Water printing process for paper printed matters

A printed matter, water-based technology, applied in the field of water-based printing technology, can solve problems such as affecting printing quality, prolonging drying time, reducing printing efficiency, etc., to improve the printing environment, prevent deformation, and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

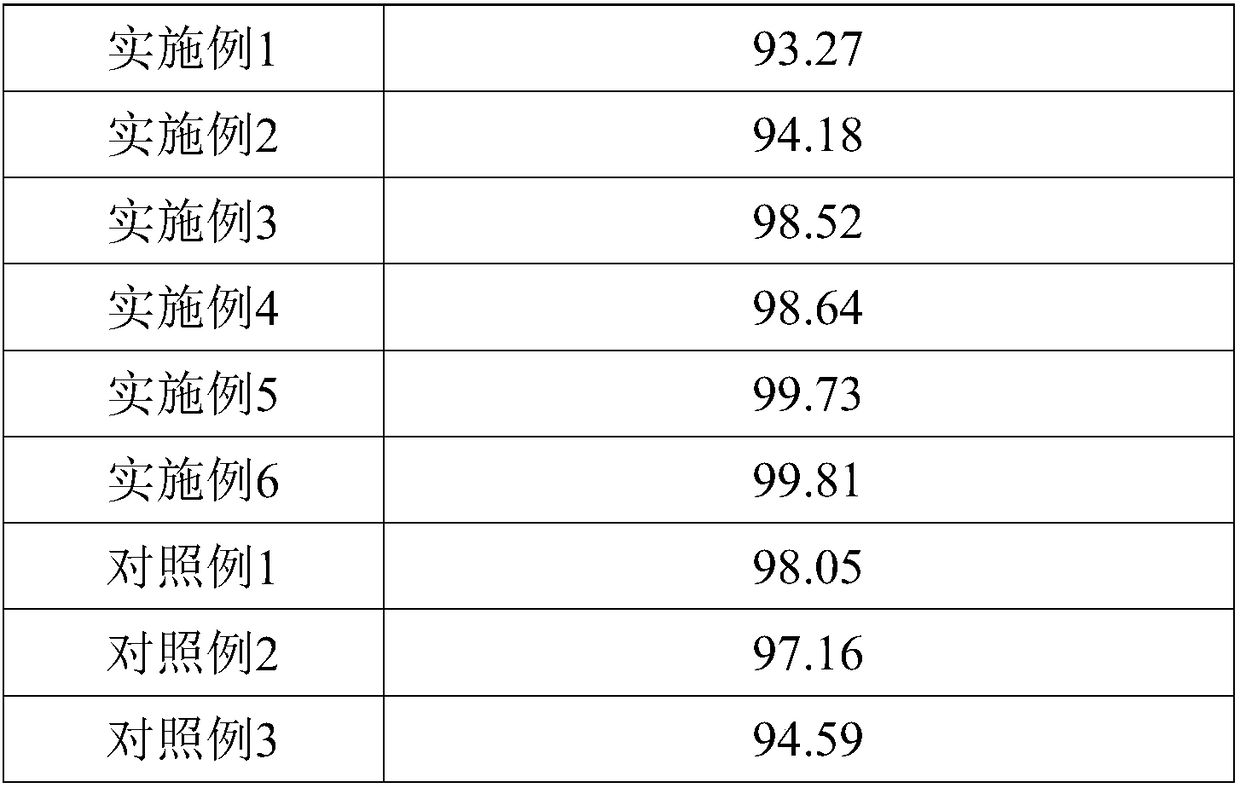

Embodiment 1

[0027] (1) Dust removal: Use the dust removal brush roller to remove dust from the paper, and the paper after dust removal is curled into rolls by the winder;

[0028] (2) Unwinding: install the paper roll on the unwinding machine and lead out the paper;

[0029] (3) Printing: the paper passes through the printing machine, and the printing machine prints water-based ink on the paper;

[0030] (4) Drying: The printed paper passes through the first-level air-drying room and the second-level air-drying room in turn to completely cure the water-based ink;

[0031] (5) Rolling: The dried paper is rolled into a roll by the winding machine, which completes the water-based printing of paper printed matter.

[0032] The brush head of the dedusting brush roller is in interference contact with the surface of the paper, and the interference height is controlled at 0.5mm; the speed of the paper passing through the dedusting brush roller is controlled at 5m / min; the water-based ink uses wa...

Embodiment 2

[0035] (1) Dust removal: Use the dust removal brush roller to remove dust from the paper, and the paper after dust removal is curled into rolls by the winder;

[0036] (2) Unwinding: install the paper roll on the unwinding machine and lead out the paper;

[0037] (3) Printing: the paper passes through the printing machine, and the printing machine prints water-based ink on the paper;

[0038] (4) Drying: The printed paper passes through the first-level air-drying room and the second-level air-drying room in turn to completely cure the water-based ink;

[0039] (5) Rolling: The dried paper is rolled into a roll by the winding machine, which completes the water-based printing of paper printed matter.

[0040] The brush head of the dedusting brush roller is in interference contact with the surface of the paper, and the interference height is controlled at 0.5mm; the speed of the paper passing through the dedusting brush roller is controlled at 5m / min; the water-based ink uses wa...

Embodiment 3

[0043] (1) Dust removal: Use the dust removal brush roller to remove dust from the paper, and the paper after dust removal is curled into rolls by the winder;

[0044] (2) Unwinding: install the paper roll on the unwinding machine and lead out the paper;

[0045] (3) Printing: the paper passes through the printing machine, and the printing machine prints water-based ink on the paper;

[0046] (4) Drying: The printed paper passes through the first-level air-drying room and the second-level air-drying room in turn to completely cure the water-based ink;

[0047] (5) Rolling: The dried paper is rolled into a roll by the winding machine, which completes the water-based printing of paper printed matter.

[0048] The brush head of the dedusting brush roller is in interference contact with the surface of the paper, and the interference height is controlled at 0.5mm; the speed of the paper passing through the dedusting brush roller is controlled at 5m / min; the water-based ink uses wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com