Manufacturing process improvement method for pluggable flexible printed circuit (FPC)

A flexible circuit board and manufacturing process technology, applied in the direction of printed circuit manufacturing, printed circuit, electrical components, etc., to improve the life of the mold and the overall punching efficiency, and ensure the effect of electrical connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

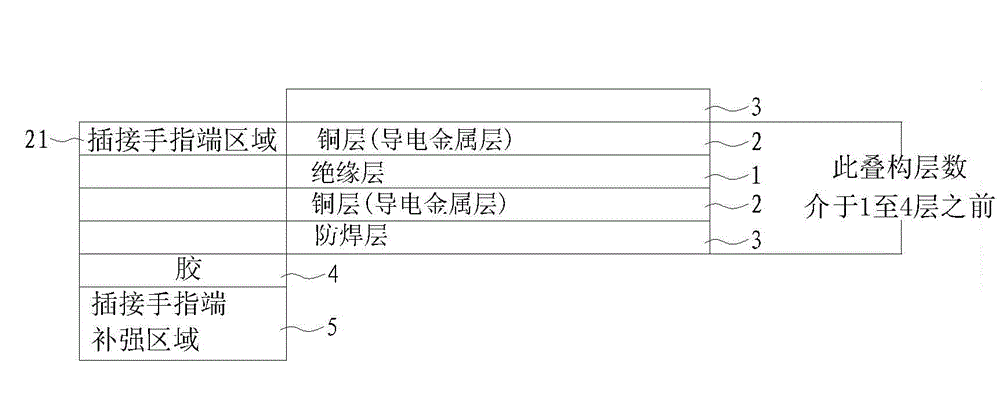

[0030] refer to figure 1 What is shown is a structure of a flexible circuit board (that is, a flexible circuit board with plug-in finger pads) that adopts plug-in connection. A conductive metal layer 2 is formed on a flexible insulating substrate 1, and the conductive metal layer 2 extends out of the flexible insulating substrate 1 , and a treated surface layer is plated on the extended conductive metal layer, thereby forming an insertion finger pad 21 . Generally, the conductive metal layer 2 is also covered with a solder resist layer 3 to protect the conductive metal layer 2 from being damaged during soldering. And on the back of the insertion finger pad 21, a reinforcing sheet 5 is bonded through the glue 4, and the physical strength of the insertion finger pad 21 is strengthened through the reinforcing sheet 5.

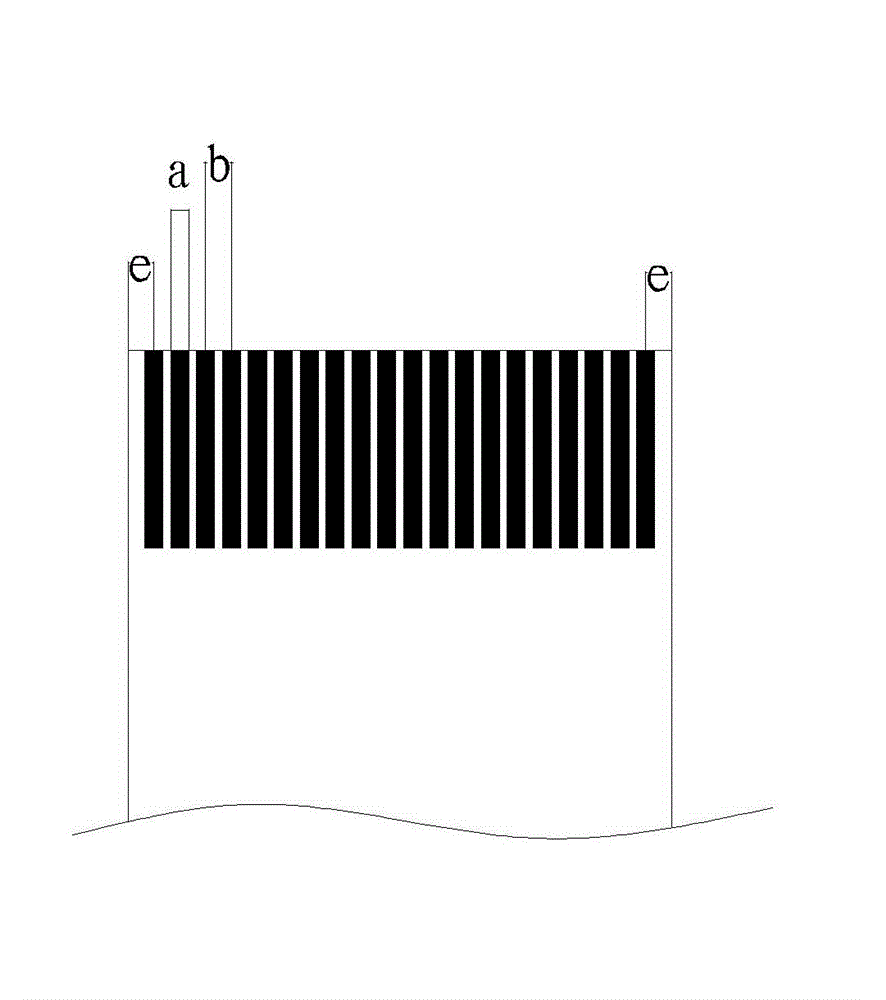

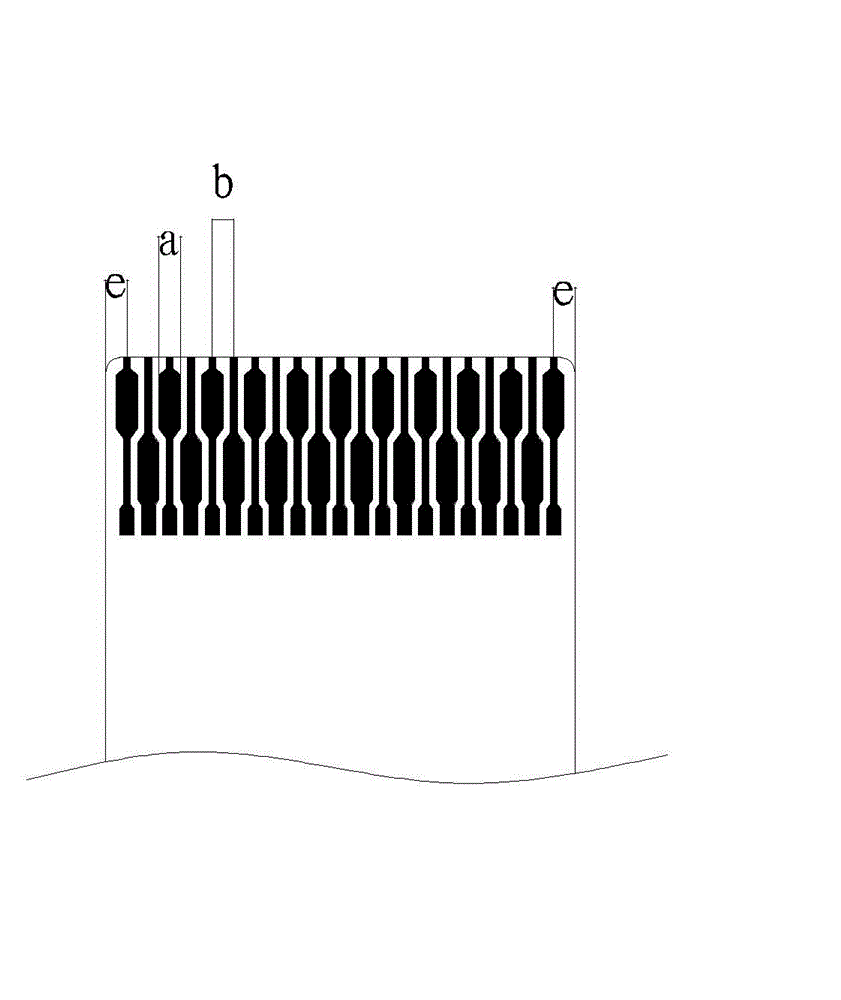

[0031] Figure 2a and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com