5000pctc lighting process for shafting of ro-ro ship

A shafting and rolling ship technology, applied in ship parts, ship construction, ships, etc., can solve the problems of poor welding accuracy of the stern shaft frame, affecting the service life of the ship, etc., to prevent secondary rework, save manpower and financial resources, and improve the overall good effect on neutral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

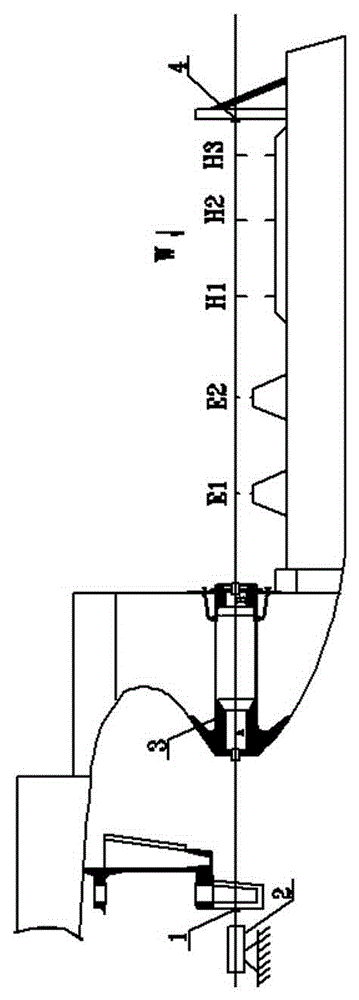

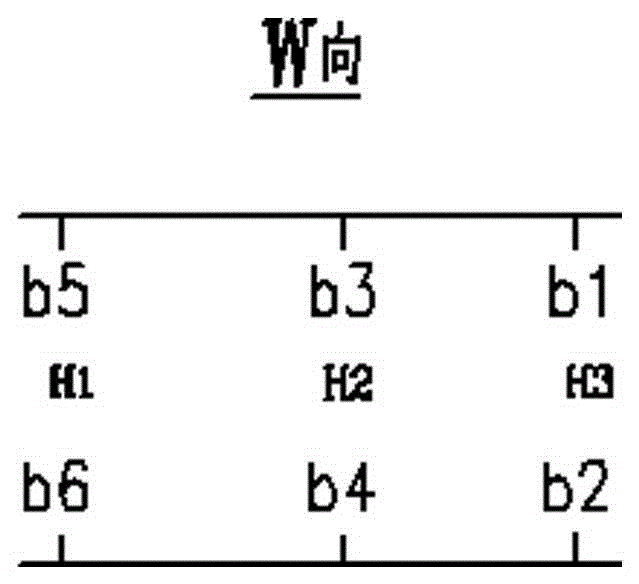

[0021] Now combined with the accompanying drawings, the lighting process of 5000PCTC vehicle-roller ship shafting consists of the following process steps:

[0022] a. Preparations before lighting the shaft system, replace the first base point 1 and the tail base point 4 with light targets with cross marks. The light targets are required to be accurate and firm. The instrument 2 workbench and the hull should not be connected to each other;

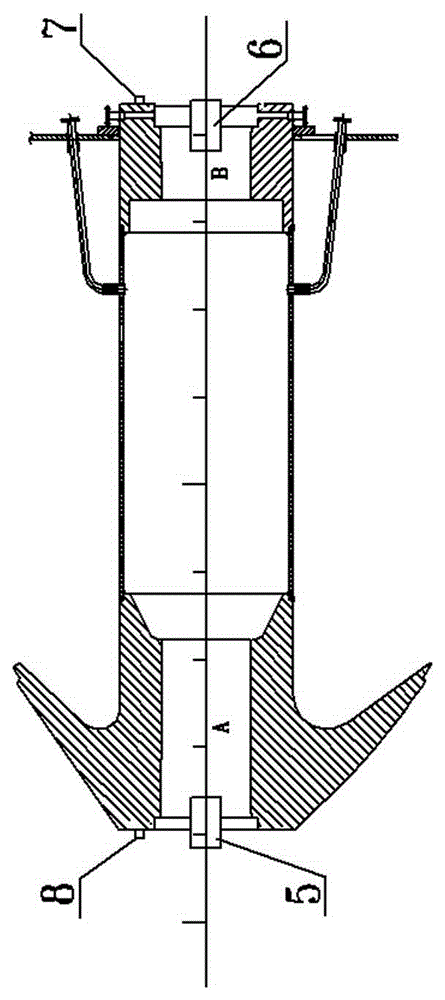

[0023] b. Set an eight-leg light target frame in the inner hole of the stern tube 3, and fix the front light target 5 and the rear light target 6 on it, and make preliminary alignment according to the inner hole; the weight frame is ready;

[0024] c. After the optometry 2 is fixed, calibrate the benchmark (crosshair) of the optometry 2 with the tail base point 4, and look at the first base point 1 after the calibration is accurate; repeat several times until the optometry 2 passes the first base point 1 and the tail base point 4. At this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com