Shield steel sleeve sealing device and installation method thereof

A sleeve sealing and sealing device technology, applied in the direction of engine sealing, earth-moving drilling, mining equipment, etc., can solve the problems affecting the receiving progress, the air tightness of the steel sleeve, etc., to avoid secondary rework and speed up construction progress, the effect of ensuring the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

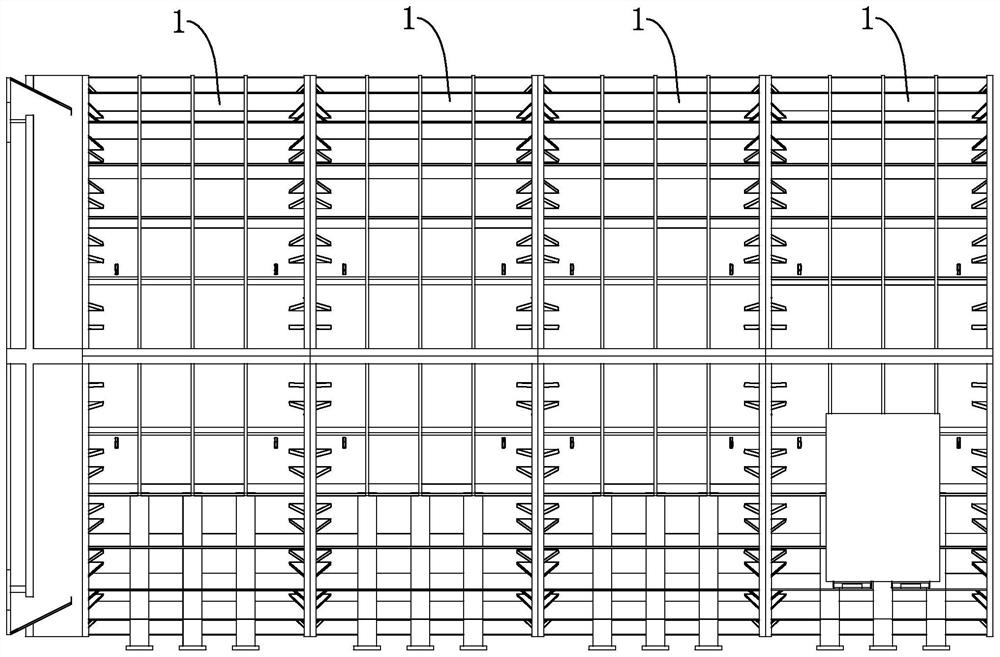

[0039] Embodiment 1: A shield steel sleeve sealing device, including a steel sleeve main body and a sealing structure, such as figure 1 As shown, the main body of the steel sleeve is formed by connecting multiple support cylinders 1 in series, and a single support cylinder 1 is welded by upper cylinder and lower cylinder, and the sealing structure is arranged between adjacent support cylinders 1 for The sealing performance between adjacent support cylinders 1 is improved.

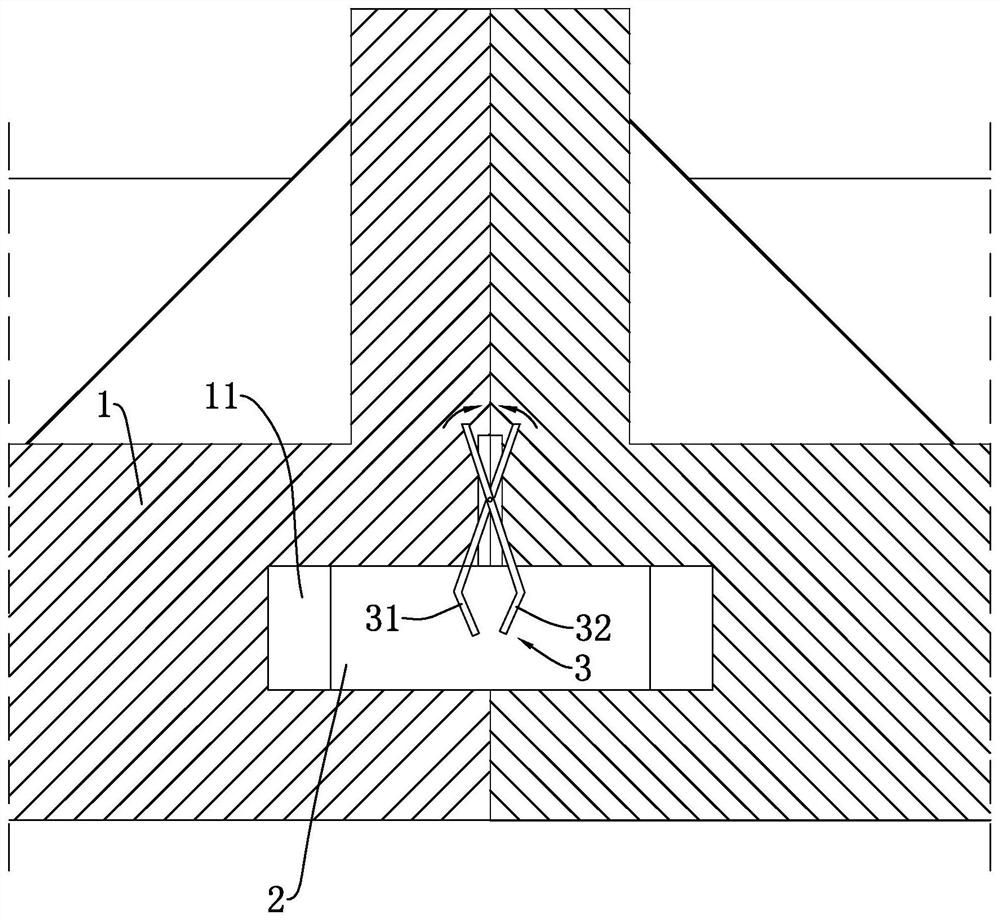

[0040] Such as figure 2 As shown, the sealing structure includes a sealing ring 2 and an adjusting frame 3, wherein the sealing ring 2 is a rubber ring whose diameter matches the diameter of the support cylinder 1, and the cross section of the sealing ring 2 is rectangular or wide in the middle and thin at both ends. Shuttle-shaped, the opposite end surfaces of two adjacent supporting cylinders 1 are symmetrically provided with relief grooves 11 matching with the sealing ring 2 , so that the sealing ring ...

Embodiment 2

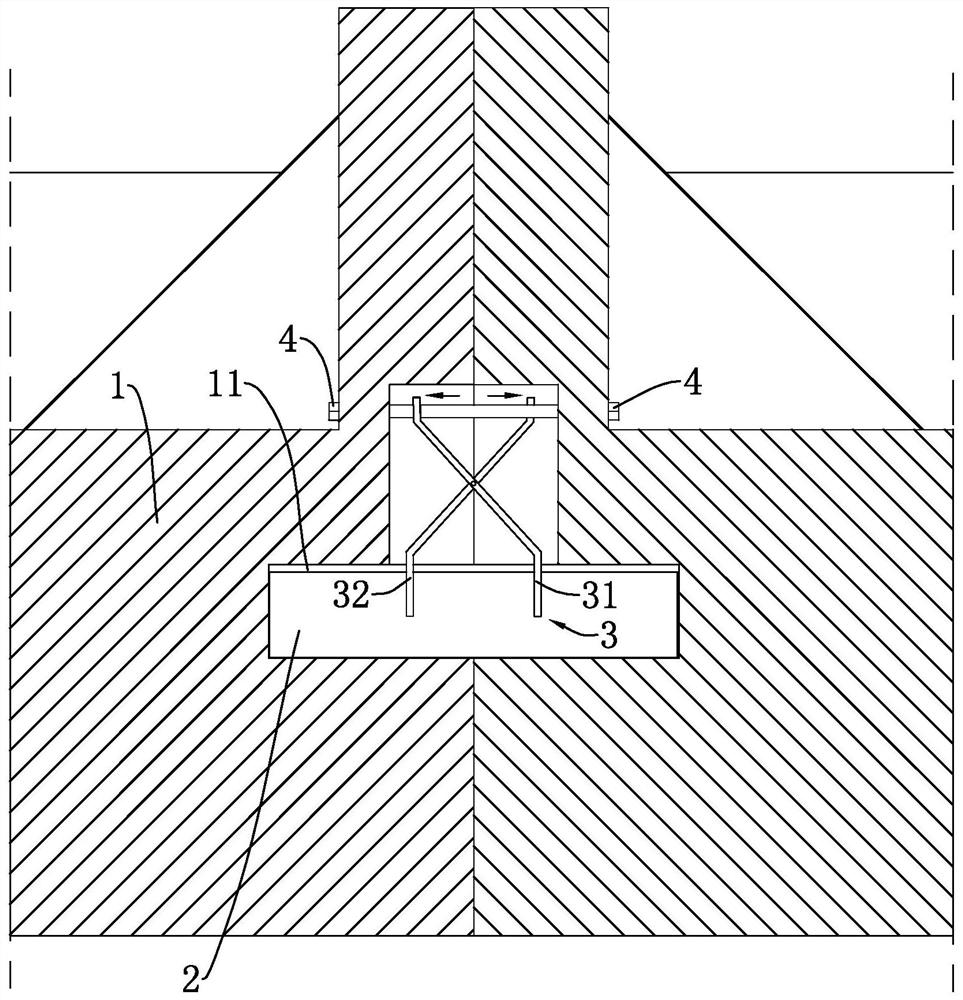

[0045] Embodiment 2: The difference between this embodiment and Embodiment 1 is that, as image 3 As shown, the sealing structure also includes adjusting bolts 4, and the relief grooves 11 symmetrically opened on the opposite end surfaces of the two adjacent supporting cylinders 1 can accommodate the sealing ring 2 and the adjusting frame 3, that is, the adjusting end of the adjusting frame 3 will not be supported. Extrusion at the end of barrel 1.

[0046] The ends of two adjacent supporting cylinders 1 are all provided with threaded holes communicating with the relief groove 11, and each group of adjusting bolts 4 is set as two, which are threadedly connected with one supporting cylinder 1 respectively, and the ends of the adjusting bolts 4 can Penetrate into the relief groove 11, press against the opposite side of the adjustment end of the main connecting piece 31 or the auxiliary connecting piece 32, increase the distance between the adjusting end of the adjusting frame 3 ...

Embodiment 3

[0048] Embodiment 3: a kind of installation method of shield steel sleeve sealing device, comprises the following steps:

[0049] Step 1. Determine the center line of the line in the foundation pit. When positioning the steel sleeve, it is required that the center line of the steel sleeve frame and the center line of the line coincide with each other.

[0050] Step 2: Assemble the first support cylinder 1 on the ground, and then lower it into the foundation pit as a whole, so that the center of the support cylinder 1 coincides with the pre-determined center line of the line, and fix it after reaching the predetermined position.

[0051] Step 3: Assembling the sealing structure, connecting the adjustment frame 3 and the sealing ring 2 into one body by hot-melting, and embed the sealing ring 2 on the end of the first section of the steel sleeve to be connected.

[0052] Step 4, repeat step 2, lower the second support cylinder 1 into the foundation pit, splice with the first supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com