Pipe-jacking three-points-and-one-line construction method

A three-point, one-line, pipe jacking technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of reducing the accuracy of pipe jacking construction, destroying underground land resources, and not easy to ensure the path, etc. problems, to achieve the effects of environmental protection and cost saving promotion, simple construction process, and standardized construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

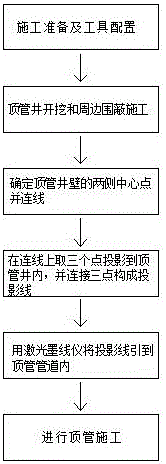

[0044] In this example, the three-point-one-line construction method of pipe jacking is used. Two pipe wells are used to determine a straight line, and three points on the line are projected into the pipe jacking well. The projected three points form a straight line to ensure the correct pipe jacking construction path, including the following steps :

[0045] (1) First, carry out construction preparation and tool configuration, the tools include: a total station for determining the projection point on the pipe jacking well; a laser ink line instrument for guiding the projection line into the pipe jacking pipeline; for determining the pipe jacking well The steel tape measure at the midpoint; the ink fountain used to mark the pipe jacking well; the hanging hammer used to project the three points selected on the connecting line into the pipe jacking well; equivalent to the connecting line, used to connect the two sides of the pipe jacking well wall White transparent plastic line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com