Automatic feeding device, automatic feeding-type punch press and automatic feeding method

A technology of automatic feeding and feeding, which is applied in the field of punching machines, can solve the problems of the limitation of the moving distance of the feeding manipulator and the material receiving manipulator of the sheet size, the lengthening of the moving distance of the feeding manipulator and the material receiving manipulator, and the increase of the labor intensity of the operator, etc., so as to save time Cost and labor costs, convenient operation, and promotional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

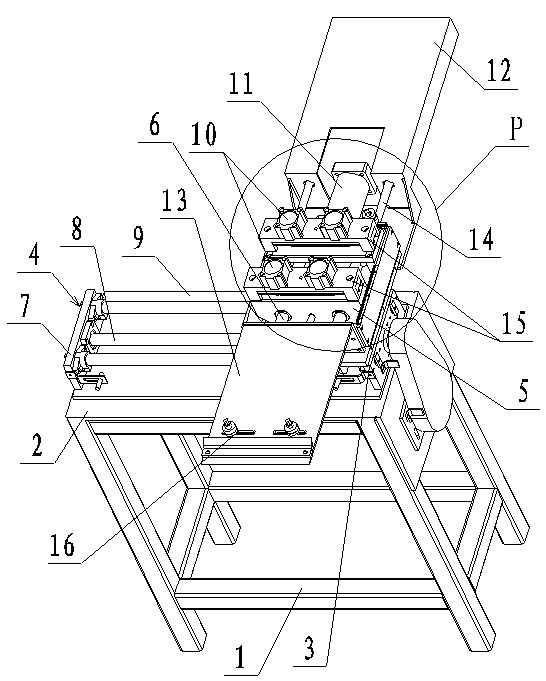

[0039] Embodiment 1: with reference to attached Figure 1-4 . An automatic feeding device, comprising a bracket 1; a worktable 2 is arranged on the top surface of the support 1; a screw drive mechanism 4 placed in the Y direction is installed on the worktable 2; the screw drive mechanism 4 includes a Y-direction screw rod 8, The motor (not shown in the figure) that controls the Y-direction screw rod 8, the fixed plate 7 fixed on the two ends of the Y-direction screw rod 8, the screw guide rail 9 between the fixed plates 7; the screw drive mechanism 4 is also provided with Sliding seat 3; sliding seat 3 slides on the screw mandrel guide rail 9 with the rotation of the Y-direction screw mandrel 8; the sliding seat 3 is provided with a fixed frame 17; the fixed frame 17 is provided with a guide rail 6 and a fixed bracket 25; Slide rail 6 is perpendicular to screw mandrel guide rail 9; Guide slide rail 6 passes fixed support 25, and the two ends of guide slide rail are fixed in f...

Embodiment 2

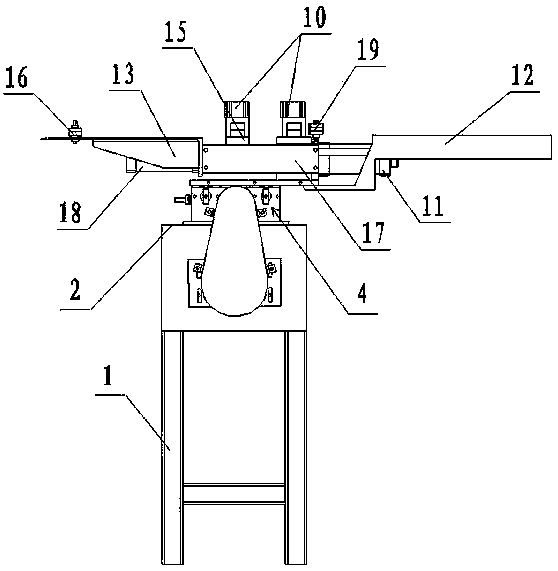

[0040] Embodiment 2: on the basis of embodiment 1, with reference to appended Figure 5 . A kind of automatic feeding type punching press, comprises punching press 23 and the mold 22 that is positioned at punching press 23; The automatic feeding device described in embodiment 1 is two, and is installed in the mold 22 both sides of punching press 23 respectively in alignment; Two automatic feeding devices The motors of the feeding device are all controlled by the control system of the electric control cabinet; the guide plates B13 of the two automatic feeding devices are all facing each other and are arranged on both sides of the mold 22 .

[0041] In the above-mentioned automatic feeding punching machine, the feeding cylinder A11 and the feeding cylinder B18 on the automatic feeding device can be designed as fixed-range push rod cylinders, so that the position of each blanking of the sheet can be controlled more accurately, and the blanking accuracy of the workpiece can be imp...

Embodiment 3

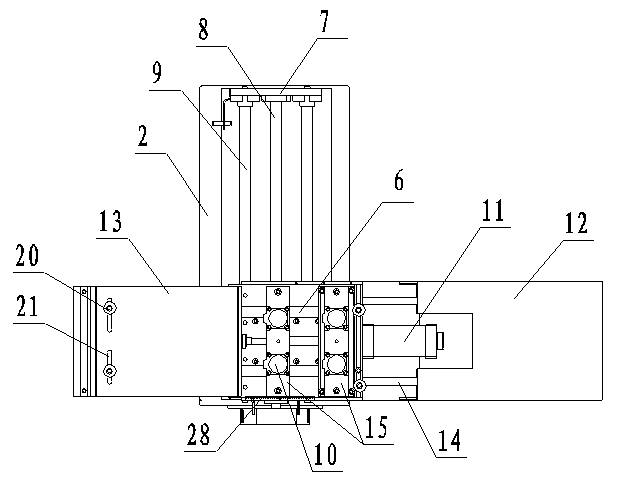

[0042] Embodiment 3: on the basis of embodiment 2, with reference to appended Figure 6 . Adopt the punch press among the embodiment 2, the method for automatic feeding, with processing attached Figure 6 The artifact shown in , as an example, includes the following steps.

[0043] (1) Calculate the displacement of the sheet.

[0044] ① Before processing, design the arrangement of the workpieces on the sheet according to the size of the sheet, aiming at punching the maximum number of workpieces on a sheet, saving the sheet and cost;

[0045] ②According to the arrangement of workpieces on the sheet, measure and calculate the moving coordinates (X, Y) of the sheet when punching the first workpiece;

[0046] ③According to the arrangement of the workpieces on the sheet in step ①, measure and calculate the distance L of adjacent workpieces in the X direction, the distance S of adjacent workpieces in the Y direction, and the dislocation distance K; use the Y-direction group punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com