Slipping and continuous feeding device for high speed perforating machine

A feeding device and punching machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low efficiency, achieve the effect of improving transmission efficiency and punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

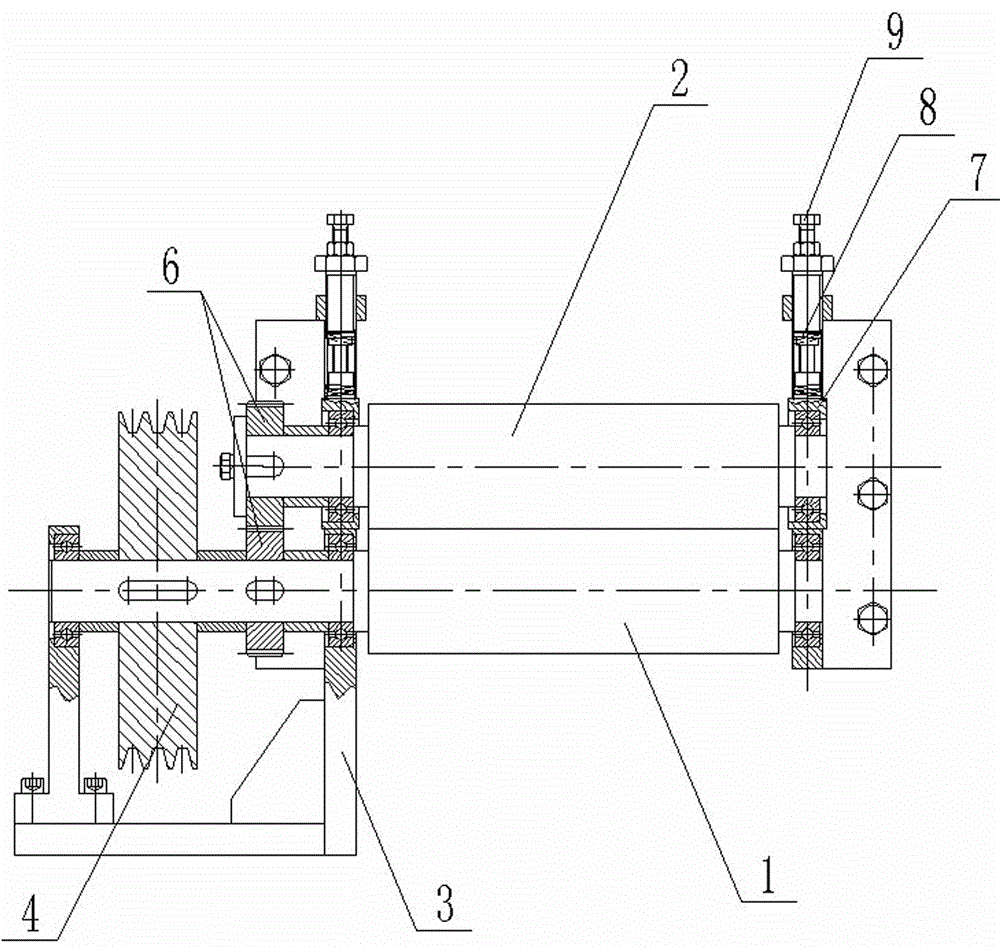

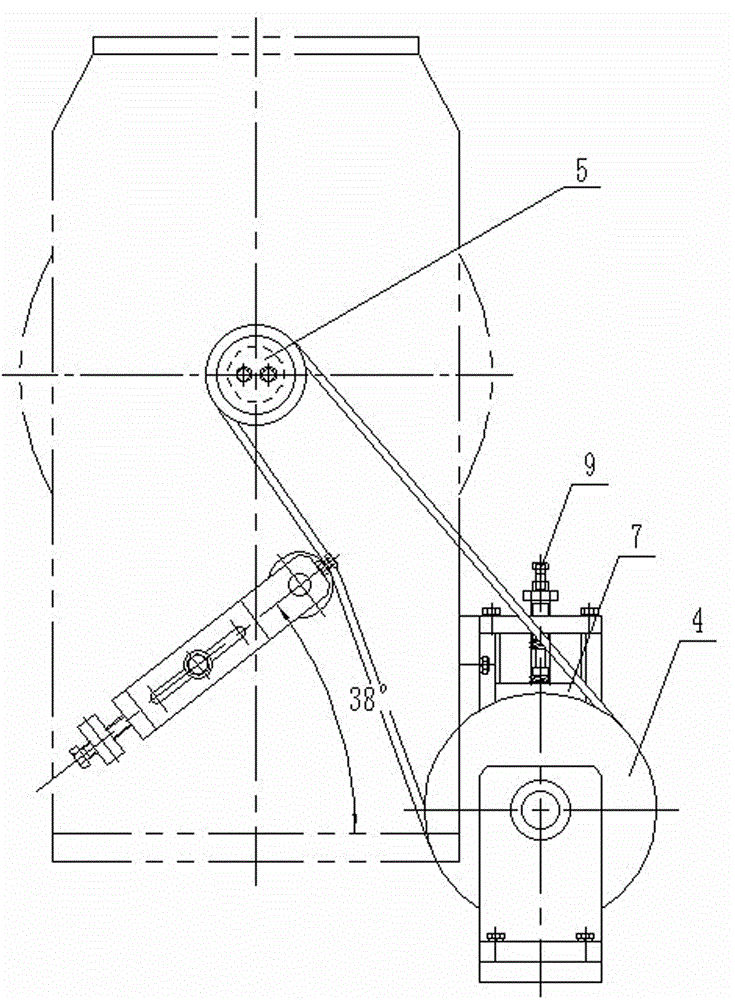

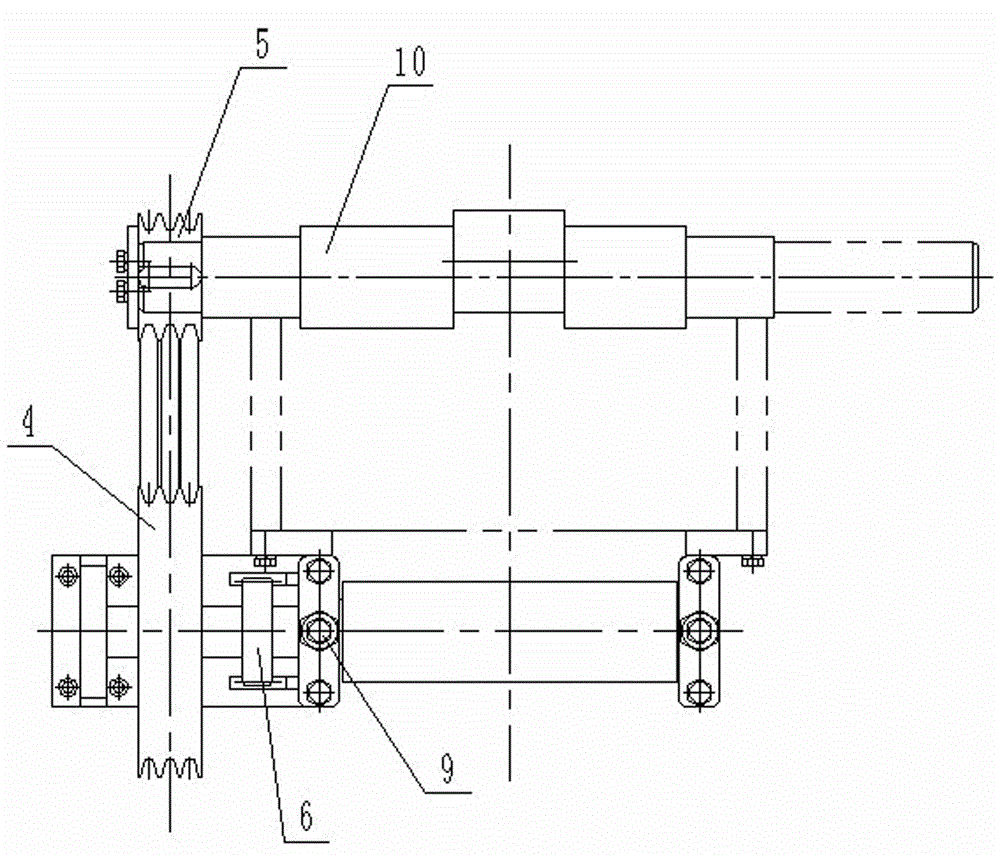

[0015] Examples of the present invention Figures 1 to 3 As shown, the slipping continuous feeding device of the high-speed punching machine is provided with a driving roller 1 and a driven roller 2 arranged in parallel up and down; the driving roller 1 is fixed on the frame 3 through a bearing, and one end of the driving roller is connected with a pulley 4 through a key, and the pulley 4 is connected with the drive wheel 5 through a belt; the drive roller 1 shaft and the driven roller 2 shaft are respectively provided with the same gear 6, and the two gears 6 are meshed for transmission, and the two sides of the driven roller 2 shaft are respectively fitted on the two shafts through bearings. On the slider 7 that moves up and down, the slider 7 is fitted on a vertical guide rail respectively, and the guide rail is fixed on the frame 3, and the guide rail is provided with a pressure adjustment device that pushes the slider 7 to the direction of the driving roller 1; the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com