A kind of all-water-based plastic film gravure printing ink

A plastic film, water-based technology, used in inks, household appliances, applications, etc., can solve the problems of physical and mental injury of industrial workers, poor adhesion and rubbing fastness, deinking, etc., to improve the printing operation environment and reduce VOC. Emissions, the effect of saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

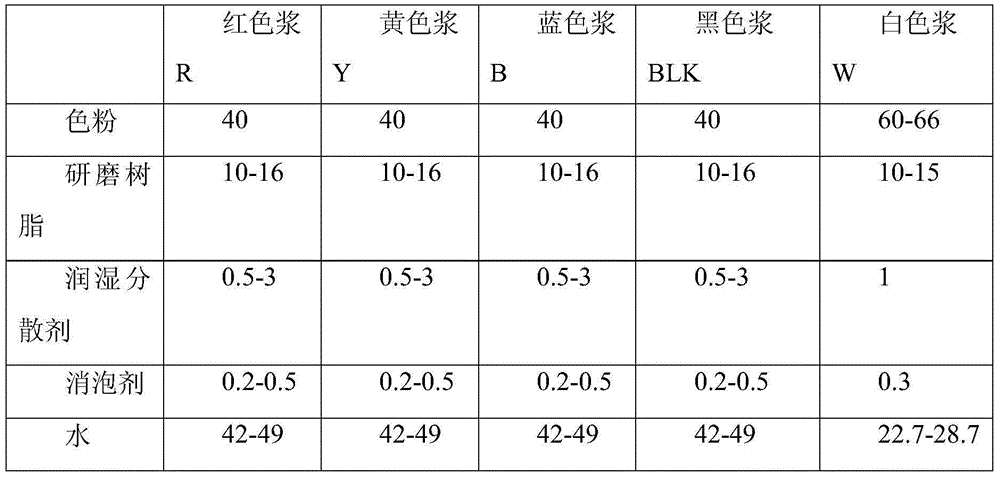

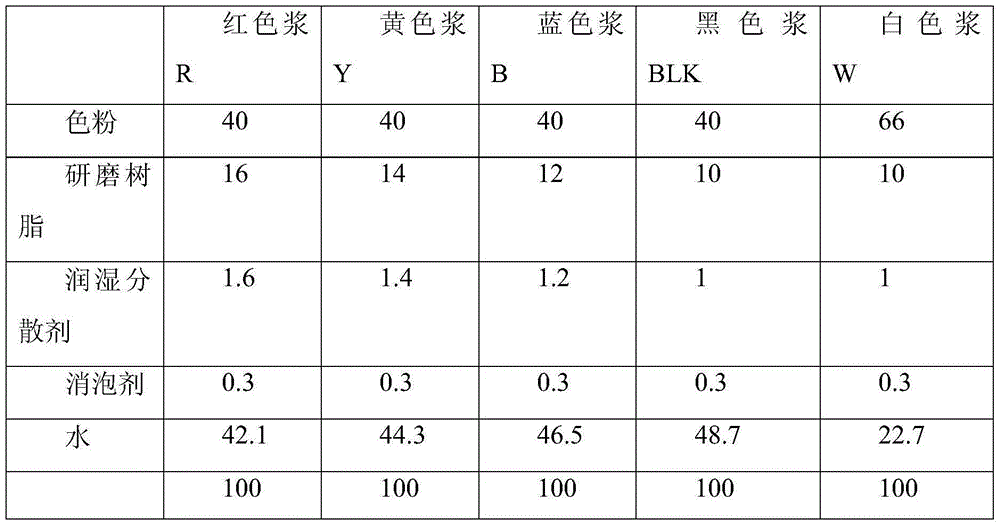

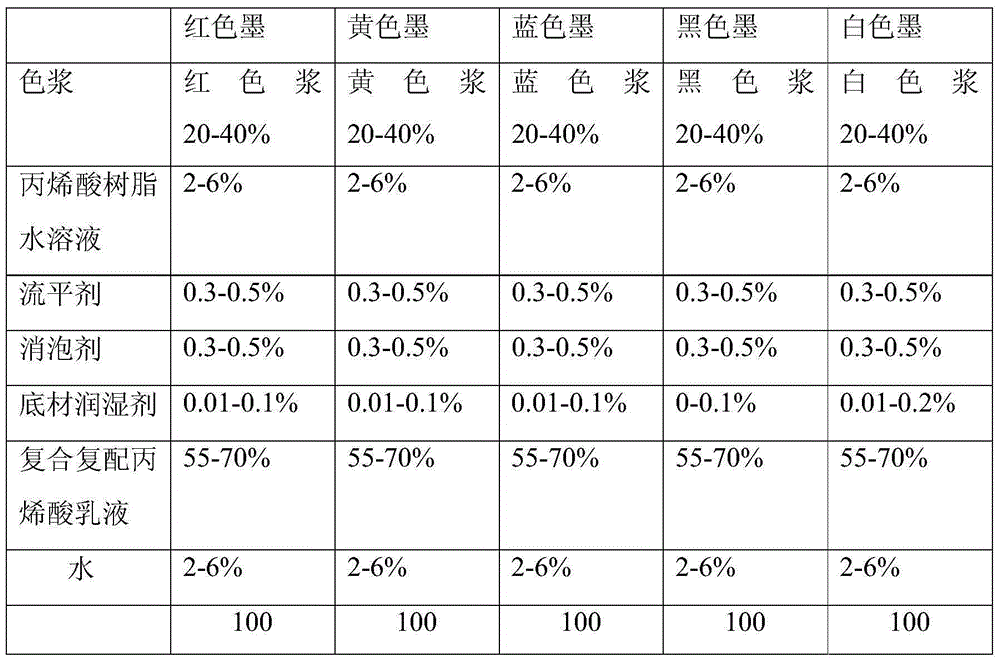

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 prepares grinding resin (acrylic acid aqueous solution resin liquid)

[0052] First, put a certain amount of hot water at 50°C in the appliance, add the designed amount of solid acrylic resin, turn on the mixer, add the aminating agent, 1000 rpm, 120 minutes, and measure the pH value after the resin is evenly dissolved. 9. Standby. Add respectively 30% of solid acrylic resin (purchased from Baoding Lanzhu Chemical Co., Ltd., 7016) with an acid value of 240, 8% of aminating agent (Japan Mitsubishi Chemical Co., Ltd., dimethylethanolamine) and 62% of water by mass percentage, dissolve Evenly detect pH 8.4.

Embodiment 2

[0053] Embodiment 2 prepares grinding resin (acrylic acid aqueous solution resin liquid)

[0054]First, put a certain amount of hot water at 50°C in the appliance, add the designed amount of solid acrylic resin, turn on the mixer, add the aminating agent, 1000 rpm, 120 minutes, and measure the pH value after the resin is evenly dissolved. 9. Standby. 20% of solid acrylic resin with an acid value of 240 (purchased from Baoding Lanzhu Chemical Co., Ltd., 7016), 10% of an aminating agent (Nippon Mitsubishi Chemical Co., Ltd., dimethylethanolamine) and 70% of water were added by mass percentage.

Embodiment 3

[0055] Embodiment 3 prepares grinding resin (acrylic acid aqueous solution resin liquid)

[0056] First, put a certain amount of hot water at 50°C in the appliance, add the designed amount of solid acrylic resin, turn on the mixer, add the aminating agent, 1000 rpm, 120 minutes, and measure the pH value after the resin is evenly dissolved. 9. Standby. 40% of solid acrylic resin with an acid value of 240 (purchased from Baoding Lanzhu Chemical Co., Ltd., 7016), 5% of aminating agent (Nippon Mitsubishi Chemical Co., Ltd., dimethylethanolamine) and 55% of water were added by mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com