Automatic punching equipment for seamless steel tube

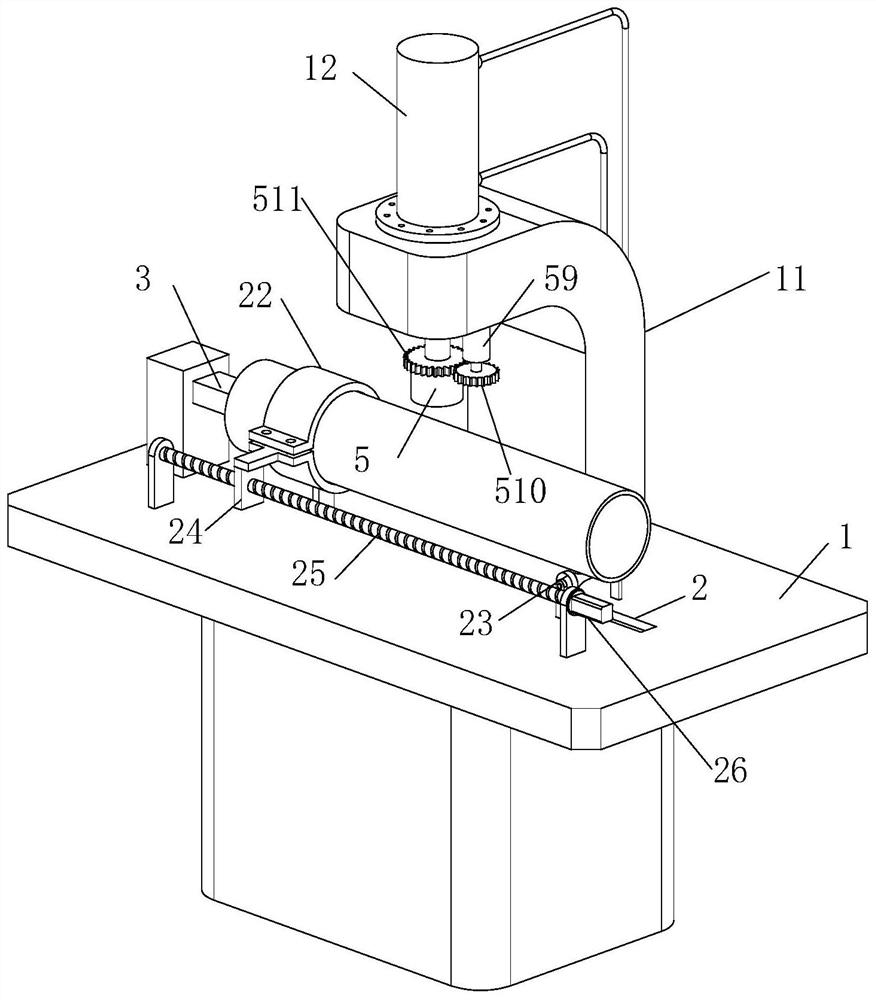

A technology for automatic punching and seamless steel pipes, applied in metal processing equipment, punching tools, feeding devices, etc., can solve the problems affecting the punching accuracy of steel pipes, the quality of steel pipe punching, and easy deformation, so as to reduce deformation and improve Punching quality and the effect of increasing punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

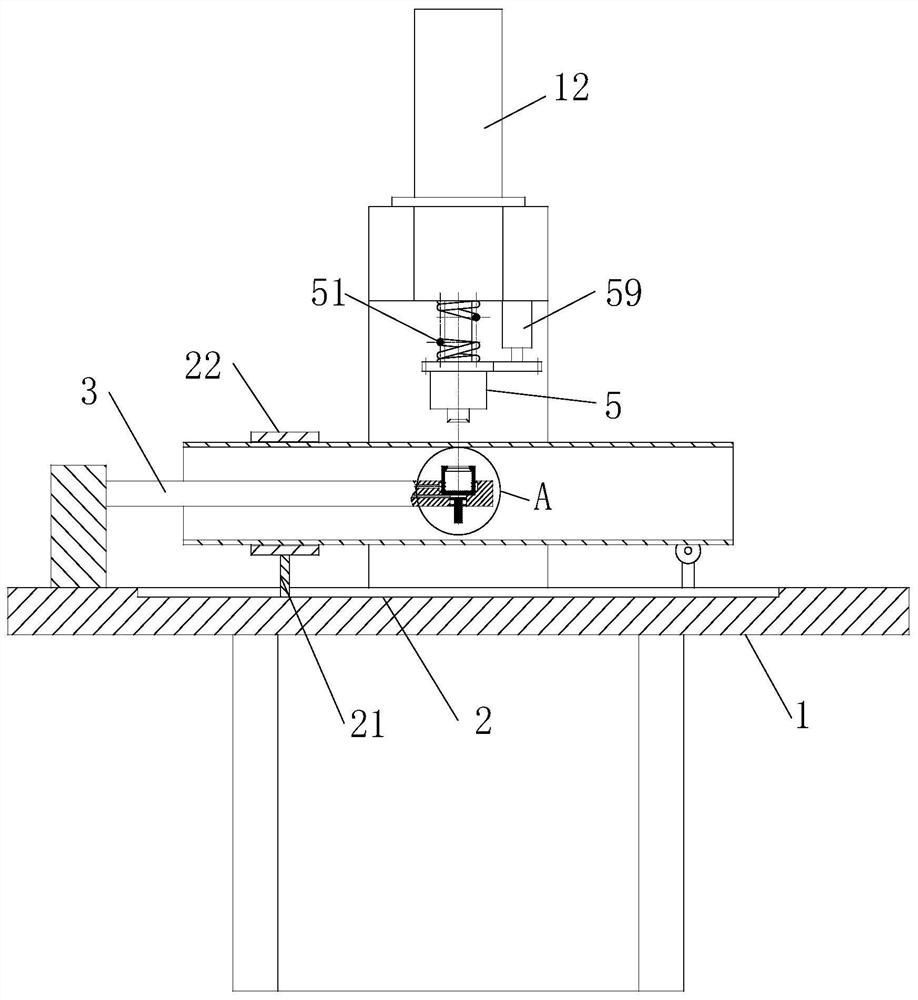

Method used

Image

Examples

Embodiment approach

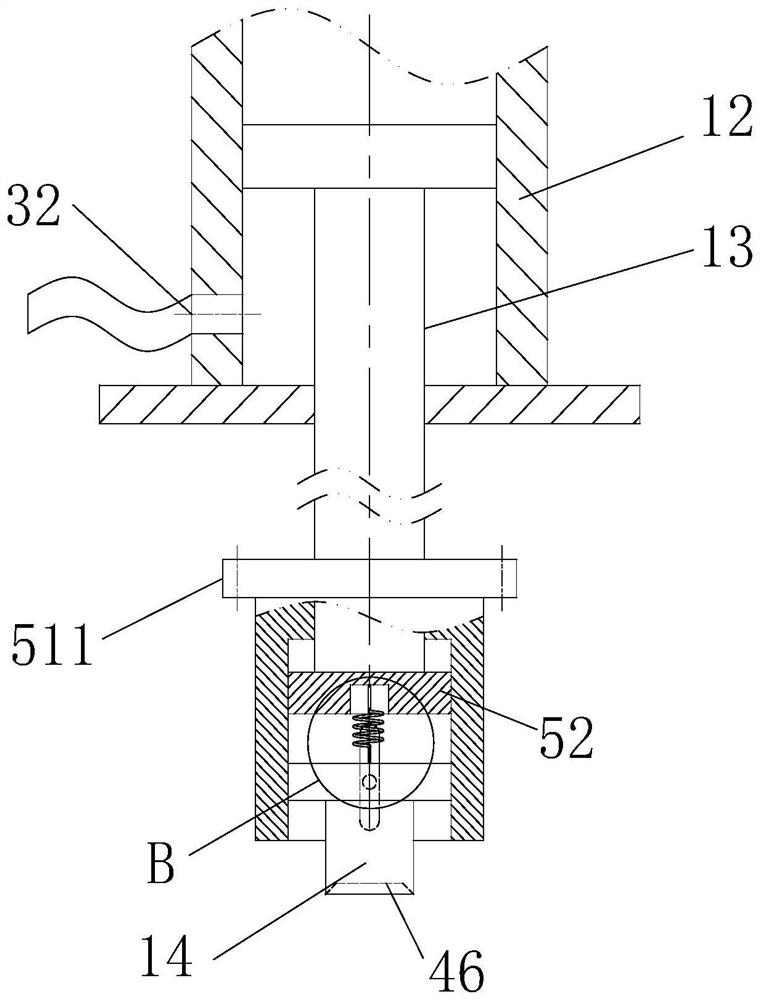

[0027] As an embodiment of the present invention, a groove 4 is opened in the support column 31, and a group of slag discharge holes 41 are evenly distributed on the inner wall of the groove 4; Annular cavity 42, annular cavity 42 communicates with the vacuum cleaner through No. 3 hole 43; No. 3 hole 43 is pumped through the vacuum cleaner, so that the metal debris formed by punching in the groove 4 passes through the slag discharge hole 41 and the annular cavity 42 Finally, it is discharged from No. 3 hole 43, thereby reducing the residue of metal debris on the inner wall of the steel pipe, further reducing the scratches on the inner wall of the steel pipe, ensuring the smoothness of the inner wall of the steel pipe, and increasing the punching quality of the steel pipe.

[0028] As an embodiment of the present invention, a bushing 5 is sleeved between the punch 14 and the piston rod 13, and the bushing 5 and the piston rod 13 are rotatably connected, and the piston rod 13 bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com