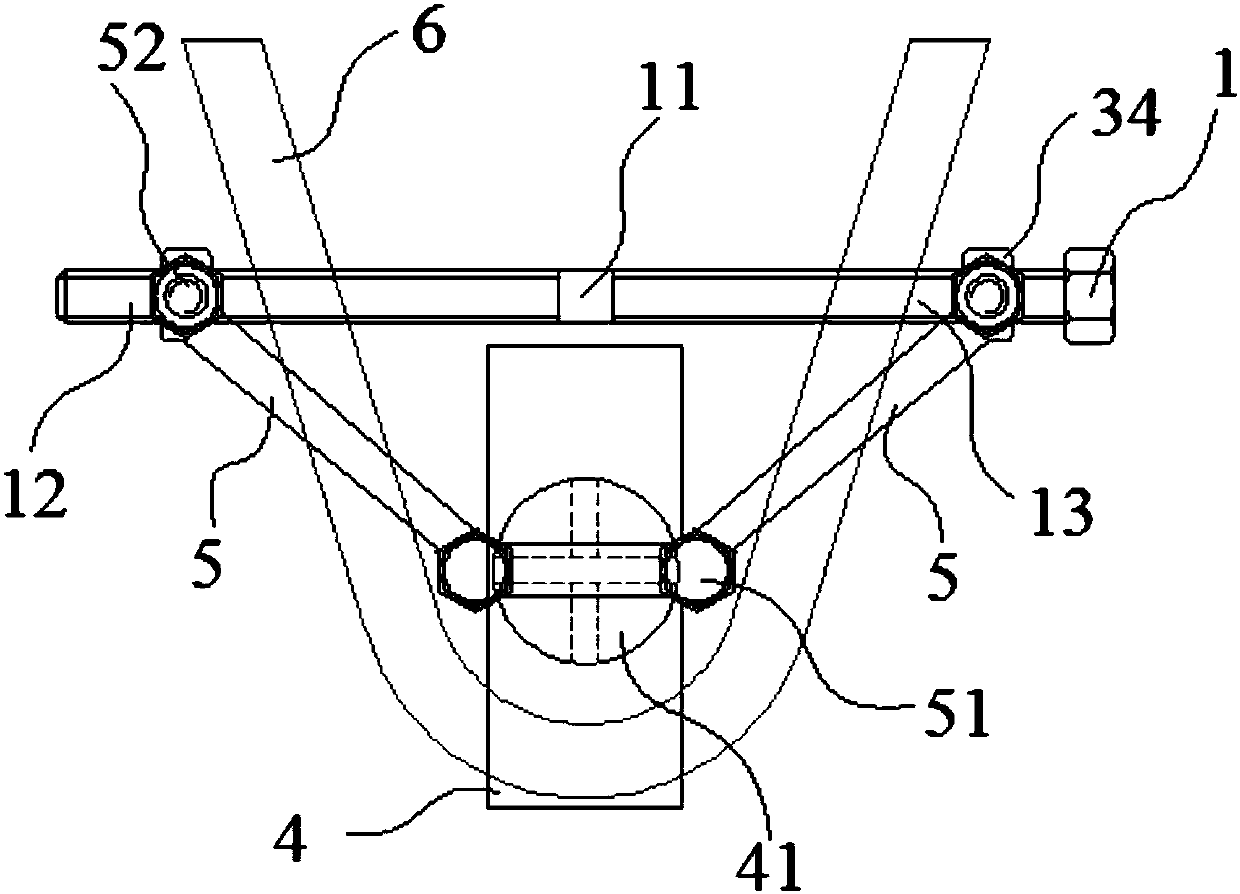

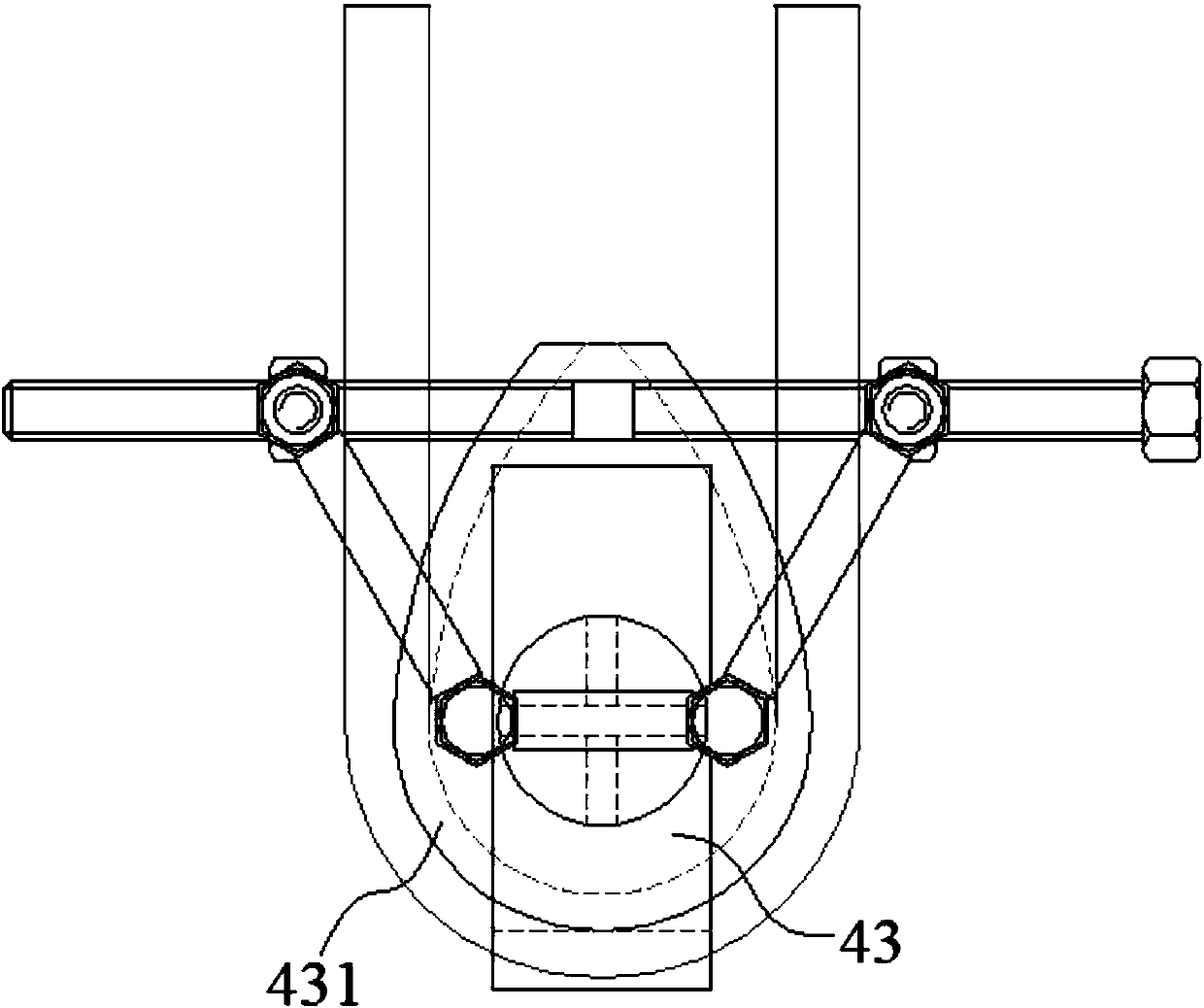

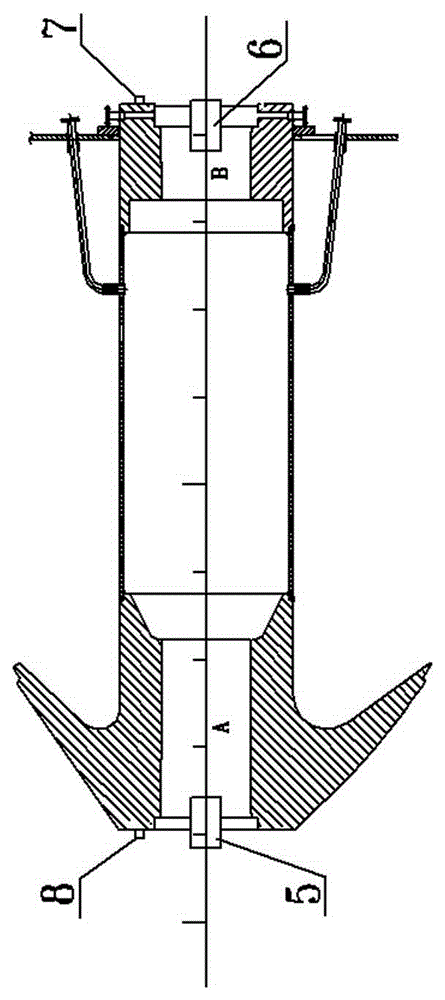

Shield steel sleeve sealing device and installation method thereof

ActiveCN111720129AFacilitate on-site process constructionCompact installationEngine sealsTunnelsStructural engineering

The invention discloses a shield steel sleeve sealing device and an installation method thereof. The device comprises a steel sleeve main body, the steel sleeve main body is formed by splicing a plurality of supporting cylinders, a sealing structure is arranged between every two adjacent supporting cylinders, each sealing structure comprises a sealing ring and an adjusting frame, each sealing ringis embedded between the two corresponding supporting cylinders, and each adjusting frame comprises a main connecting piece and an auxiliary connecting piece which are rotatably connected; one ends ofthe main connecting pieces and one ends of the auxiliary connecting pieces are fixedly connected with the sealing rings, and distances exist between the other ends of the main connecting pieces and the other ends of the auxiliary connecting pieces. When the distances are changed, the radial expansion and contraction amount of the sealing rings is synchronously changed. The shield steel sleeve sealing device and the installation method thereof can improve the sealing property of the steel sleeve main body and reduce the possibility of rework of a steel sleeve.

Owner:北京城建中南土木工程集团有限公司

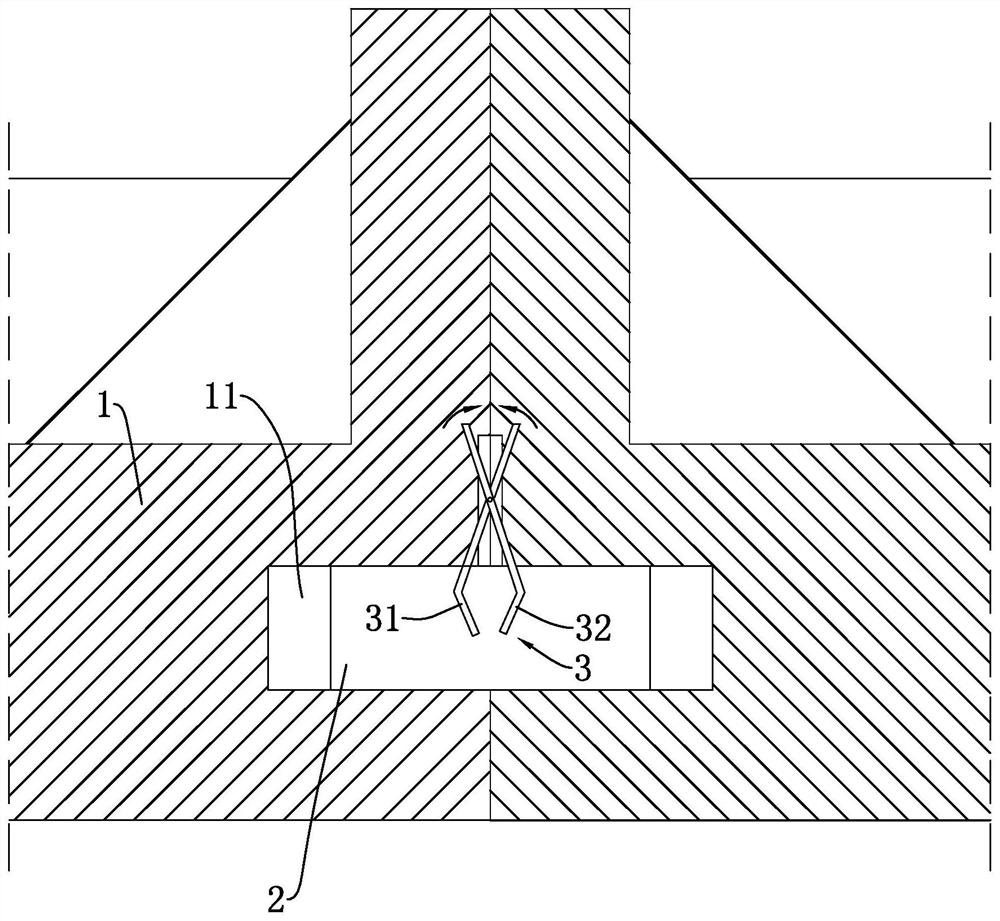

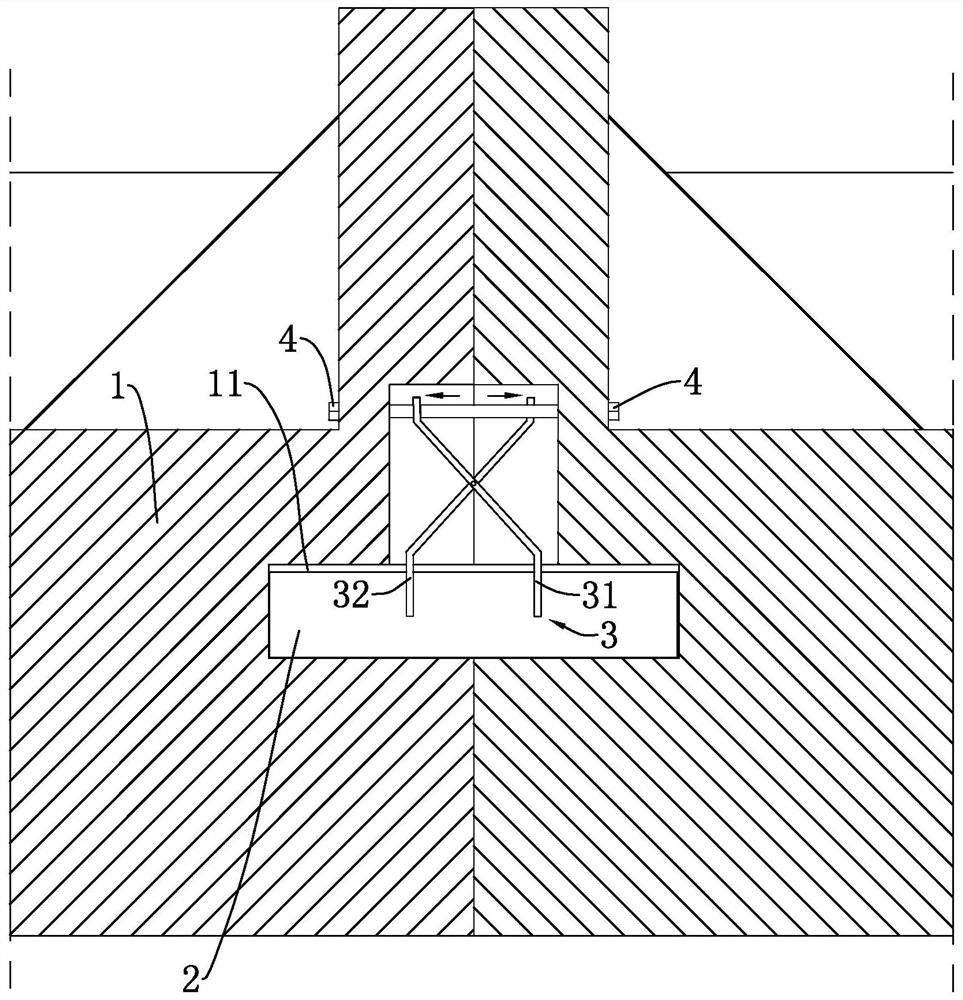

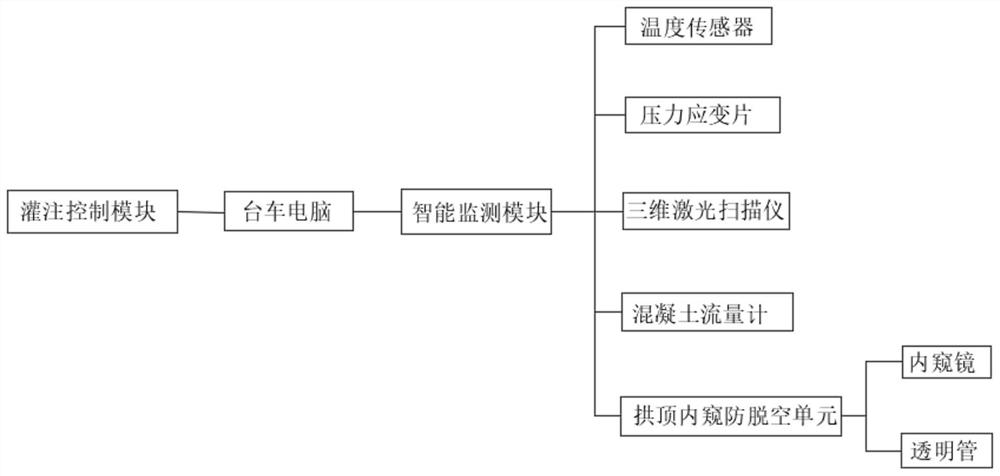

Intelligent monitoring system for secondary lining concrete pouring of tunnel

PendingCN112855218AEffectively guide on-site constructionAvoid secondary reworkMining devicesUnderground chambersData controlArchitectural engineering

The invention is applicable to the technical field of tunnel lining processing and detection, and provides an intelligent monitoring system for secondary lining concrete pouring of a tunnel. The intelligent monitoring system comprises an intelligent monitoring module, a trolley data control center and a pouring control module, wherein the intelligent monitoring module is used for monitoring pouring parameters in the secondary lining concrete pouring process of the tunnel; the trolley data control center is connected with the intelligent monitoring module, and is used for receiving the pouring parameter data and analyzing and processing the data; and the pouring control module is connected with the trolley data control center, and is used for judging the concrete pouring fullness according to the analysis result of the trolley data control center on the pouring parameter data, determining the concrete pouring stopping time, and guiding the pouring control module. The intelligent monitoring system for the secondary lining concrete pouring of the tunnel has the advantages that the secondary lining concrete pouring process can be monitored in real time, so that the site construction is effectively guided, the secondary rework is avoided, and the working efficiency is greatly improved.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD +2

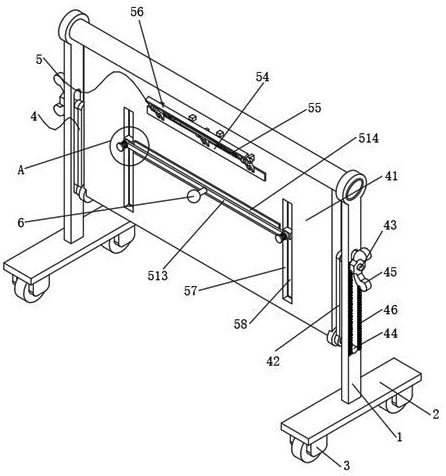

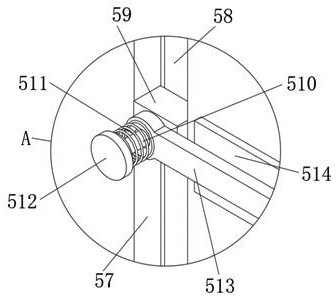

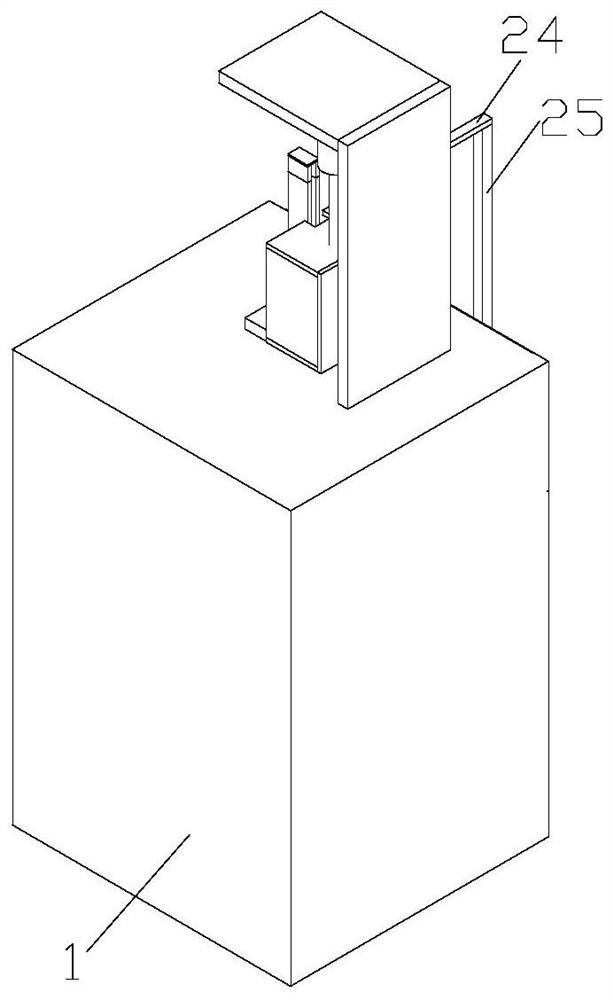

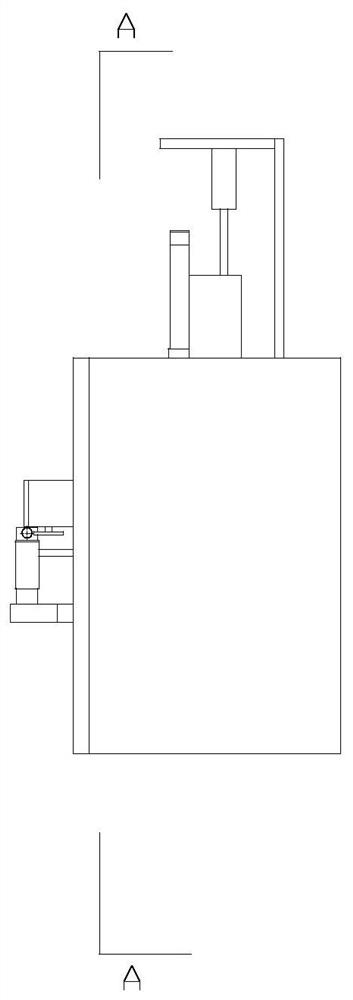

Construction leveling device for spring vibration-isolated foundation chapiter and construction method thereof

InactiveCN105220705AImprove flatnessImprove the quality of vibration isolation installationProtective foundationLeveling effectVibration isolation

The invention discloses a construction leveling device for a spring vibration-isolated foundation chapiter and a construction method thereof. The construction leveling device comprises a circle of angle iron frame arranged at the top of a foundation chapiter template; one face of the angle iron frame is arranged parallel to the side wall of the top of the template, and the other face of the angle iron frame is horizontally arranged in an elevation position of a capital of the top face of the template and points towards the inner side of the template. When concrete is poured to the foundation chapiter template, the top face of the concrete is flush with the horizontal top face of the angle iron frame, and the flatness of the foundation chapiter is ensured through the scraping and leveling effect of a darby on the horizontal edge of the angle iron frame. According to the construction leveling device for the spring vibration-isolated foundation chapiter and the construction method, the flatness of the foundation chapiter surface is greatly improved; the quality of the installation of the spring vibration isolation is improved; the foundation for stable and safe operation of equipment is laid; the secondary reworking caused by the fact that the requirement for the flatness is not met is avoided; the engineering economy is improved and construction period is shortened.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

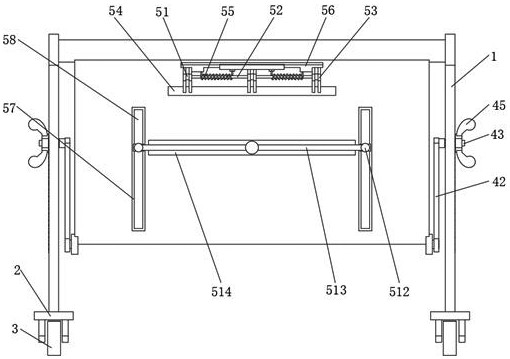

BIM technology-assisted double-curved-surface aluminum veneer construction method

The invention discloses a BIM technology-assisted double-curved-surface aluminum veneer construction method. The method comprises the steps of 1, auditing and confirming a drawing, putting the construction drawing on a drawing placement frame, carefully knowing the construction drawing of aluminum veneer installation, and knowing parameters of all installation nodes and a related spatial position relationship; and 2, establishing a BIM three-dimensional model, analyzing and confirming the two-dimensional design construction drawing, and establishing a three-dimensional BIM visual construction model on the basis; before construction, performing data analysis and extraction through a special-shaped structure part in the three-dimensional model so as to assist in field construction; according to the BIM construction technology, visual construction management is carried out on the project, three-dimensional visualization, controllability and intelligent refinement of field construction are achieved, the purposes of enhancing the construction quality and reducing the construction cost are achieved, the construction time is greatly shortened, and the material cost is reduced; and the drawing placement frame is arranged, so that the angle of the drawing on the placement plate can be adjusted, the drawing can be conveniently watched, the watching effect is improved, the method is relatively perfect, drawings with different sizes can be conveniently fixed, and the application range of equipment is enlarged.

Owner:贵州建工集团第二建筑工程有限责任公司

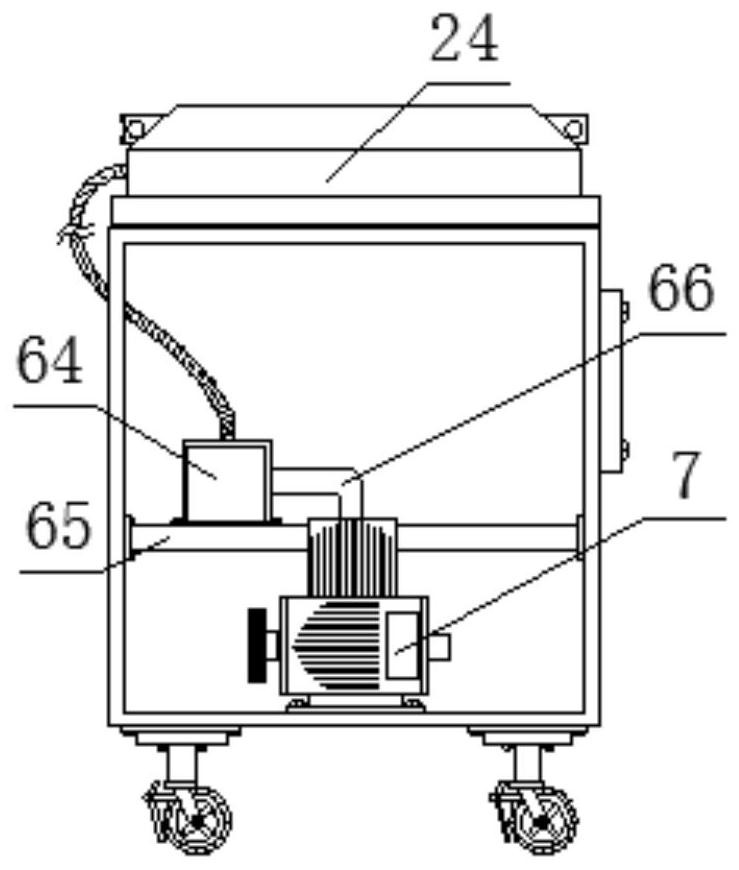

Dust recovery device for industrial automatic control workshop

InactiveCN112536303AImprove stabilityAvoid secondary reworkDispersed particle filtrationCarpet cleanersAutomatic controlElectric machine

The invention relates to the technical field of dust recovery, and discloses a dust recovery device for an industrial automatic control workshop. The dust recovery device comprises a box body, the inner wall of the box body is fixedly connected with a first partition plate, the inner wall of the box body is fixedly connected with a second partition plate, and the rear side of the bottom of the boxbody is fixedly connected with a straight-row brush. An electric vehicle is fixedly installed at the bottom of the box body, wheels are connected to the left side and the right side of the electric vehicle through rotating rods, a rotating motor is fixedly installed at the bottom of the first partition plate, a gear shaft is fixedly connected to the output end of the rotating motor, a chain is connected to the outer ring of the bottom of the gear shaft in an engaged manner, and gears are in transmission connection to the inner rings of the front side and the rear side of the chain. Accordingto the dust recovery device, through cooperative use of a first dust collection box, dust is recycled into a dust box, then the dust in the first dust collection box is subjected to dust falling through an annular atomizing spray head, the situation that after the dust box is pulled out, the dust flies in the environment again is avoided, and the dust treatment difficulty is reduced.

Owner:无锡硕凯智能科技有限公司

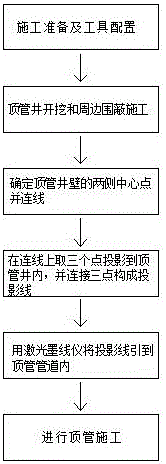

Pipe-jacking three-points-and-one-line construction method

ActiveCN106764055AHigh precisionAvoid secondary reworkPipe laying and repairEngineeringProjection line

The invention discloses a pipe-jacking three-points-and-one-line construction method. The method comprises the steps of 1, conducting construction preparation and tool allocation; 2, excavating a pipe-jacking well, and constructing surrounding enclosing shelters; 3, determining central points of the two sides of a wall of the pipe-jacking well, and connecting the central points to form a line; 4, picking three points on the connection line, projecting the three points into the pipe-jacking well, and connecting the three points into a projection line; 5, guiding the projection line into a pipe-jacking pipeline through a laser snapline instrument; and 6, conducting pipe-jacking construction. According to the pipe-jacking three-points-and-one-line construction method, the straight line is determined through two pipe wells; the three points on the straight line are picked and projected into the pipe-jacking well; the projected three points form a straight line; and a longitudinal line of a cross line obtained through projection conducted through the laser snapline instrument coincides with the projection line, a transverse line coincides with a pipe-jacking left quadrantal point and a pipe-jacking right quadrantal point, and the midpoint of the cross line coincides with the midpoint of the pipe-jacking pipeline. By means of the pipe-jacking three-points-and-one-line construction method, it is guaranteed that a pipe-jacking construction route is correct; the jacked pipe is prevented from being shifted in the ingress process; and pipe-jacking construction precision is improved.

Owner:THE THIRD CONSTR & ENG OF CCFED

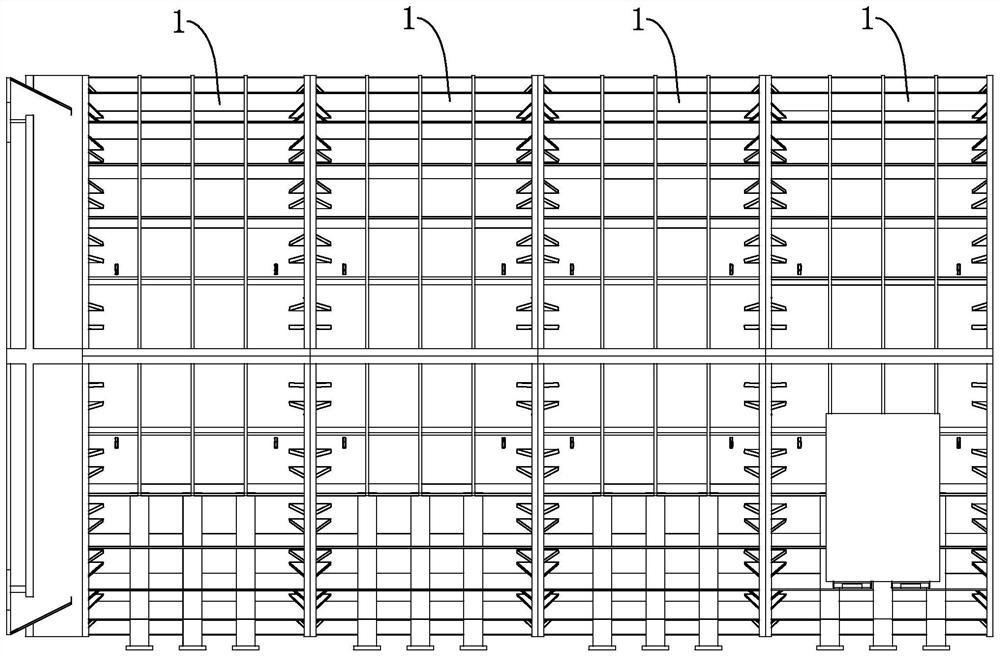

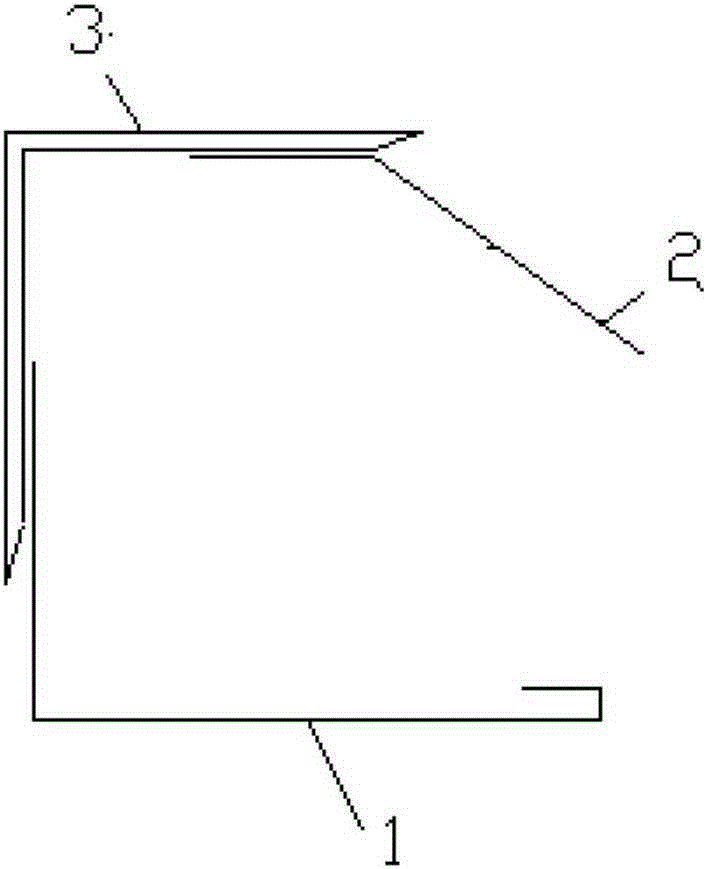

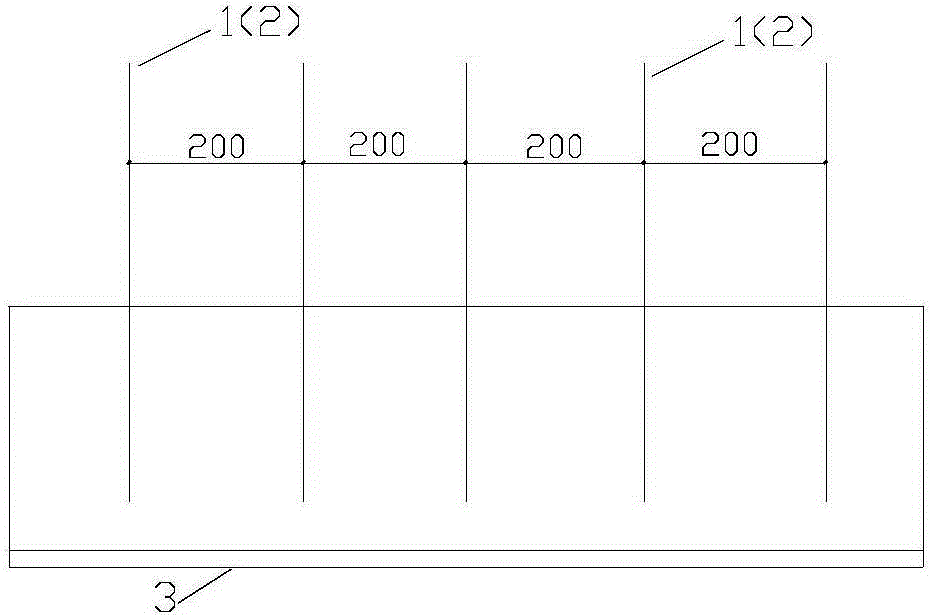

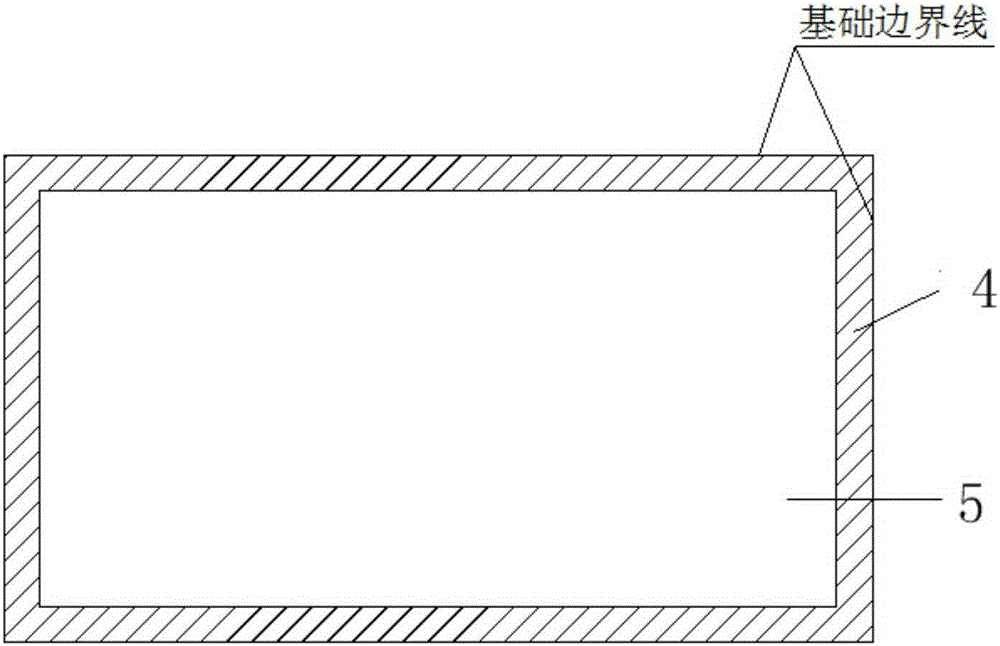

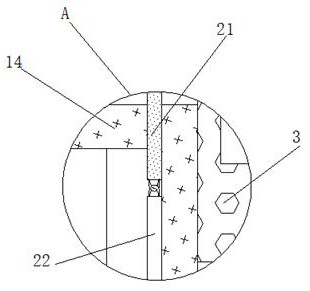

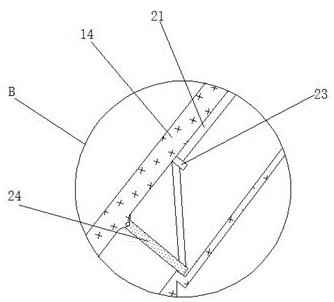

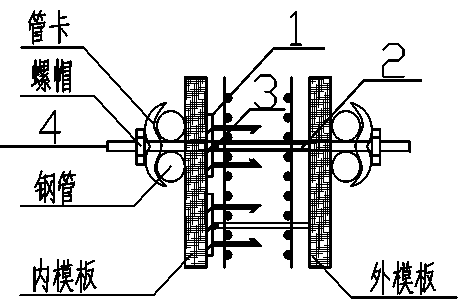

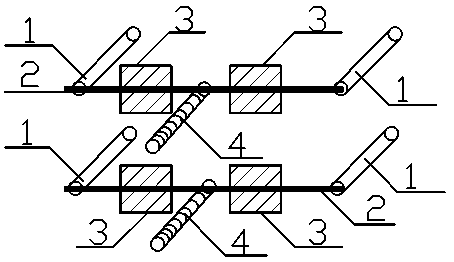

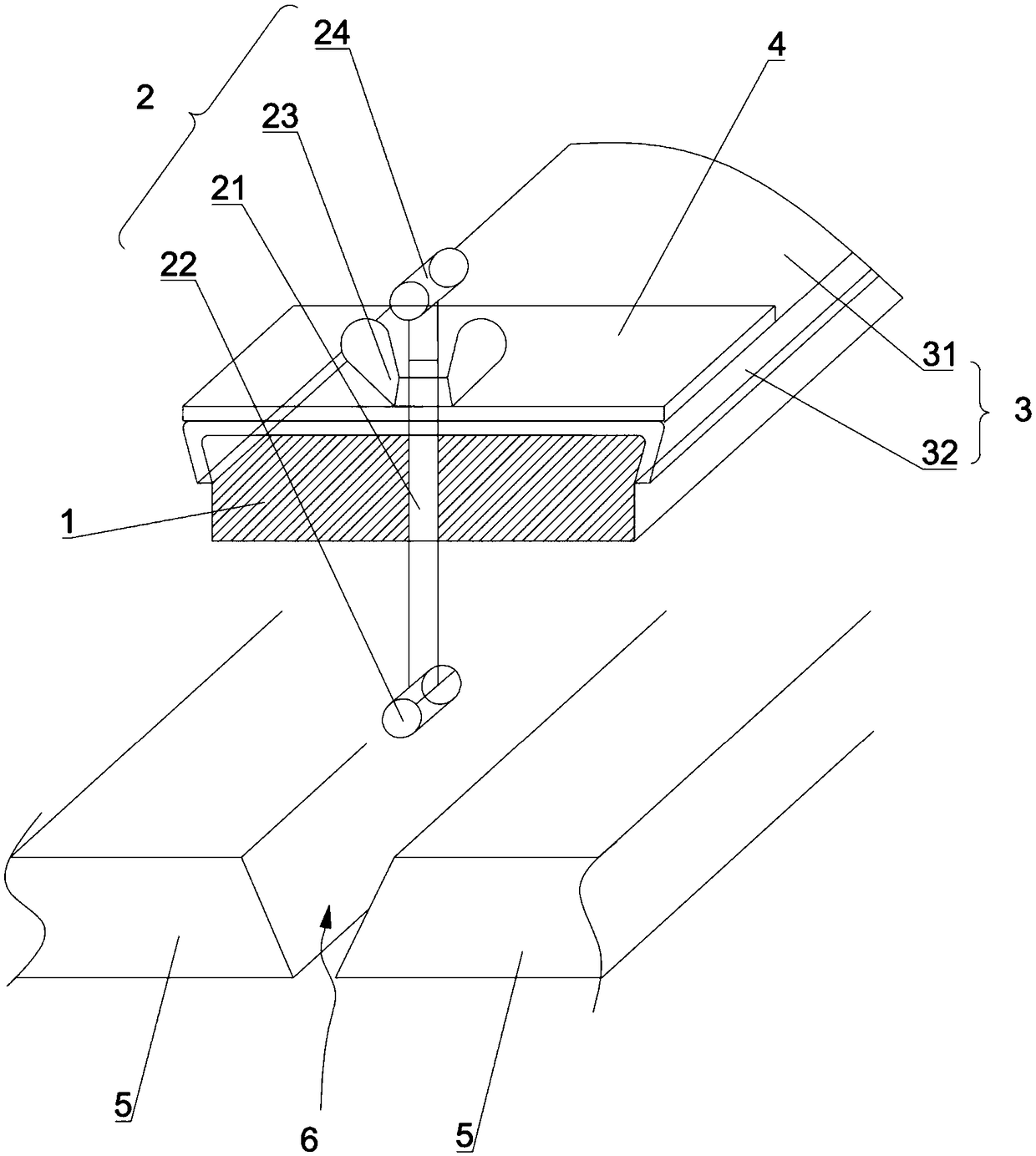

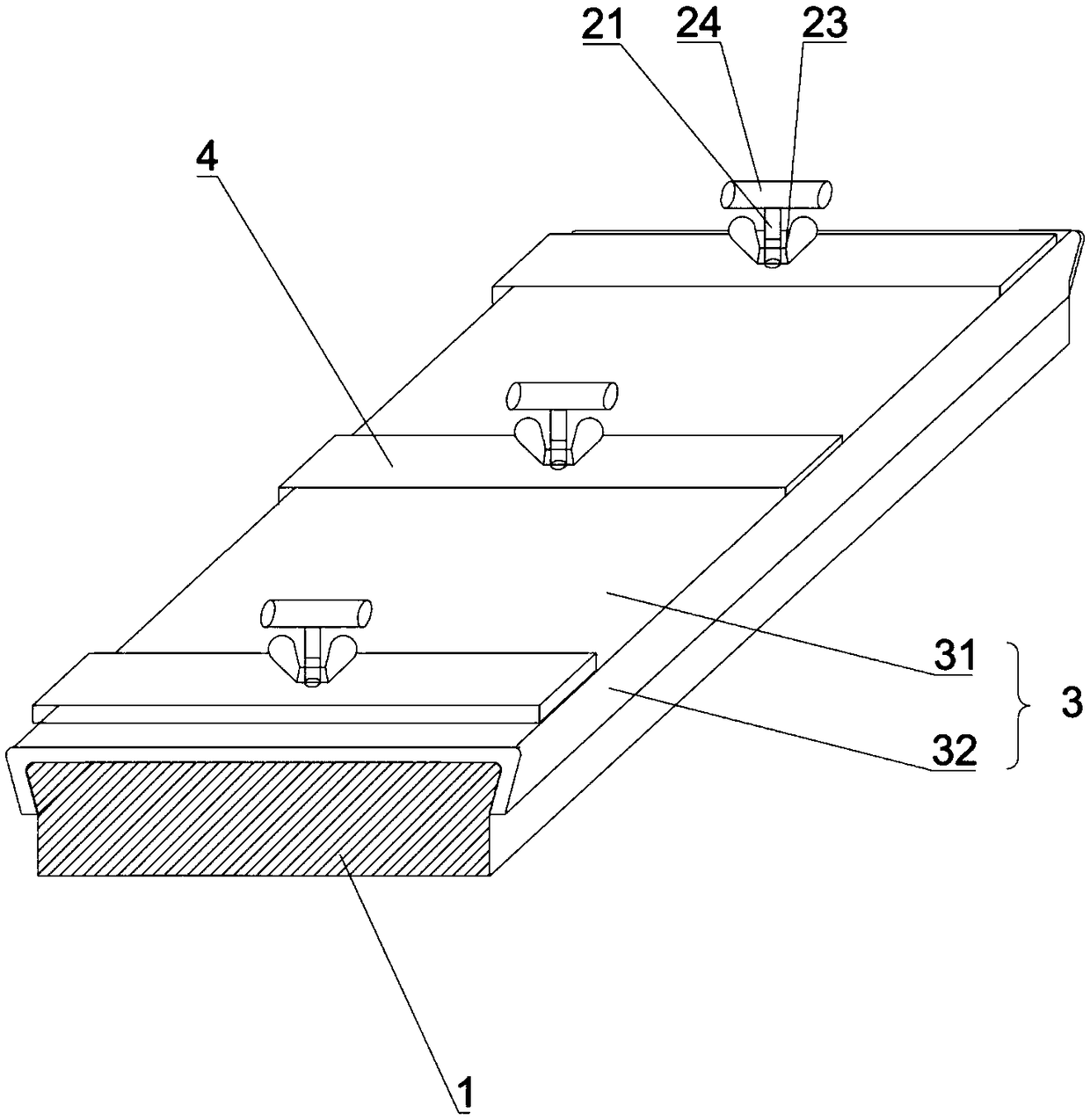

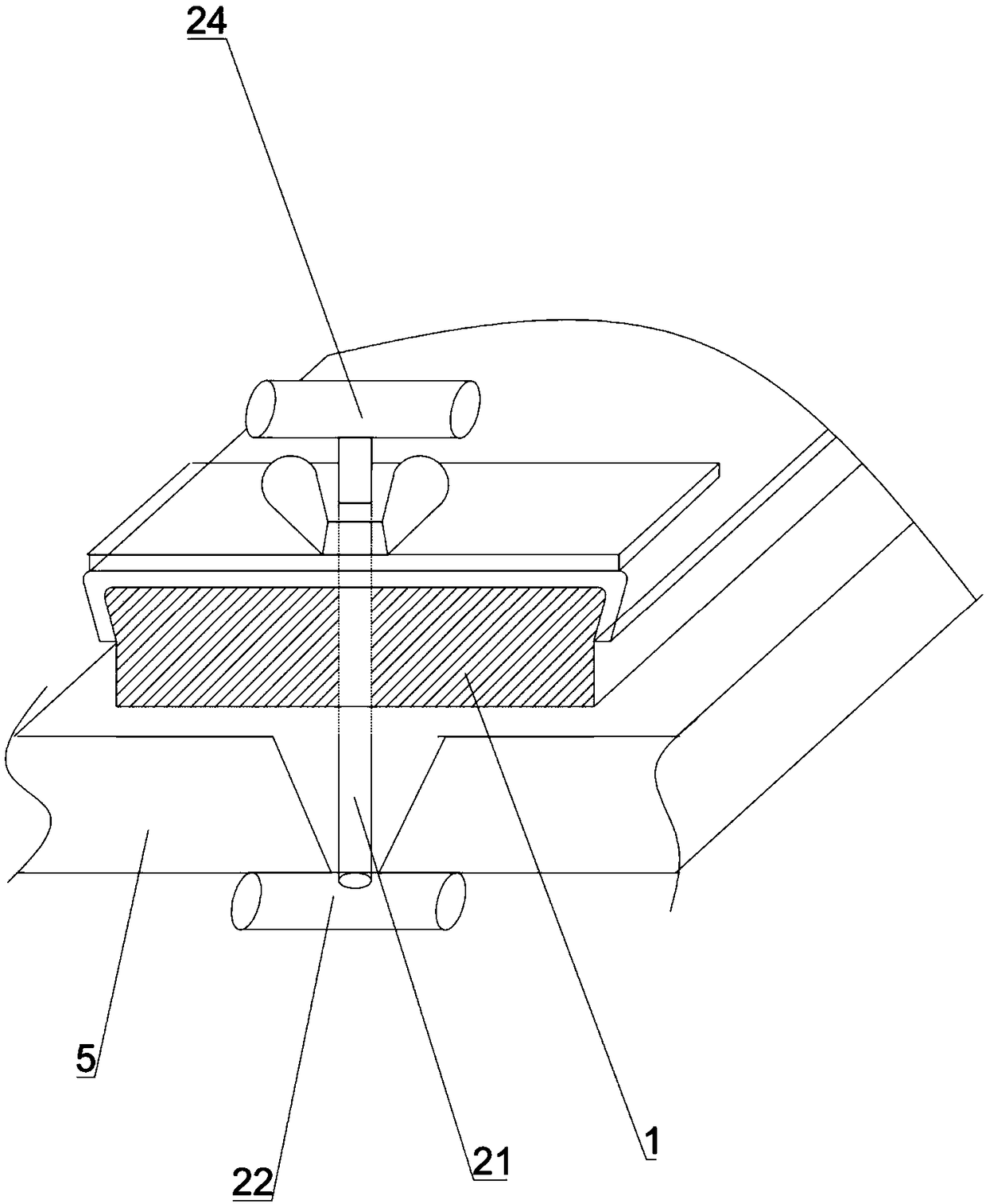

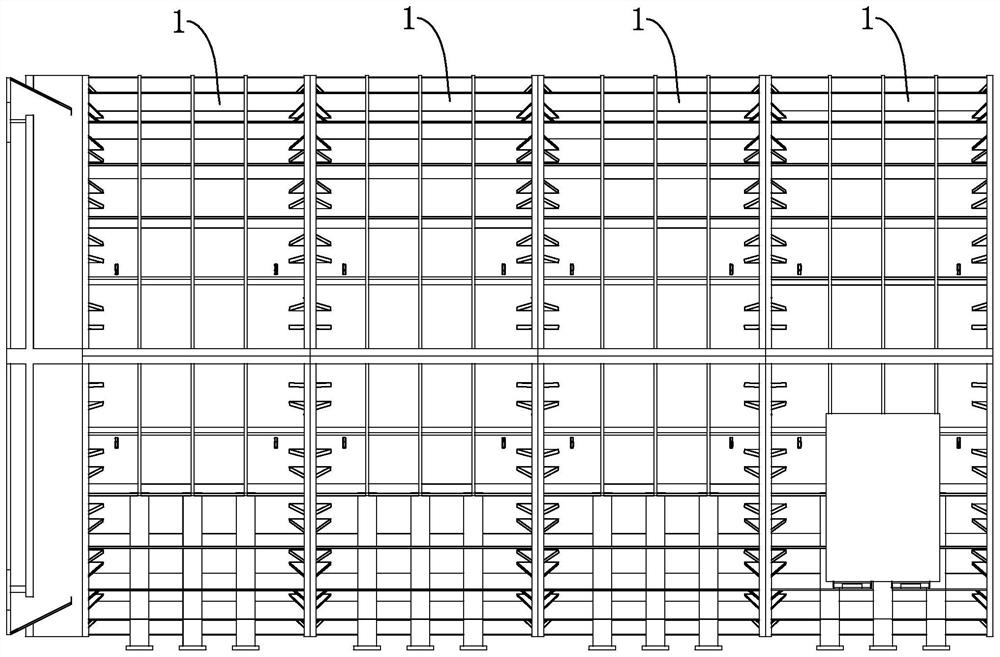

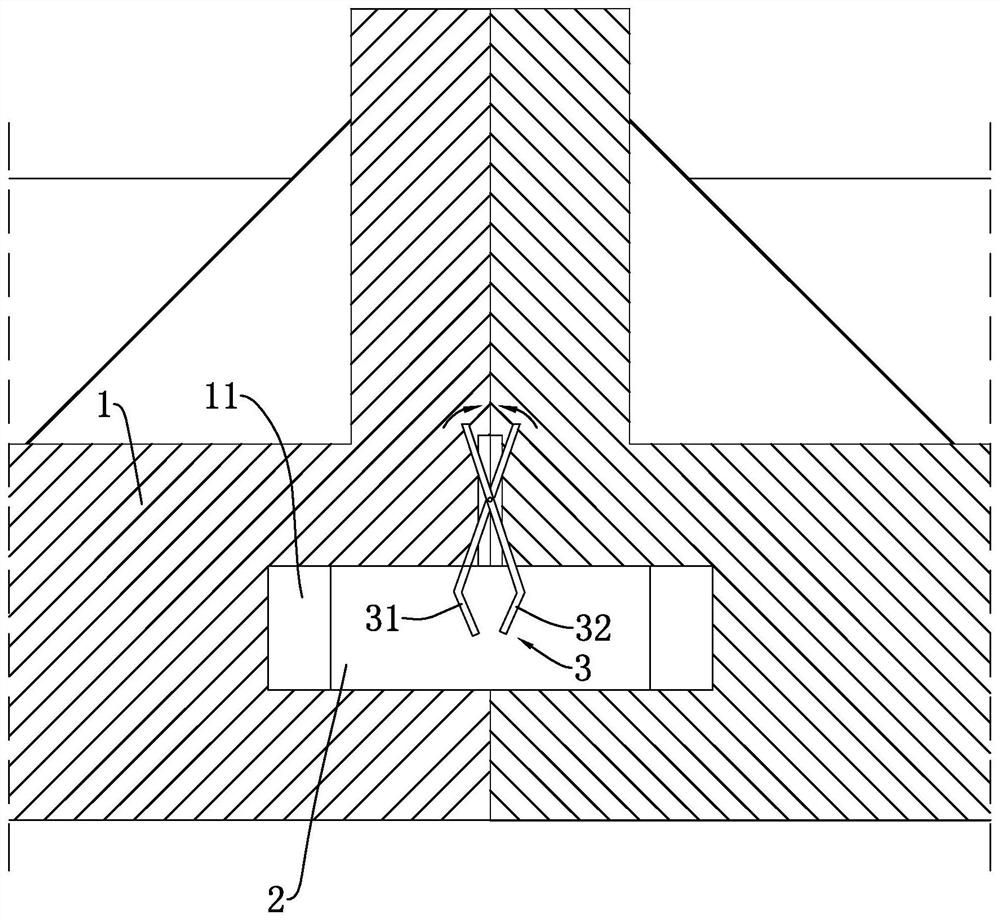

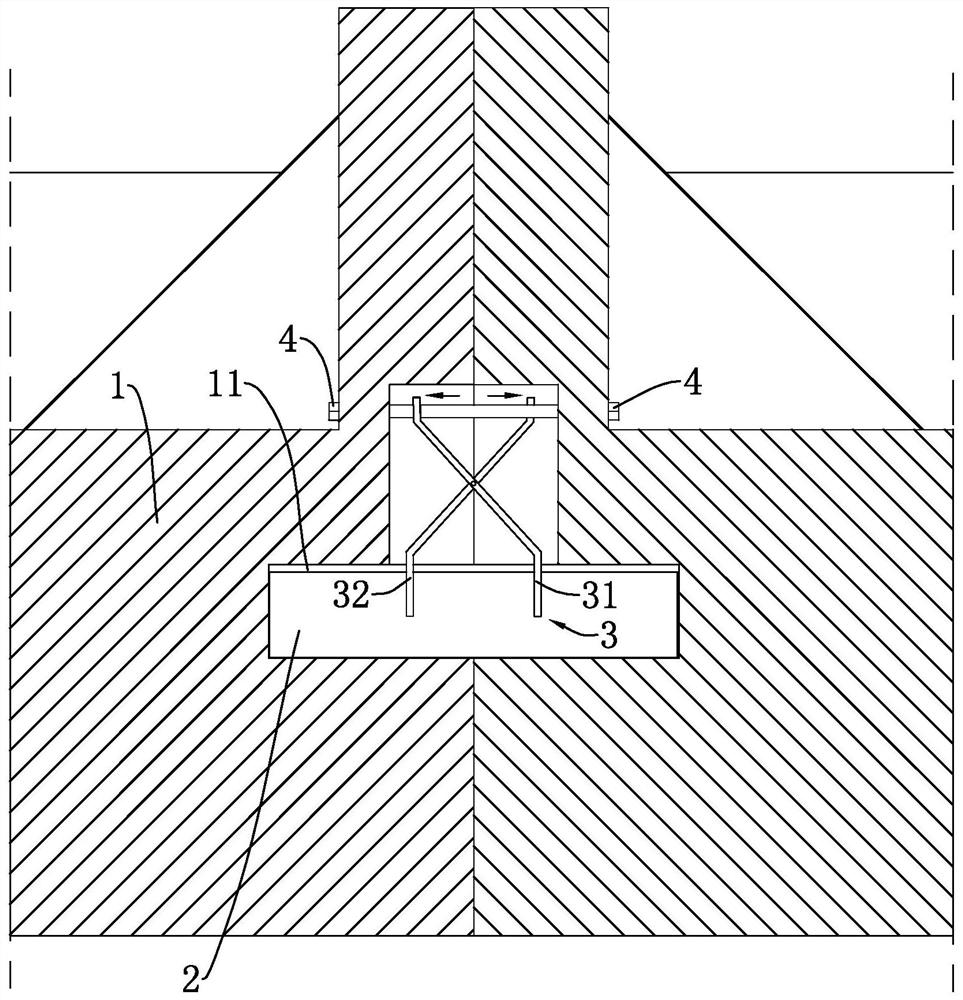

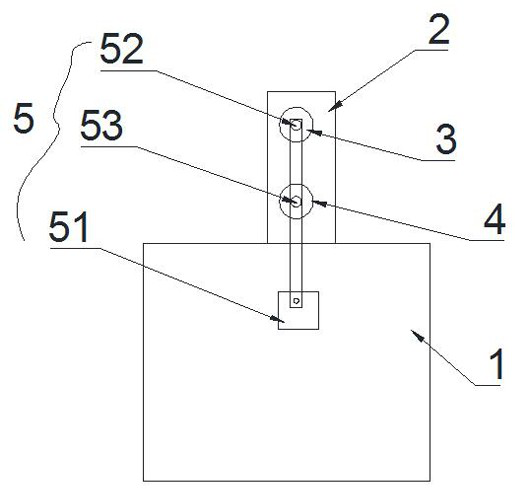

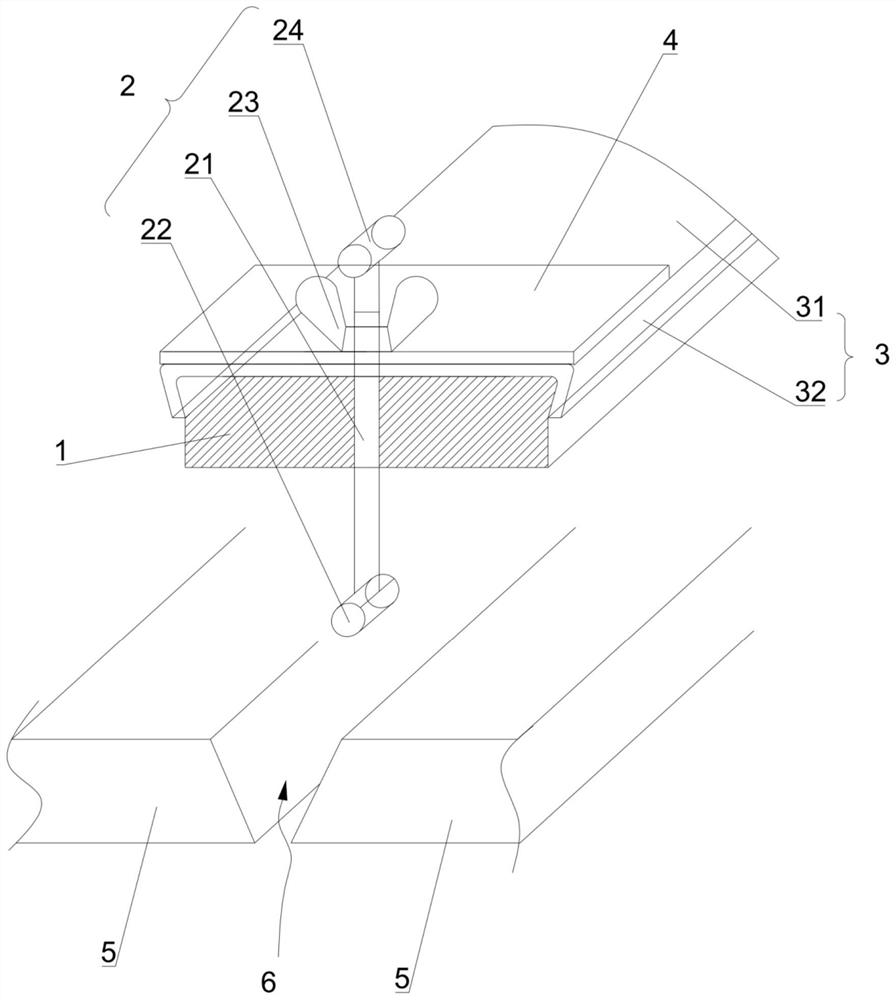

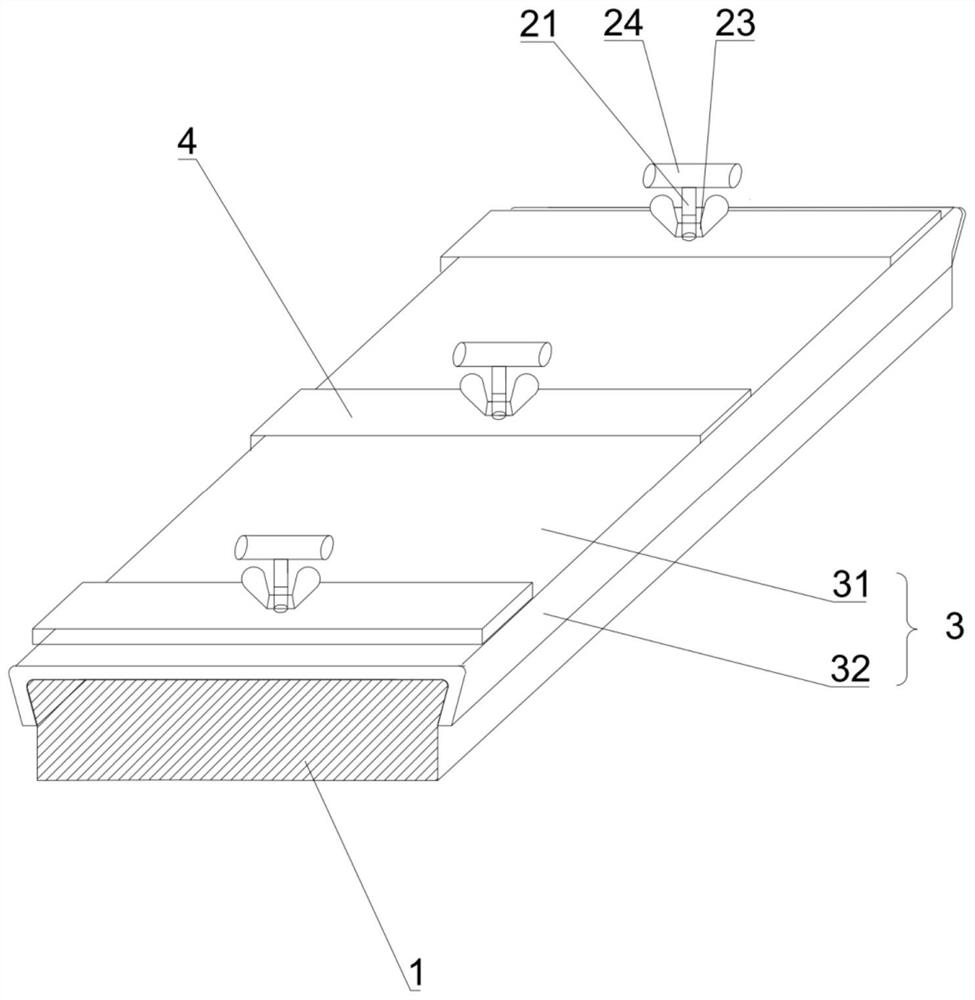

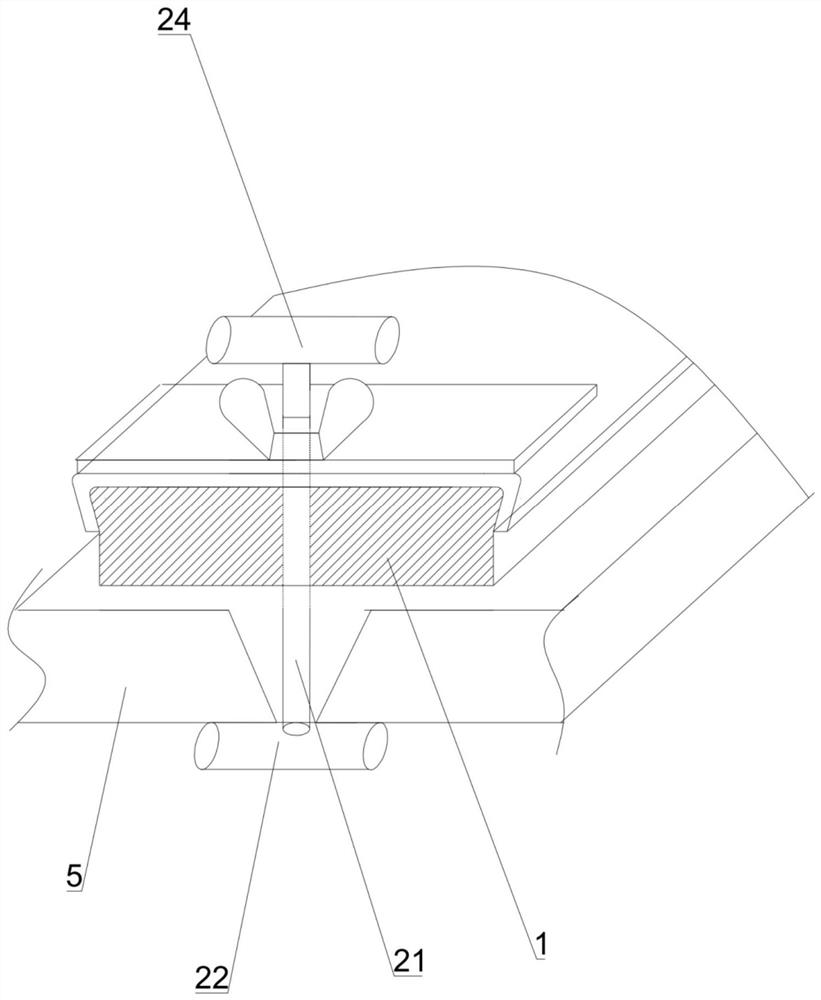

Wallboard embedded part complete set construction method

InactiveCN111576638ASolve the problem that the accuracy cannot be guaranteedGuaranteed accuracyAuxillary members of forms/shuttering/falseworksBuilding material handlingEngineeringBench grinder

The invention discloses a wallboard embedded part complete set construction method. The method is characterized by comprising the following steps that horizontal center lines of embedded parts along the height direction are determined; one back shore support (1) with length equal to wall thickness is welded at each of the two ends of a wallboard along the horizontal center lines, and a construction line is tied at the end parts of the back shore brackets (1); a fixing support (2) and the back shore supports (1) are connected in a welded mode in the horizontal direction; the central positions of the embedded parts are marked on the fixing support (2), and the middle parts of the embedded parts (3) are welded along the fixing support (2); screw rods (4) are welded on to the fixing support (2) in a uniform distribution mode; a formwork is punched in a typesetting mode; the formwork is sealed, and the screw rods (4) reserved on the outer side of the formwork are fastened by using pipe clamps and nuts; concrete is poured, vibrated and compacted; and after the concrete curing age reaches the standard, the formwork is removed, opposite-pull screw rods are cut through a grinding machine, and the screw rods at the end parts of pull rods are recycled. The method is the construction method capable of still guaranteeing the one-time mounting qualification rate of the embedded parts even under the condition of large-batch embedded part operation.

Owner:SHANGHAI BAOYE GRP CORP

Modelling control method of decorative surface

InactiveCN102864917AFirmness and stabilityStable flatnessBuilding constructionsComputer Aided DesignQuality control

The invention provides a modelling quality control method of a decorative surface. The method comprises the following steps of A) examining and verifying construction drawings, finding out a circle centre of a surface model, decomposing an irregular surface into a plurality of circles, and determining the circle centre, a radius, an arc length and a positioning coordinate; B) decomposing and optimizing the surface model by using computer aided design (CAD), wherein field sizes and paying-off is required to be in accordance with the designed drawings strictly; using a computer to assist the paying-off, so that precision can be ensured; and C) inspecting and checking quality for nodes constructed on a cambered surface, and reducing unnecessary dimensional deviations. The flatness of the cambered surface is ensured, and firmness and construction quality are ensured. By the method disclosed by the invention, the stability and firmness of the steel structure foundation of the surface model, and the flatness and radian of the cambered surface meet the specified requirements. Impression effects meet a predetermined aim, the percent of pass is above 95%, and secondary rework is avoided.

Owner:苏州苏明装饰股份有限公司

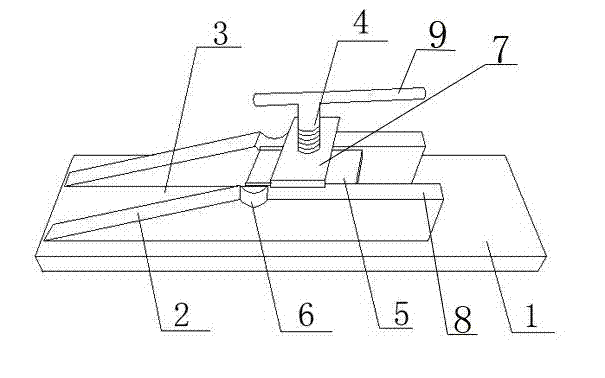

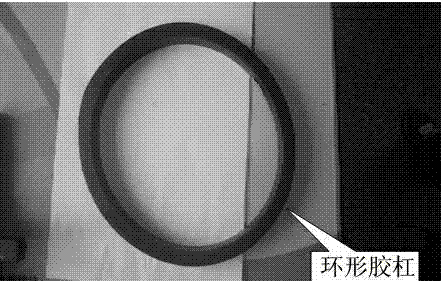

Fixed-angle chamfering method and special tool of square rubber bar

ActiveCN103192419AReduce workloadEasy to operateMetal working apparatusTransformerMechanical engineering

The invention relates to a fixed-angle chamfering method and a fixed-angle chamfering special tool of a square rubber bar and belongs to the technical field of overhauls of power supply transformers. The technical scheme is that the fixed-angle chamfering special tool of the square rubber bar includes a base (1), two vertical plates (8) which are arranged in parallel, a press plate (5), a support plate (7) and a pressing lead screw (4), wherein the two vertical plates which are arranged in parallel form a groove structure (3), the width of the groove structure is matched with that of the square rubber bar, the height of each of the vertical plates is larger than that of the square rubber bar, the two parallel-arranged vertical plates are metal plates, the side edges of the two vertical plates are all an inclined plane (3) with an angle of 20-30 degrees, and the side edge length, the angle and the height of the two vertical plates are completely the same. The fixed-angle chamfering special tool of the square rubber bar is simple in operation, easy to master, guarantees the tight sealing and the overhaul quality, greatly avoids secondary reworking caused by man-made reasons, and reduces the workload of staff; and greatly increases the working efficiency due to the fact that the work which needs one hour to complete can be done only in 20 minutes now.

Owner:STATE GRID CORP OF CHINA +1

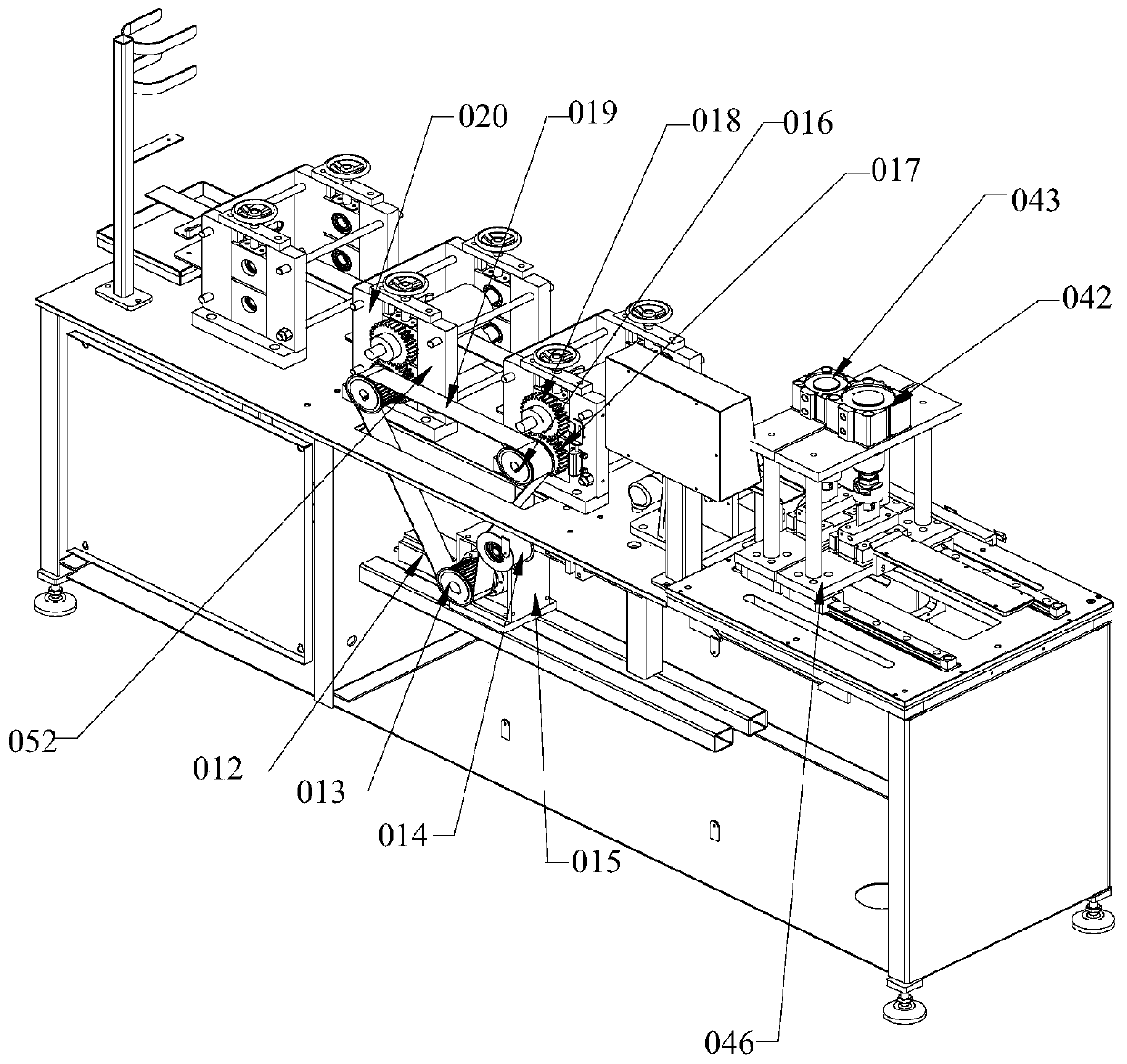

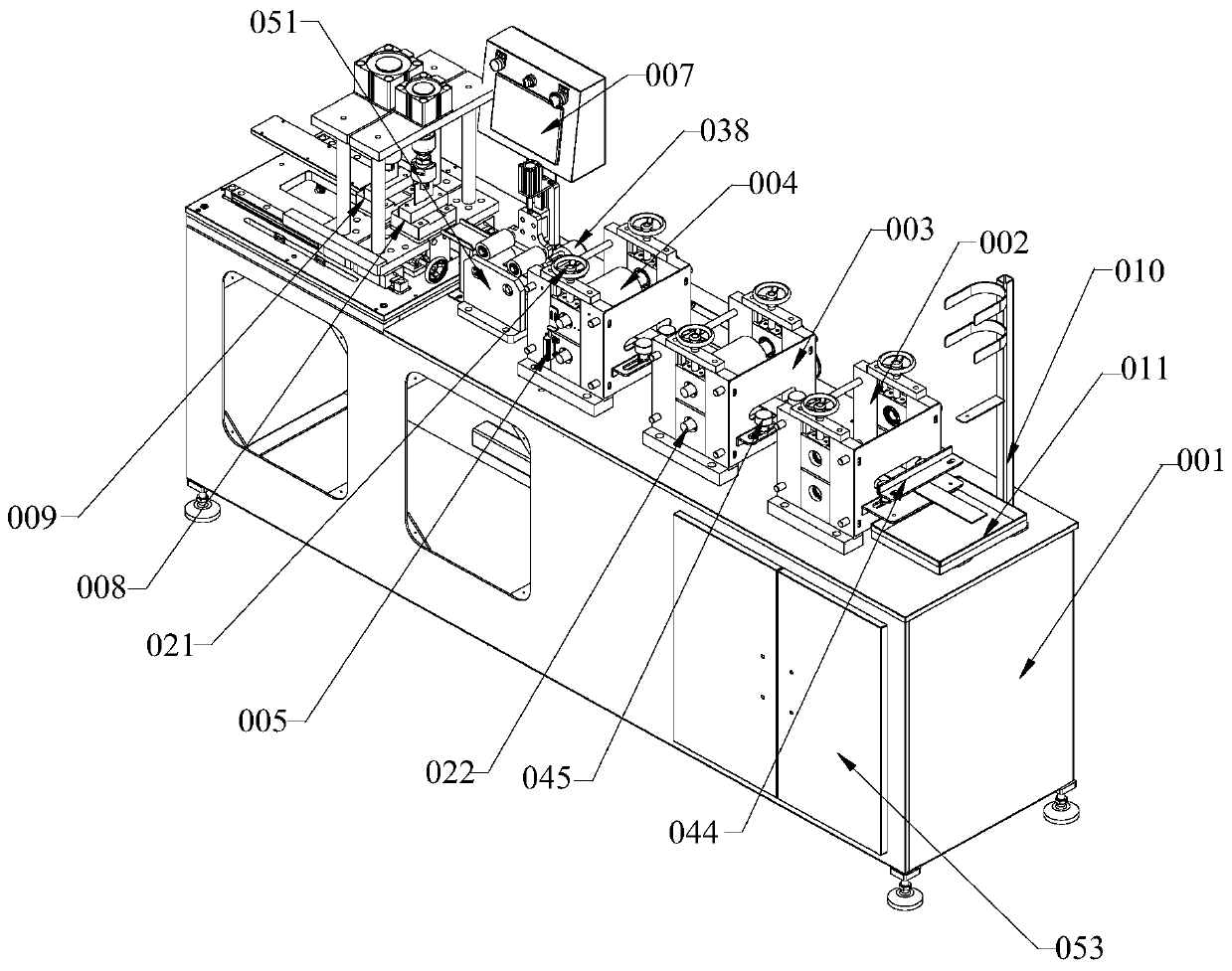

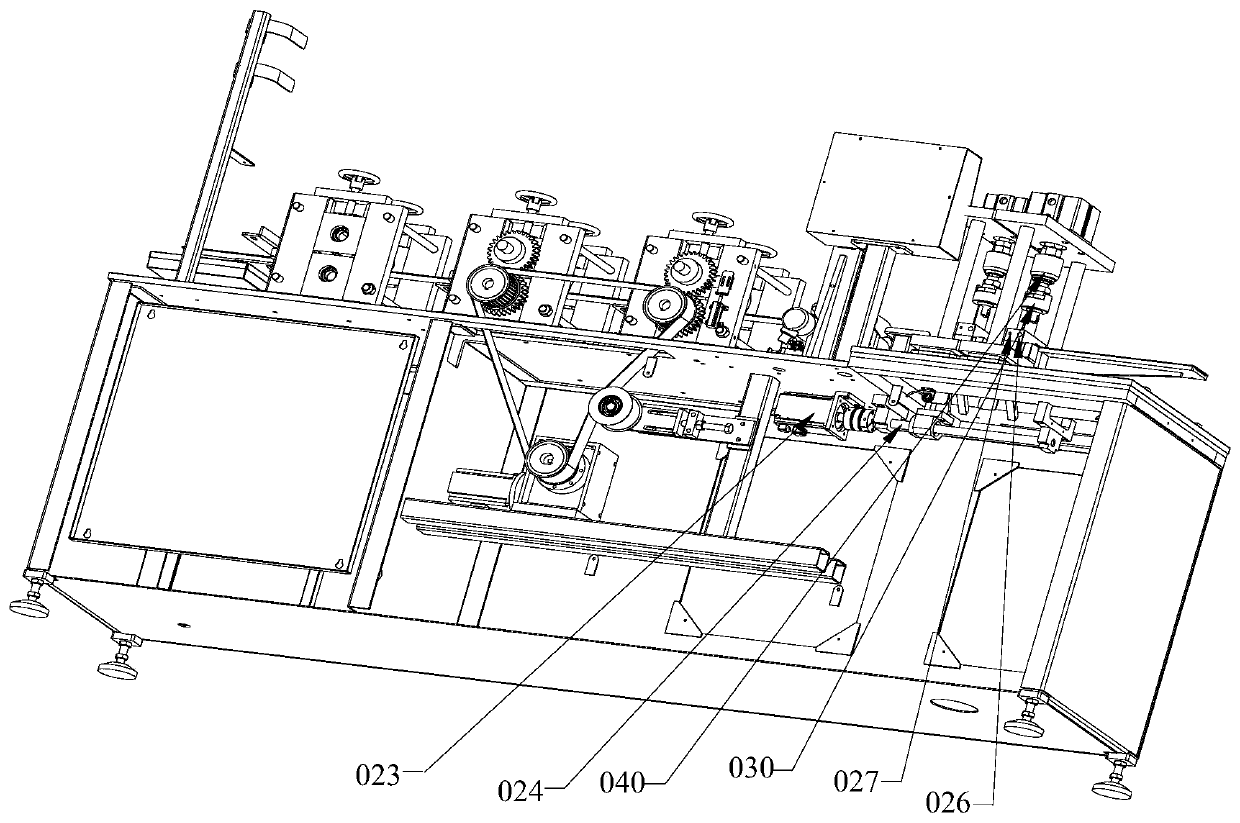

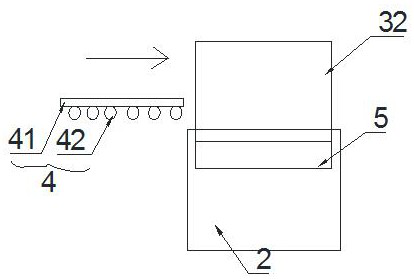

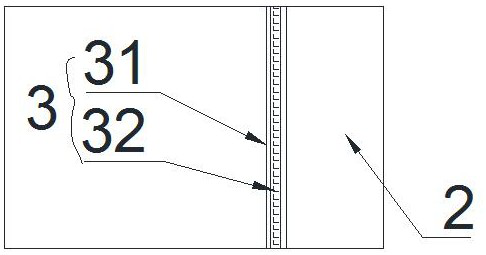

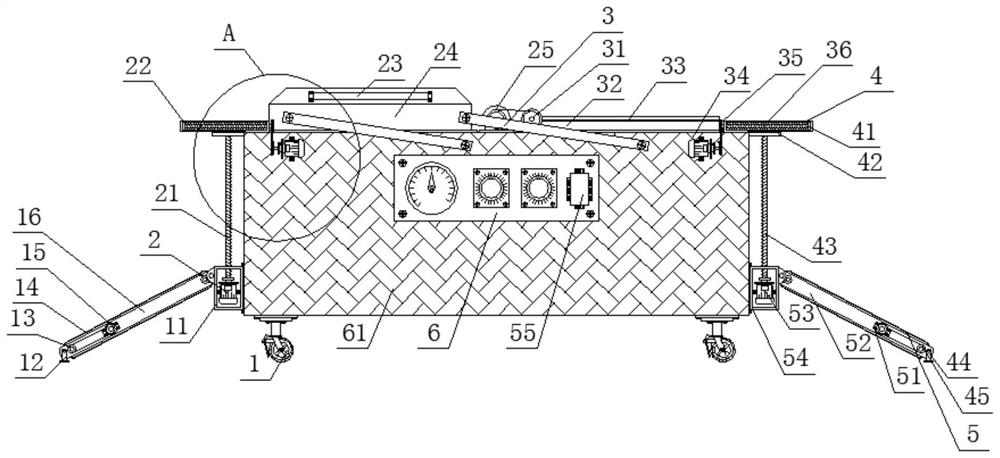

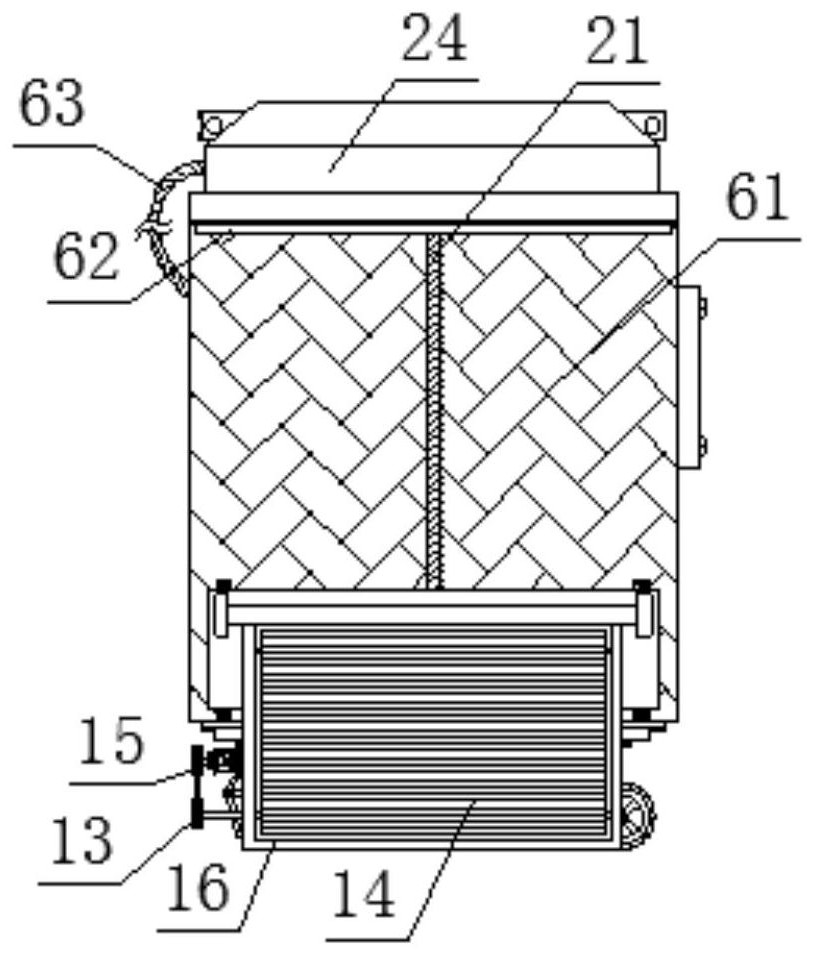

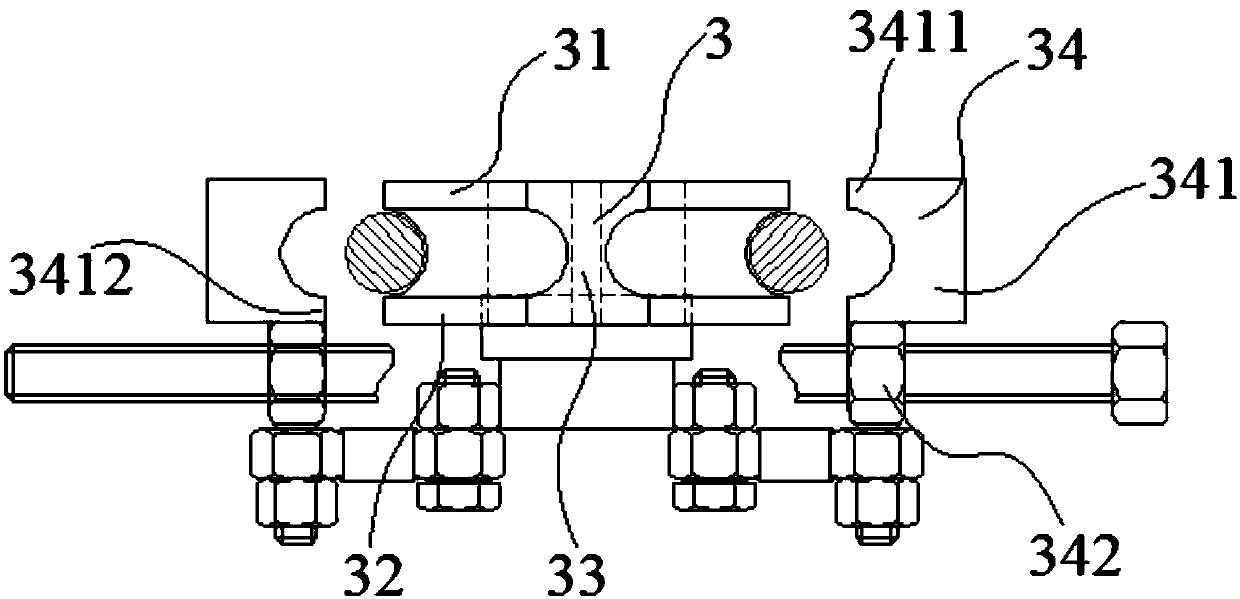

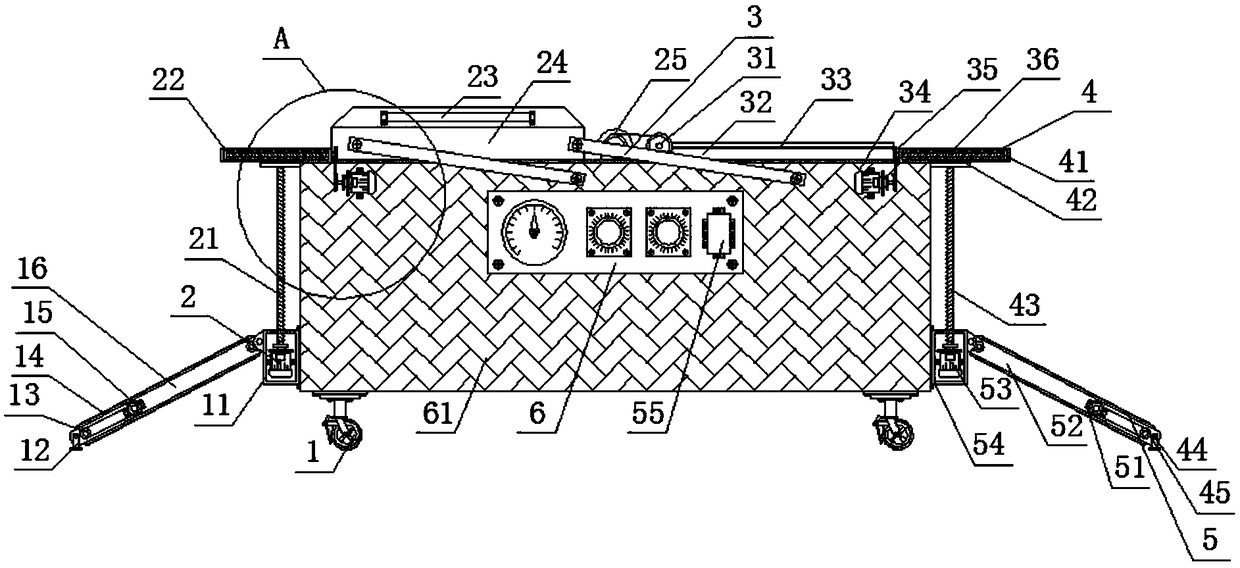

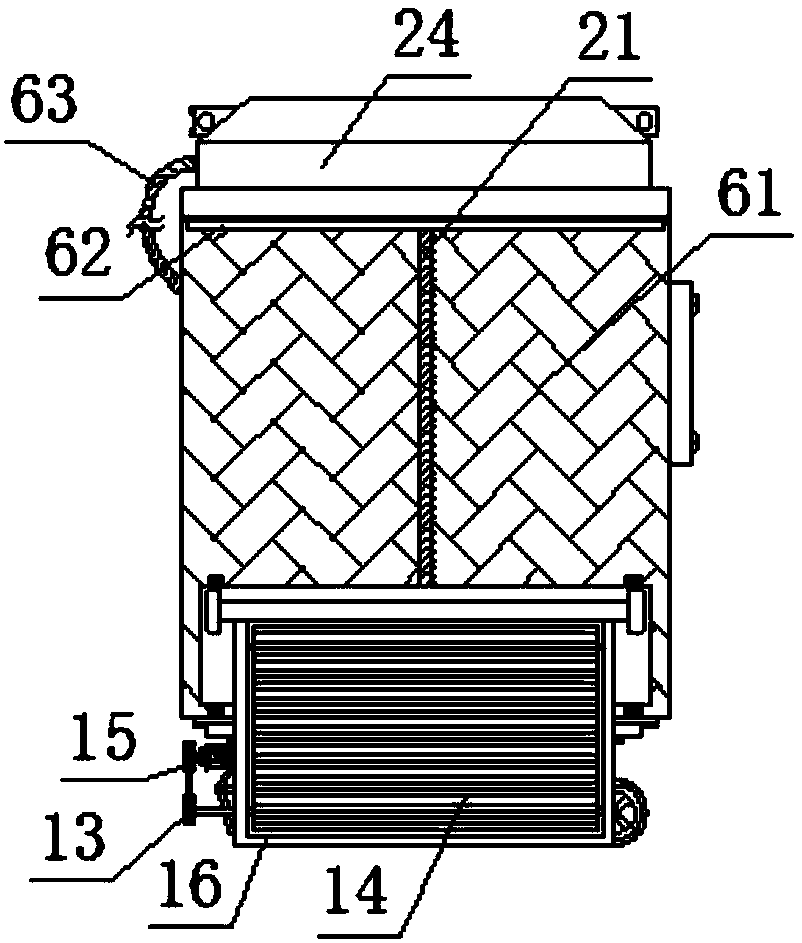

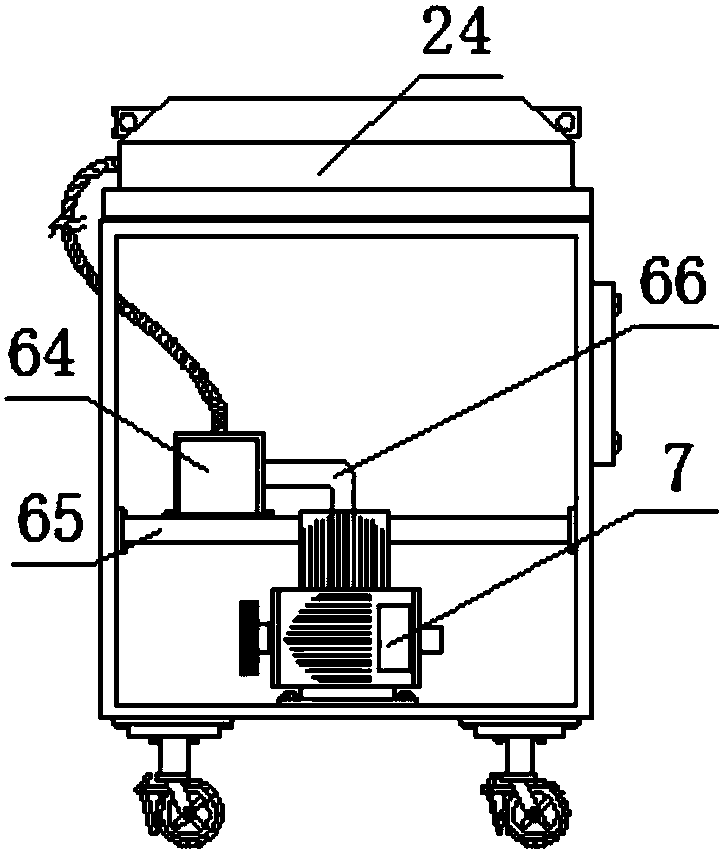

Traction, cutting and punching integrated machine

PendingCN109732354AAdjust in timeSave manpower and material resourcesOther manufacturing equipments/toolsPunchingKnurling

The invention provides a traction, cutting and punching integrated machine. The traction, cutting and punching integrated machine comprises a machine body, a static electricity removal device, a knurling roll assembly, a traction assembly and a synchronous sliding table cutting and punching assembly, wherein the static electricity removal device, the knurling roll assembly, the traction assembly and the synchronous sliding table cutting and punching assembly are arranged on the table face of the machine body. The static electricity removal device, the knurling roll assembly, the traction assembly and the synchronous sliding table cutting and punching assembly are arranged on the table face of the machine body in a manner of an assembly line to form the integrated machine of the brand-new concept, the static electricity removal device is arranged to eliminate the static electricity influence of profile static electricity on function devices on the assembly line, the overall integrated machine can independently distribute and machine traditional profiles, integrated assembly line type treatment is achieved, and manpower and material resources are greatly reduced; and due to the factthat machining is achieved on one machine, components can be adjusted conveniently in time, and secondary reworking is avoided.

Owner:上海禹研自动化设备有限公司 +1

Groove waterproof device and using method of same

ActiveCN108907523APrevent infiltrationAvoid secondary reworkWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineering

The invention relates to the technical field of ship building and assembly operation, and particularly discloses a groove waterproof device and a using method of the same. The groove waterproof devicecomprises a sealing plate and a locking assembly, wherein the sealing plate is used for covering a groove of a workpiece to be welded; and the locking assembly is used for pressing the sealing plateto abut against the workpiece to be welded, and the locking assembly is arranged through penetrating through the sealing plate and can move up and down relative to the sealing plate. According to thegroove waterproof device, when the groove of the workpiece to be welded is polished to be bright and reaches a welding requirement, the sealing plate is put to cover the groove of the workpiece to bewelded, the locking assembly is made to penetrate through the groove and is used for locking the sealing plate, so that the sealing plate is tightly pressed against the workpiece to be welded, the groove is covered by the sealing plate, so that liquids such as rainwater cannot enter the groove from the sealing plate, the rainwater and other liquids can be prevented from seeping into the groove, therefore the groove is effectively prevented from being rusted, secondary reworking and polishing of the groove are avoided, the construction progress is accelerated, and the construction efficiency isimproved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Shield steel sleeve sealing device and installation method thereof

ActiveCN111720129BCompact installationGuaranteed tightnessEngine sealsTunnelsClassical mechanicsStructural engineering

The invention discloses a shield steel sleeve sealing device and an installation method thereof. A sealing structure, the sealing structure includes a sealing ring and an adjusting frame, the sealing ring is embedded between two supporting cylinders, the adjusting frame includes a main connecting piece and a secondary connecting piece that are rotatably connected, and the main connecting piece and One end of the secondary connecting piece is fixedly connected to the sealing ring, and there is a gap between the main connecting piece and the other end of the secondary connecting piece. When the spacing changes, the radial expansion and contraction of the sealing ring changes synchronously. The sealing device of the shield steel sleeve and the installation method thereof of the invention can improve the sealing performance of the main body of the steel sleeve and reduce the possibility of rework of the steel sleeve.

Owner:北京城建中南土木工程集团有限公司

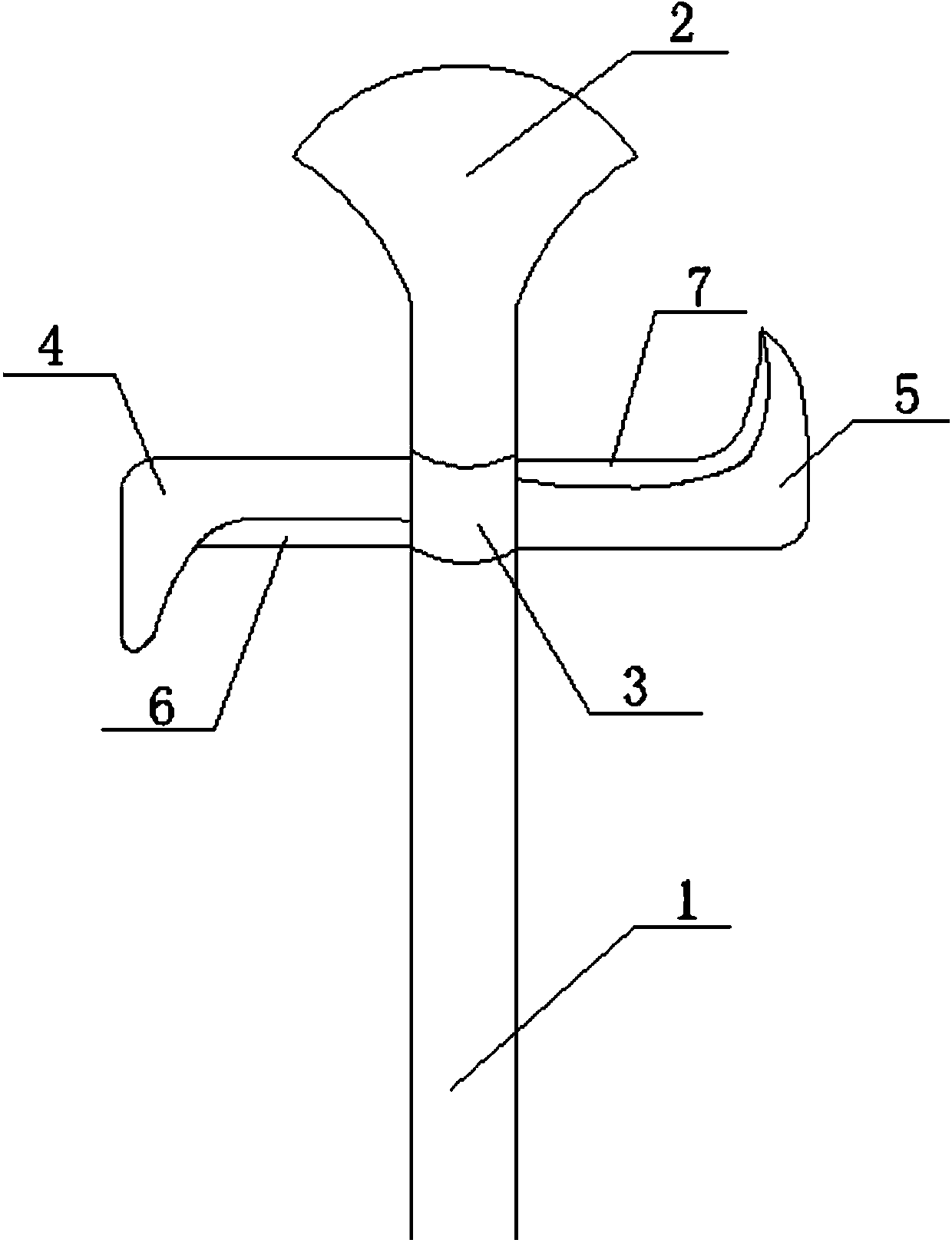

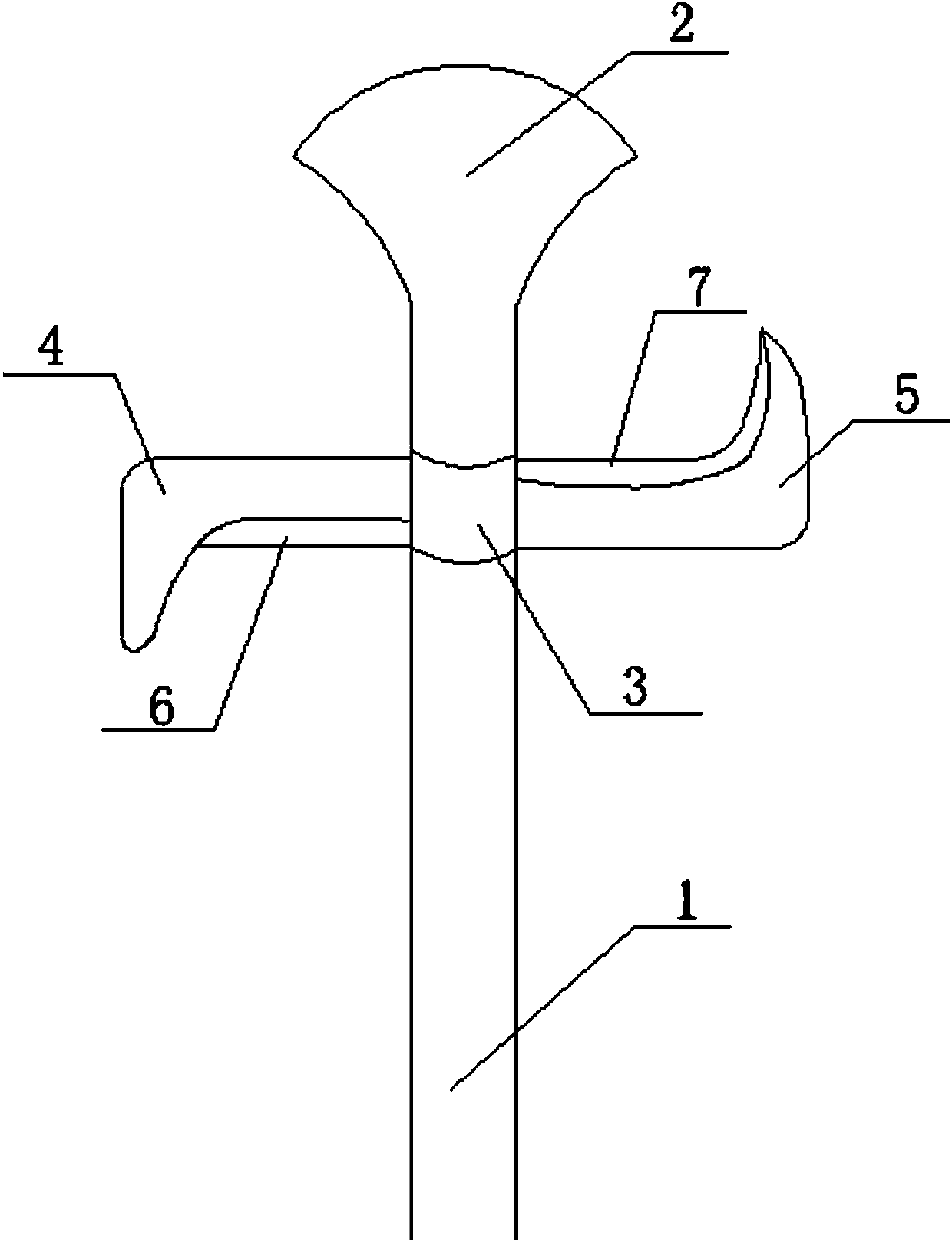

Pruning shovel structure

The invention discloses a pruning shovel structure. The structure comprises an insulating rod, a shovel head, connecting hoops, a lower hook, an upper hook, a lower hook blade and an upper hook blade;the shovel head is arranged at the top end of the insulating rod, the upper hook and the upper hook are arranged on the insulating rod through the connecting hoops, the lower hook and the upper hookare symmetrically downward and upwards bent, and the lower hook and the upper hook are provided with the lower hook blade and the upper hook blade respectively. The pruning shovel can be operated in an electrified mode, can be operated by one hand or two hands, can be pulled, can be used for puncturing and cutting, is convenient to use and durable, is easy to master, can guarantee the quality, greatly avoids secondary reworking caused by manual reasons, and reduces the workload of workers. The work needs to be completed in one hour only needs several minutes at present, and the working efficiency is greatly improved.

Owner:陕西秦能电力科技股份有限公司

A double-cross-flow air-conditioning motor scrapped stator assembly winding recovery device

ActiveCN107994737BAvoid damageImprove recycling ratesManufacturing dynamo-electric machinesElectric machineBall screw

The invention discloses a recycling device for a double-cross-flow air conditioner motor waste stator assembly winding. The recycling device comprises a base, a support plate, a drive motor, a ball screw, a left clamp, a right clamp, a winding collecting tank, a hydraulic machine and a cutting machine and is characterized in that the left clamp and the right clamp are arranged on the upper sides of a left slide sleeve and a right slide sleeve, fixing blocks are symmetrically arranged on the lower side of lifting plate, electromagnets are arranged on the inner sides of the fixing blocks, magnets are embedded into the left and right sides of a slider, and the cutting machine is fixedly mounted on the lower side of the slider through a support. The recycling device has the advantages that theleft clamp and the right clamp move towards the middle by the aid of the rotation of the ball screw to clamp a stator assembly so as to prevent displacement, which causes stator iron core damage, during the cutting of the winding of the stator assembly, and the recycling rate of the stator iron core is increased greatly; the residual winding on the surface of the stator assembly can be cut by theleft-right movement of a cutting wheel during cutting, the back flushing work of the winding cannot be affected by the residual winding, and rework is avoided.

Owner:砀山县展望罐头食品厂

Cotton sleeving process for intelligent sofa frame

ActiveCN113400660AAvoid secondary reworkEasy alignmentMetal working apparatusAgricultural engineeringStructural engineering

The invention discloses a cotton sleeving process for an intelligent sofa frame. The cotton sleeving process specifically comprises the following steps of: S1, detecting sponge; S2, cutting the sponge: cutting the sponge according to the specification of a sofa, and in the sponge cutting process, adopting automatic sponge cutting equipment to ensure that the linear edge of the sponge is kept in a straight state and the arc-shaped edge of the sponge is kept in a smooth state; S3, adhering the sponge: cleaning sundries on the sponge, and uniformly spraying glue to the adhering surface of the sponge and the adhering surface of the sofa frame by using a glue sprayer; and S4, making the sponge: tightly adhering the adhering surface of the sponge to the adhering surface of the sofa frame, and then warming and cooling the edge of the sponge in sequence, so that the edge of the sponge can be shrunk according to the shape of the sofa frame. The cotton sleeving process ensures the alignment of the edge of the sponge and the edge of the sofa frame, and avoids the phenomenon of cotton leakage of the edge of the sponge on the edge of the sofa frame subsequently.

Owner:南通思凯林家居有限公司

A vacuum packaging machine convenient for fixing food

ActiveCN108466717BImprove handling efficiencyImprove work efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringDrive wheelElectric machinery

The invention discloses a vacuum packaging machine with food convenient to fix. The vacuum packaging machine with the food convenient to fix comprises a main body. Moving wheels are fixedly connectedwith the bottom of the main body through bolts. A control panel is fixedly connected with one side of the main body through bolts. A KS02Y controller is installed on one side of the control panel. A first protective frame is fixedly connected with the side, adjacent to the control panel, of the main body through bolts. A second protective frame is fixedly connected with the other side, not adjacent to the control panel, of the main body through bolts. A separation plate is fixedly connected with the interior of the main body through bolts. The vacuum packaging machine with the food convenientto fix is provided with a first driven wheel, a first conveyer belt, a first motor, a first outer frame, a first rising motor, a first lead screw, a first rising plate, a second conveyer belt, a second motor, a second outer frame, a second rising motor, a second driven wheel, a second rising plate and a second lead screw, the first rising plate and the second rising plate move to remove a packaging bag to an appropriate position, the carrying efficiency of a user is improved, and the working efficiency of the user is improved.

Owner:嘉兴莲馨食品有限公司

Skin covering and facing process for outer surface of intelligent sofa

PendingCN113558420AAvoid secondary reworkGuaranteed uniformitySofasCouchesStructural engineeringManufacturing engineering

The invention discloses a skin covering and facing process for the outer surface of an intelligent sofa. The process specifically comprises the following steps: S1, a procedure before self-inspection: performing seam sleeve detection, wooden frame detection and sponge bonding detection; S2, cotton stuffing: stuffing non-glue cotton into a seam sleeve, and pressing and rolling the surface of the seam sleeve to ensure that the non-glue cotton is in place at the inner corner of the seam sleeve; S3, skin covering and facing: sleeving a wooden frame bonded with sponge by using the seam sleeve in the step S2, and performing tidy nailing through a gun; and S4, a post-self-inspection procedure: performing leather scratch detection and suturing gun nail position detection. According to the process, the aesthetic property of final forming of the sofa is ensured.

Owner:南通思凯林家居有限公司

Steel wire rope bending device and method thereof

The invention discloses a steel wire rope bending device and a method thereof and belongs to the technical field of steel wire rope machining. The steel wire rope bending device comprises a screw, follower levers, a supporting plate, a supporting shaft and clamping parts, wherein the supporting plate is provided with the supporting shaft and movably connected with one ends of the two follower levers, the other ends of the two follower levers are movably connected with the clamping parts correspondingly, the two ends of the screw are a reverse thread part and a forward thread part, and the twoclamping parts are located at the two ends of the screw correspondingly and matched with the reverse thread part and the forward thread part correspondingly. Aiming at the problem that in the prior art, steel wire rope bending operation is inconvenient, the steel wire rope bending device can bend a steel wire rope quite conveniently and is high in portability.

Owner:马鞍山港口(集团)有限责任公司

Vacuum packaging machine facilitating food fixing

InactiveCN108622467AImprove handling efficiencyImprove work efficiencyPackaging by pressurising/gasifyingDrive wheelOperations management

The invention discloses a vacuum packaging machine facilitating food fixing. The vacuum packaging machine comprises a main body, the bottom of the main body is fixedly connected with moving wheels through bolts, and one side of the main body is fixedly connected with a control panel through bolts; a KS02Y controller is arranged on one side of the control panel; one side, adjacent to the control panel, of the main body is fixedly connected with a first protection frame through bolts, and the other side, adjacent to the control panel, of the main body is fixedly connected with a second protection frame through bolts; and the inner part of the main body is fixedly connected with a partition plate through bolts. According to the vacuum packaging machine, a first driven wheel, a first conveyingbelt, a first motor, a first outer frame, a first ascending motor, a first screw rod, a first ascending plate, a second conveying belt, a second motor, a second outer frame, a second ascending motor,a second driven wheel, a second ascending plate and a second screw rod are arranged, the first ascending plate and the second ascending plate move to move a packaging bag to a proper position, so that the carrying efficiency of a user is improved, and the working efficiency of a user is improved.

Owner:方宣锋

A groove waterproof device and the use method of the device

ActiveCN108907523BPrevent infiltrationAvoid secondary reworkWelding/cutting auxillary devicesAuxillary welding devicesPolishingStructural engineering

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

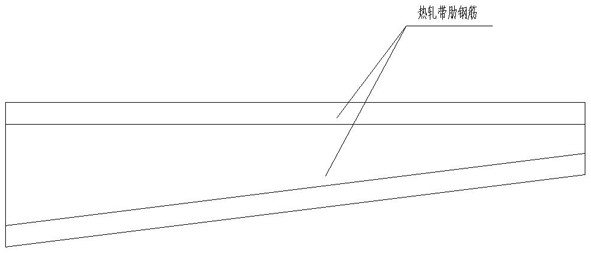

Winter outdoor apron construction method

InactiveCN113062363ASolve the problem of foundation settlementAvoid secondary reworkArtificial islandsEmbankmentsArchitectural engineeringRebar

The invention discloses a winter outdoor apron construction method, and relates to the field of apron slope building construction. The method comprises the steps that hot-rolled ribbed steel bars are added after an apron foundation is tamped to form a bracket structure, the side face of a ground beam is chiseled, the bonding effect of concrete and the ground beam is improved, a bracket formwork is supported and poured, the bracket formwork is detached after 75% of strength is reached, the bracket lifting amount is small, and the supporting effect of the concrete formwork is improved; and backfilling, formwork supporting, pouring and heat preservation treatment are carried out on an apron area, the formwork is detached after the apron area is completely cured, and expansion joint construction is carried out. According to the method, the foundation cannot settle after a frozen soil layer is opened in summer during winter outdoor apron construction, the construction quality is guaranteed, and secondary repair construction is avoided.

Owner:CHINA 22MCC GROUP CORP

Cold-rolled steel bar screw conveyor

The invention discloses a cold-rolled steel bar screw conveyor. The cold-rolled steel bar screw conveyor comprises a shell, wherein a disc is rotatably connected to the surface of the shell, an insertion plate is fixedly connected to the top end of the shell, a fixing seat is fixedly connected to the top end of the shell, a fixing hook is rotatably connected to the surface of the fixing seat, a clamping block is slidably connected to the interior of the fixing seat, a first toothed bar is inserted into the top end of the fixing seat, a gear is rotationally connected into the fixed seat, an original device for adjusting discs in a scattered mode is changed into a device for adjusting the height integrally, operation is convenient and easy, one-by-one rotating height adjustment is not needed as before, it is guaranteed that the heights of all the discs are the same, straightness of reinforcing steel bars is guaranteed, it is avoided that the overall bending of the reinforcing steel bars later is not influenced, the cold-rolled steel bar screw conveyor has small-amplitude bending with pits, saves the working time of workers, lays a good foundation for subsequent bending, improves the working efficiency, and increases the functionality and practicability of the device.

Owner:河南省鼎鼎实业有限公司

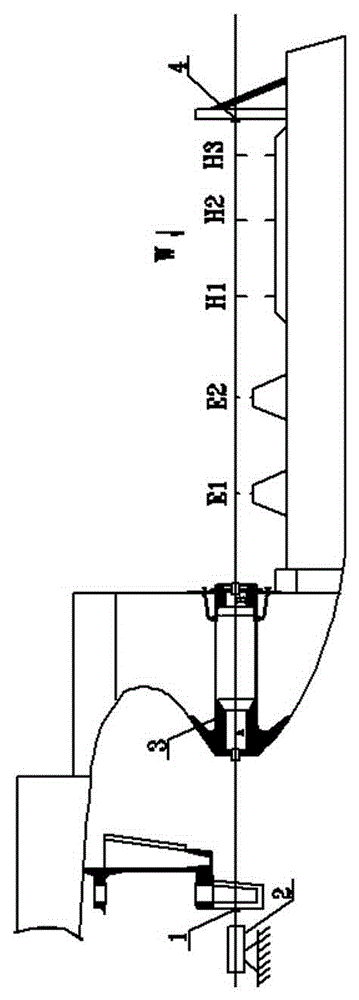

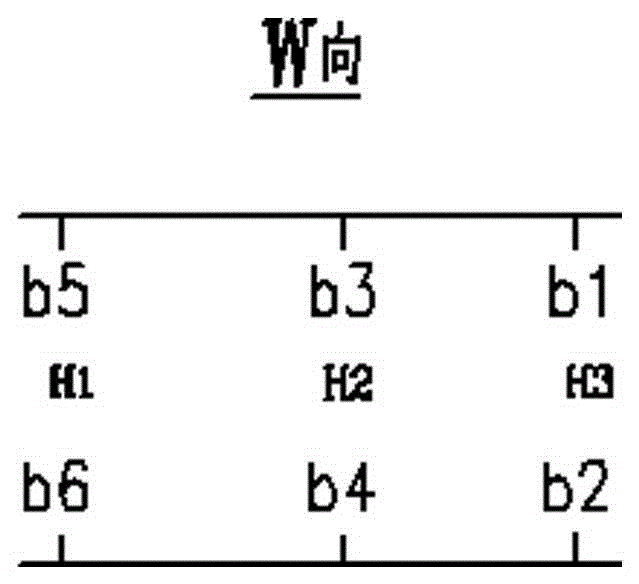

5000pctc lighting process for shafting of ro-ro ship

The invention relates to a 5,000PCTC (pure car and truck carrier) shafting irradiation process and belongs to the technical field of ships. The 5,000PCTC (pure car and truck carrier) shafting irradiation process comprises the following steps: enabled light targets with crossed scribed lines to be arranged on a head base point and a tail base point, and enabling a sighting instrument to be located at the back of the tail base point; arranging eight-leg light target frames in an inner hole of a tail shaft pipe, enabling the front light target and the rear light target to be fixed on the eight-leg light target frames, and performing preliminary alignment according to the inner hole; correcting the standard of the sighting instrument according to the tail base point; performing operation repeatedly until the sighting instrument passes through the head base point and the tail base point; respectively adjusting the light target frames of the front light target and the rear light target in the tail shaft pipe to enable two light target centers to coincide with the head base point and the tail base point; checking centering conditions according to the well adjusted center positions of the front light target and the rear light target in the inner hole of the tail shaft pipe; adjusting the focus of the sighting instrument, and checking left-and-right centering conditions of a bearing block; hanging a counter weight, and checking left-and-right centering conditions of a base; measuring relative positions of the shafting center line and rudder center line; and check and correcting positions of a bow base point and a stern base point until the requirements are met.

Owner:浙江东海岸船业有限公司

A kind of NdFeB magnet manufacturing method

ActiveCN110246676BStir wellAvoid the need for secondary reworkInductances/transformers/magnets manufactureCrucibleHydrogen treatment

The invention discloses a method for manufacturing a neodymium iron boron magnet. The method comprises steps of raw material preparation and pretreatment, a magnet is weighed, broken, cut and derusted by a steel cutter and a barrel polishing machine; smelting, the pretreated magnet is smelted by a vacuum smelting furnace to form neodymium iron boron alloy; hydrogen explosion, hydrogen explosion of the smelted neodymium iron boron alloy is performed by a vacuum hydrogen treatment furnace; milling, a magnet crusher is utilized to break neodymium iron boron alloy pieces after hydrogen explosion into powder; molding orientation, the powder is shaped through utilizing a magnetic field press and an isostatic press; sintering, a formed semi-finished product is sintered by a vacuum sintering furnace; and machining, the sintered NdFeB magnet is machined through utilizing a grinding machine. The method is advantaged in that the method is simple to implement, can fully stir the magnet pieces heated in a crucible to achieve uniform heating, and avoid the need for secondary rework due to uneven heating due to local heat unevenness.

Owner:ZHEJIANG SHEENSEN MAGNETICS TECH CO LTD

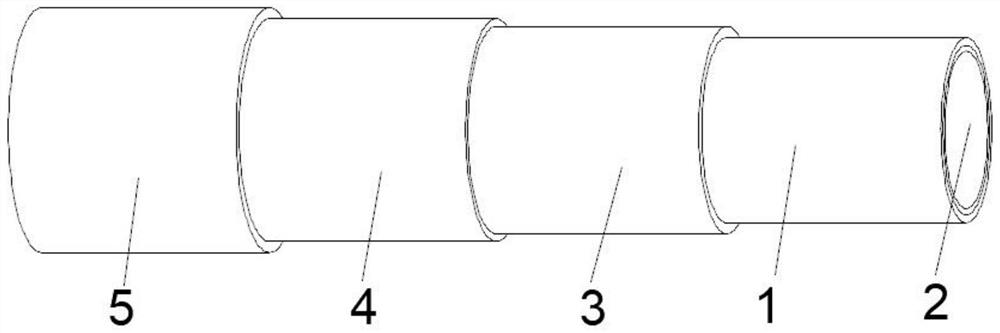

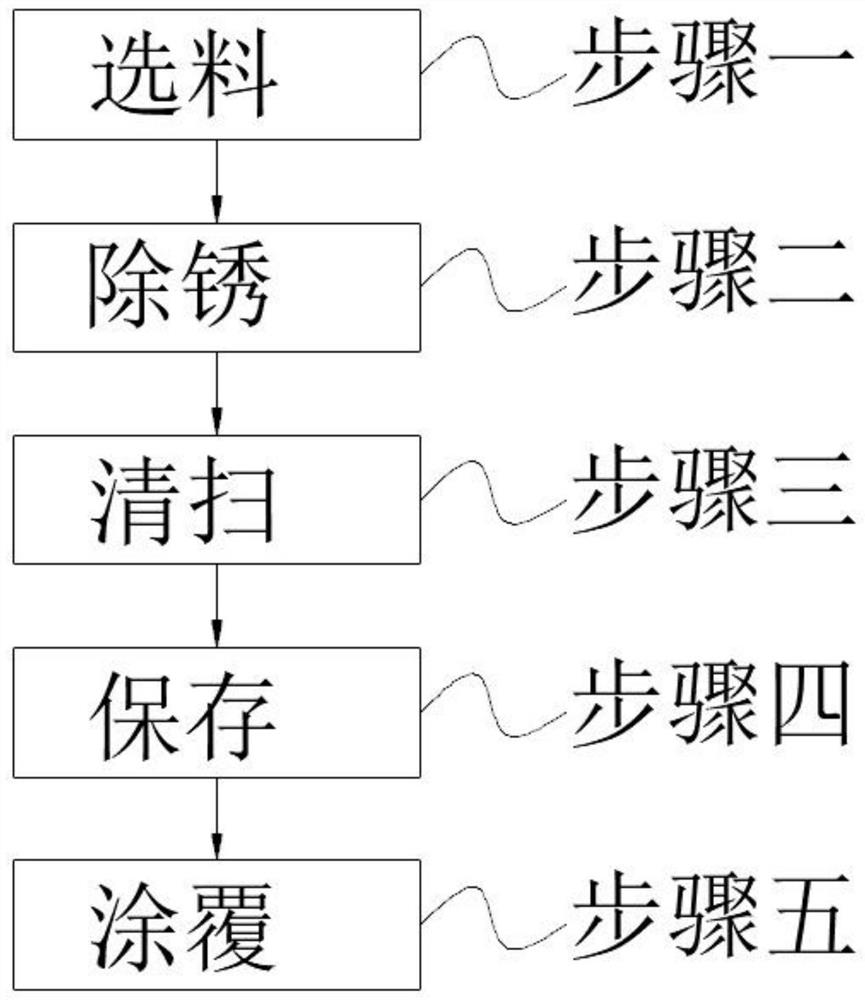

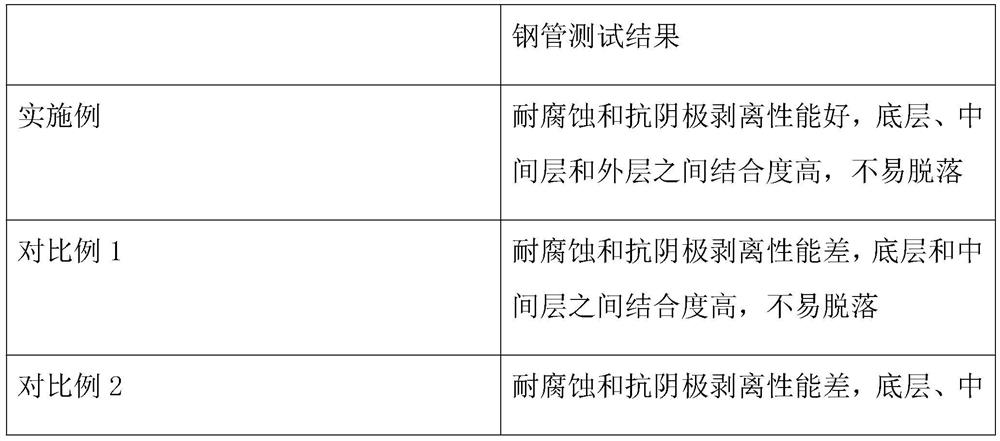

TPEP hot-melting 3PE anti-corrosion steel pipe and preparation process thereof

InactiveCN112974195AAccelerated corrosionImproved resistance to cathodic disbondmentPretreated surfacesCoatingsEpoxyAdhesive cement

The invention discloses a TPEP hot-melting 3PE anti-corrosion steel pipe and a preparation process thereof.The TPEP hot melting 3PE anti-corrosion steel pipe comprises a steel pipe body, an inner layer, a bottom layer, a middle layer and an outer layer, and the inner layer is coated inside the steel pipe body. According to the steel pipe, the sintered epoxy powder is adopted as the bottom layer, chemical bonding with the middle layer is facilitated, such that the corrosion resistance and cathodic disbonding resistance of the steel pipe are improved, and meanwhile, the middle layer is a copolymer adhesive, plays a role in bonding the bottom layer and the outer layer and is beneficial to resisting a shear force caused by soil movement and temperature change, and at the same time, the outer layer is arranged, so that the steel pipe has excellent moisture resistance, the bottom layer and the middle layer are convenient to protect, the coating process can be completed through the same process, such that the cost for purchasing needed production equipment is reduced, and the needed energy consumption is reduced; meanwhile, the quality of the steel pipe is improved, the steel pipe is wrapped with antirust paper, then moisture in the environment for storing the steel pipe is reduced, such that a phenomenon of secondary rusting of the steel pipe is avoided, and thus, the working efficiency is further improved.

Owner:LIAONING YITONG STEEL PLASTIC COMPOSITE PIPE MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com