Roof exhaust pipe fixing device and manufacturing method thereof

A technology for fixing devices and manufacturing methods, applied in roof ventilation, heating methods, household heating, etc., can solve problems affecting the roof, water seepage at the edge of the exhaust pipe, shaking of the exhaust riser, etc., so as to avoid secondary rework and manufacture Convenience and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The roof exhaust pipe fixing device of the present invention includes a fixing bracket and a protective cover.

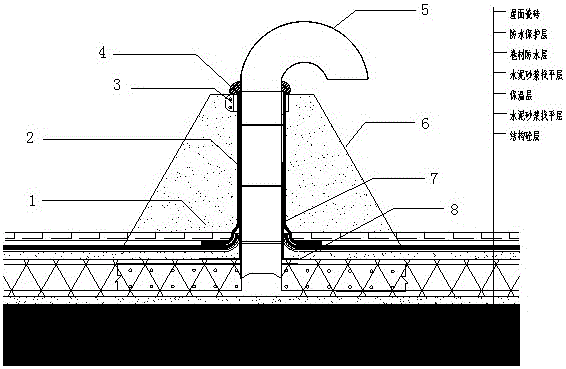

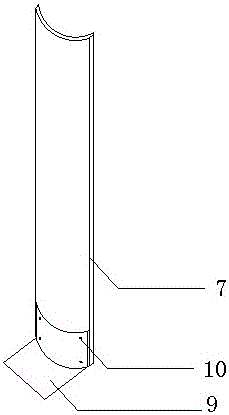

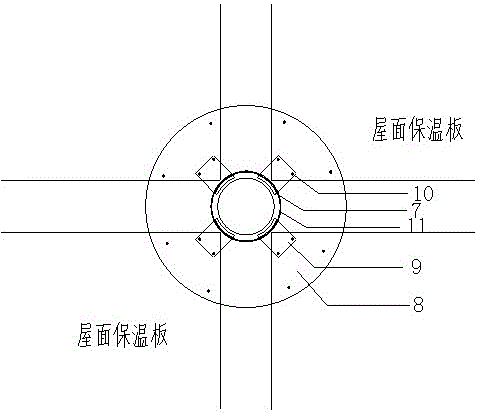

[0037] See now figure 1 with image 3 , figure 1 It is a schematic diagram of the structure and use state of the roof exhaust pipe fixing device of the embodiment of the present invention, image 3 It is a schematic top view of a roof exhaust pipe fixing device according to an embodiment of the present invention. As shown in the figure, the fixing bracket is provided with a base 8 and a set of pillar pieces 7. The base is a circular color steel plate, which is fixed to the roof insulation board with a number of nails 10, and its inner circle diameter is slightly larger than the roof The exhaust pipe has a diameter of 5 to allow the roof exhaust pipe to pass through. The width of the annular color steel plate is 200mm; the set of pillar pieces is provided with four PVC pipe arcs, and the four PVC pipe arcs are equally divided according to the arc of the circle. ...

Embodiment 2

[0040] A method for manufacturing a roof exhaust pipe fixing device, which is characterized by comprising the following steps:

[0041] a. Choose materials

[0042] According to the size and form of the roof exhaust pipe required by the design drawings, the selection includes the PVC pipe used for the fixing bracket, the protective cover steel plate and the plastic tie; the PVC pipe of the roof exhaust pipe fixing device is selected according to Table 1.

[0043] Table 1 Comparison table of PVC pipe size used for roof exhaust pipe and fixing device

[0044]

[0045] b. Make upright pieces

[0046] Choose PVC pipes according to the diameter of the roof exhaust pipes, and cut them into sections according to the exposed height of the roof exhaust pipes. The cut PVC pipe sections are axially sectioned and divided into eight arc-shaped pieces, and 4 pieces are taken to form a set of pillar pieces 7 spare;

[0047] c. Make a base, the base is a ring-shaped steel plate, the ring-shaped steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com