Wallboard embedded part complete set construction method

A construction method and technology of embedded parts, applied in the field of complete set of wallboard embedded parts, can solve the problems of laborious, low positioning accuracy of embedded parts, time-consuming and other problems, and achieve the effect of convenient construction, high accuracy and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further illustrated below by specific examples.

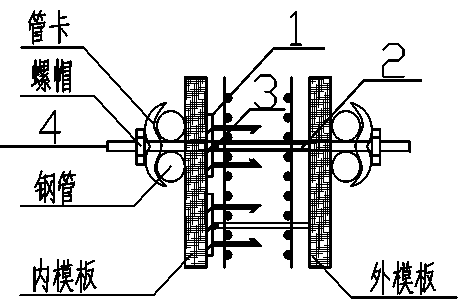

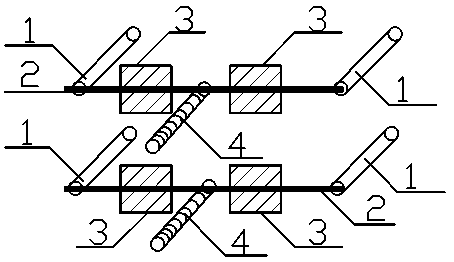

[0023] Such as figure 1 , figure 2 As shown, a complete set of construction method for wall panel embedded parts, including:

[0024] 1. After the steel bars of the wall board are bound, first weld a top support bracket 1 with the same length as the thickness of the wall board at both ends of the wall board in the horizontal direction, and then mark the level of the embedded part on the construction line of the top support bracket 1. The centerline of the direction is welded with the top support bracket 1 along the center line of the horizontal direction with a fixed support 2, and the fixed support 2 connects the top support supports 1 at both ends.

[0025] 2. Then use a steel ruler to mark the specific position of each embedded part 3 on the fixed bracket 2 according to the size of the drawing. And the middle part of the embedded part 3 is welded with the fixed bracket 2.

[0026] 3. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com