A double-cross-flow air-conditioning motor scrapped stator assembly winding recovery device

A stator assembly and recovery device technology, applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of reducing recovery efficiency, secondary rework, and stator assembly scrapping, so as to improve efficiency and avoid secondary Effects of rework and increased recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

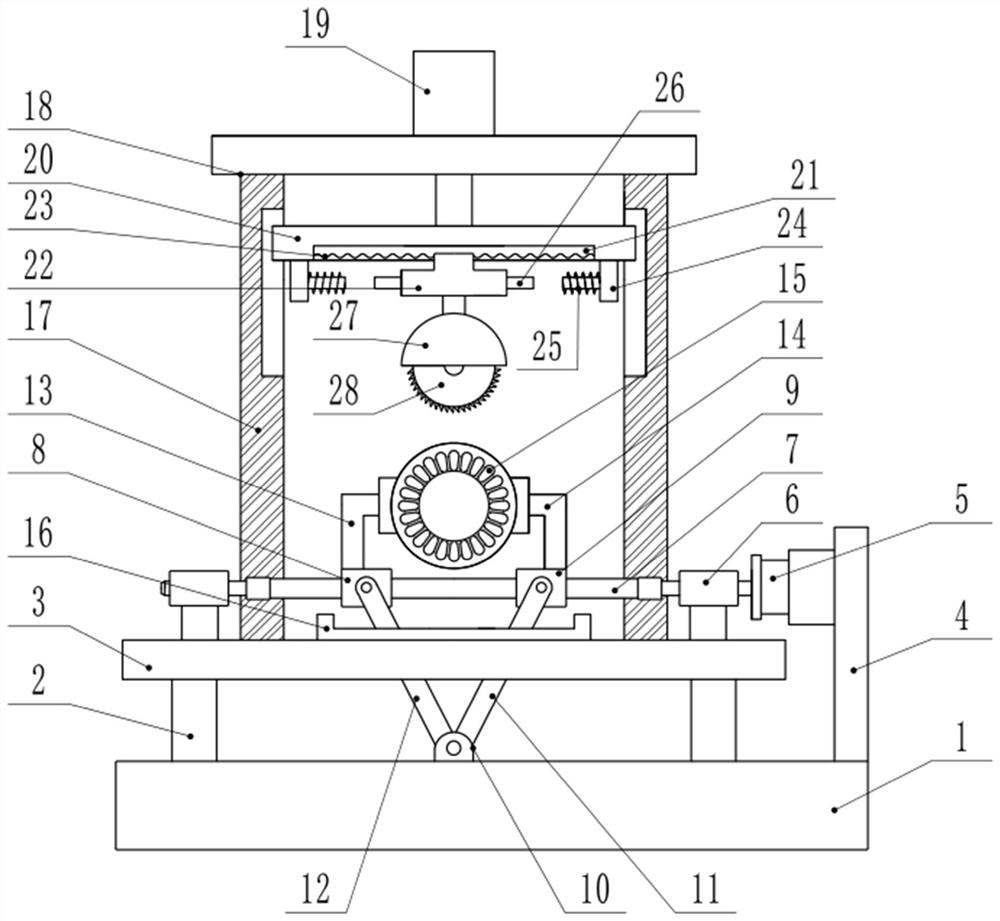

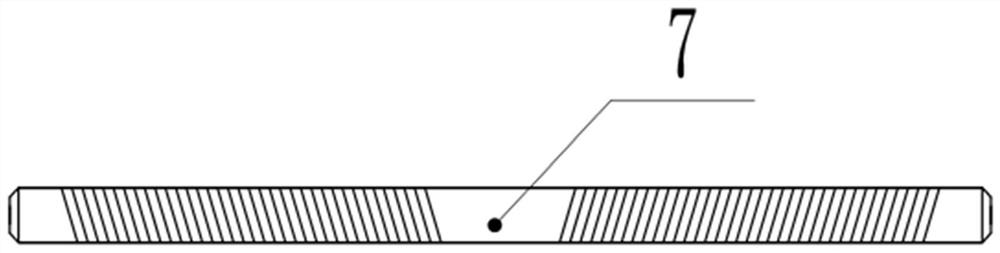

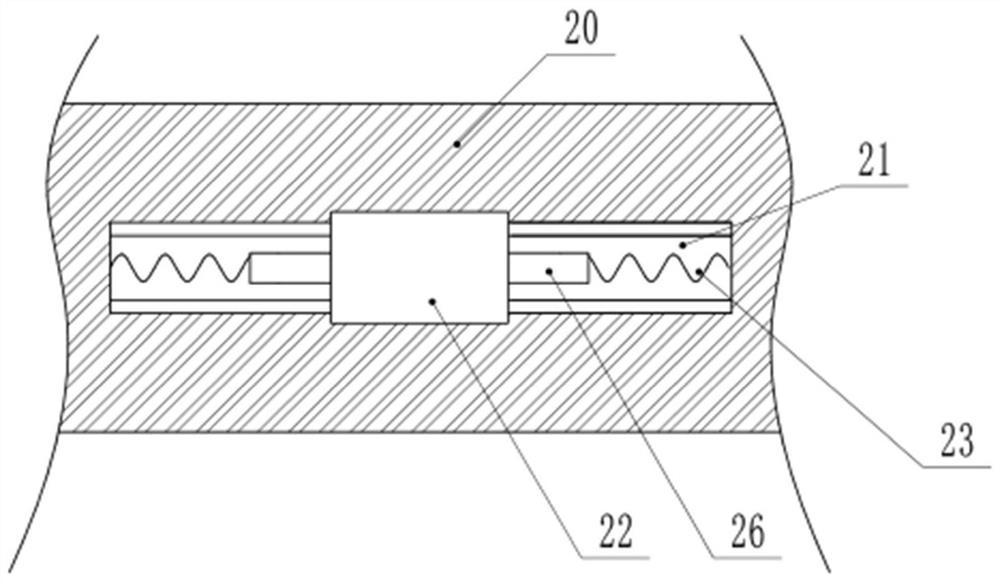

[0021] see Figure 1-3 , a double cross-flow air conditioner motor scrapped stator assembly winding recovery device, including a base 1, a support plate 3, a drive motor 5, a ball screw 7, a left clamp 13, a right clamp 14, a winding receiving tank 16, a hydraulic press 19 and Cutting machine 27, the upper surface of the base 1 is symmetrically welded with a support column 2, the upper side of the support column 2 is also welded with a support plate 3, and the right side of the upper surface of the base 1 is also fixed with a vertical plate 4 by screws, The riser 4 is perpendicular to the upper surface of the base 1, the left side of the riser 4 is fixedly installed with a drive motor 5 through a bracket, the output shaft of the drive motor 5 is horizontal to the left, and the support plate 3 is fixedly installed with a Shaft sleeve 6, bearings ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com