Cotton sleeving process for intelligent sofa frame

A sofa and frame technology, which is applied in the field of cotton covering technology of smart sofa frame, can solve the problems of induration of the edge of the sofa frame, leakage of cotton, and leakage of sponge to the outer side of the sofa, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

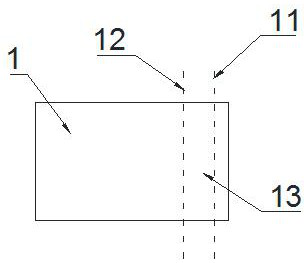

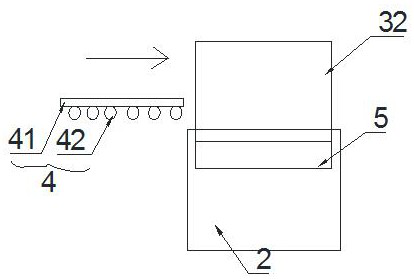

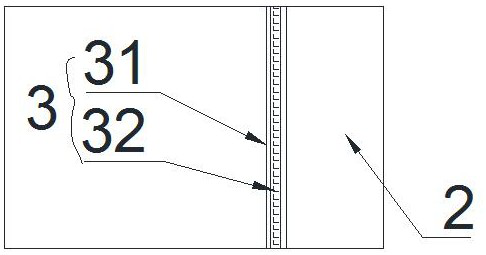

[0028] Such as Figure 1 to Figure 2 A specific embodiment of the present invention specifically includes the following steps:

[0029] S1, detection of sponge 1;

[0030] S2. Cotton cutting: Cut the sponge 1 according to the specifications of the sofa. During the cutting process of the sponge 1, an automatic sponge cutting device 2 is used to ensure that the straight edge of the sponge 1 is kept straight and the curved edge of the sponge 1 is kept in a straight state. smooth state;

[0031] S3. Cotton sticking: clean the sundries on the sponge 1, and use a glue sprayer to evenly spray glue on the bonding surface of the sponge 1 and the bonding surface on the sofa frame;

[0032] S4. Cotton making: stick the adhesive surface of sponge 1 tightly to the adhesive surface of the sofa frame, then heat and cool down the edge of sponge 1 in turn, so that the edge of sponge 1 can shrink according to the shape of the sofa frame .

[0033] In the present invention, the detection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com