FPC reinforcing equipment

A stick-reinforcing, automatic technology, applied in packaging machines, packaging, transportation and packaging, etc., can solve the problems of increased single-piece lamination time, lamination speed bottlenecks, affecting lamination efficiency, etc., to improve alignment efficiency and action. The effect of cycle reduction and faster lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the invention will be explained in detail below in conjunction with the accompanying drawings.

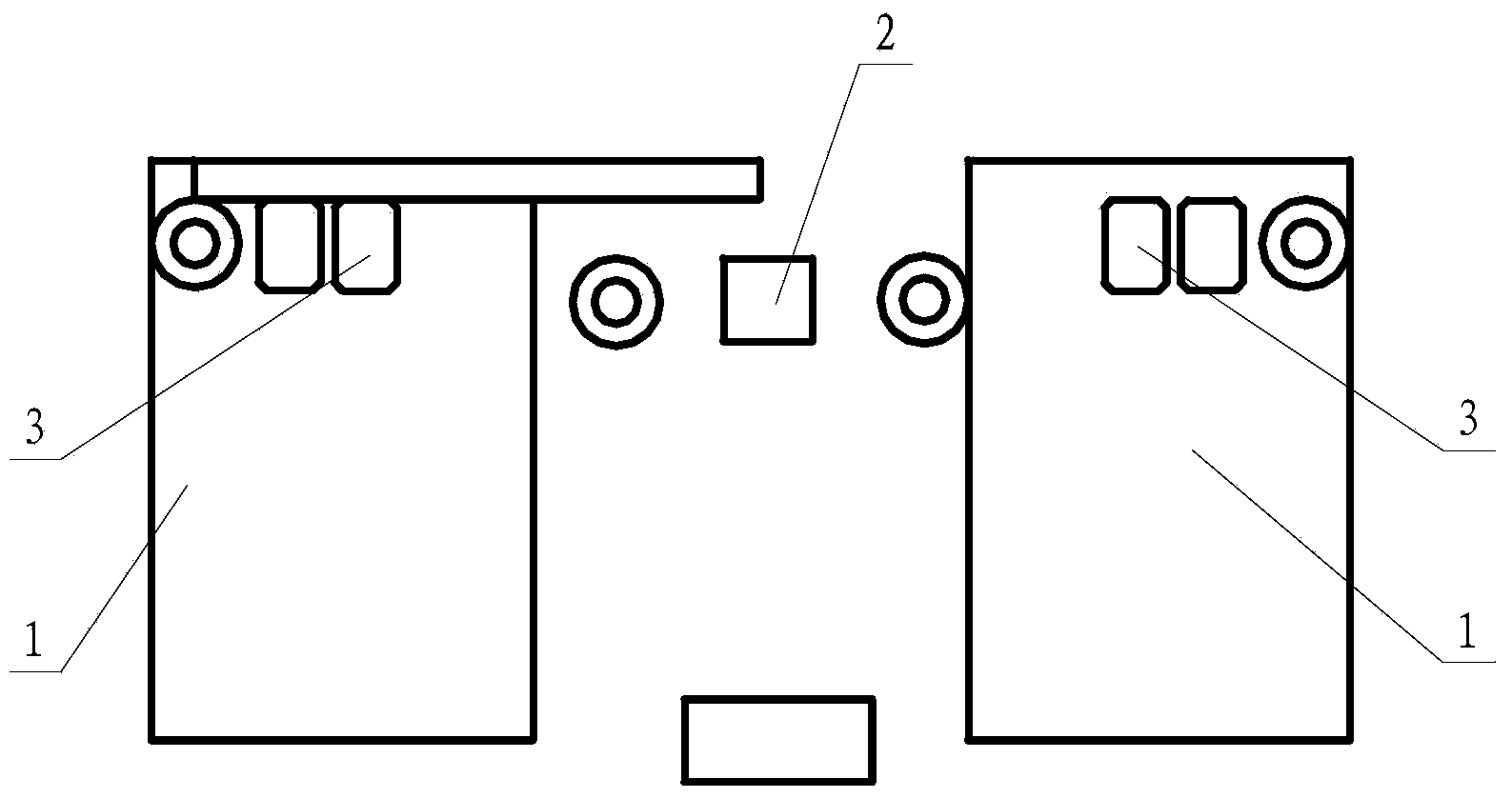

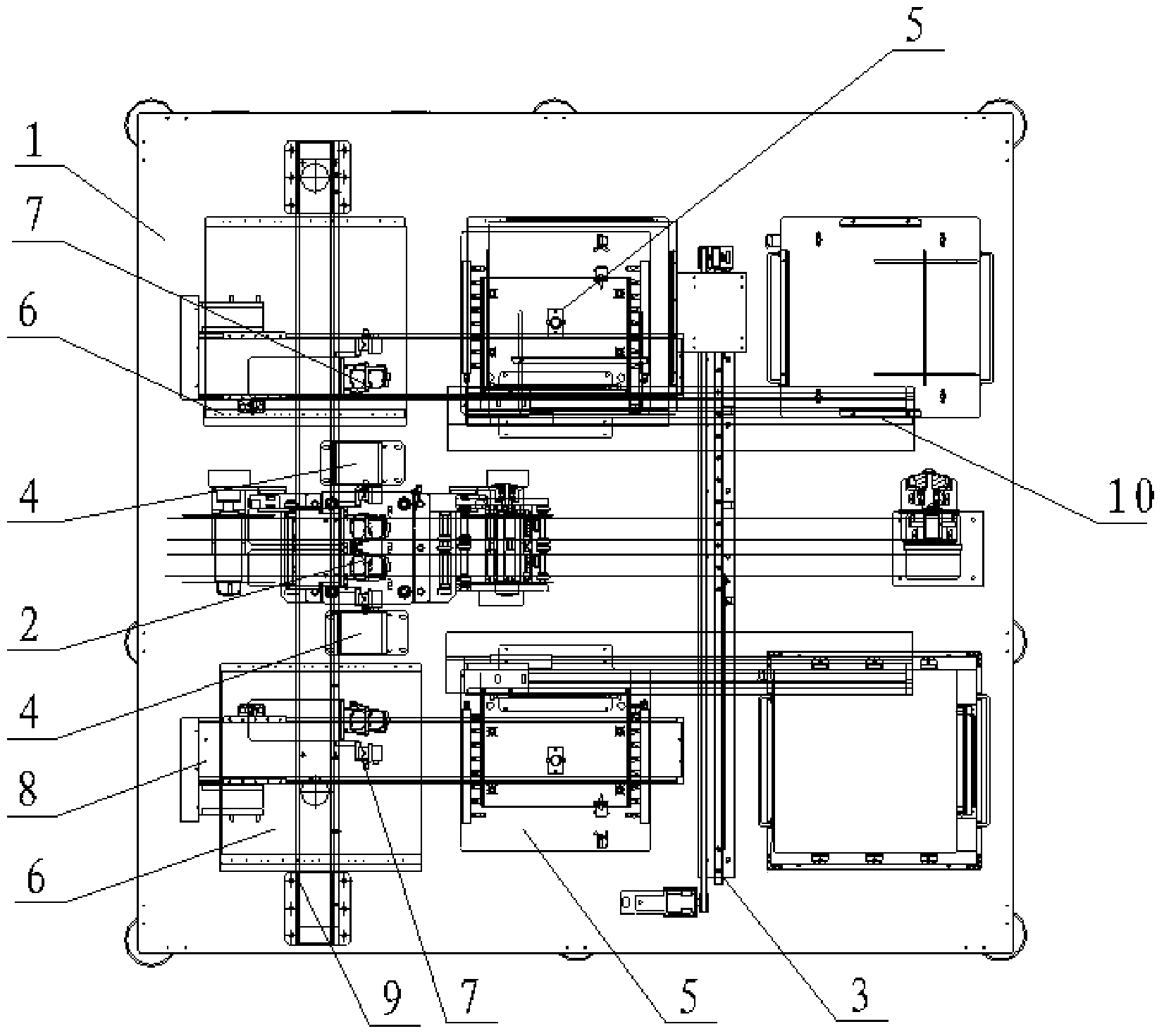

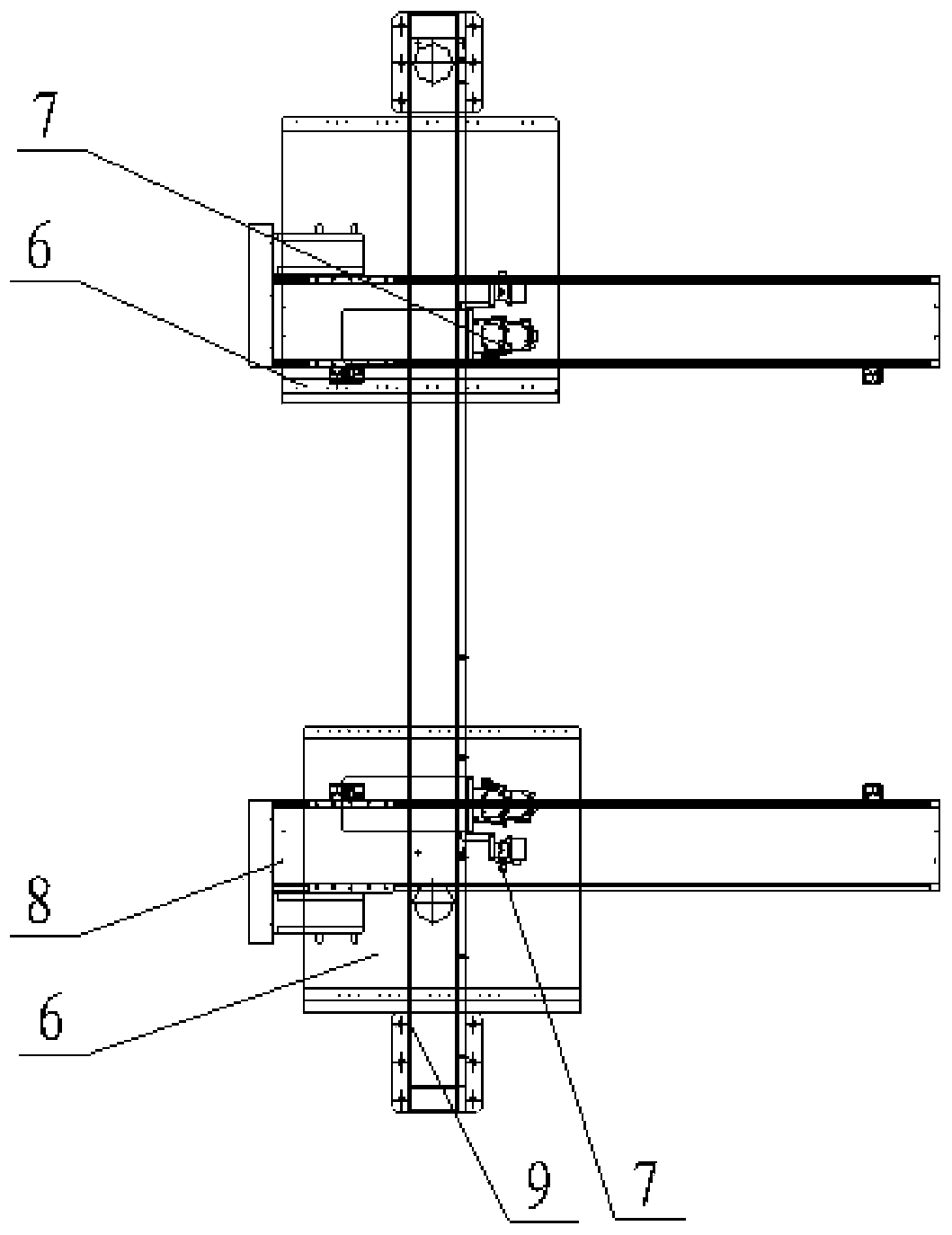

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a kind of automatic pasting and reinforcing equipment, including a table top 1, a die mechanism 2, and it also includes two sets of laminating mechanisms and a moving mechanism, the die mechanism 2 is fixed in the middle, and the two laminating mechanisms are respectively fixed on On the table tops 1 on both sides of the die mechanism 2, an automatic board expansion and contraction correction device 4 is arranged between the die mechanism 2 and each set of bonding mechanisms. The bonding mechanism includes a guide rail, a bonding platform 6, a suction cup 7, a guide rail It is fixed on the table top 1, the bonding platform 6 is placed on the guide rail, the suction cup 7 is installed on the bonding platform 6, and the next operation equipment of the bonding mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com