Method for adhesive magnetron sputtering thick film

A magnetron sputtering and thick film technology, which is applied in sputtering plating, processes for producing decorative surface effects, decorative arts, etc., can solve the problems of serious environmental pollution by electroplating method and poor quality of thermal evaporation deposited films, etc. Achieve the effect of avoiding environmental pollution problems, solving poor quality and wide process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Clean the substrate (SiC material):

[0034] The SiC material 1 to be etched is sequentially subjected to the following cleaning steps:

[0035] Organic contamination removal: 1# cleaning solution (ammonia: hydrogen peroxide: pure water = 1:1:5), temperature 70° for 5 minutes; inorganic contamination removal 2# cleaning solution (hydrochloric acid: hydrogen peroxide: pure water = 1:1 :5), temperature 70°, time 5 minutes; BOE cleaning solution (hydrofluoric acid: ammonium fluoride = 1:20), room temperature, time 30 seconds; acetone ultrasonication 5 minutes; isopropanol ultrasonication 5 minutes; DI water rinse 5 minutes Divide, dry, and set aside.

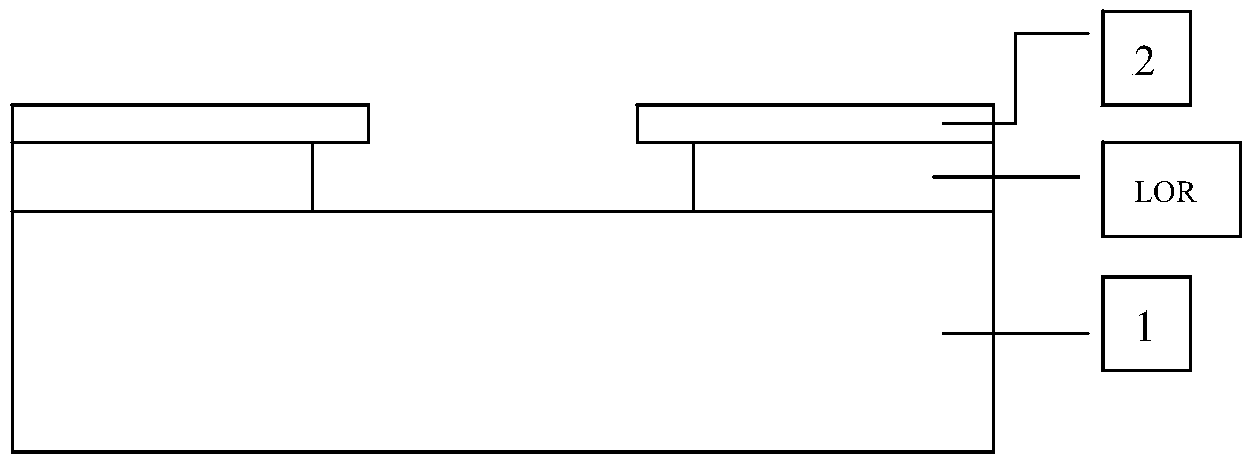

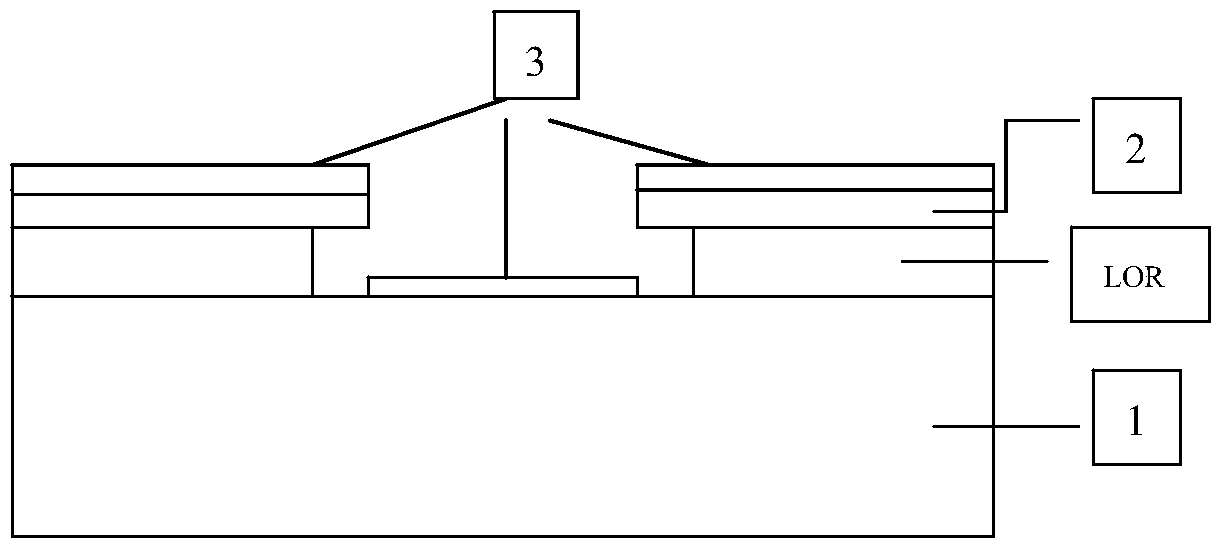

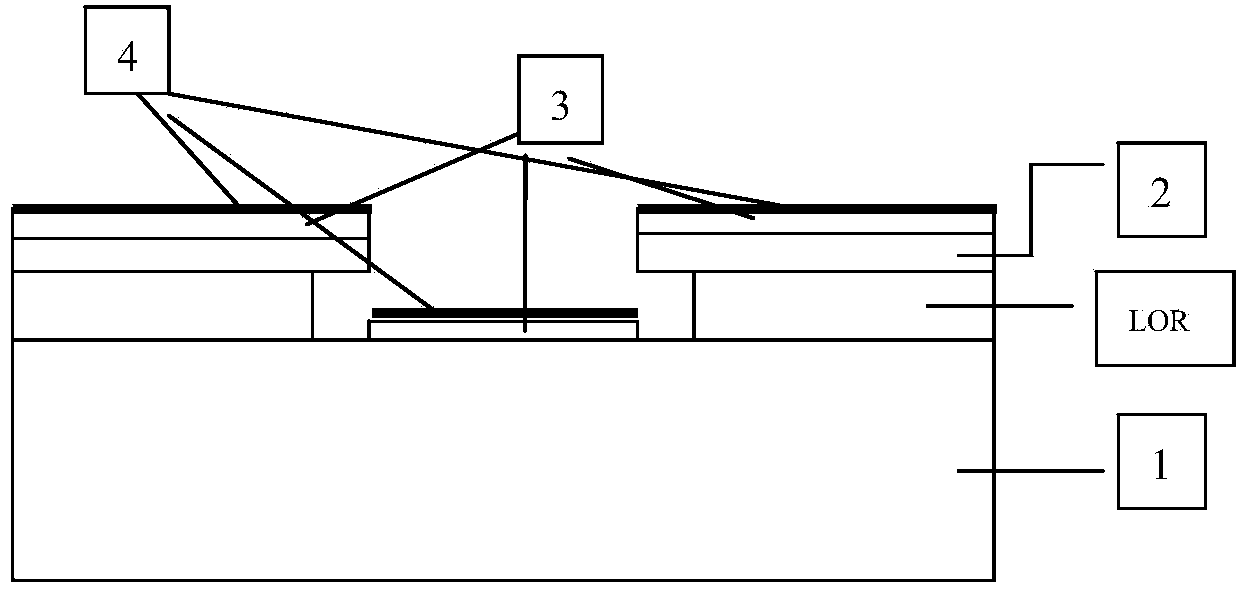

[0036] 2) Substrate photolithography, the process flow is as follows:

[0037] Glue coating: Vapor-phase coating of tackifier; spin-coating of LOR20B type peeling glue, the speed is 3000 rpm, the thickness is about 2um, and the baking time is 120s at 170°. Spin-coat photoresist 2, the glue type is 5214, the thickness i...

Embodiment 2

[0049] 1) Clean the substrate (glass):

[0050] The SiC material 1 to be etched is sequentially subjected to the following cleaning steps:

[0051] Sonicate for 5 minutes in acetone; 5 minutes in isopropanol; rinse with DI water for 5 minutes, dry and set aside.

[0052] 2) Substrate photolithography, the process flow is as follows:

[0053] Coating: Vapor-phase coating of tackifier; spin-coating photoresist 2, glue type 4620, thickness 7um; pre-baking at 100 degrees Celsius for 180 seconds; SUSS MA6 photolithography machine contact exposure for 18 seconds; post-baking at 95 degrees Celsius for 20 seconds; 3038 The developing solution is developed for 45s; 110°, the time is 120s to harden the film, such as Image 6 shown.

[0054] 3) Substrate primer: M4L plasma glue remover primer, the process parameters are as follows:

[0055] Oxygen O2 flow rate 150sccm, RF power 200W, gluing time 2 minutes, base film inspection.

[0056] 4) High-power fast magnetron sputtering film:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com