TPEP hot-melting 3PE anti-corrosion steel pipe and preparation process thereof

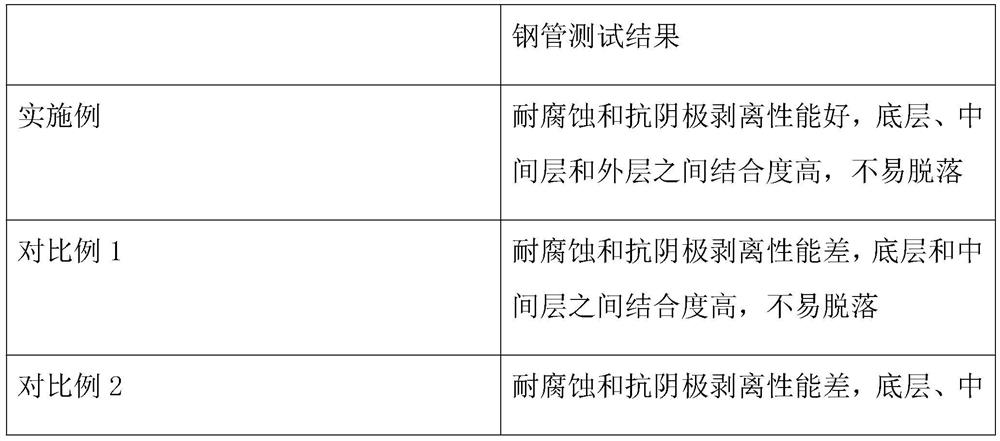

A kind of anti-corrosion steel pipe and technology of preparation process, which is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems such as vacuum parts prone to appear in the anti-corrosion layer, large amount of anti-corrosion steel pipe used, and reduced work efficiency. Achieve the effects of improving corrosion resistance and cathodic disbonding resistance, reducing storage humidity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

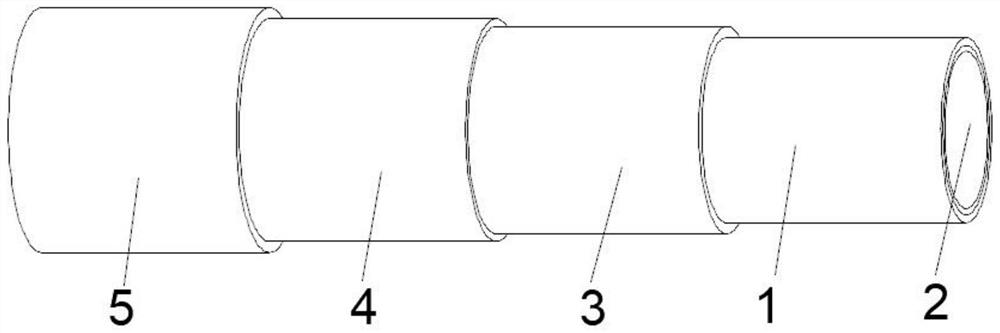

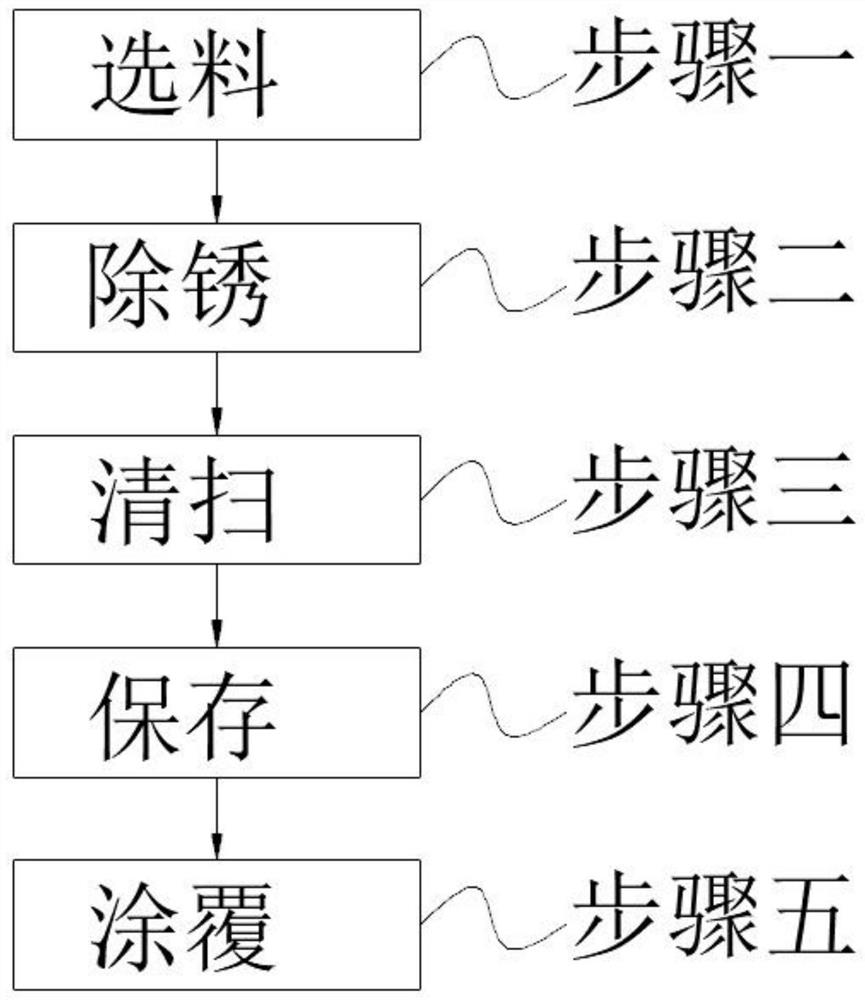

[0025] The preparation process of TPEP hot-melt 3PE anti-corrosion steel pipe includes step 1, material selection; step 2, rust removal; step 3, cleaning; step 4, preservation; step 5, coating;

[0026] Wherein in the above-mentioned step 1, firstly select the steel pipe 1 whose weld seam reinforcement height is 0-2.5mm, and the weld seam should transition smoothly, and the pipe diameter is 50-300mm;

[0027] Among them, in the above-mentioned step 2, the attachments such as grease and dirt on the surface of the steel pipe 1 are subsequently removed, and the steel pipe 1 is preheated to carry out projectile derusting or spray derusting, and before performing projectile derusting or spray derusting, the surface of the steel pipe 1 The temperature should be 3-10°C higher than the dew point temperature. At the same time, the quality of the derusted steel pipe 1 should meet the requirements of sa2.5 grade specified in GB / T8923, the depth of the anchor pattern should reach 50-90μm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com