Alignment punch press system

A punching machine and automatic alignment technology, which is applied in metal processing and other fields, can solve the problems of low production efficiency, low alignment accuracy, and high production costs, and achieve the goal of saving enterprise labor costs, high alignment efficiency, and high accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The invention will be described in detail below in conjunction with the accompanying drawings.

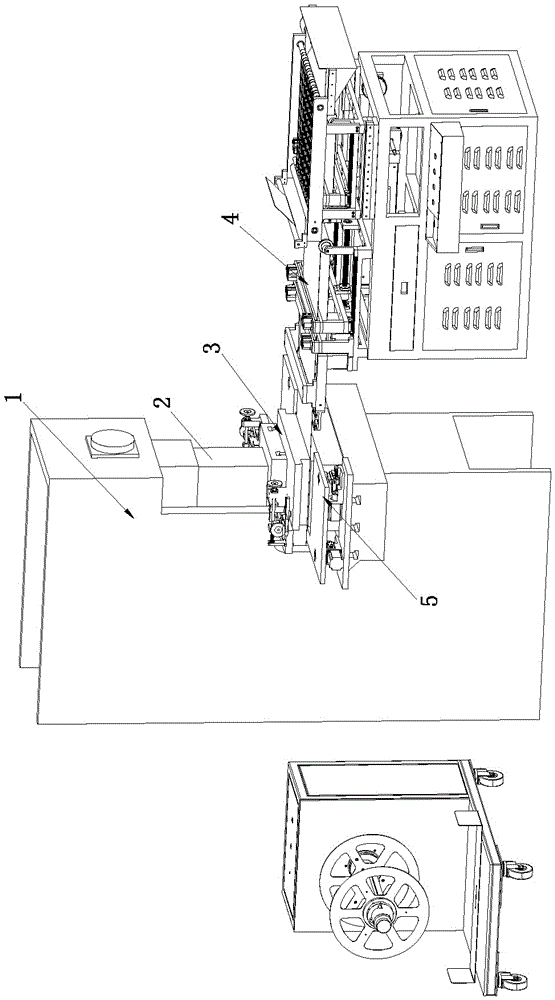

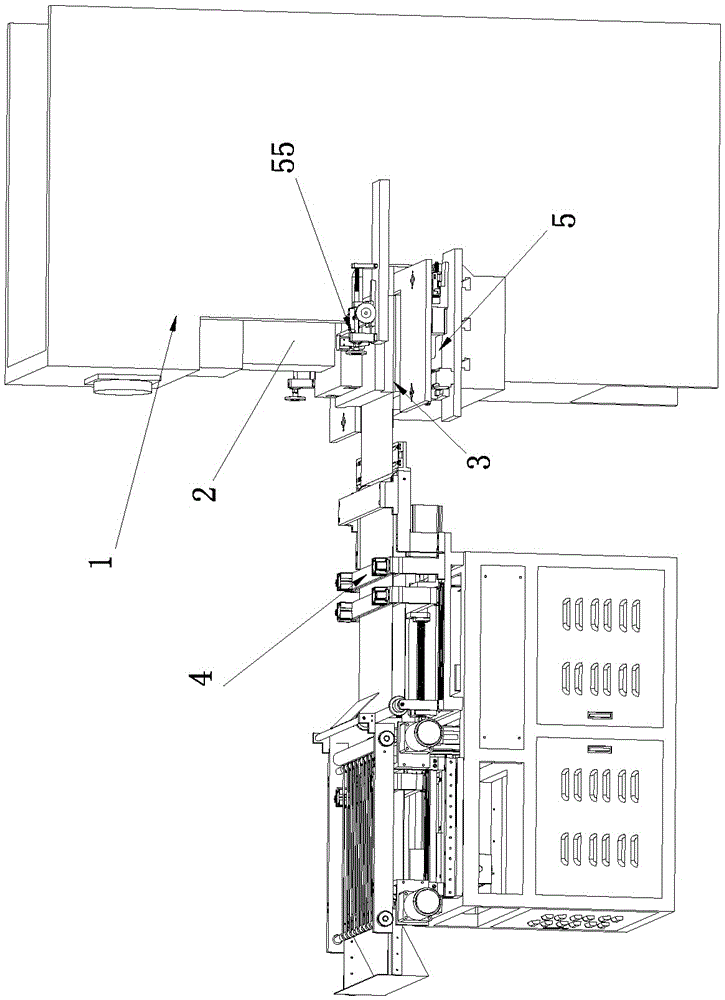

[0044] Such as Figure 1~9 As shown, the inventive alignment punching machine system includes a punching device 1, the punching device 1 is provided with a punch 2 for punching, and also includes a four-axis automatic alignment platform 5, and the four-axis automatic alignment platform 5 includes a base plate 51 and A workbench 52 for adjusting the position of materials, a bottom plate 51 is arranged on the punching device 1, a punching station 3 is arranged between the punch 2 and the workbench 52, and four groups of The XYθ alignment unit used to drive the worktable 52 to realize XY axis translation and rotation, the four sets of XYθ alignment units are distributed on the bottom plate 51 in a rectangular shape, and the rotating shafts 538 of the four sets of XYθ alignment units are respectively rotatably connected to the workbench 52 The four-axis automatic alignment plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com