Patents

Literature

72results about How to "Avoid compromising print quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

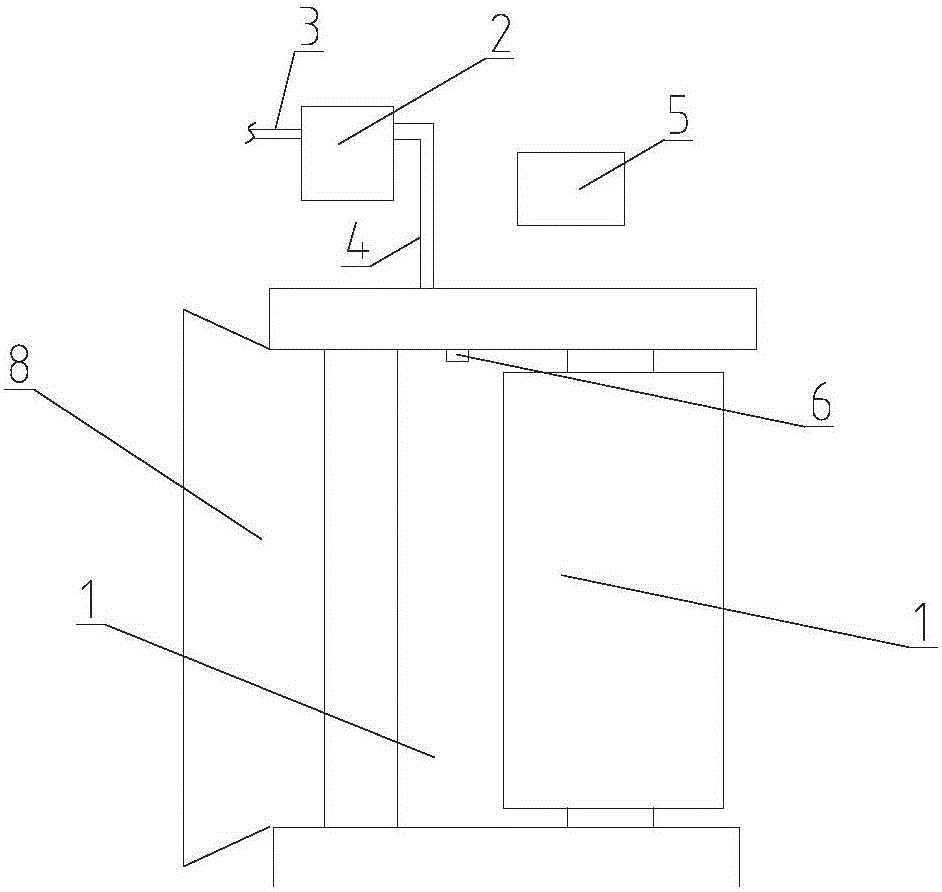

Printing device for biodegradation film production

ActiveCN106379055ASolve problems that cannot be immediately packaged into productsQuality improvementTypewritersOther printing apparatusEngineeringPrinting press

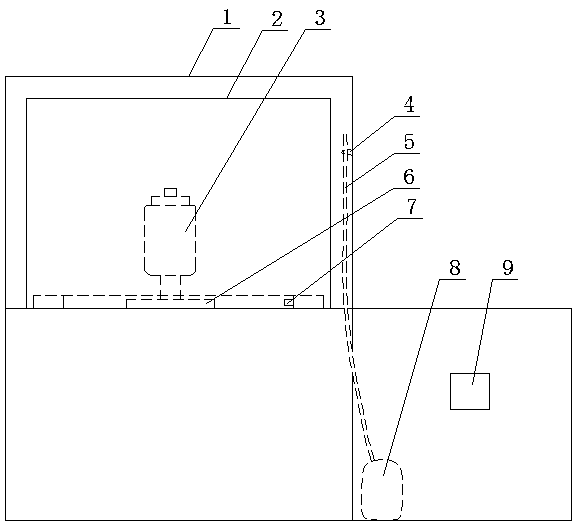

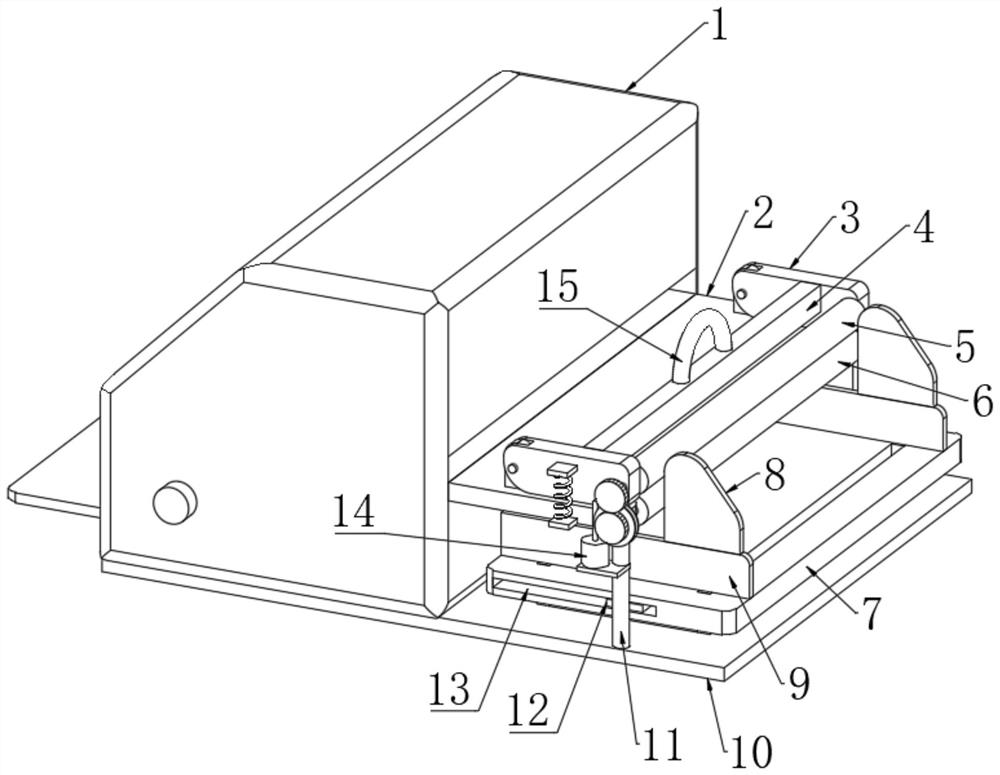

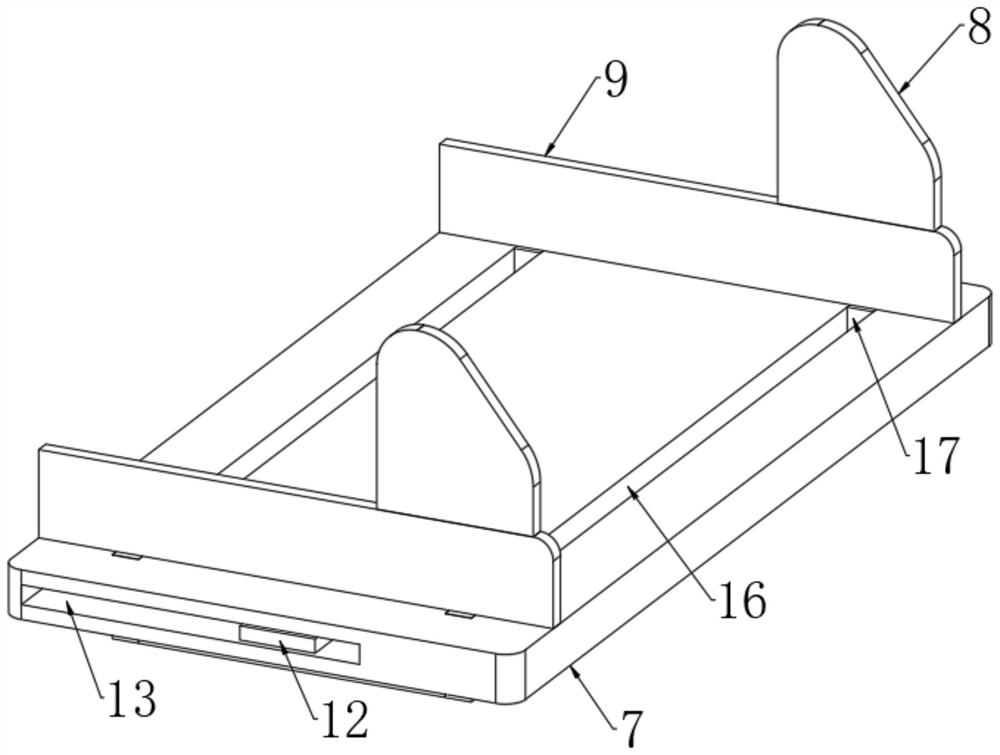

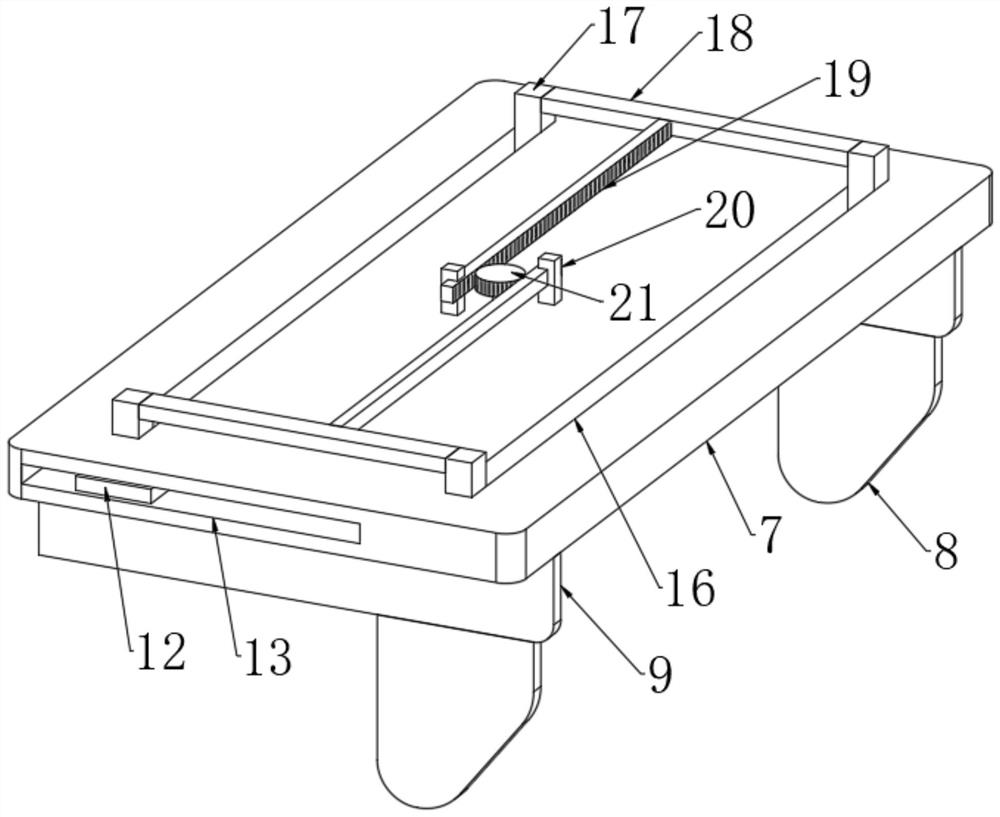

The invention discloses a printing device for biodegradation film production. The printing device comprises a base, a motor, a printing device body, a printing platform and a rolling shaft. The printing platform is arranged above the base, and a hot air blower is mounted in the center of the bottom of the printing platform. An electric extending-and-contracting stop block is mounted at the position, above the rolling shaft, of the inner side wall of each fixing bracket. An electric extending-and-contracting rod which extends downwards vertically is mounted at the top of the printing device body. The output end of a control panel is electrically connected with the motor, an electric cutting knife, the electric extending-and-contracting rod, an ink jetting controller, the hot air blower and the input ends of the electric extending-and-contracting stop blocks through wires correspondingly. Compared with traditional printing machines, the printing device is provided with the hot air blower and the electric cutting knife, the problem that a printed biological film cannot be packed into a product immediately is effectively solved, and production efficiency is improved; by means of the arranged motor and the rolling shaft, the biodegradation film can be subjected to transmission printing, and the situation that printing quality is influenced due to seizure and pause occurring in the printing process is avoided; and printing efficiency is improved.

Owner:HUNAN KELAIBAO BIO ENERGY TECH CO LTD

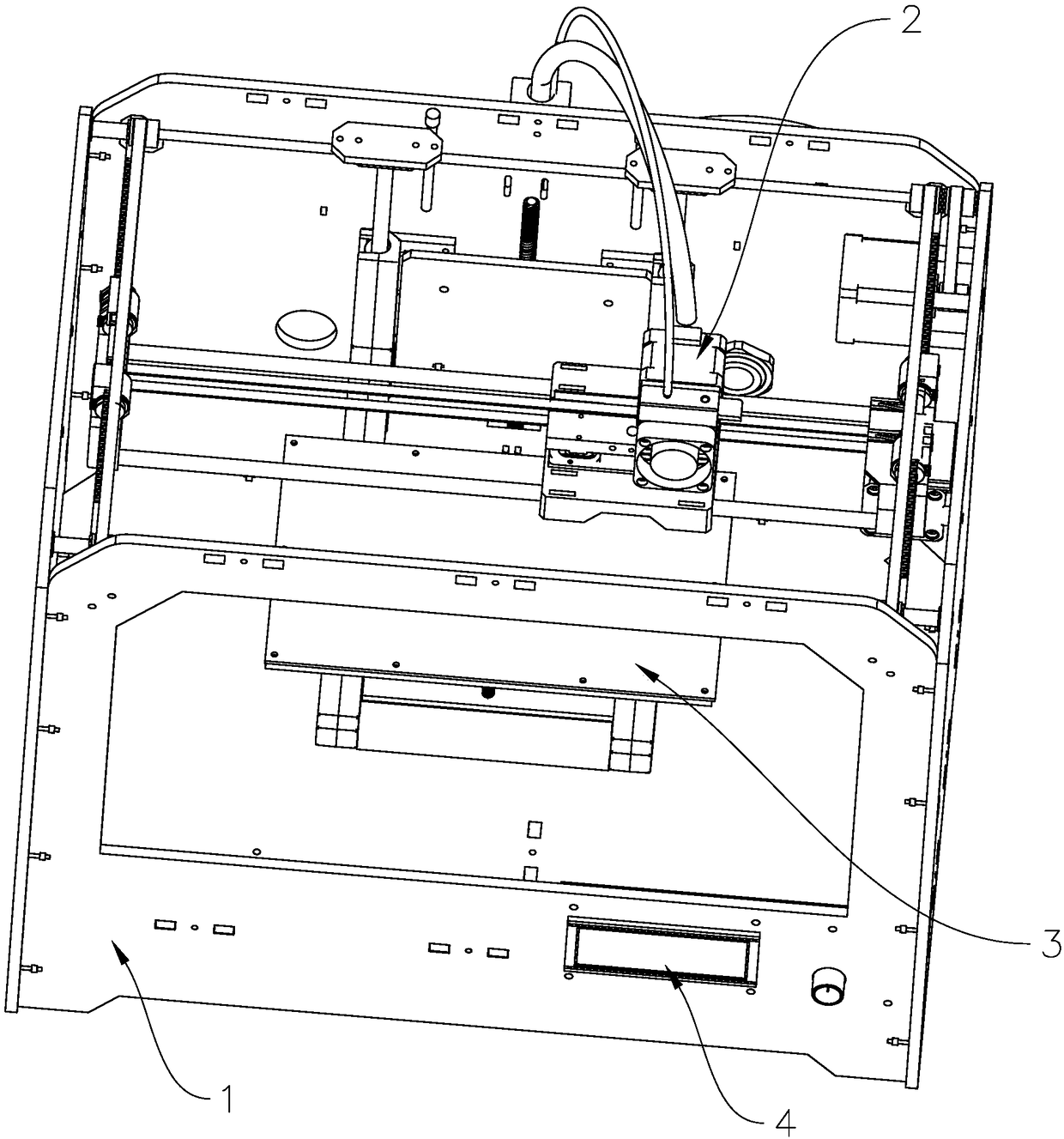

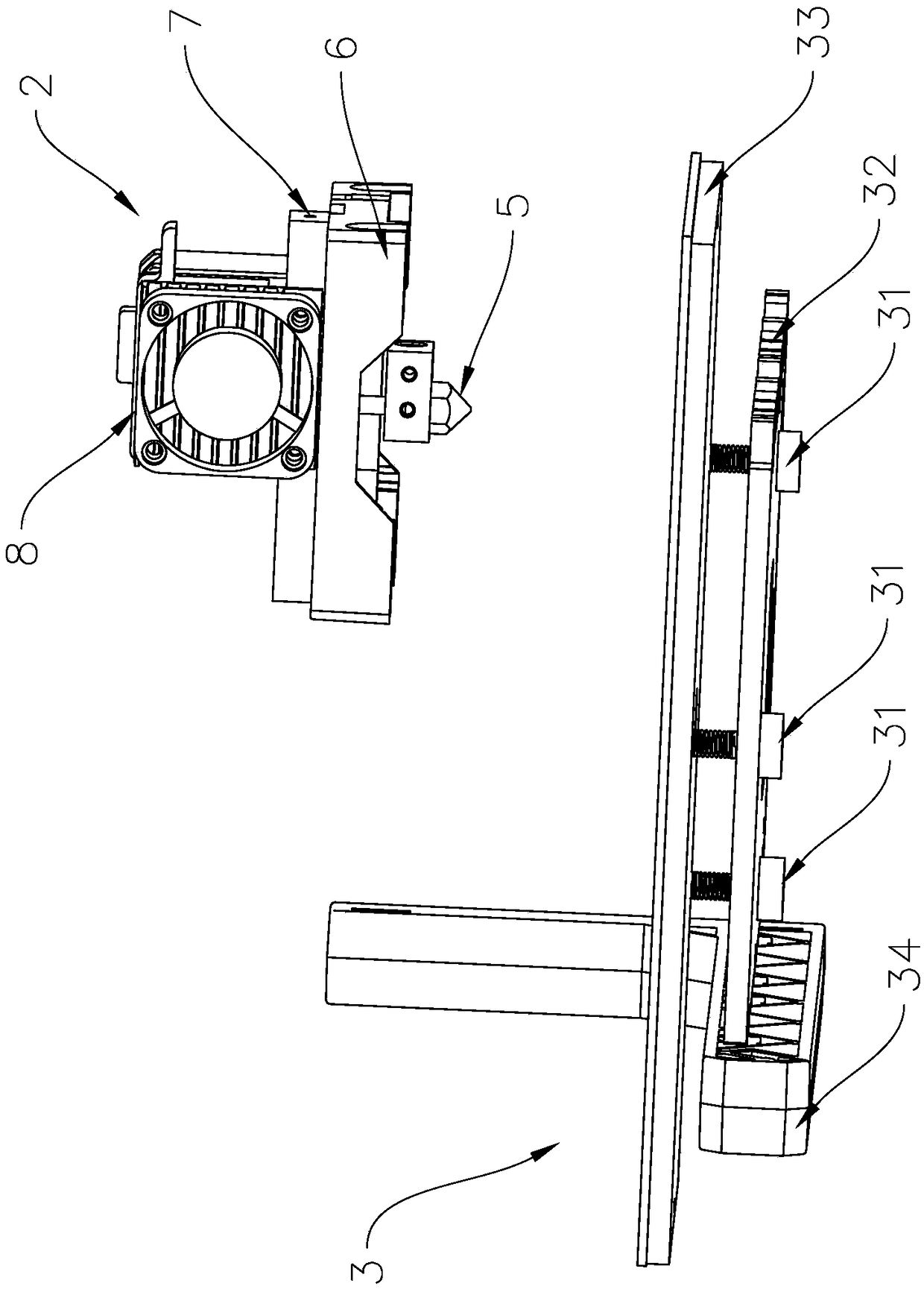

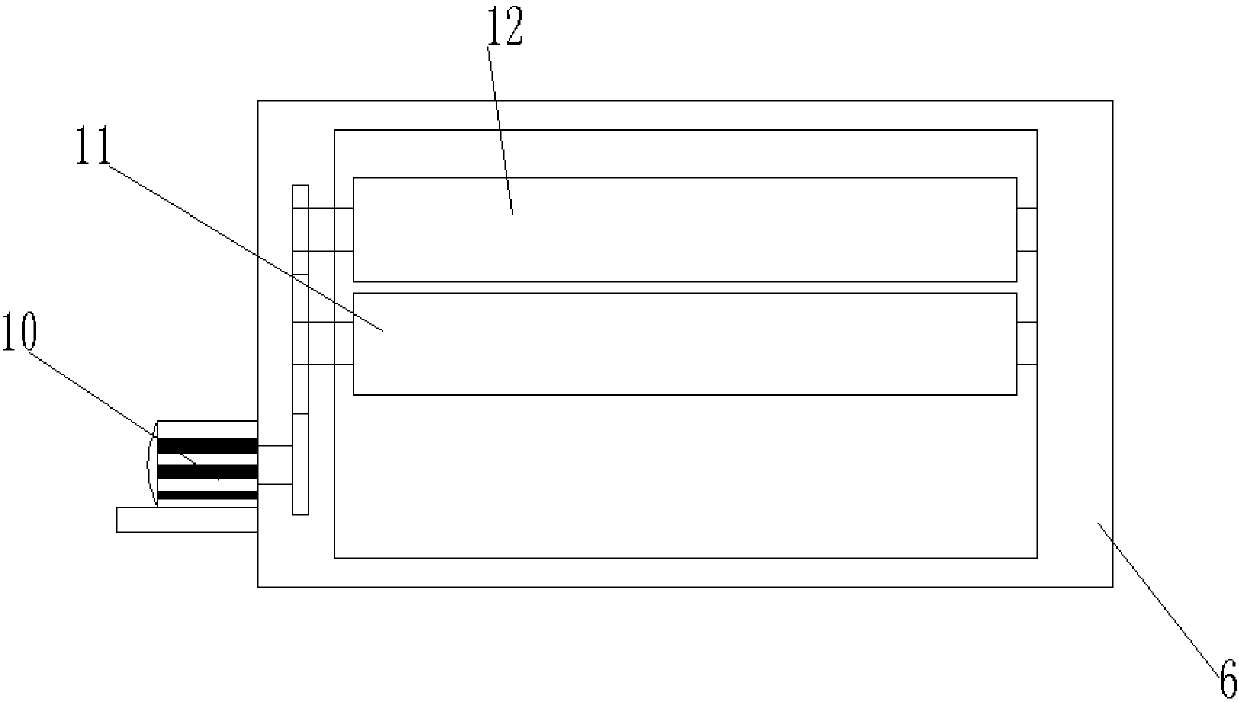

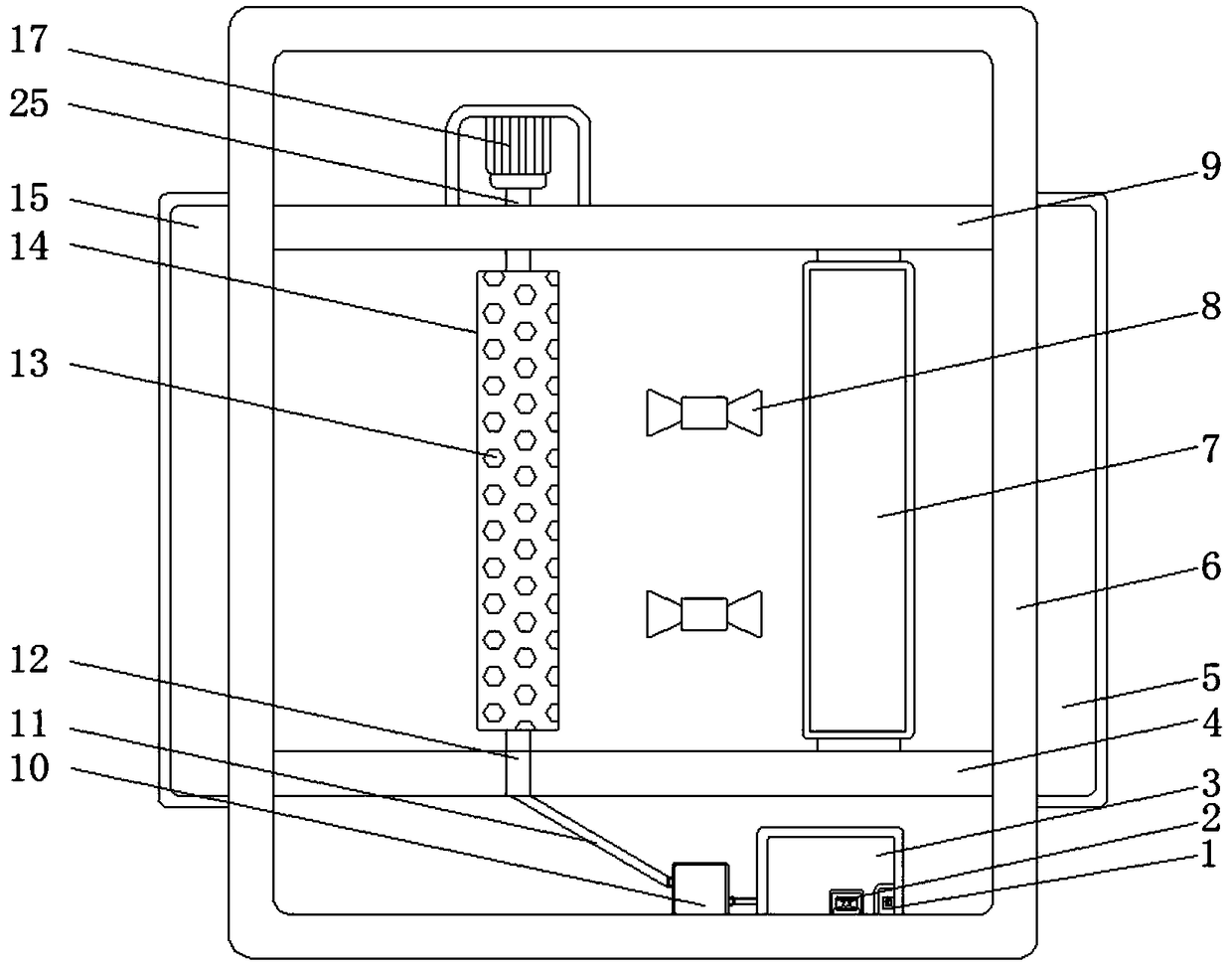

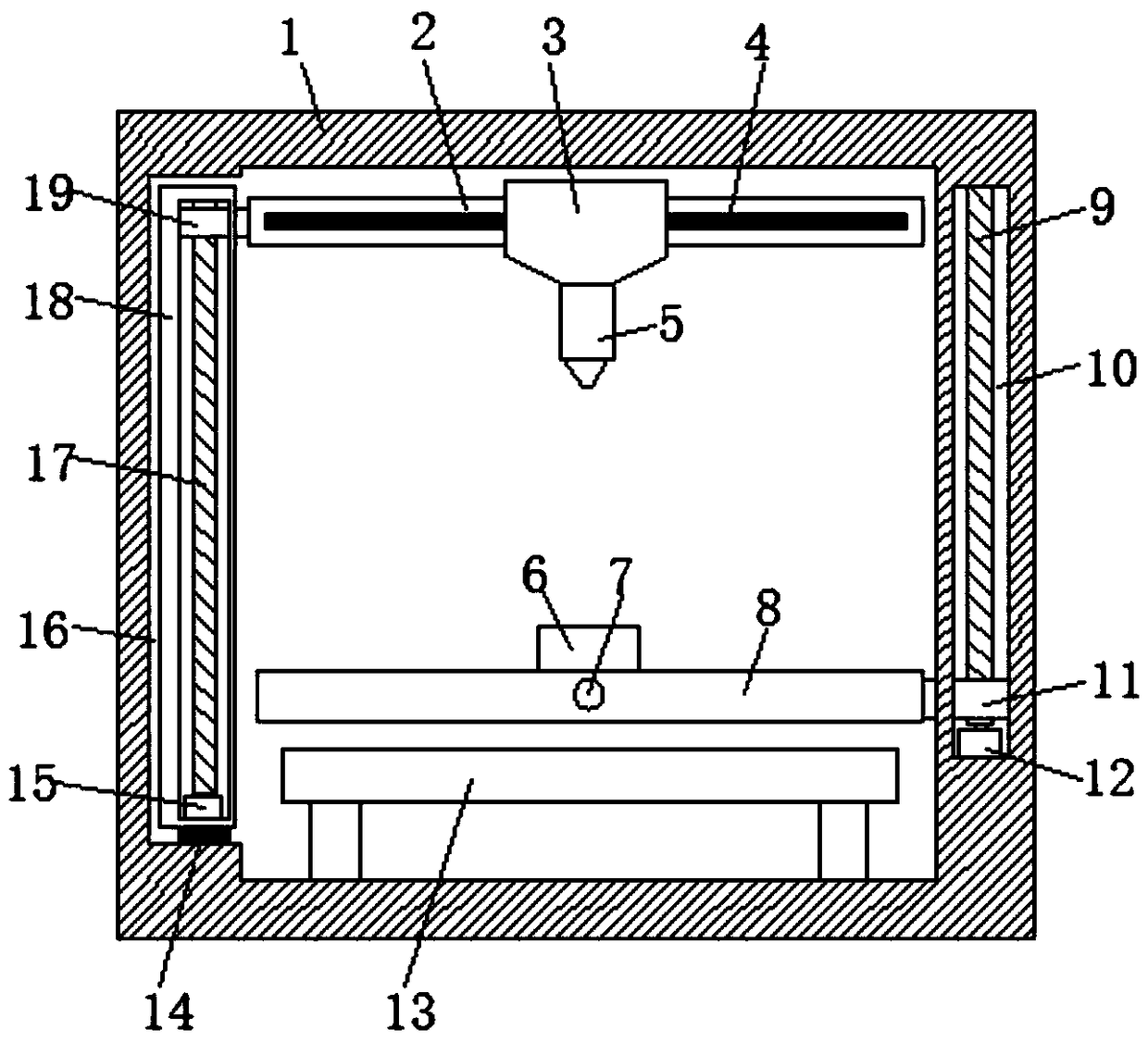

Three-dimensional printer and three-dimensional printing platform adjustment method

PendingCN108481741AReduce in quantityWeight increaseManufacturing platforms/substratesManufacturing heating elementsComputer moduleEngineering

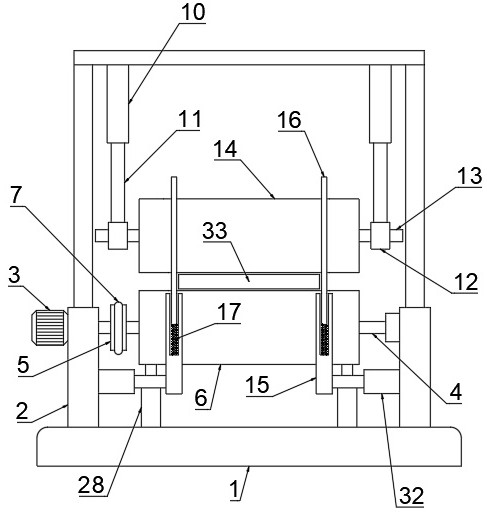

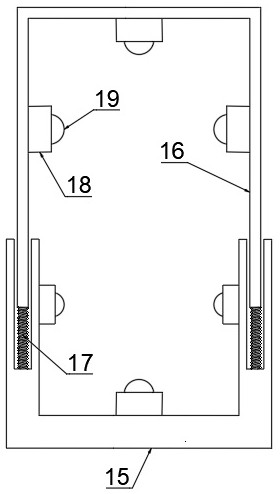

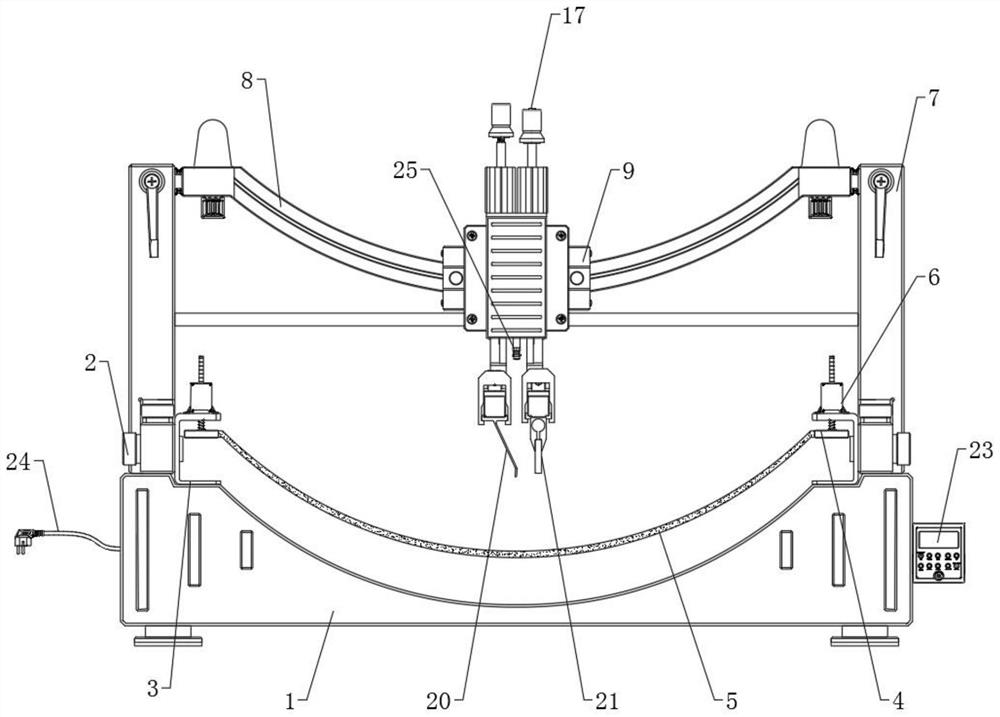

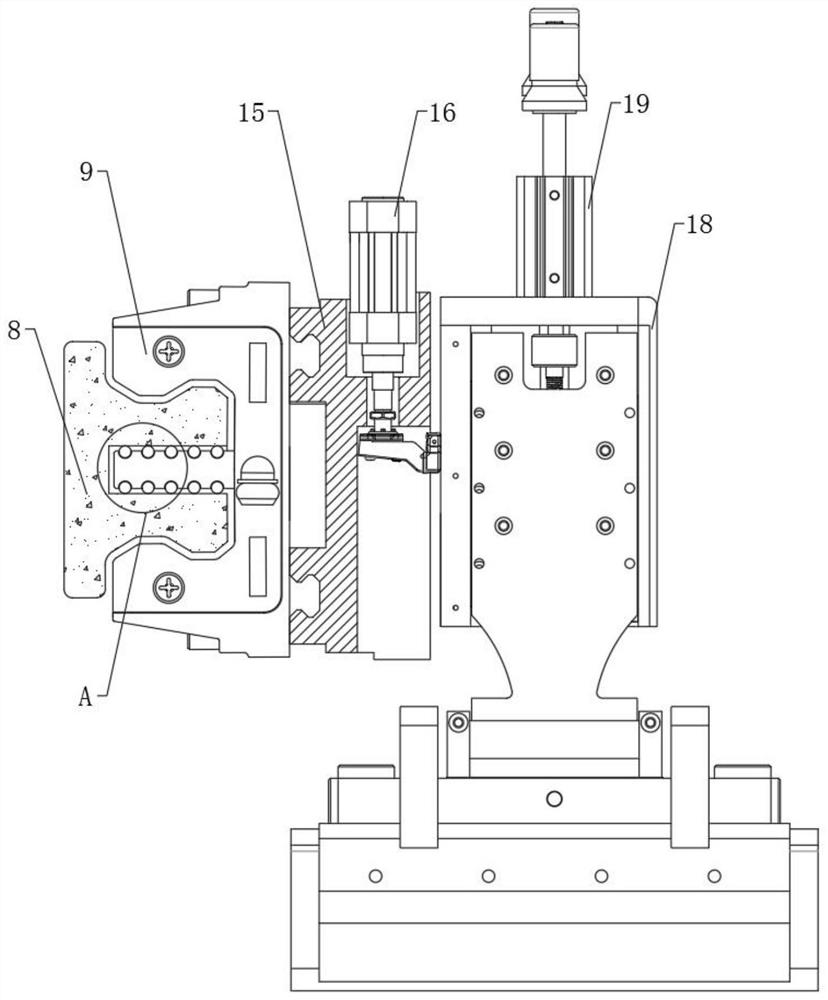

The invention provides a three-dimensional printer and a three-dimensional printing platform adjustment method. The three-dimensional printer comprises a printing head device moving in a horizontal plane, a three-dimensional printing platform moving in a vertical direction, a control unit and a display unit, wherein the printing head device comprises a permanent seat, a printing head and a pressure sensor module; the pressure sensor module is detachably arranged on the permanent seat; the printing head is detachably arranged on the pressure sensor module; the three-dimensional printing platform comprises more than three adjusting components, a loading plate and a supporting table; the loading plate is arranged on the multiple adjusting components; and the multiple adjusting components respectively penetrate through the supporting table, are detachably connected to the loading plate and are used for enabling the loading plate to move in the vertical direction. According to the three-dimensional printing platform adjustment method, the loading plate is used for corresponding to the position of the first adjusting component so as to measure a first pressure value which serves as the calibration reference of other adjusting components. According to the three-dimensional printer, the weight of the printing platform can be reduced, the cost is reduced, and the adjustment accuracy ofthe three-dimensional printing platform can be improved.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

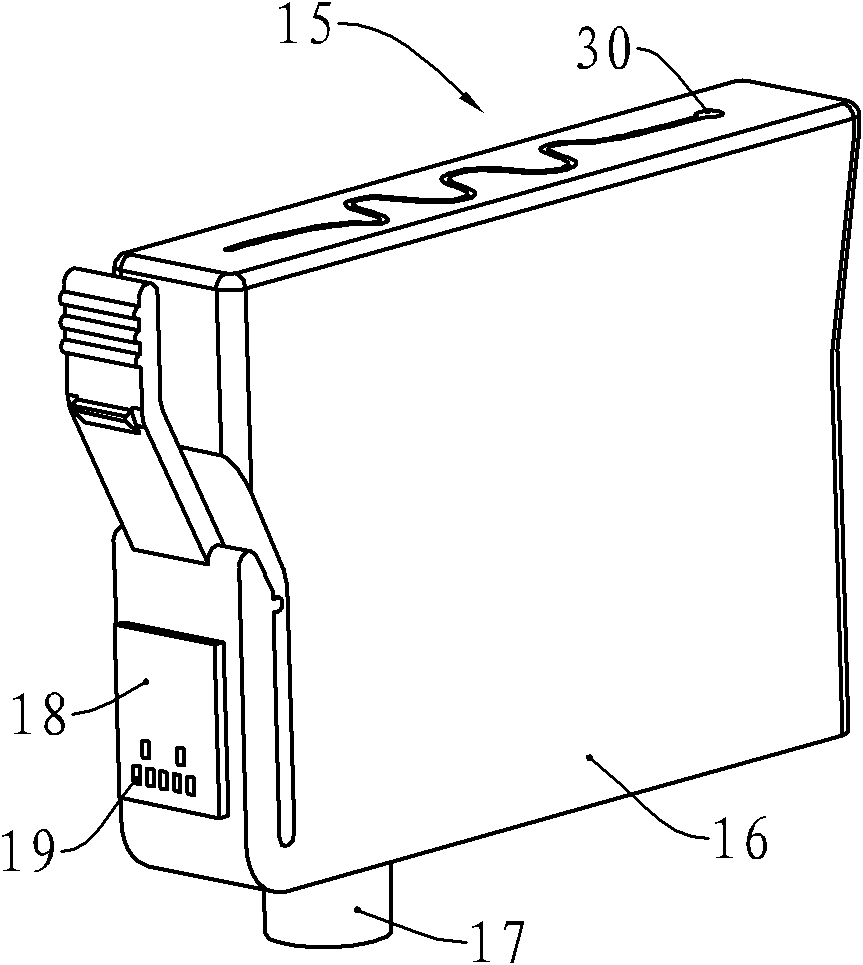

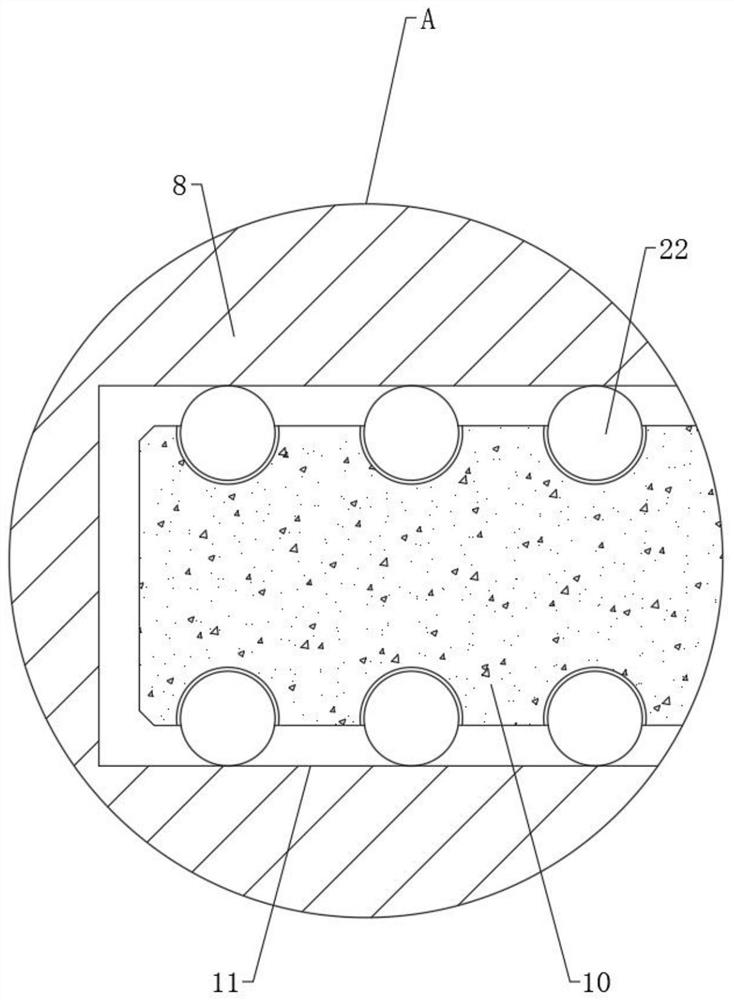

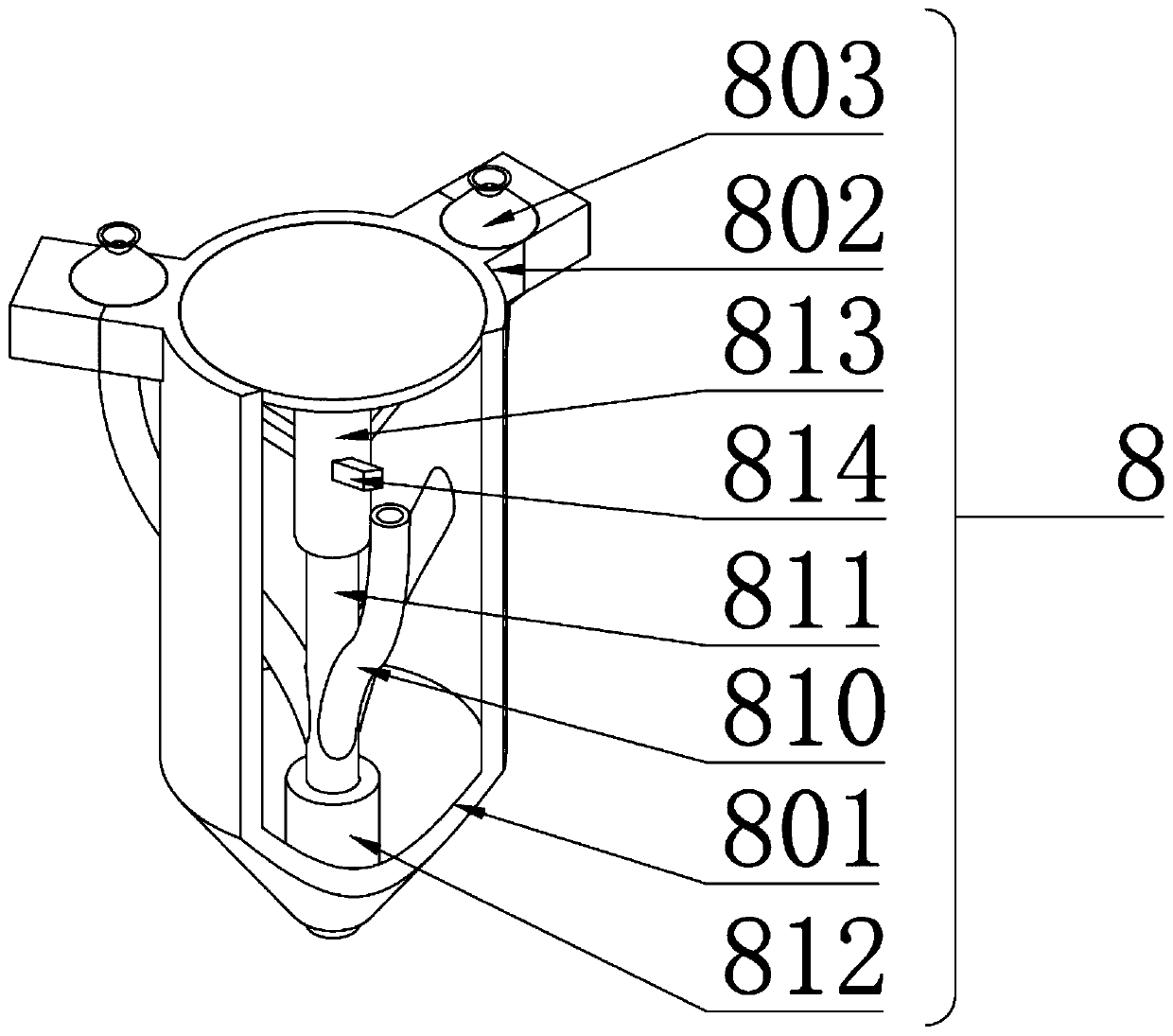

One-way valve and manufacturing method thereof as well as ink box and manufacturing method thereof

InactiveCN103240997AAffecting workSimple preparation processPrintingValve housingsChlorideMechanical engineering

The invention provides a one-way valve and a manufacturing method thereof as well as an ink box and a manufacturing method thereof. The one-way valve comprises a valve body formed by an elastic thin wall, wherein an opening is formed in one end of the valve body; a valve cavity communicated with the opening is arranged inside the valve body, and a cutting opening penetrating the inner surface and the outer surface of a side wall is formed in the side wall of the valve body; and an oxidation layer formed by oxidation of calcium chloride solution is formed on the section of the cutting opening. The manufacturing method for the one-way valve comprises the following steps: hot pressing is performed to form the valve body of the one-way valve, the opening is formed in one end of the valve body, and the valve cavity communicated with the opening is arranged inside the valve body; the cutting opening is formed by cutting in the side wall of the valve body, and penetrates through the inner surface and the outer surface of the side wall; and the one-way valve with the cutting opening is placed in 5% of calcium chloride solution for immersion for the predetermined time, and then the one-way valve is taken out from the solution, and dried in air. According to the invention, bonding of the cutting opening of the one-way valve can be greatly reduced, normal use of the one-way valve can be ensured, production efficiency of the one-way valve is improved, and production cost is reduced.

Owner:ZHUHAI TIANWEI TECH DEV CO LTD

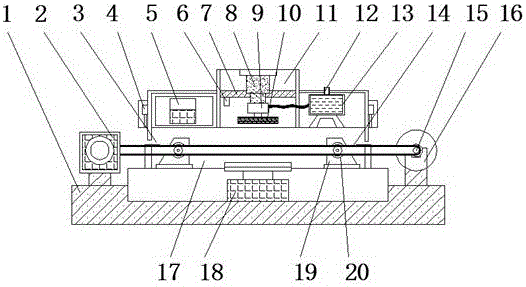

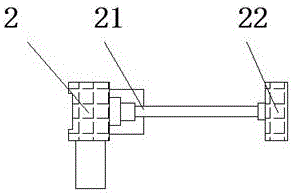

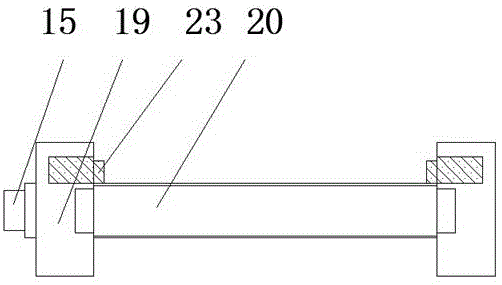

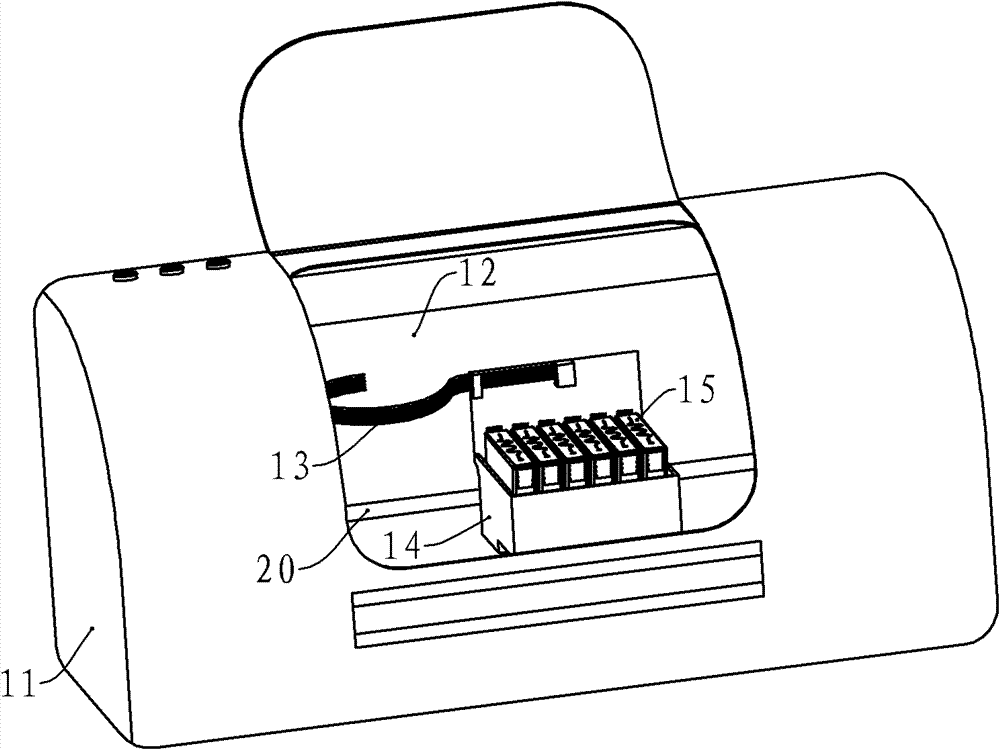

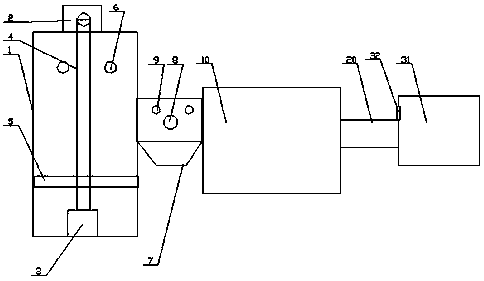

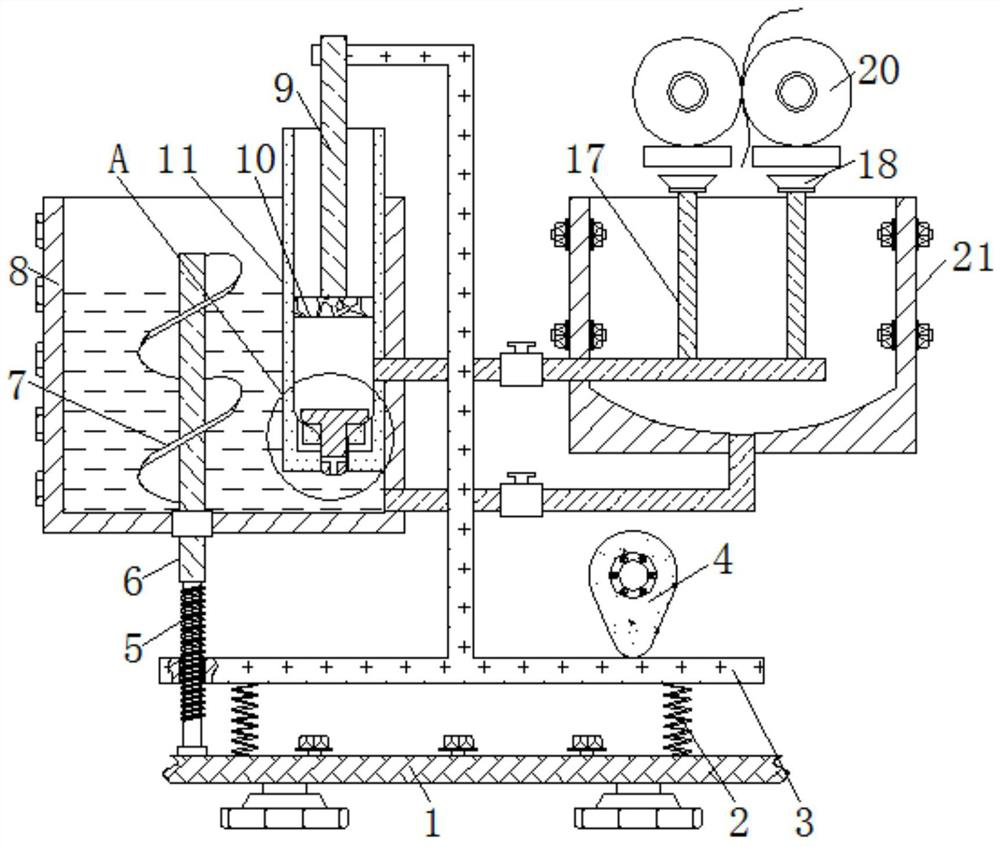

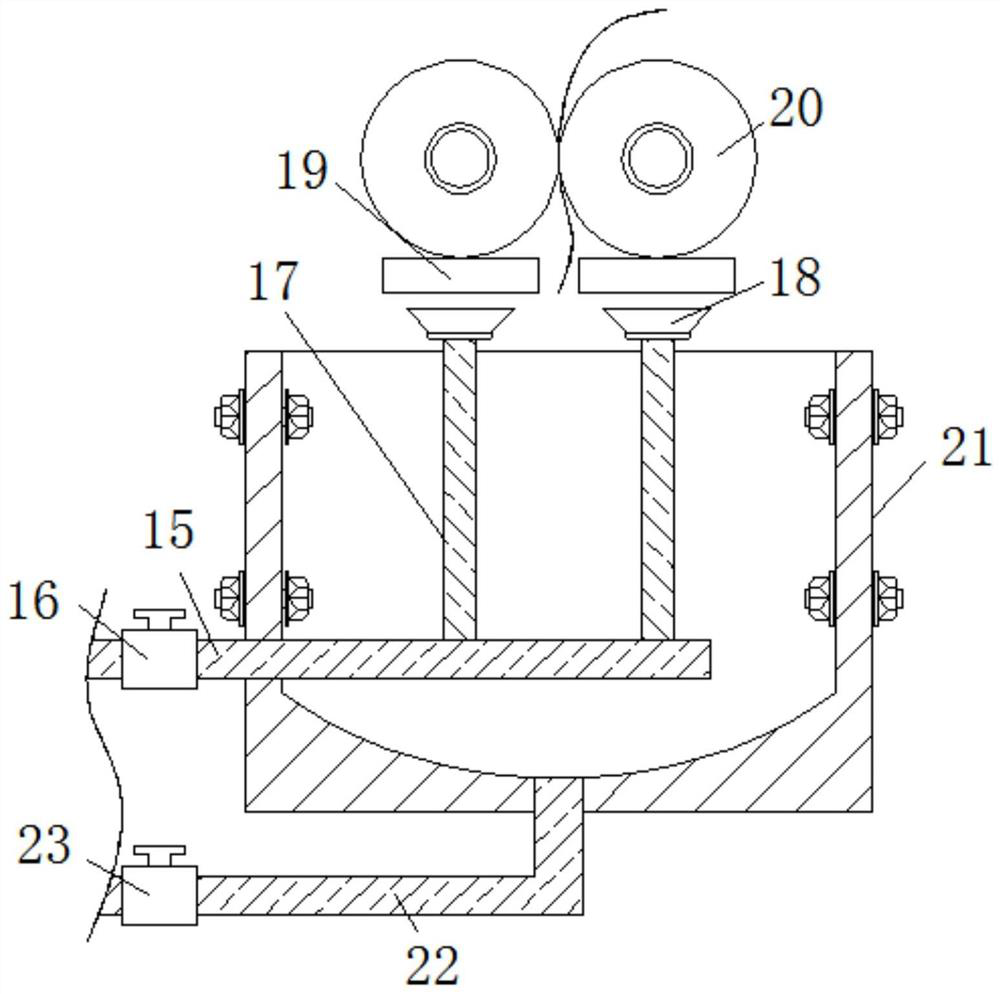

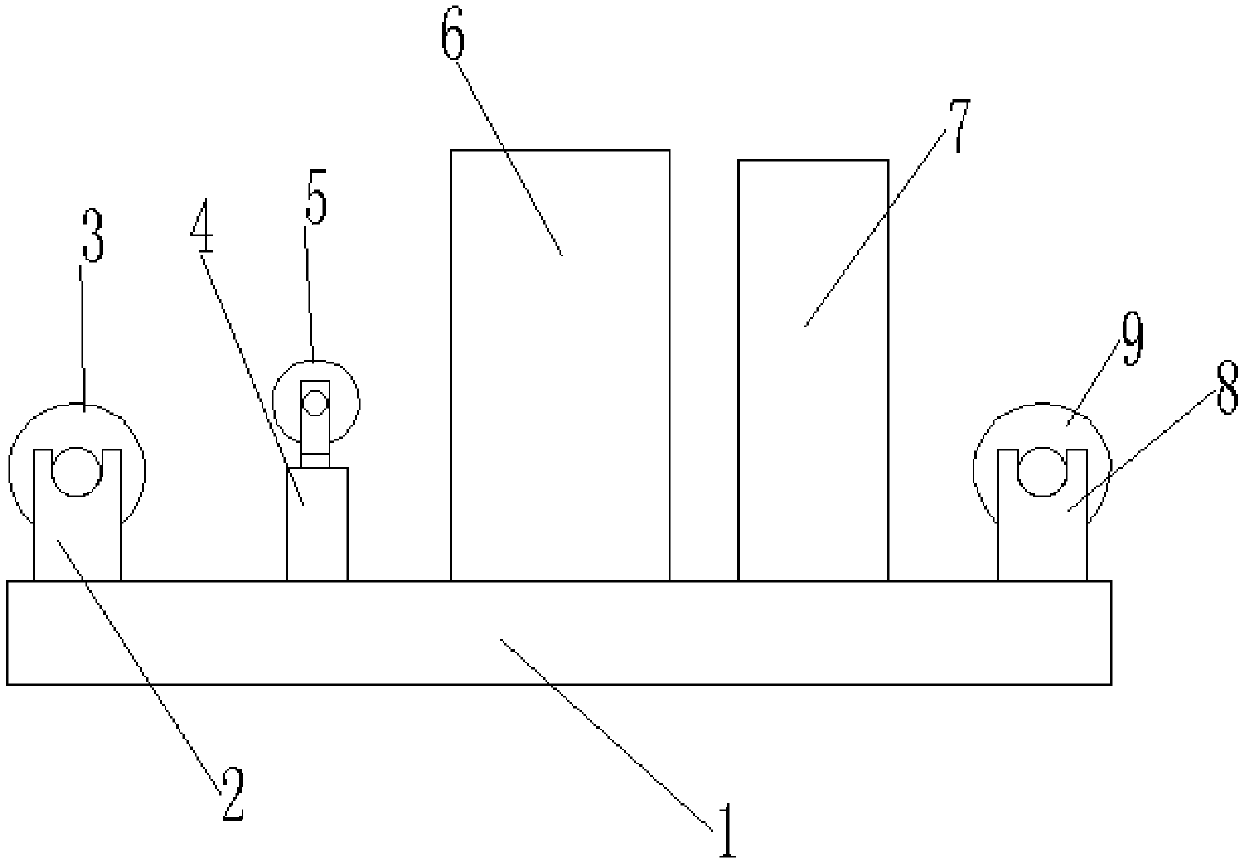

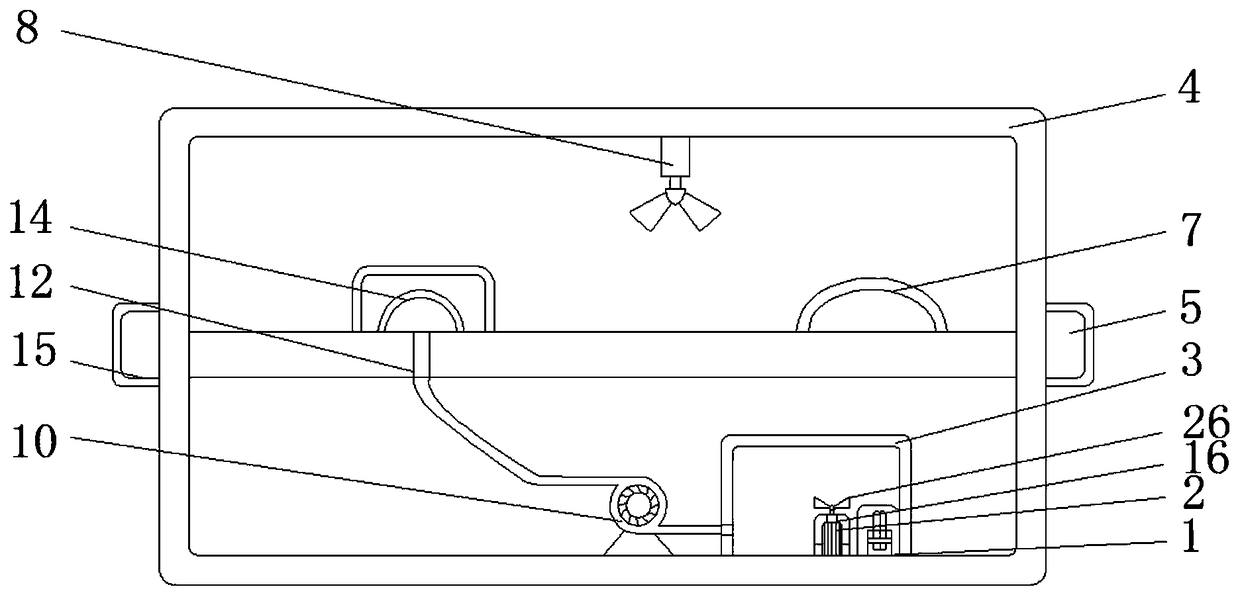

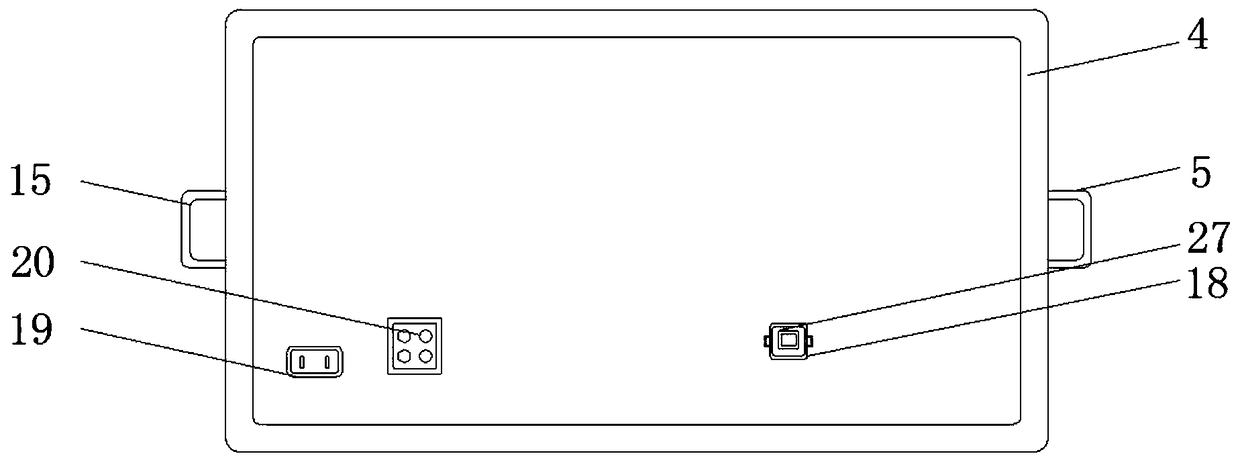

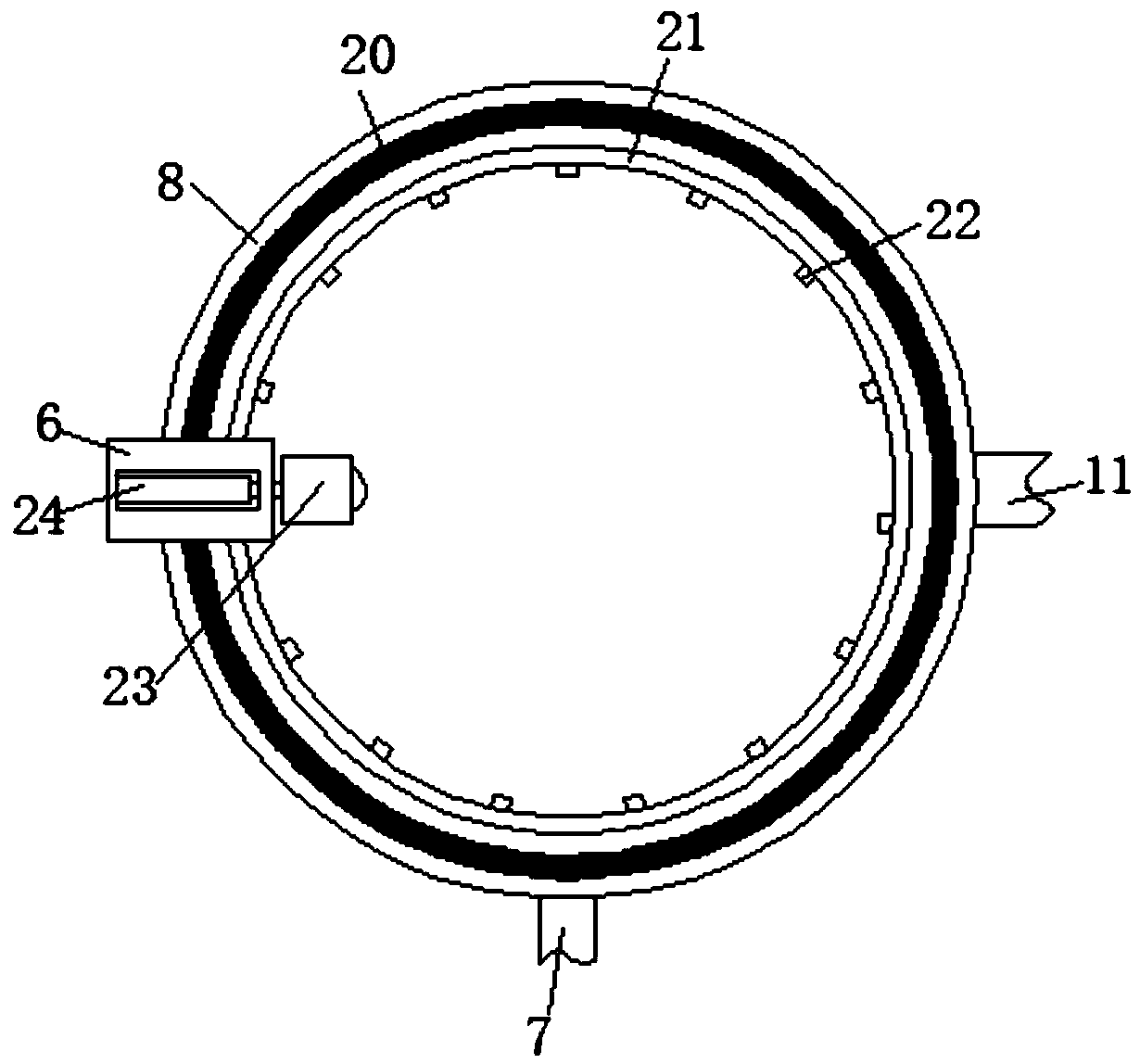

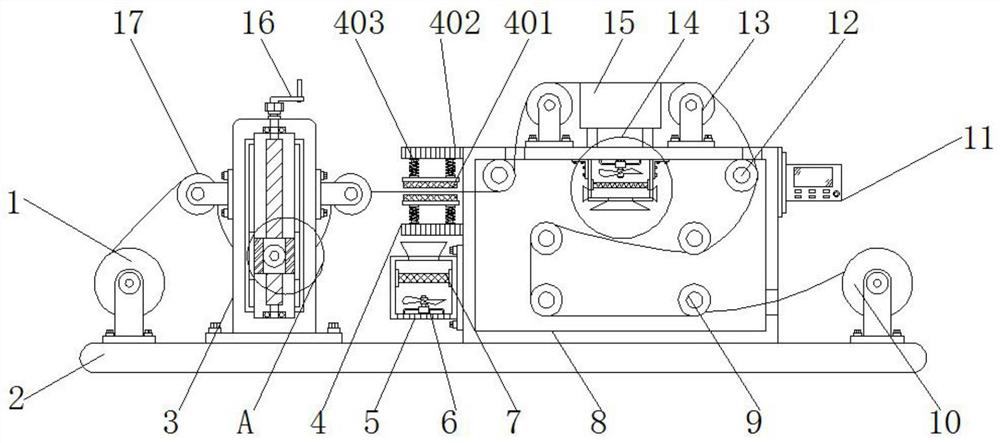

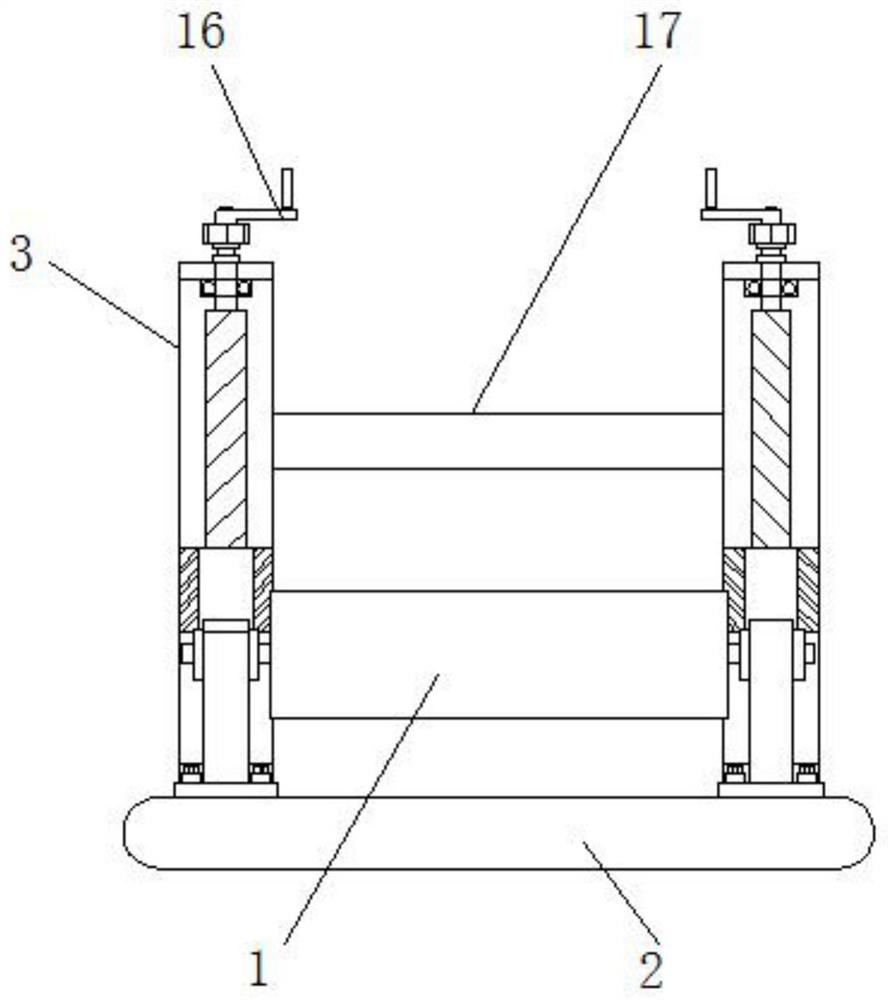

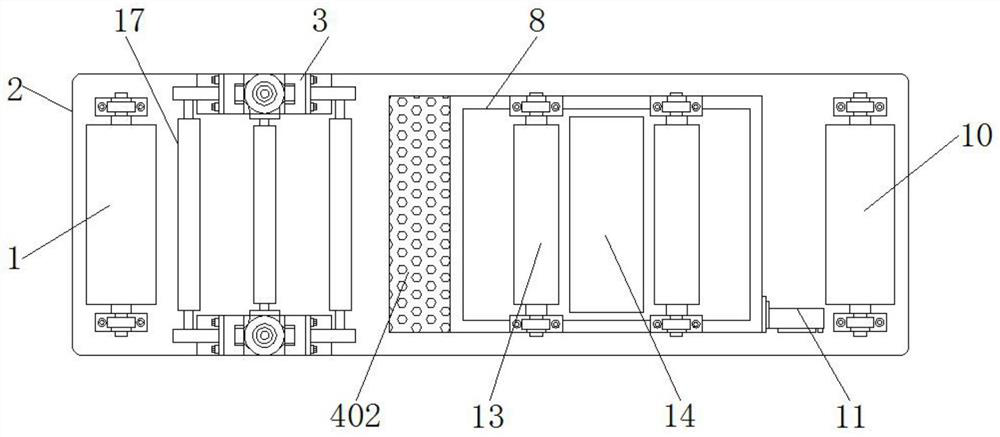

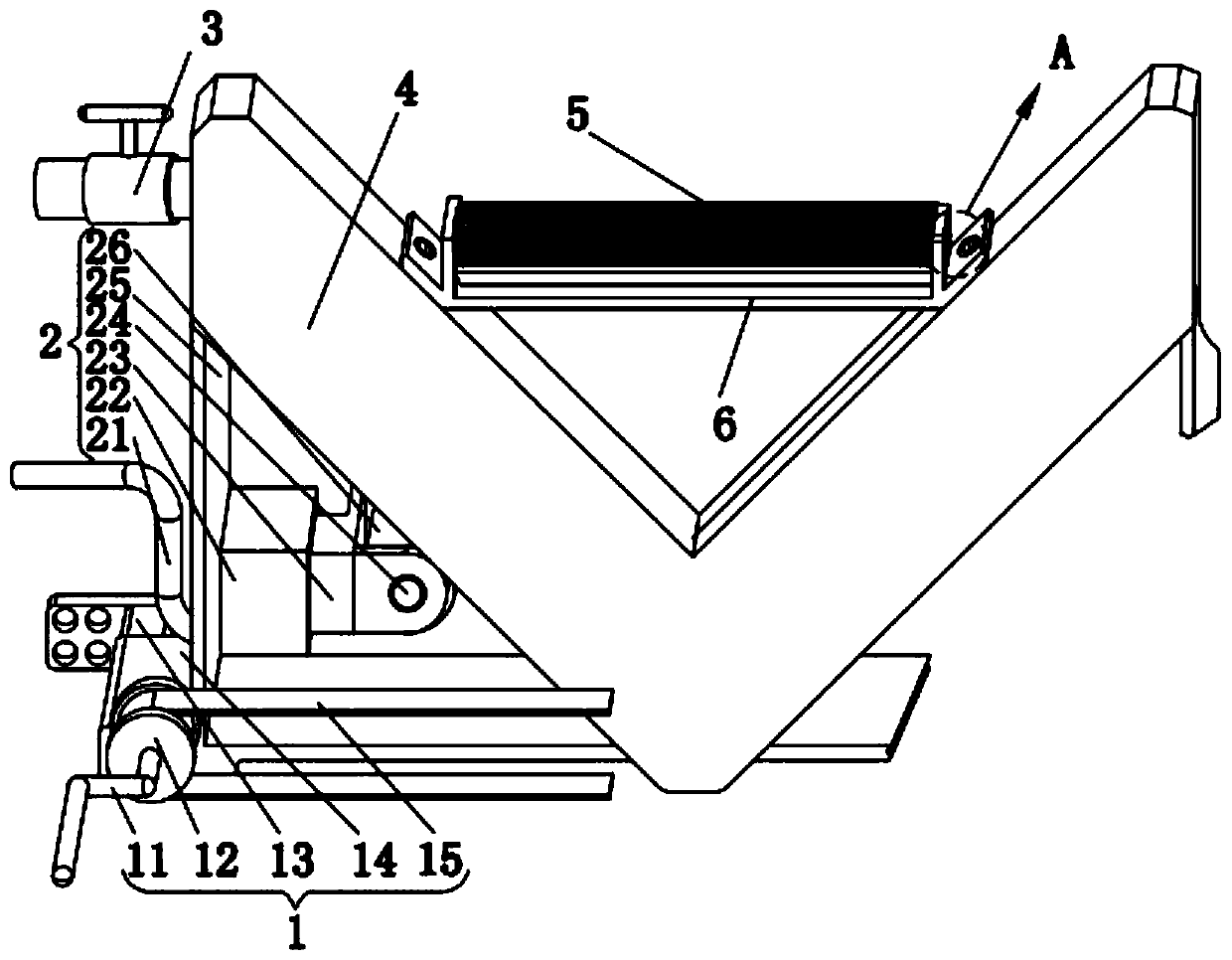

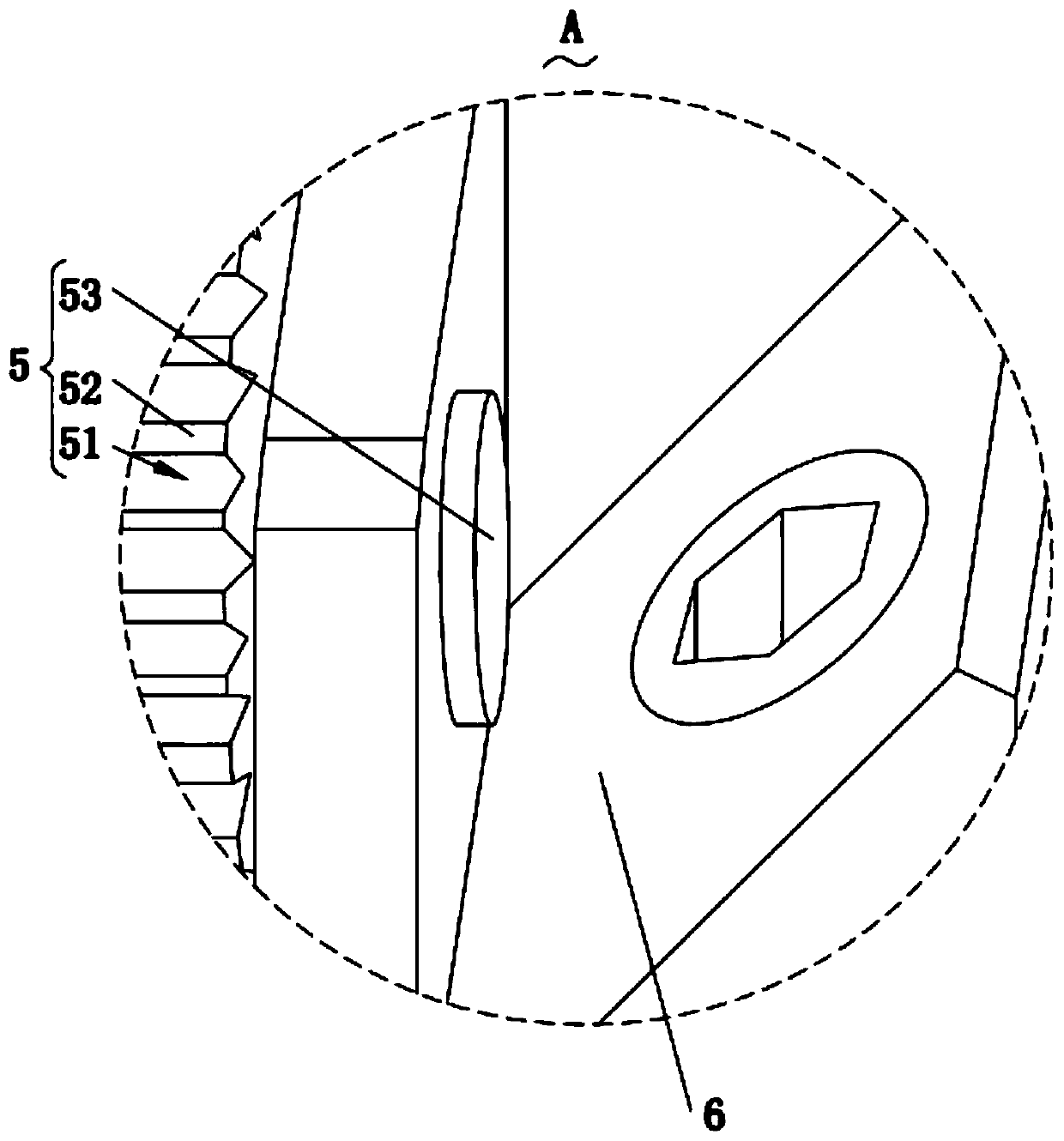

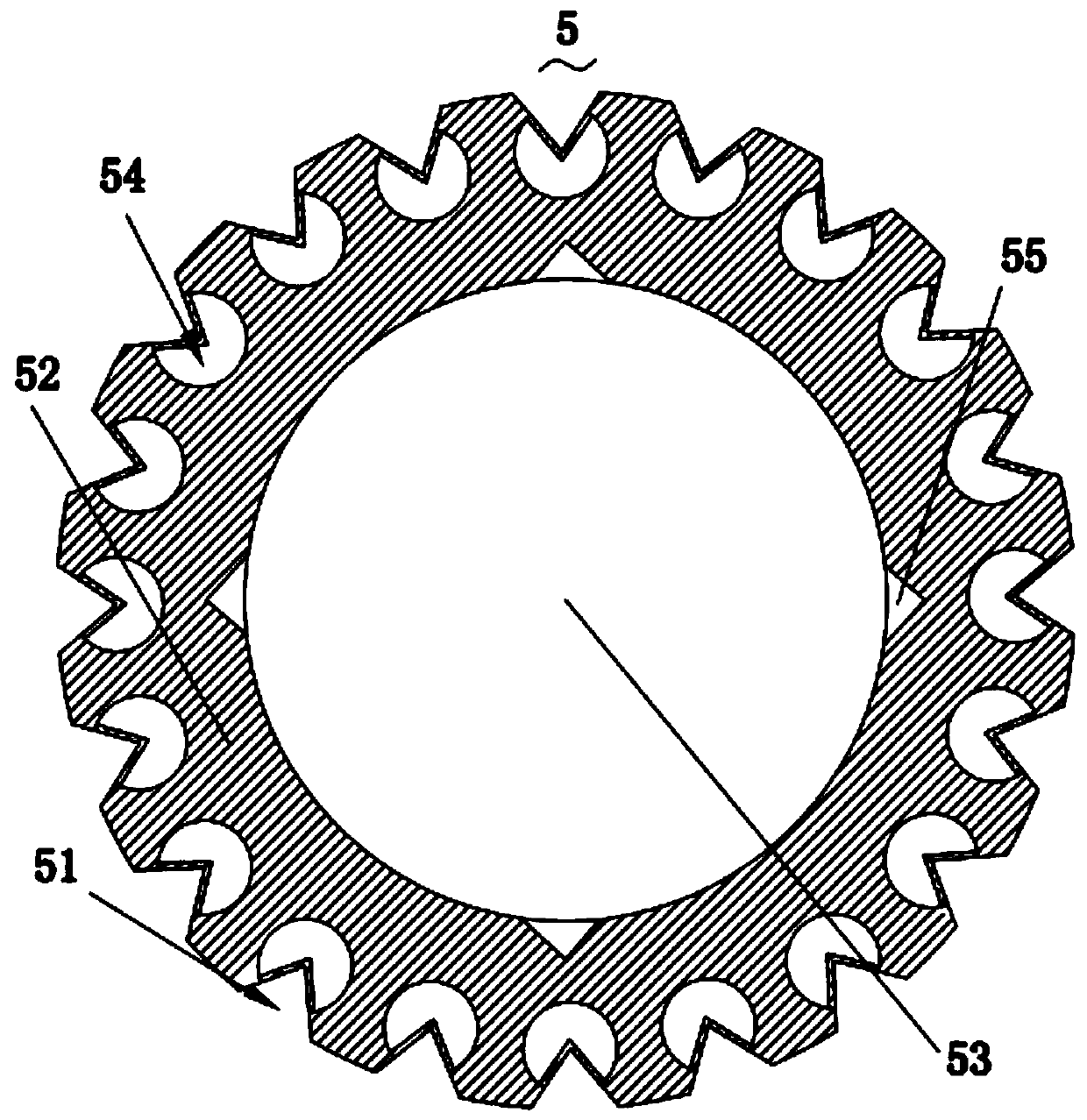

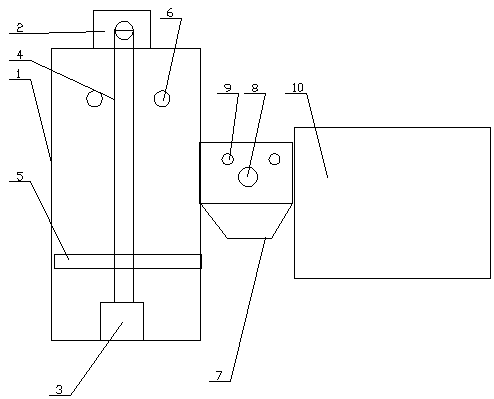

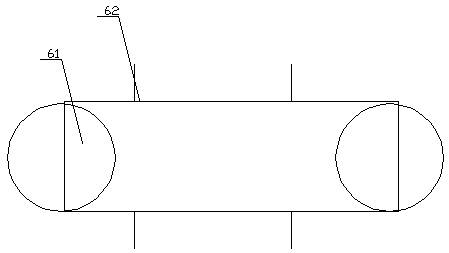

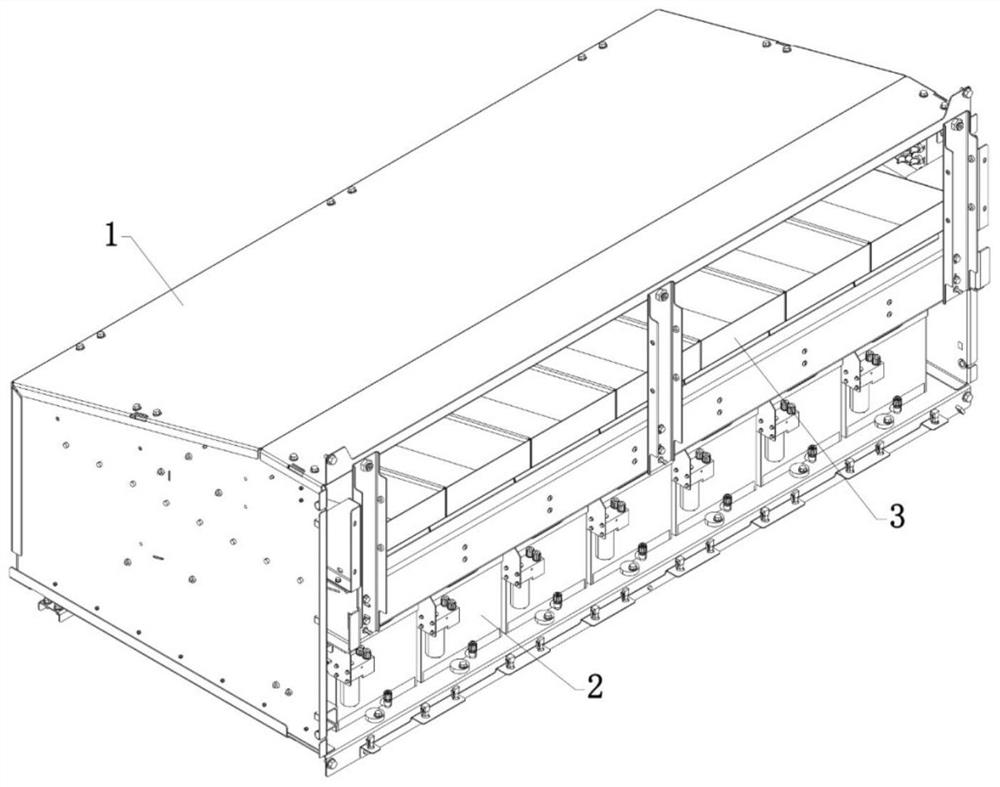

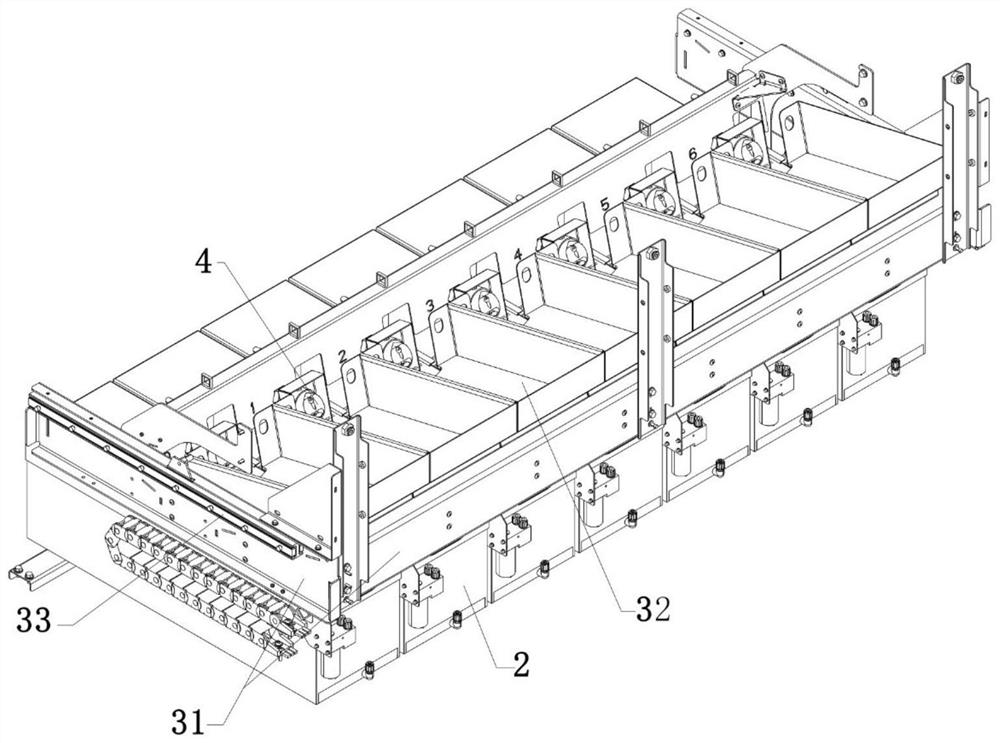

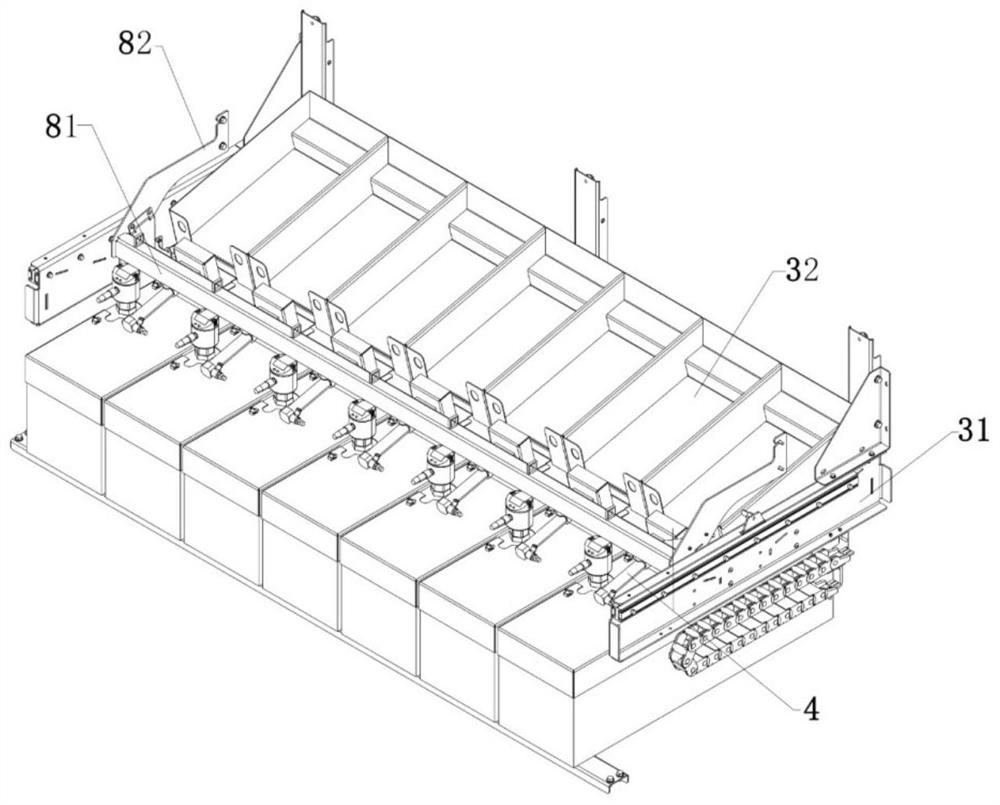

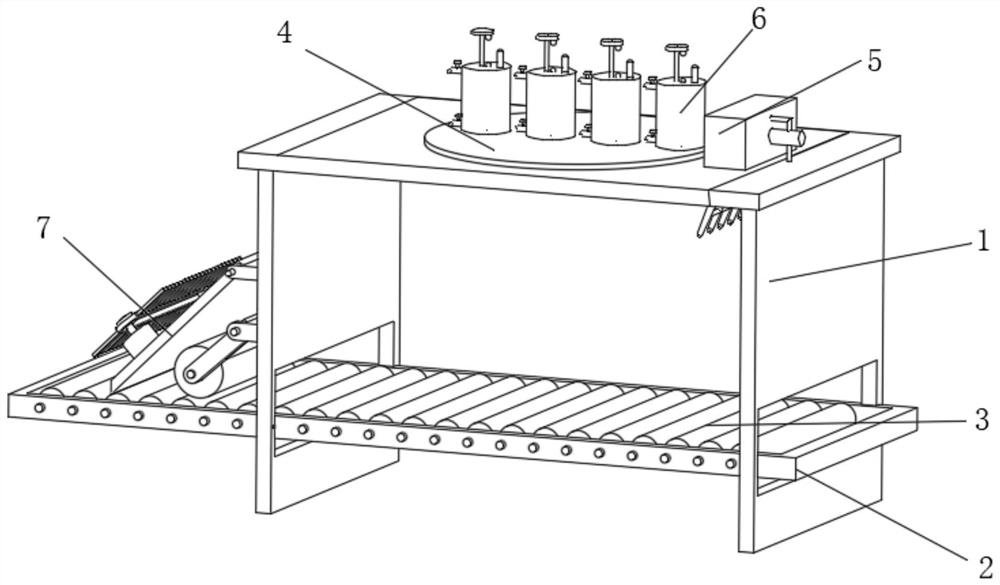

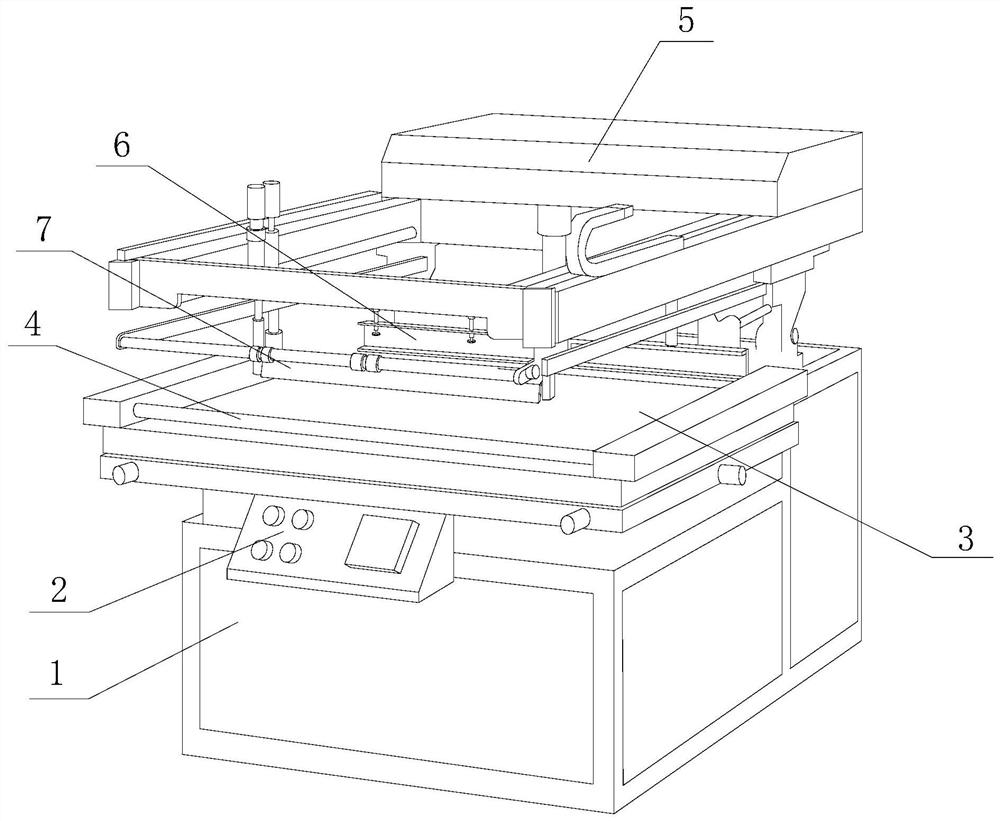

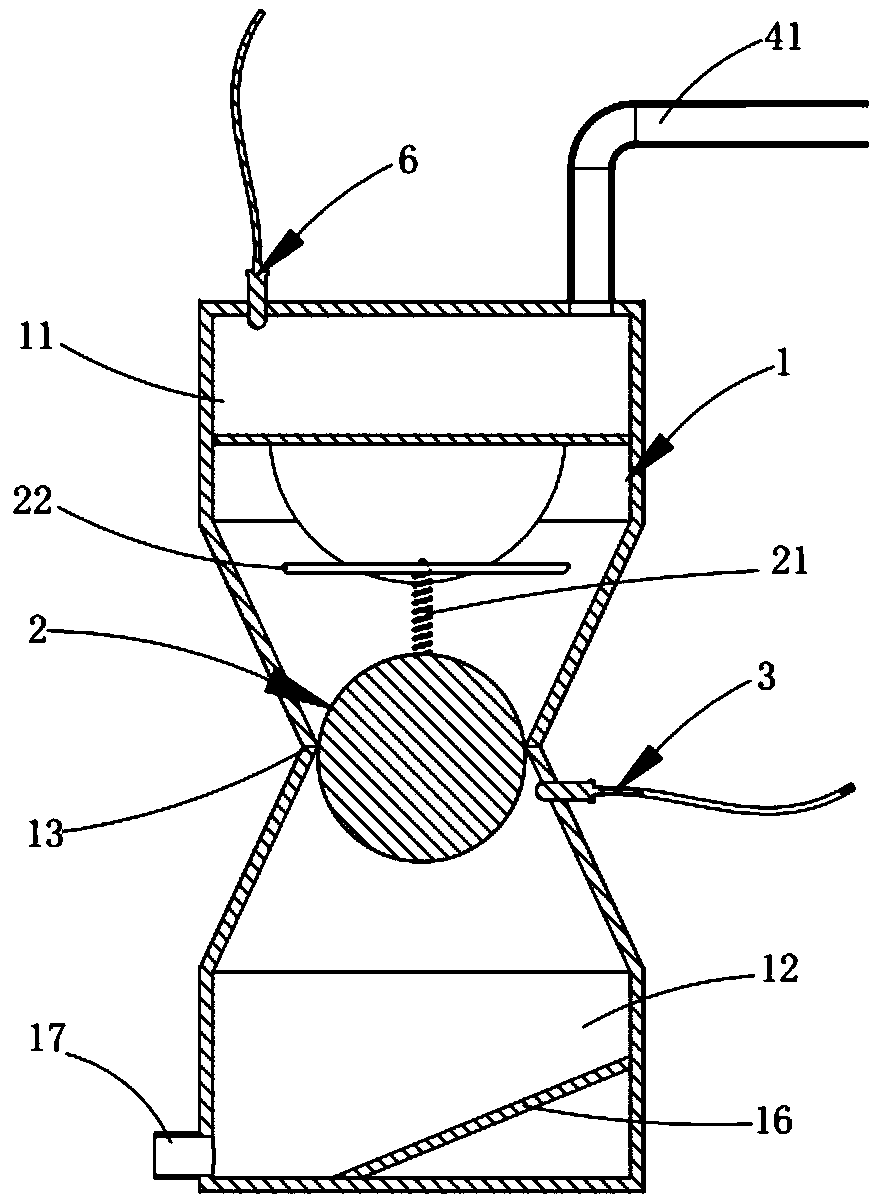

Feeding cooling system for printing machine

InactiveCN107697671AImprove printing qualityWon't scratchDomestic cooling apparatusLighting and heating apparatusPrinting inkEngineering

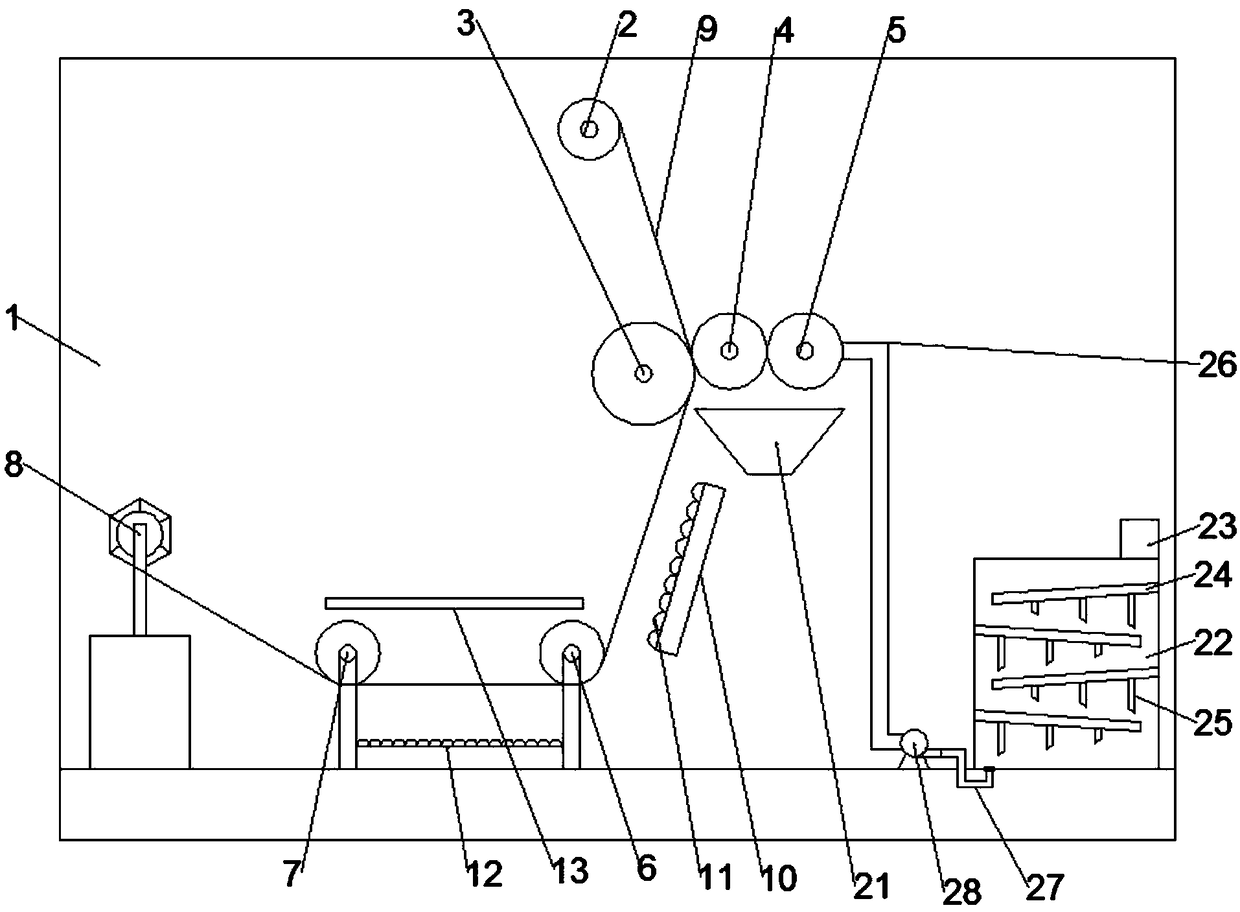

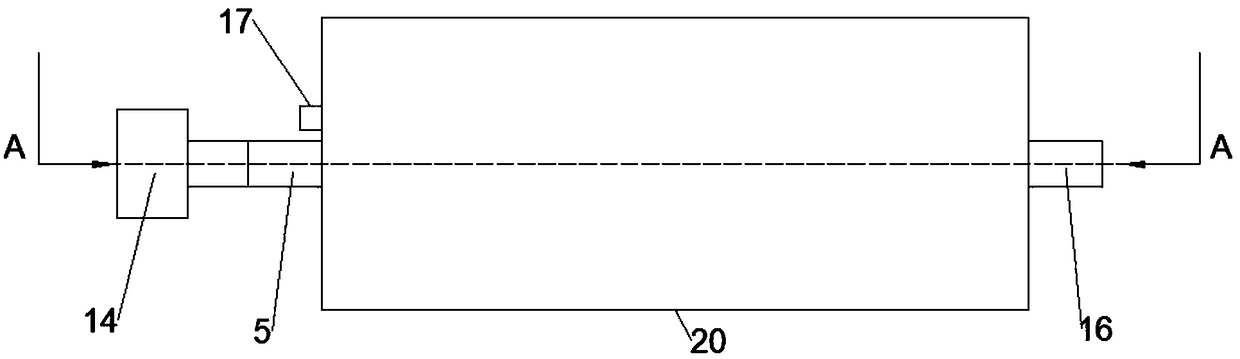

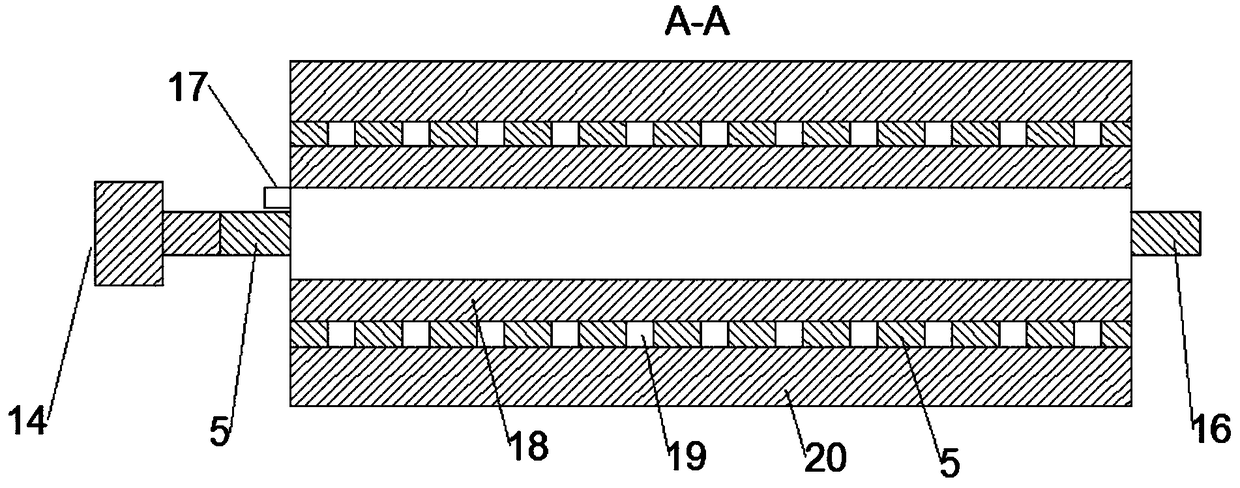

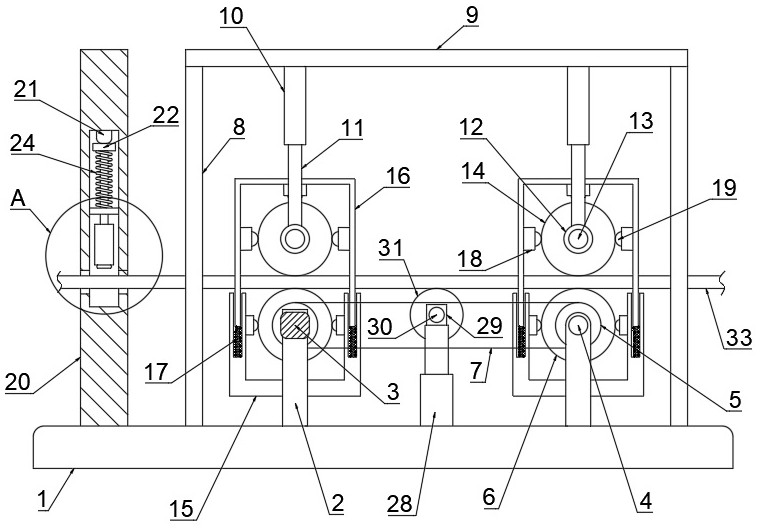

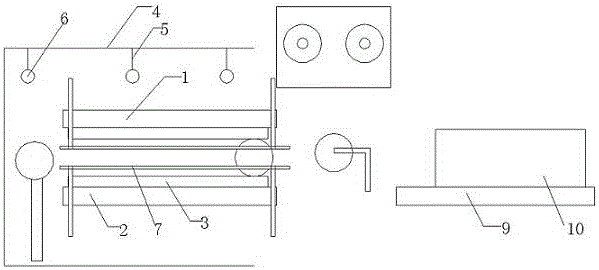

A feeding cooling system for a printing machine comprises a paper feeding section, the printing machine (10), a cooling section (20) and a discharging section. The paper feeding section comprises a paper feeding device and a dust removing device. The paper feeding device comprises a rack (1), a double-shaft motor (2), a pair of chain boxes (3), a pair of chains (4), a material stacking plate (5) and one or one set of paper rubbing wheels (6). The feeding cooling system for the printing machine has the advantages that the feeding cooling system can effectively prevent particles from falling onto paper, and the printing quality cannot be affected; through the cooling section arranged behind the printing machine, it is guaranteed that printing ink cannot be scratched, and the printing qualityis improved.

Owner:HUBEI HOUDONG PRINTING & PACKAGING

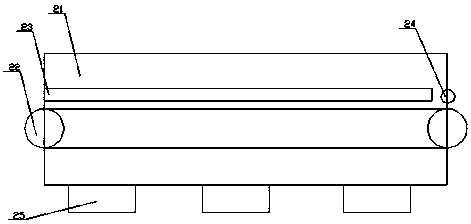

Printing device for plastic package bags

InactiveCN109228630AAffect qualityAvoid compromising print qualityRotary pressesPrinting press partsPulp and paper industry

The invention discloses a printing device for plastic package bags. The printing device comprises a machine frame. An unwinding roller is arranged on the machine frame. A supporting roller is arrangedon the lower right side of the unwinding roller and tangent to a printing roller. An ink roller is arranged on one side of the printing roller. A first guide roller and a second guide roller are arranged on the lower left side of the supporting roller. A winding roller is arranged on one side of the second guide roller. A motor is arranged on the machine frame. The output end of the motor is fixedly connected with one end of a rotating shaft. The other end of the rotating shaft is fixedly connected with one end of the ink roller. A first ink inlet is formed in one end of the ink roller. An annular sponge is arranged on the inner wall of the ink roller. Ink outlets are evenly formed in the wall of the ink roller. An ink sleeve is arranged on the outer wall of the ink roller. An ink tank isarranged at the bottom of the machine frame. A second ink inlet is formed in the upper end of the ink tank. An ink outlet is formed in the bottom end of the ink tank and connected with a pump throughan ink outlet pipe. The pump is connected with the first ink inlet through an ink inlet pipe. By means of the printing device for the plastic package bags, ink can be evenly laid on the printing roller, and the printing quality is improved.

Owner:ANHUI GUOTAI PACKING PRINTING

Printing advertisement production device

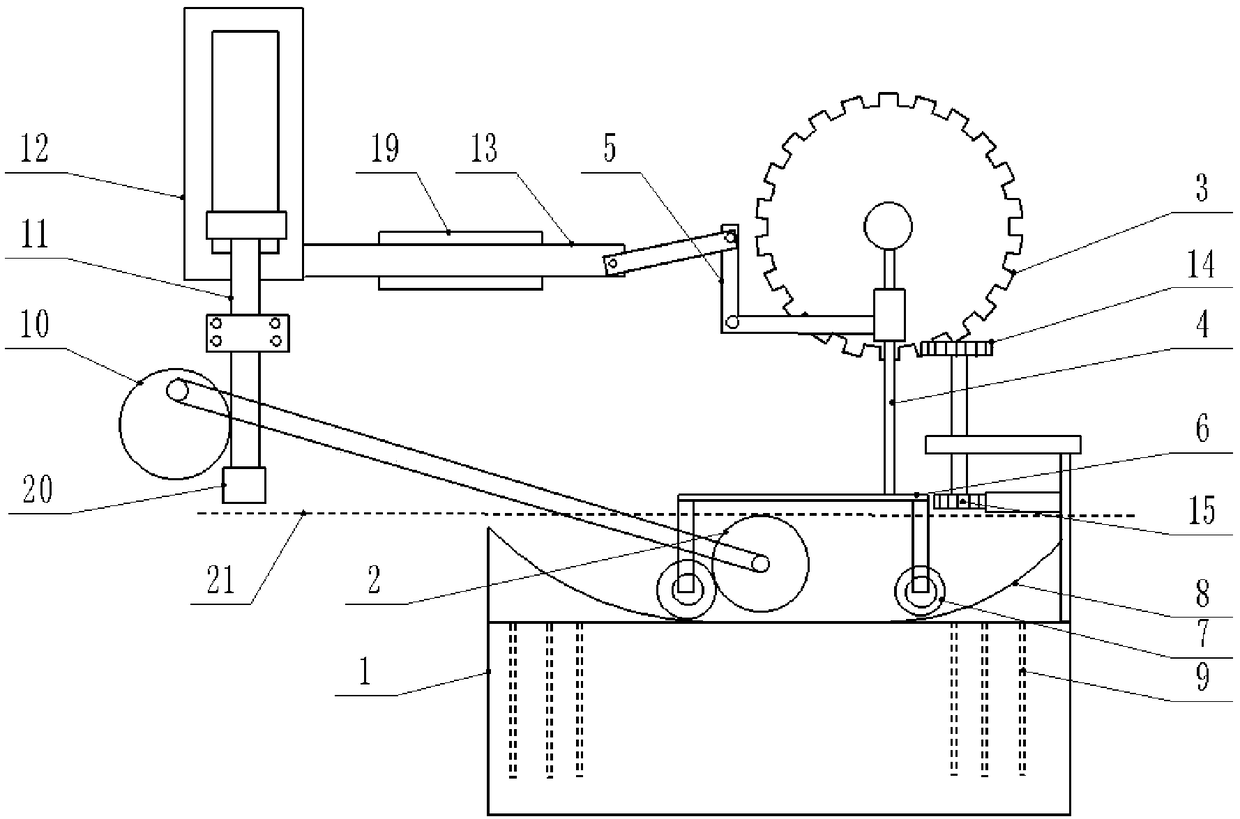

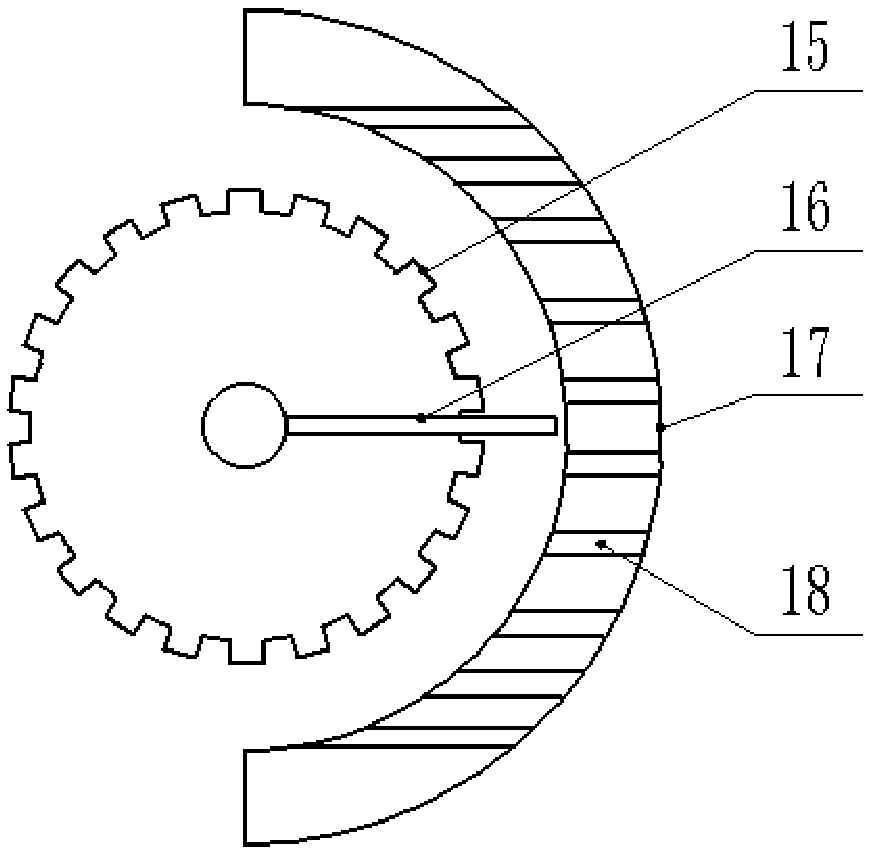

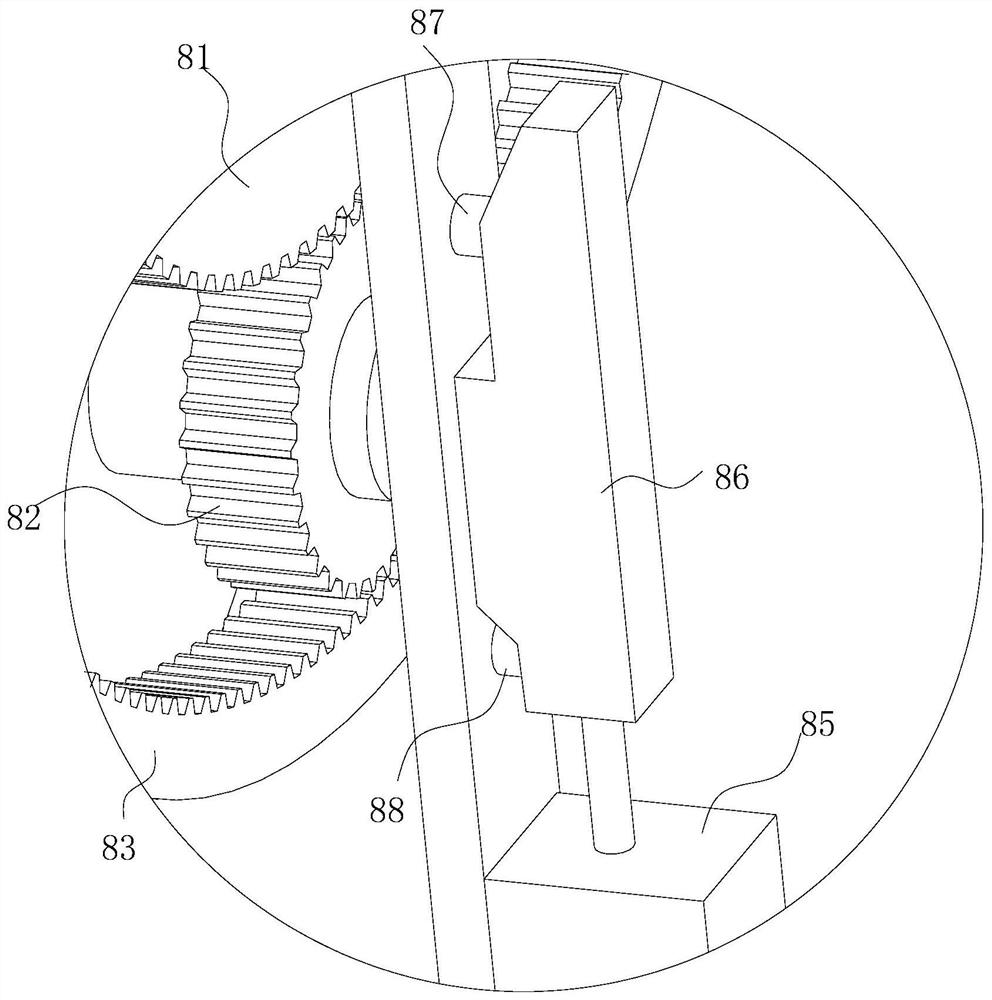

ActiveCN108357188APrevent throwingAvoid flyingCylinder pressesSpraying apparatusGear wheelEngineering

The invention relates to the technical field of printing production, and discloses a printing advertisement production device. The printing advertisement production device comprises an ink tank and aprinting roller located above the ink tank. An ink conveying mechanism is further included and comprises a rotationally-arranged main gear. A swinging rod is fixedly connected to the main gear and extends in the radial direction of the main gear. A rotationally-arranged L-shaped ejector rod is arranged on the outer side of the swinging rod, one end of the ejector rod is connected with a reciprocated swinging mechanism, and the other end of the ejector rod is hinged to the swinging rod. A swinging frame is hinged to the free end of the swinging rod and rotationally connected with an ink roller.The roller face of the ink roller abuts against the roller face of the printing roller. A sliding rail is arranged on the top of the ink tank, sponge is laid on the sliding rail, cotton threads penetrate the sponge, the end portions of the cotton threads are immersed in ink liquid in the ink tank, and the ink roller can slide to the sliding rail in the motion process. By means of the printing advertisement production device, the problem that in the prior art, when the printing roller conducts ink rolling, ink liquid in the ink tank is prone to being thrown out can be solved.

Owner:重庆新锐科技服务有限公司

Energy-saving printing device capable of preventing printing quality from being influenced by ink splashing

InactiveCN112918105AAffect printing qualityAvoid compromising print qualityInking apparatusPrinting press partsEngineeringMechanical engineering

The invention relates to the technical field of printing, and discloses an energy-saving printing device capable of preventing printing quality from being influenced by ink splashing. The energy-saving printing device comprises a supporting plate, wherein a compression spring is fixedly connected to the top of the supporting plate, a movable rod is fixedly connected to the side, away from the supporting plate, of the compression spring, an eccentric cam is movably connected to the top of the right side of the movable rod, a screw rod is in threaded connection with the interior of the left side of the movable rod, and a stirring rod is fixedly connected to the top of the screw rod. According to the energy-saving printing device capable of preventing the printing quality from being influenced by ink splashing, during printing, the movable rod can periodically move up and down under the action of the eccentric cam and the compression spring, an impeller is further made to periodically rotate forwards and backwards in an ink pool, and therefore the effect of preventing the printing quality from being influenced by ink precipitation is achieved. The movable rod drives a piston rod to periodically move up and down, and ink in a piston cylinder can be periodically sprayed to a sponge block, so that the effect of avoiding ink waste caused by ink splashing is achieved.

Owner:王川

Screen printing machine

The invention discloses a screen printing machine, and relates to the field of solar silicon cell piece production equipment. The screen printing machine is used for manufacturing back surface fields, back electrodes and positive grid line electrodes. The screen printing machine comprises a rack. A printing platform and a printing device are arranged in the rack; an opening door is hinged to the rack; a humidifier is arranged in the rack; a humidification pipe is connected to the humidifier; the other end of the humidification pipe is arranged on the upper portion in the rack; a humidification inductor is connected to the printing platform; the signal output end of the humidification inductor is connected to a temperature and humidity controller of the humidifier. Due to the adoption of the design, when the humidity around the printing platform of the printing machine is reduced, the humidification inductor sends signals to ensure that the humidifier works to humidify the space of the printing machine in the rack, and accordingly the problem that because metal sizing agents become dry, the printing quality is affected is solved.

Owner:YANGZHOU XINJING PHOTOVOLTAIC TECH

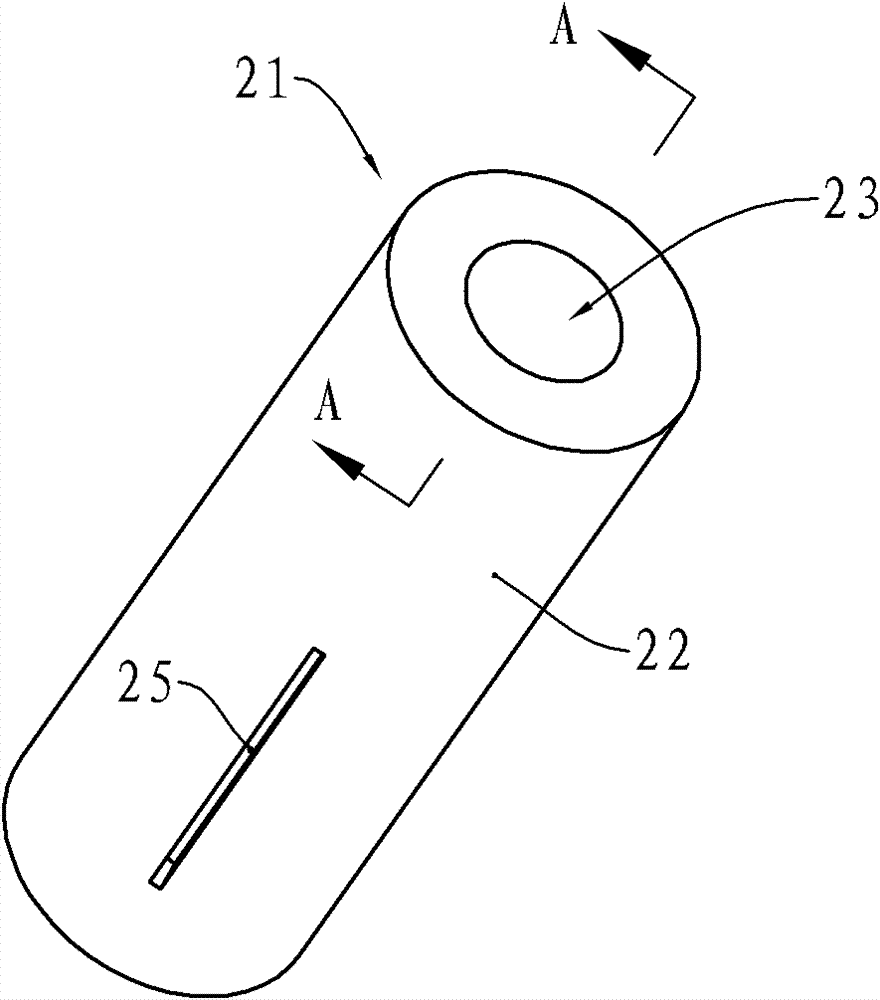

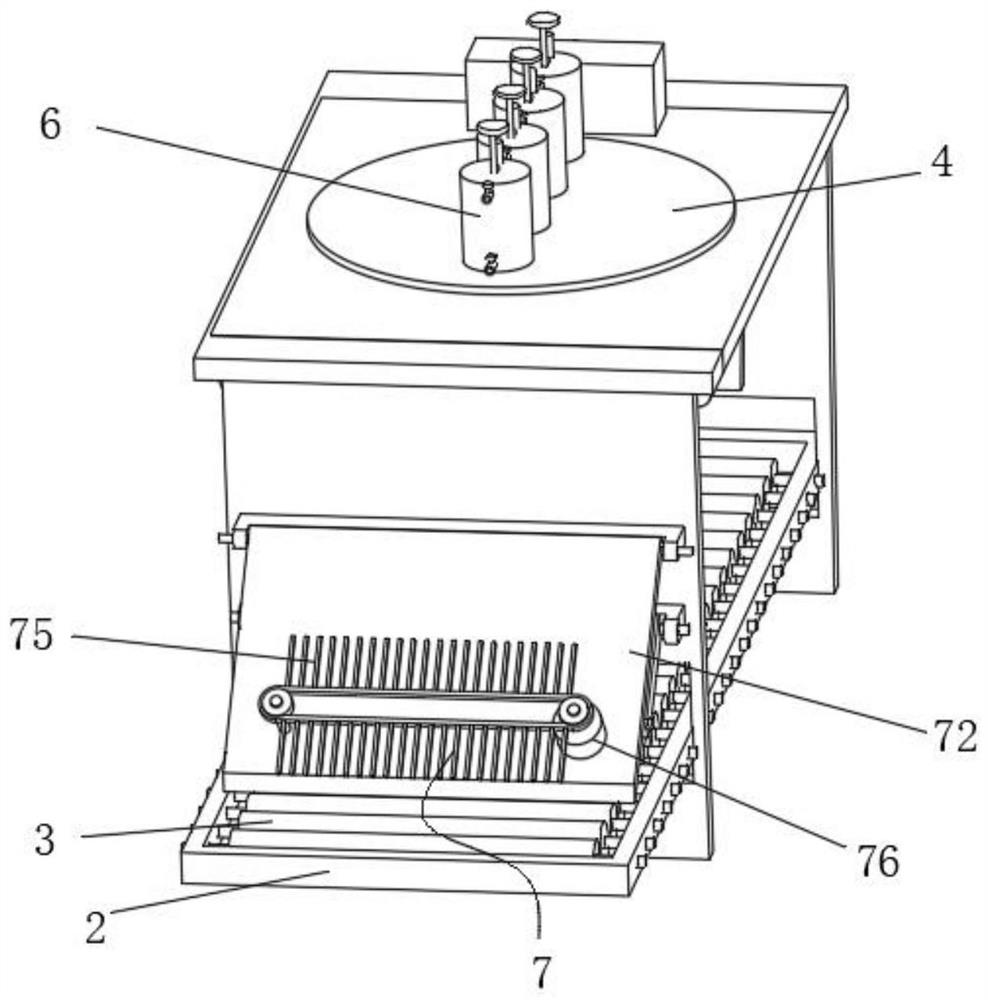

Automatic paper feeding device for continuously printing labels

PendingCN112897161AImprove practicalityStable without driftWebs handlingTransmission beltElectric machinery

The invention discloses an automatic paper feeding device for continuously printing labels. The automatic paper feeding device comprises a base, wherein two paper feeding mechanisms are fixedly arranged on the upper side wall of the base, the paper feeding mechanisms comprise two supports fixedly connected to the upper side wall of the base, a first rotating shaft is arranged between the two supports, the outer wall of each first rotating shaft is fixedly sleeved with a paper feeding roller, the outer wall of each first rotating shaft is fixedly sleeved with a transmission wheel, the two transmission wheels are jointly sleeved with a transmission belt, and the outer wall of one support is fixedly connected to a motor. According to the paper feeding device, through self-adaptability of stretchable springs, the paper feeding device can press paper with different thicknesses, so that the application range of the paper feeding device is expanded, the practicability of the paper feeding device is improved, meanwhile, through extension and retraction of the driving end of an electric telescopic rod, deviation prevention positioning can be conducted on the two sides of the paper with different widths, and the paper is more stable and does not deviate in the conveying process.

Owner:张加叶

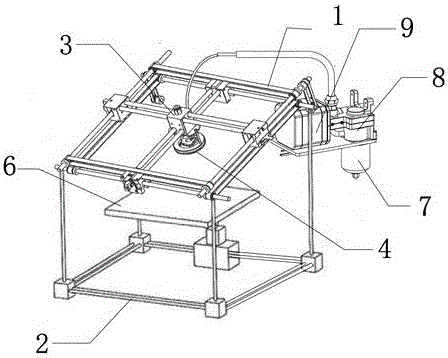

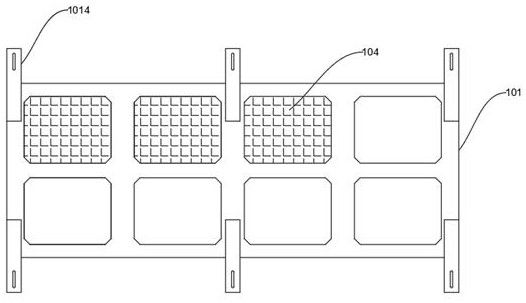

3D printing bone platform

InactiveCN106215233ALarge space for activitiesLarge adjustment spaceAdditive manufacturing apparatusTissue regenerationBiological bodyBiocompatibility Testing

The invention discloses a 3D printing bone platform and belongs to the field of 3D printing. The 3D printing bone platform comprises an upper bracket and a lower bracket which are movably connected with each other, wherein the upper bracket is of square shape; the bottom of the lower bracket is of square shape; the lower bracket comprises four support rods along the vertical direction; the vertex of the upper bracket is connected with the vertex of the bottom of the lower bracket through the support rods; the support rods are moveably connected with the upper bracket; the upper bracket can be overturned around the joint point; a print head is arranged on the upper bracket; a fusing device is fixedly arranged above the lower bracket; the fusing device is connected with the print head through a sampling pipe. The 3D printing bone platform provided by the invention has excellent biocompatibility and can supply growth cavity to the tissue cells; the print bone transplanted into the biological body can survive and be integrally fused with the transplant receptor; the printing precision is ultrahigh; the platform can correct at any time and accurately control the flow, so that the artificial bone completely matched with the original bone system can be acquired.

Owner:成都测迪森生物科技有限公司

High-efficiency wallpaper printing production device with high printing quality

InactiveCN107672299ASimple structureUse less electrical componentsRotary pressesPrinting press partsCost savingsEngineering

The invention discloses a high-efficiency wallpaper printing production device with high printing quality, which includes a workbench, a first U-shaped support frame is welded on both sides of the outer wall on one side of the top end of the workbench, and the openings of the two first U-shaped support frames The same input roller is provided at each place, and the two ends of the input roller are respectively placed on the opening inner walls of the two first U-shaped support frames, and the first cylinder is fixed on both sides of the outer wall at the top of the workbench by screws. The printing box is fixed on the outer wall of the top of the table by screws, and the first air cylinders are located between the printing box and the first U-shaped support frame. The invention has simple structure, less use of electrical components, lower cost, and the use of the dryer can dry the printed wallpaper in time, avoiding self-pollution during collection and affecting the printing quality, and the first cylinder and the second cylinder cooperate in time Adjust the tension of the wallpaper to avoid looseness or breakage, improve the printing quality and save the cost.

Owner:湖北巴萨装饰材料股份有限公司

Composite printing structure of corrugated board production line

ActiveCN109649000AImprove the quality of printing and processingAvoid compromising print qualityCylinder pressesPlaten pressesForeign matterProduction line

The invention relates to the field of corrugated board production equipment, in particular to a composite printing structure of a corrugated board production line. The composite printing structure comprises a height adjusting structure, limiting structures, a gas valve, a clearing sleeve, a guide structure, a fixing frame and a clearing structure; the height adjusting structure is arranged on theclearing sleeve, the guide structure used for guiding a corrugated board is arranged on the part, at one end of the clearing sleeve, of the fixing frame, and the other end of the clearing sleeve is provided with the limiting structures used for limiting the corrugated board; and the clearing sleeve is provided with the clearing structure used for clearing foreign matter on the corrugated board through gas, and the gas valve penetrates through the clearing sleeve. According to the structure, the gas valve in the clearing sleeve is matched with the clearing structure so that the foreign matter on the corrugated board can be conveniently and rapidly cleared; the guide structure is used so that the corrugated board in the conveying process can be conveniently guided; and meanwhile, the limiting structures are used so that the corrugated board can be limited conveniently, deviation of the corrugated board in the conveying process is avoided, and therefore, the printing quality of the corrugated board is greatly improved.

Owner:苏州佳华印刷包装有限公司

Coated paper bag production equipment

InactiveCN108749296AEfficient printingUniform printingInking apparatusRotary pressesPulp and paper industryCoated paper

The invention discloses coated paper bag production equipment. The coated paper bag production equipment comprises an ink box, a box body and a door body. The bottom end inside the box body is provided with the ink box, the ink box is internally provided with a first servo motor, the output end of the first servo motor is provided with a first rotating shaft, and the two sides of the first rotating shaft are both provided with stirring paddles. A water pump is installed at the position, on one side of the ink box, inside the box body. The input end of the water pump is connected with the ink box through an anti-explosion pipe. The box body is internally provided with a first rolling plate and a second rolling plate, a second servo motor is arranged at the position, on one side of the second rolling plate, inside the box body, the output end of the second servo motor is provided with a second rotating shaft, and the surface of the second rotating shaft is provided with an ink roller. Through the arrangement of a series of structures, the coated paper bag production equipment has the advantages of uniform printing, preheating of ink, accelerating of drying and the like.

Owner:平阳县星星塑料包装有限公司

Green and environment-friendly printing device and printing method

ActiveCN113580731AAutomatic temperature adjustmentThe viscosity of the ink is automatically adjusted when the temperature risesRotary lithographic machinesPrinting press partsProcess engineeringPrinting ink

The invention discloses a green and environment-friendly printing device and a printing method in the field of package printing. The green and environment-friendly printing device comprises a printing plate roller installed on a rack; the printing roller is provided with a dampening mechanism and an ink supply mechanism; the dampening mechanism is connected with a water storage bin fixed to the rack; the ink supply mechanism comprises an ink supply bin and a cooling bin; the ink supply bin is located in the cooling bin; the two ends of the cooling bin are communicated with the water storage bin and the dampening mechanism through a first communicating pipe and a second communicating pipe correspondingly; and a control mechanism is further arranged on the cooling bin and controls the flow of water entering the cooling bin from the water storage bin according to the viscosity of printing ink in the ink supply bin. According to the green and environment-friendly printing device provided by the invention,water in the dampening mechanism can be used for cooling the printing ink, and the situation that the viscosity of the printing ink is too small due to temperature rise, and the printing quality is affected is avoided; and the viscosity change of the printing ink can be measured in real time in the printing process, the temperature of the printing ink can be automatically adjusted, it is guaranteed that the printing ink has proper viscosity and fluidity, manual adjustment is avoided, the labor intensity of workers is reduced, and the production efficiency is improved.

Owner:TAIZHOU YIDA COLOR PRINTING PACKING

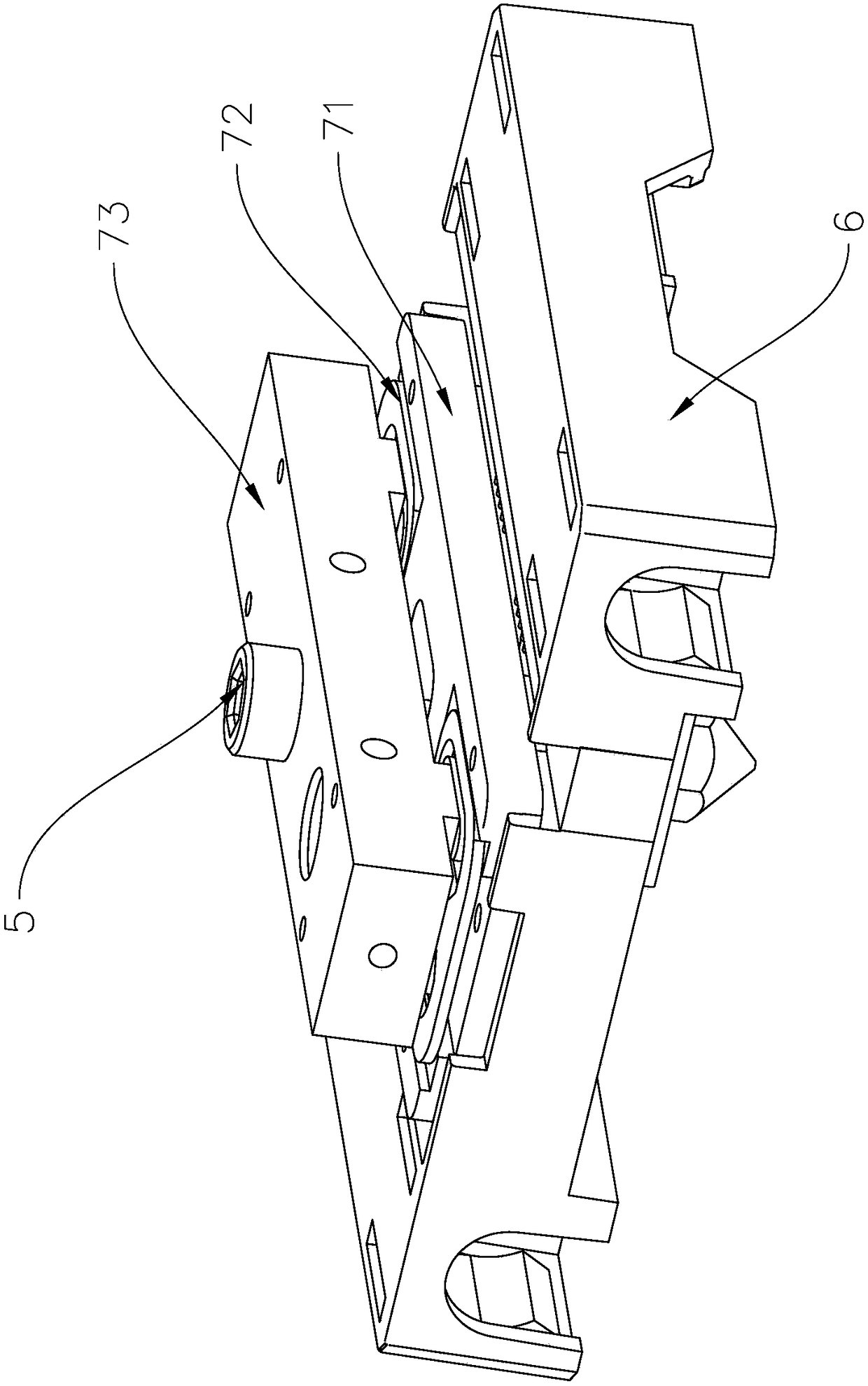

a printer

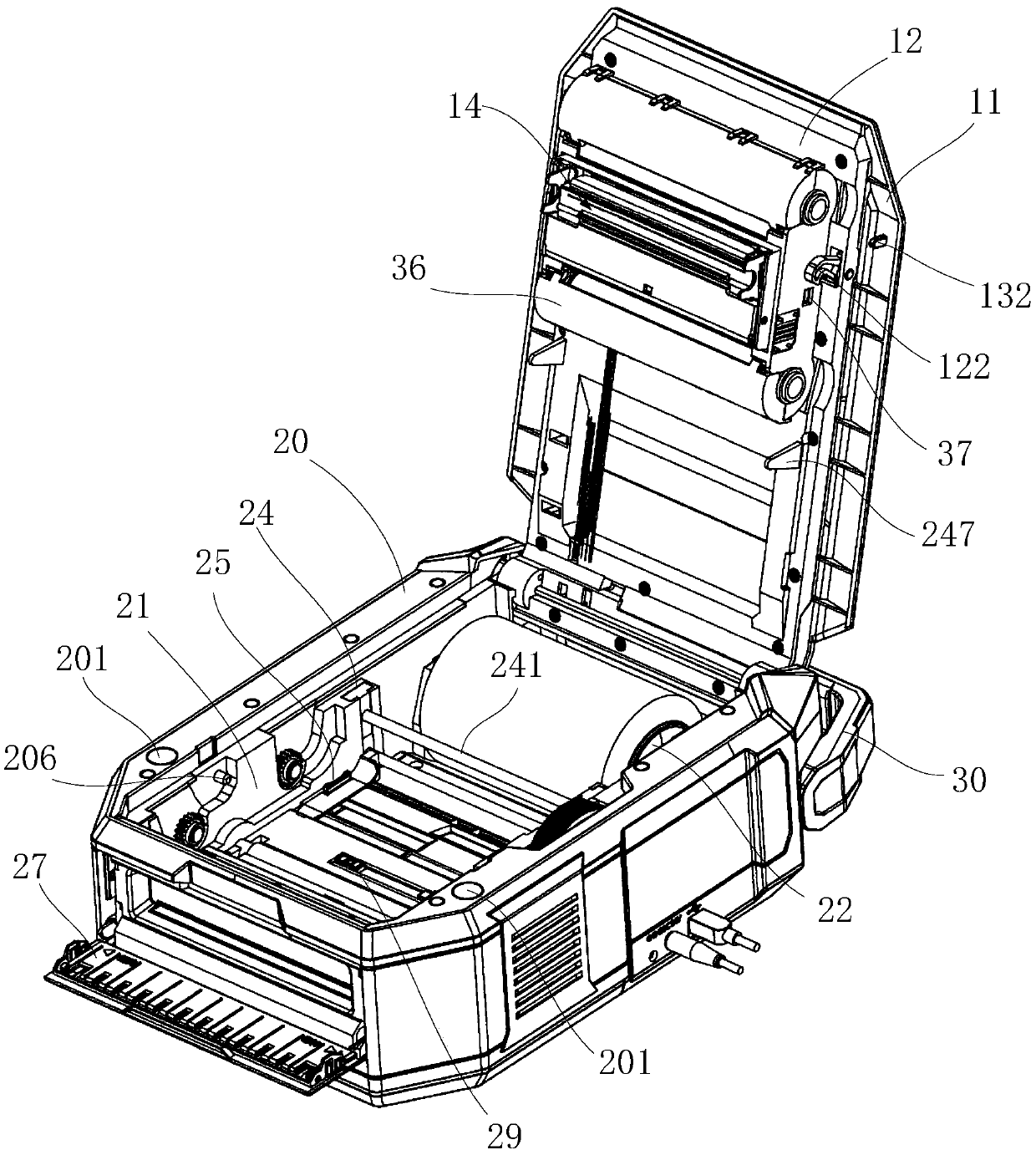

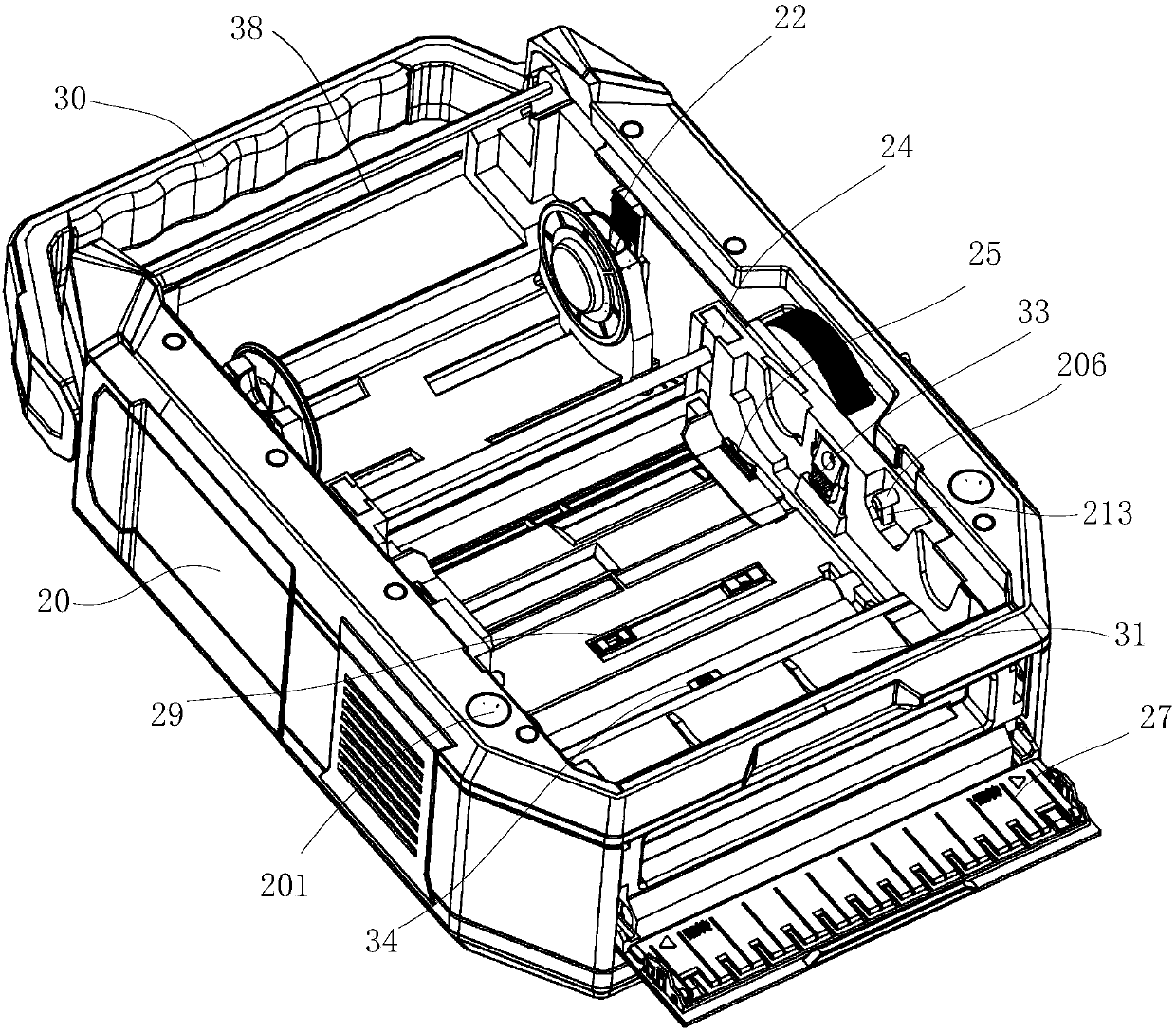

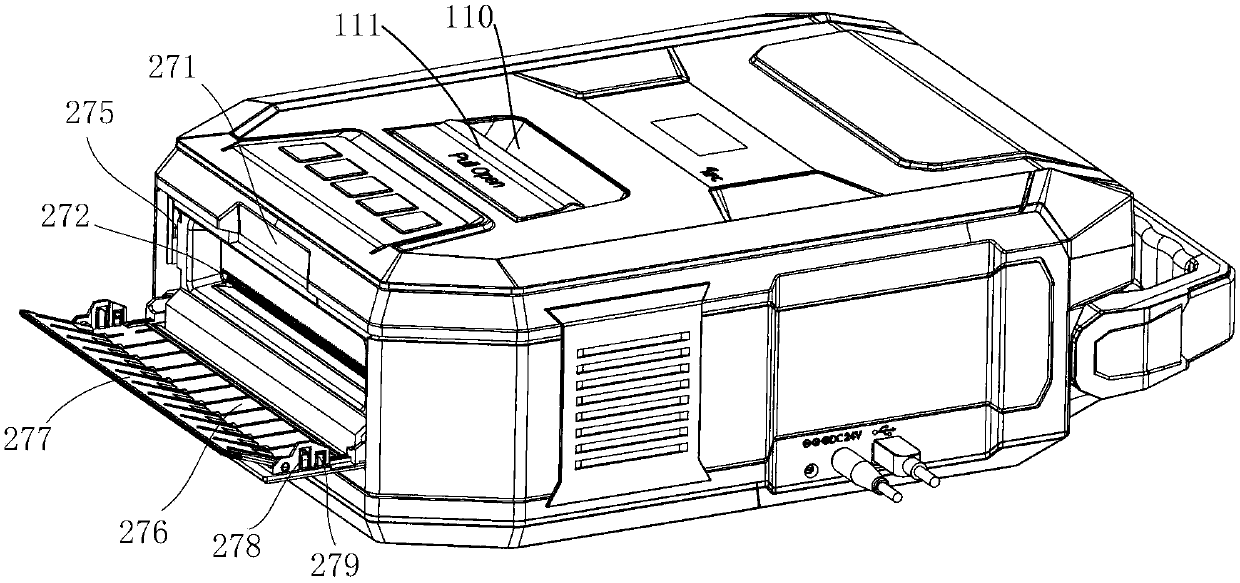

ActiveCN106183462BImprove versatilityAvoid compromising print qualityTypewritersOther printing apparatusComputer engineering

The invention provides a printer. The printer comprises an upper shell module and a lower shell module; a label paper inlet for feeding outer hanging labels is formed in the back end of the lower shell module; a label frame paper clamping mechanism is arranged in the lower shell module, and includes a label frame and left and right two poking discs; the left and right two poking discs oppositely or reversely move through a transmission mechanism; and the lower shell module is provided with a fixing mechanism for fixing the two poking discs in the left and right end positions. The label paper inlet is formed in the back end of the lower shell module for adapting to feeding of external labels; and when the poking discs move left and right to reach maximum values, the fixing mechanism is used for fixed limiting to reserve a channel for the external labels to prevent wrinkling of the labels caused by left-right movement of the poking discs to influence the printing quality, so that the generality of the printer is improved.

Owner:CHONGQING PINSHENG TECHNOLOGY CO LTD

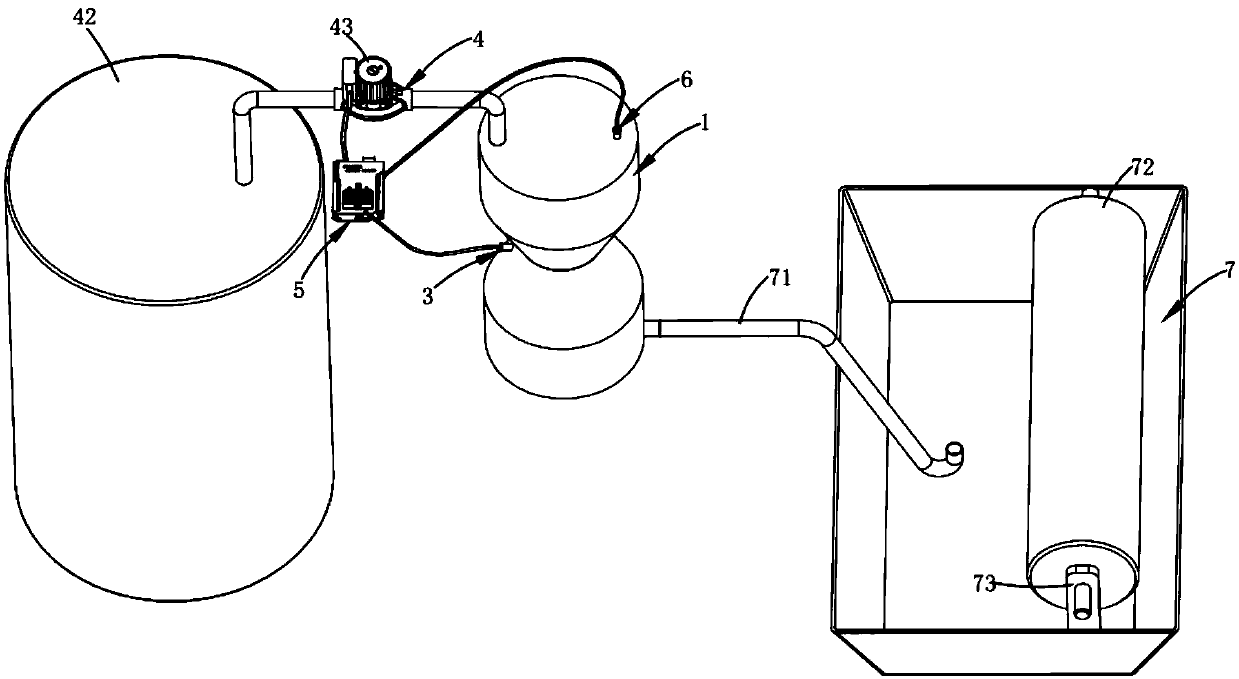

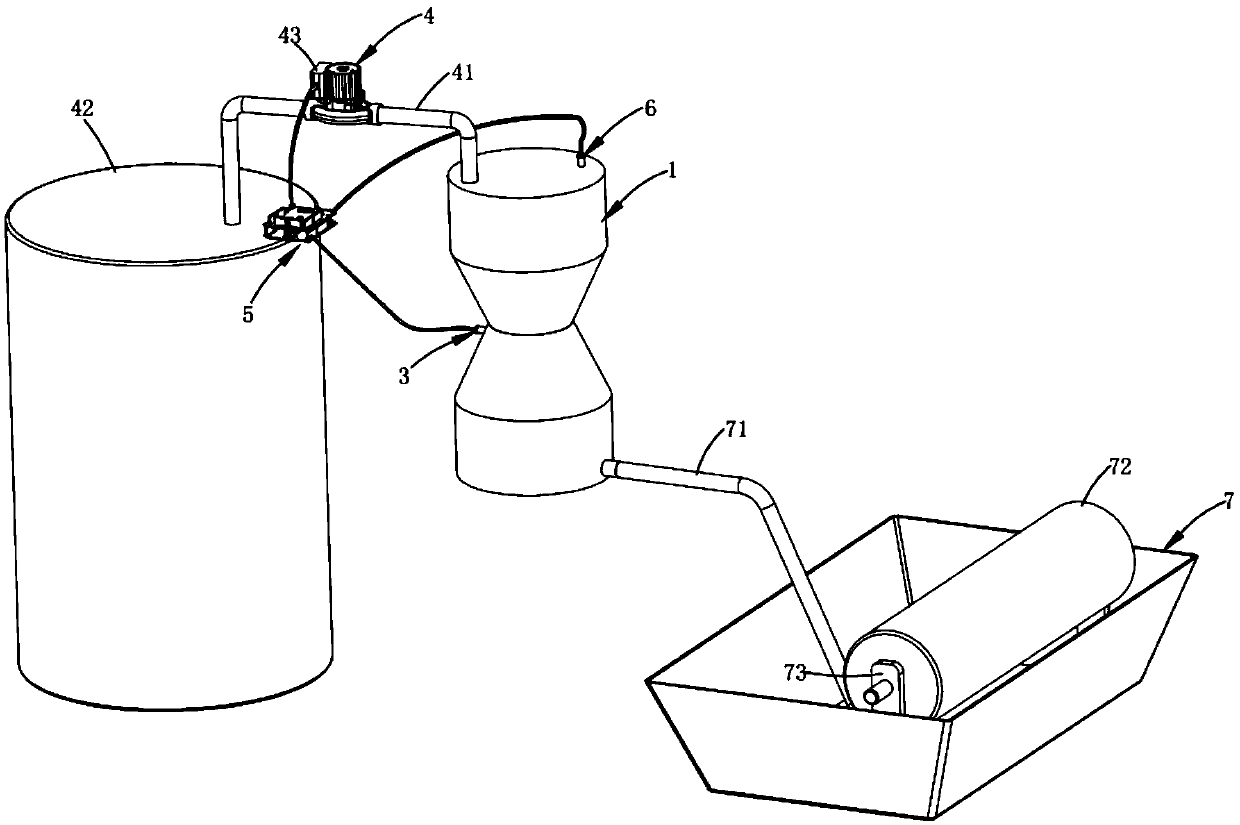

Automatic detection type ink supply system for printer

The invention belongs to the field of printing equipment, and particularly relates to an automatic detection type ink supply system for a printer. The automatic detection type ink supply system for the printer comprises a printing roller set, an ink box and an ink supply pump. An ink inlet pipe and an ink outlet pipe are connected to the ink supply pump. A controller and a flow sensor are mounted in the ink box. The controller is connected with the flow sensor and the ink supply pump. A gun nozzle is arranged at the ink outlet end of the ink box. The gun nozzle is of a rectangular structure and corresponds to the printing roller set. The controller is used for controlling the flow sensor, when the ink flow exceeds a set flow value, the controller controls the ink supply pump to stop supplying ink, and thus ink in the ink box is prevented from exceeding a certain liquid level; and under the influence of the acting force generated when the printing roller set rotates, the ink in the ink box can fluctuate and thus is prevented from overflowing out of the ink box.

Owner:昆明富新春彩色印务有限公司

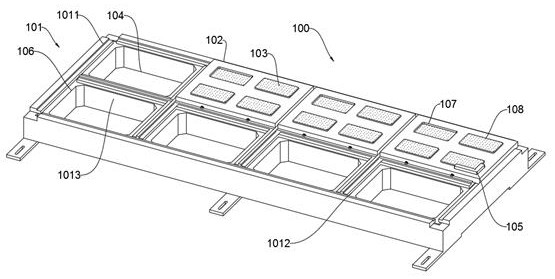

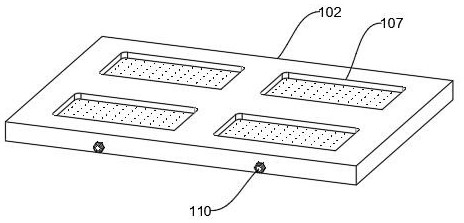

Ultra-thin glass jet-printing jig and process method thereof

PendingCN112590395AEasy to printPrecise positioningDuplicating/marking methodsTypewritersEngineeringStructural engineering

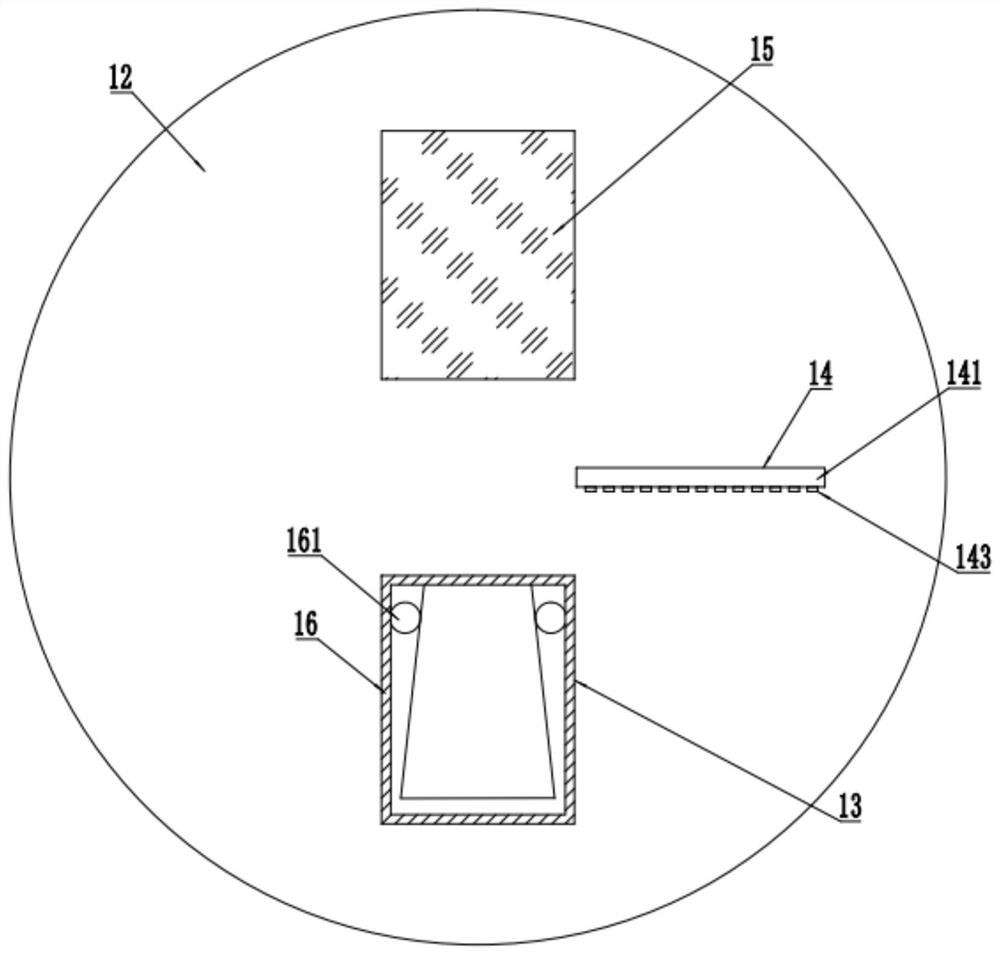

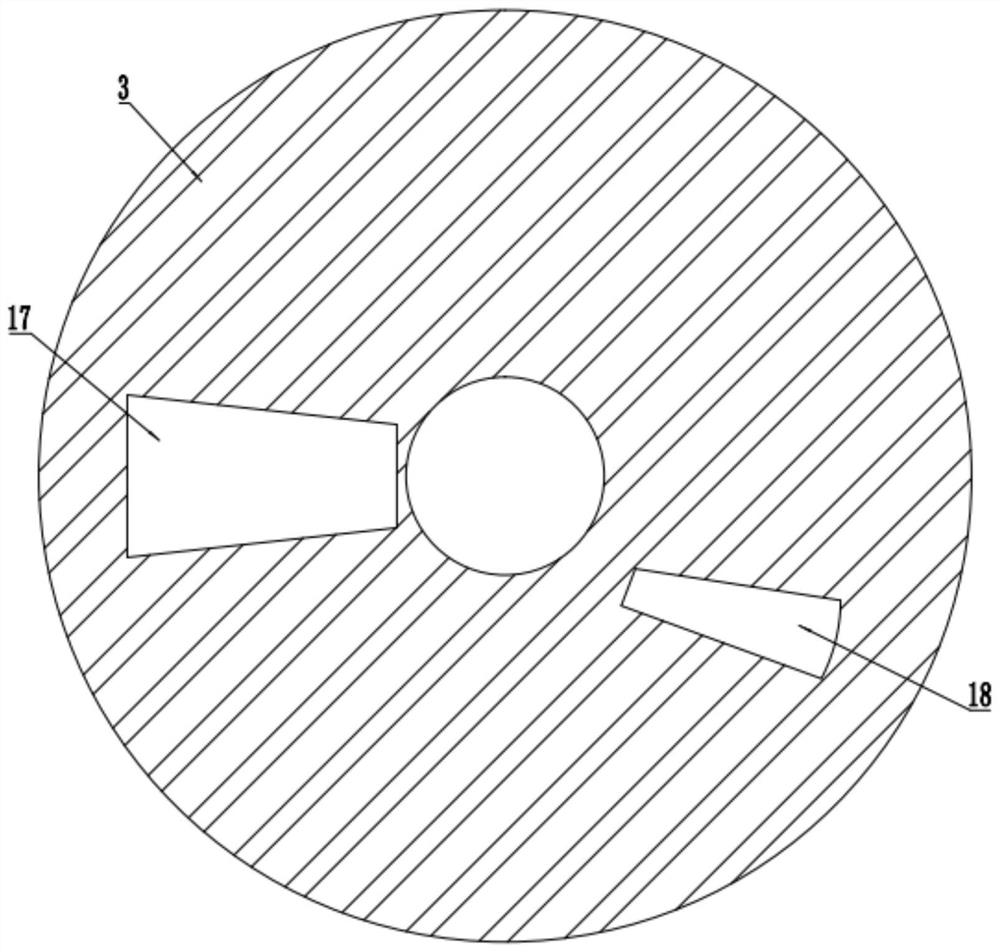

The invention discloses an ultra-thin glass jet-printing jig. The jig comprises a jig body, wherein the jig body comprises a locating jig, jig plates, carrying platforms, heating plates and locating pieces; the locating jig comprises an outer frame, a plurality of vertical locating columns, a transverse locating column and a plurality of mounting sheets arranged at the two sides of the outer frame, and the vertical locating columns are symmetrically distributed at the two sides of the transverse locating column and divide the two sides of the transverse locating column in the outer frame intoa plurality of working areas; and a plurality of grooves matched with the carrying platforms are formed in the jig plates, a plurality of through holes are formed in the grooves, the jig plates are arranged on the upper portions of the working areas, the heating plates are arranged on the lower portions of the jig plates in the working areas, and a plurality of vent holes matched with the throughholes are formed in the carrying platforms. According to the jig, the jig plates and the carrying platforms are arranged, the prefabricated jig plates and carrying platforms are mounted on the locating jig during printing, and glass of different sizes can be printed conveniently by adopting the modular form.

Owner:KAYMAO TECH SHENZHEN +1

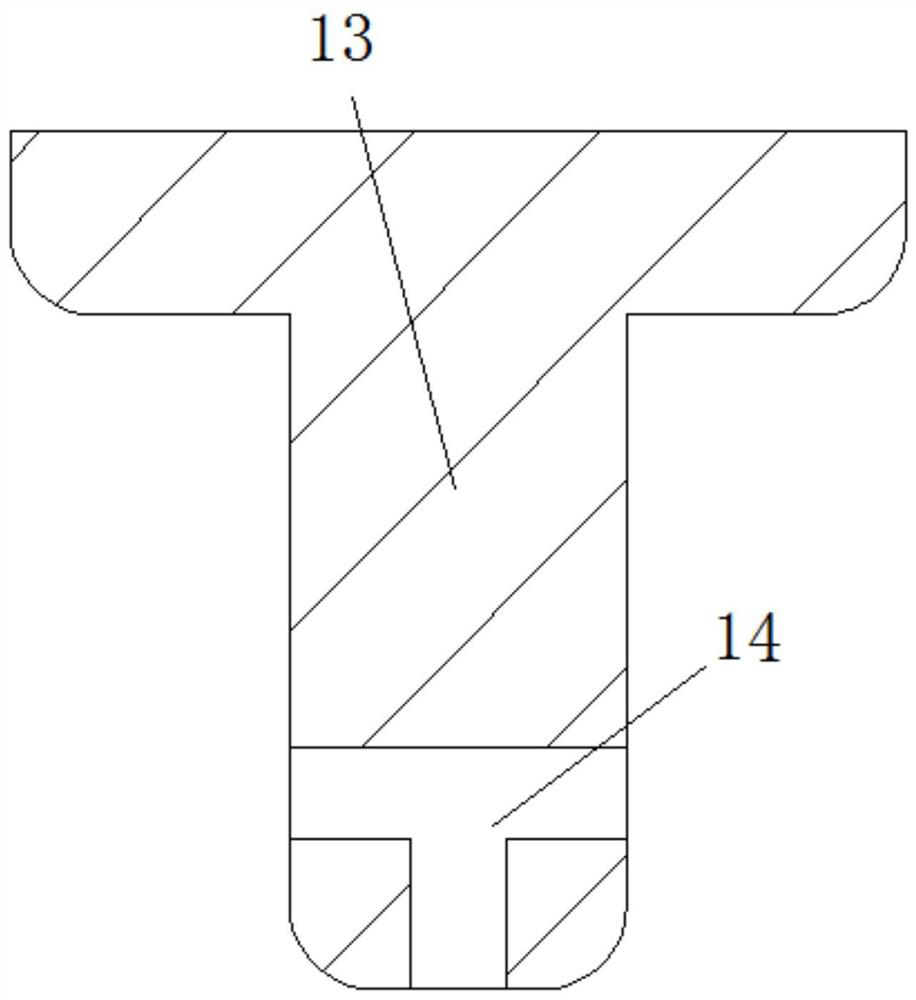

Financial account table and invoice rapid printing device

ActiveCN113022148AAccurate and efficient replacementImprove work efficiencyTypewritersOther printing apparatusComputer printingRolling-element bearing

The invention relates to the technical field of printers, and discloses a financial account table and invoice rapid printing device. The device comprises a base and a printer body fixed to the upper end of the base, two supporting rods are fixedly connected to the upper end of the base, a transverse plate is fixedly connected to the upper ends of the two supporting rods together, and one end of the transverse plate is in contact connection with the printer body. A notch is formed at the other end of the transverse plate, transmission shafts are rotationally connected to the two opposite sides of the notch through first rolling bearings, two mounting rods are rotationally connected to the upper end of the transverse plate through rotating shafts, supporting shafts are rotationally connected to the opposite sides of the two mounting rods through second rolling bearings, and transmission mechanisms are connected to the shaft walls of the transmission shafts and the shaft walls of the supporting shafts. According to the financial account table and invoice rapid printing device, voucher paper can be fed smoothly and is not prone to being clamped and broken, the position of the voucher paper can be rapidly adjusted when the voucher paper is replaced, and the voucher paper entering a printer is not prone to inclining.

Owner:SHIJIAZHUANG VOCATIONAL TECH INST

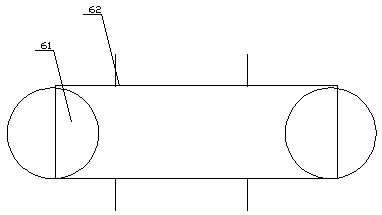

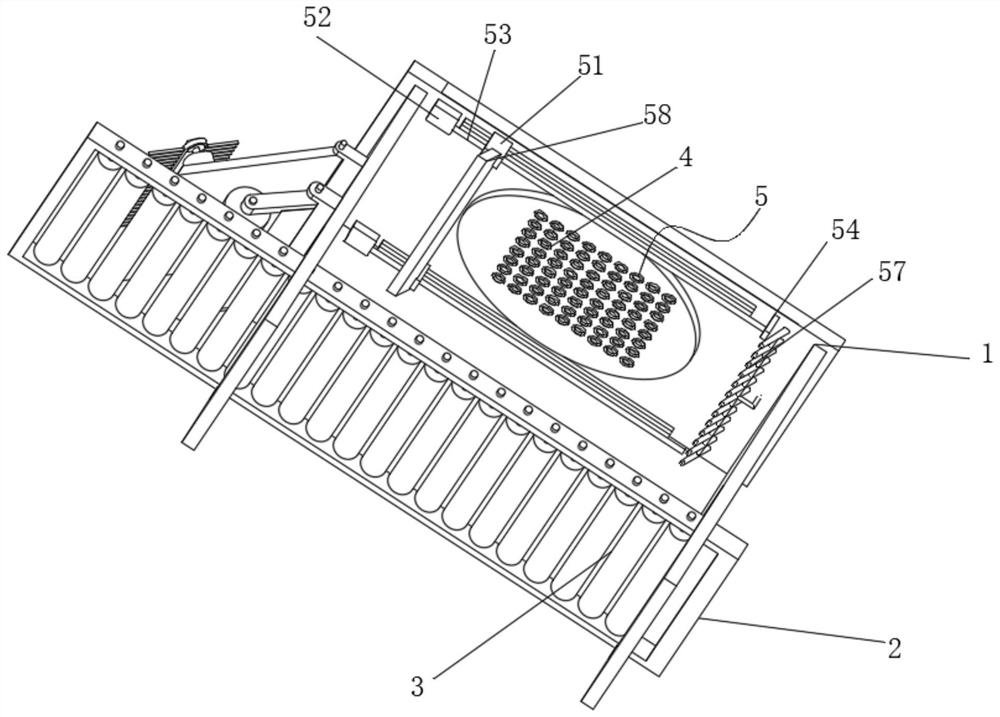

Printing conveying device for encrypted light disk production line

ActiveCN106076893AAvoid scratchesAvoid compromising print qualityFouling preventionCleaning using toolsProduction lineEngineering

The invention discloses a printing conveying device for an encrypted light disk production line. Detected light disks are placed on a qualified product conveying belt set and a disqualified product conveying belt through mechanical arms and vacuum suction cups. The qualified product conveying belt set comprises an upper conveying belt and a lower conveying belt. Each of the upper conveying belt and the lower conveying belt is provided with a rubber strip with a gap in the middle. Supporting frames are arranged on the front side and the rear side of the upper conveying belt and the front side and the rear side of the lower conveying belt. A film is arranged between the supporting frames on the front side and the rear side of the upper conveying belt, and a film is arranged between the supporting frames on the front side and the rear side of the lower conveying belt. The printing conveying device is simple in structure, reasonable and novel in design and convenient to operate, manual operation is completely not needed after detection, the light disks are directly conveyed into printing equipment to be printed, labor force is saved, and the production efficiency is improved.

Owner:李玲

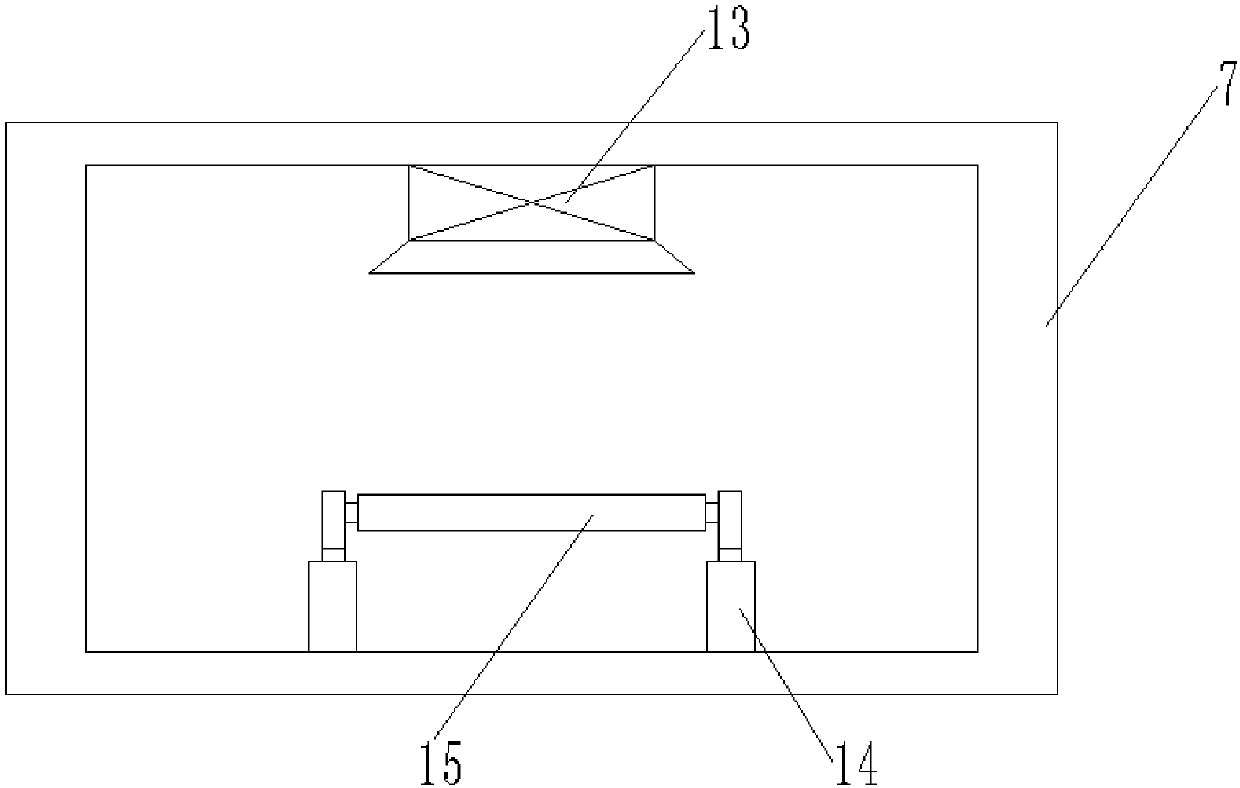

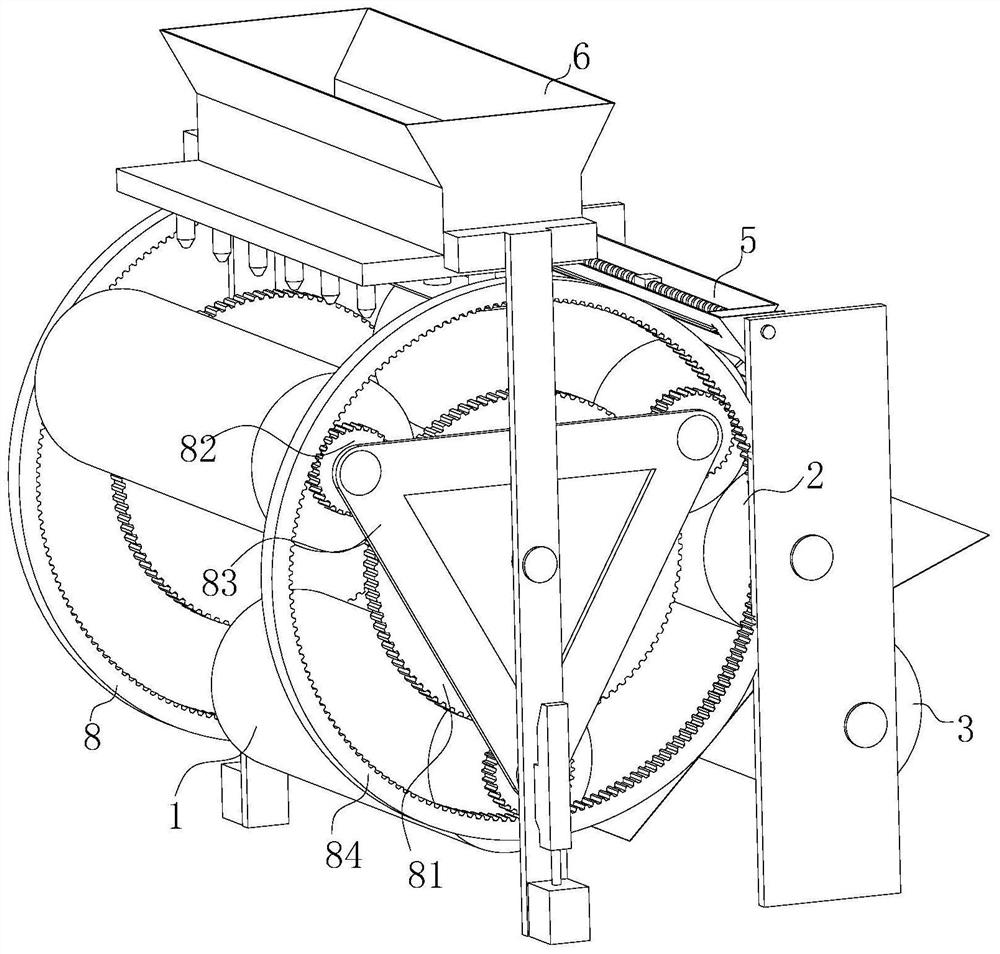

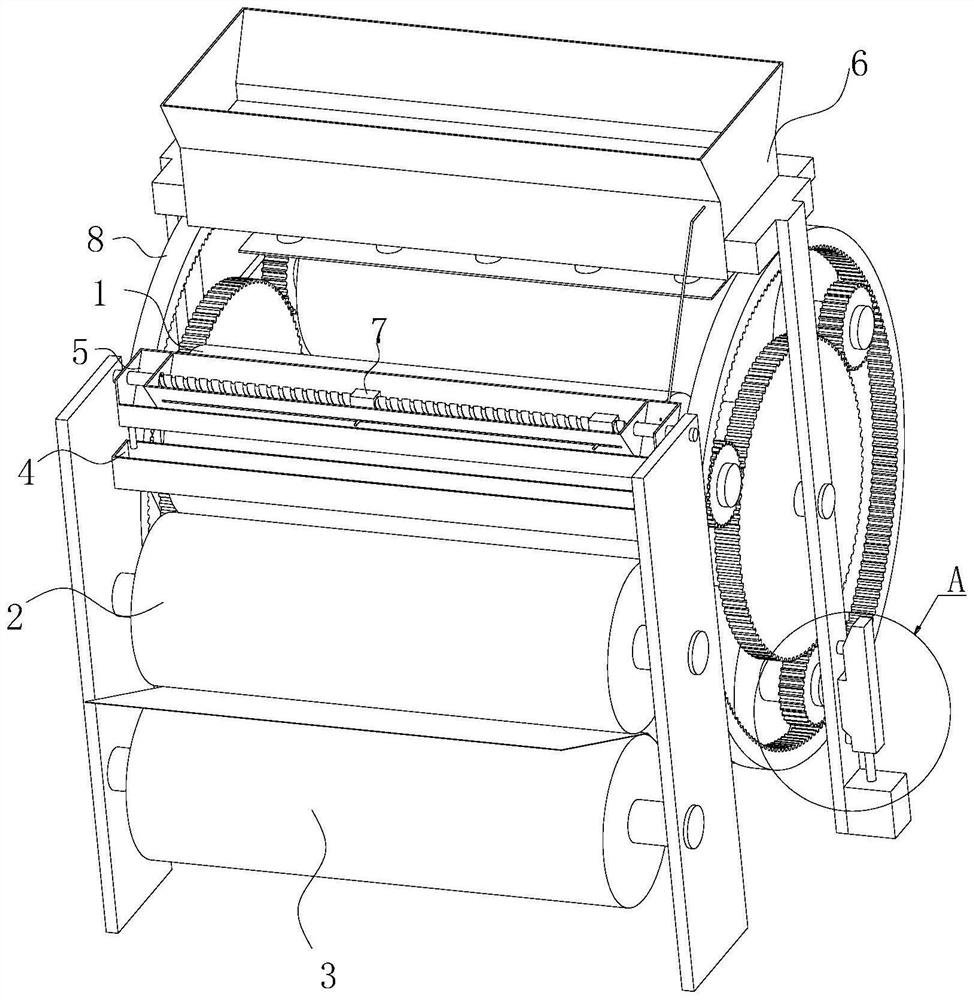

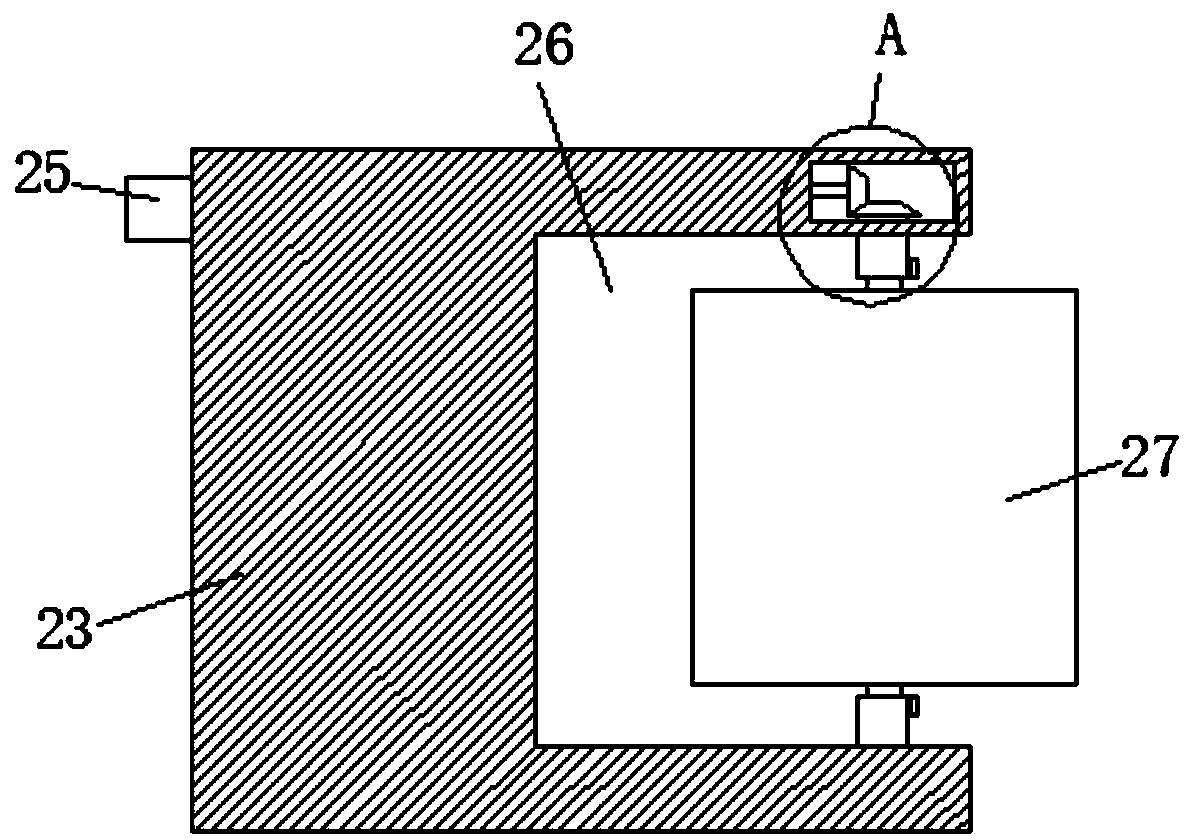

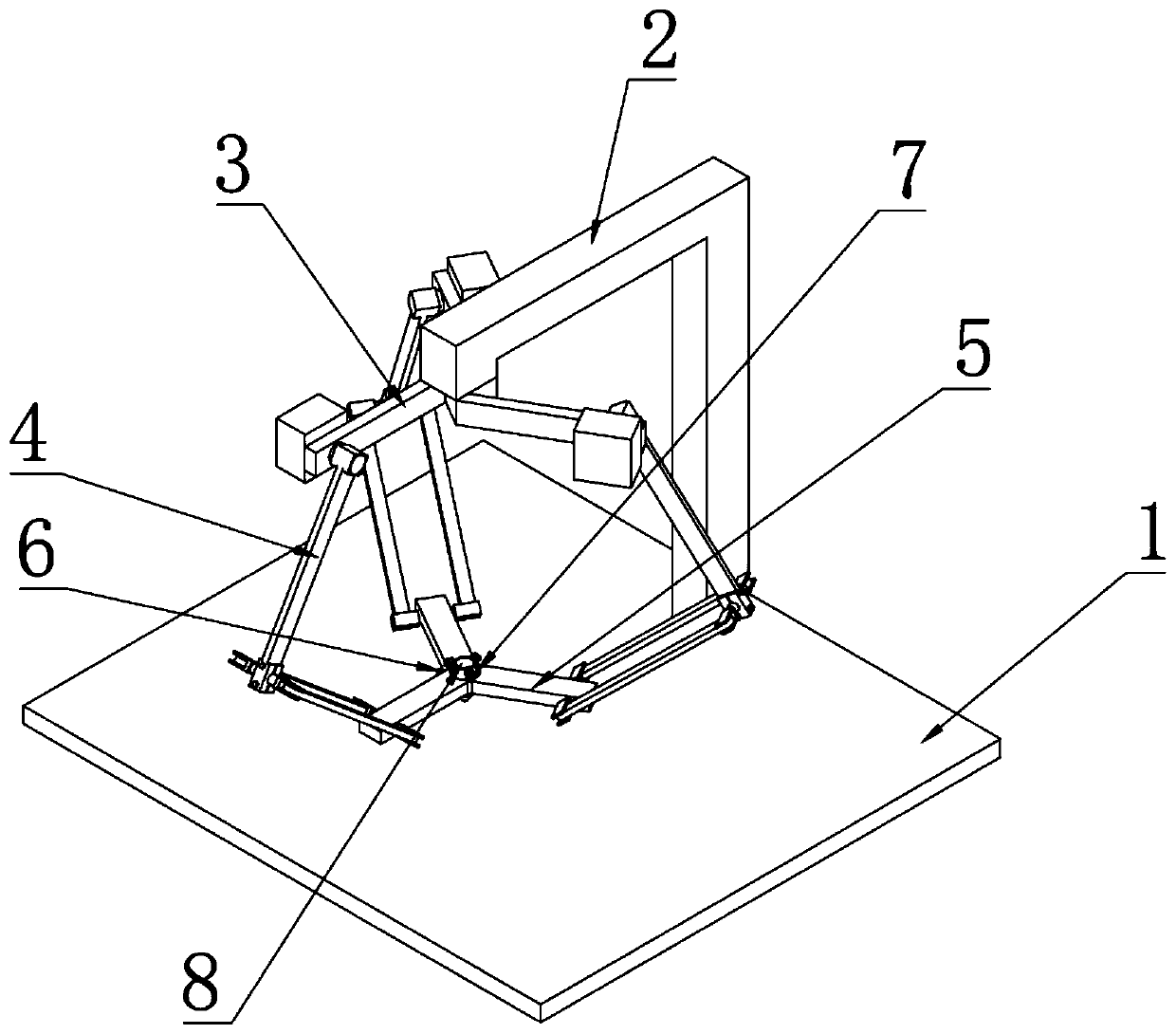

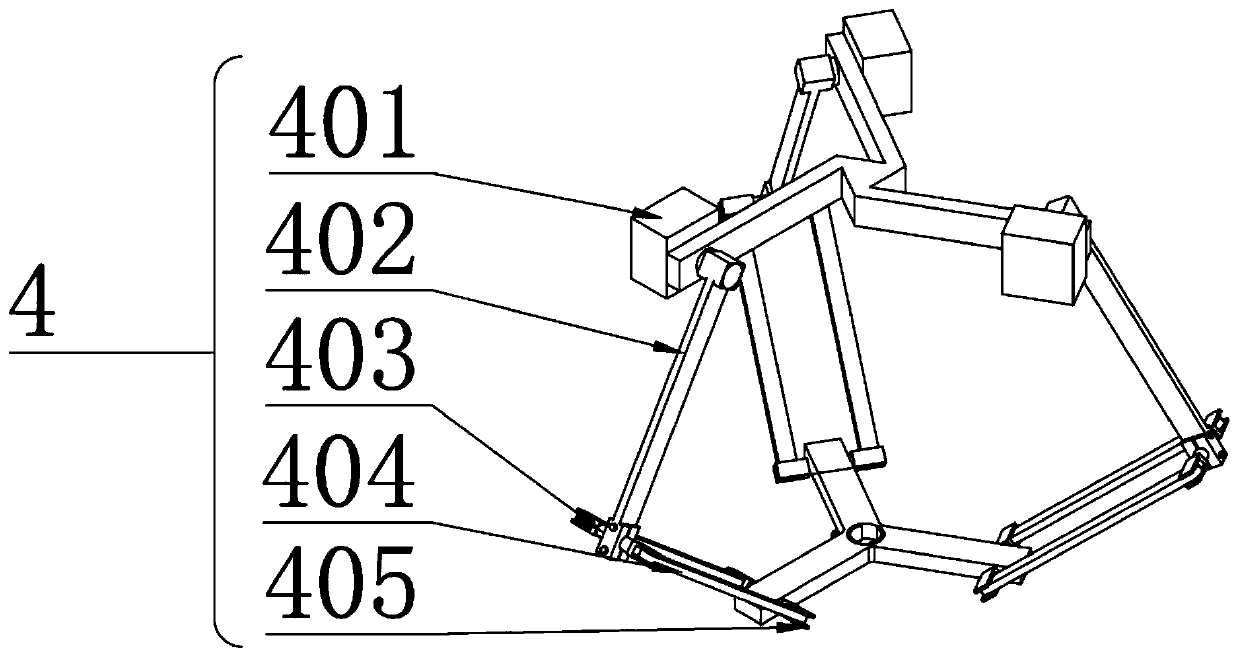

Furniture 3D printer used for additive and subtractive hybrid machining

ActiveCN109177165ARealize printingAvoid compromising print qualityAdditive manufacturing apparatusManufacturing auxillary operations3d printerMachining

The invention discloses a furniture 3D printer used for additive and subtractive hybrid machining. The furniture 3D printer used for additive and subtractive hybrid machining comprises a shell. A printing table is fixedly connected to the inner bottom of the shell. A sliding groove is formed in the inner wall of the left side of the shell. A first electric sliding rail which is horizontally arranged is fixedly connected to the inner wall of the lower end of the sliding groove. A sliding rod is slidably connected to the upper end of the first electric sliding rail. A first strip-shaped cavity is formed in the sliding rod. A height adjustment mechanism is arranged in the first strip-shaped cavity and is connected with a cross rod. A second electric sliding rail is fixedly connected to the side wall of the cross rod. A hopper is slidably connected to the side wall of the second electric sliding rail. A material extruding head is connected to the lower end of the hopper. A discharging portis formed in the lower end of the hopper. An abutting rod penetrates through the upper end of the hopper. The furniture 3D printer used for additive and subtractive hybrid machining is reasonable instructure; the discharging port can be dredged repeatedly, so that non-uniform feeding is avoided; and products can be rapidly cooled and can be polished, so that the product effect is better.

Owner:湖南哈工三维科技有限公司

Material guiding equipment for water-based ink printing of decorative paper

InactiveCN112875384AIncrease printing speedAvoid compromising print qualityPrinting press partsWebs handlingEngineeringStructural engineering

The invention discloses material guiding equipment for water-based ink printing of decorative paper. The equipment comprises a discharging barrel, a base, adjusting plates and a mounting groove, the discharging barrel is rotationally connected to one side of the top end of the base, the adjusting plates are correspondingly fixedly connected to two ends, on one side of the discharging barrel, of the top end of the base, auxiliary rollers are rotationally connected to the upper ends of two sides of the adjusting plate, a working frame is mounted at the top end of the base on one sides, away from the discharging barrel, of the adjusting plates, a cleaning structure is fixedly connected to the upper end of one side, close to the adjusting plates, of the working frame, auxiliary rollers are rotationally connected to the upper ends of two sides in the working frame, extension rollers are rotationally connected to the two sides in the working frame, a drying structure is fixedly connected to the middle position of the top end inside the working frame, and main material rollers are correspondingly and rotationally connected to two sides of the top end of the working frame. According to the equipment, an adjusting roller is driven to move up and down by rotating a rotating handle to be matched with a lead screw and a sleeve, so that the tightness degree of a paper material is conveniently adjusted through the height change of the adjusting roller.

Owner:李杰

Composite printing structure for corrugated cardboard production line

ActiveCN109649000BImprove the quality of printing and processingAvoid compromising print qualityCylinder pressesPlaten pressesForeign matterStructural engineering

The invention relates to the field of corrugated board production equipment, in particular to a composite printing structure of a corrugated board production line. The composite printing structure comprises a height adjusting structure, limiting structures, a gas valve, a clearing sleeve, a guide structure, a fixing frame and a clearing structure; the height adjusting structure is arranged on theclearing sleeve, the guide structure used for guiding a corrugated board is arranged on the part, at one end of the clearing sleeve, of the fixing frame, and the other end of the clearing sleeve is provided with the limiting structures used for limiting the corrugated board; and the clearing sleeve is provided with the clearing structure used for clearing foreign matter on the corrugated board through gas, and the gas valve penetrates through the clearing sleeve. According to the structure, the gas valve in the clearing sleeve is matched with the clearing structure so that the foreign matter on the corrugated board can be conveniently and rapidly cleared; the guide structure is used so that the corrugated board in the conveying process can be conveniently guided; and meanwhile, the limiting structures are used so that the corrugated board can be limited conveniently, deviation of the corrugated board in the conveying process is avoided, and therefore, the printing quality of the corrugated board is greatly improved.

Owner:苏州佳华印刷包装有限公司

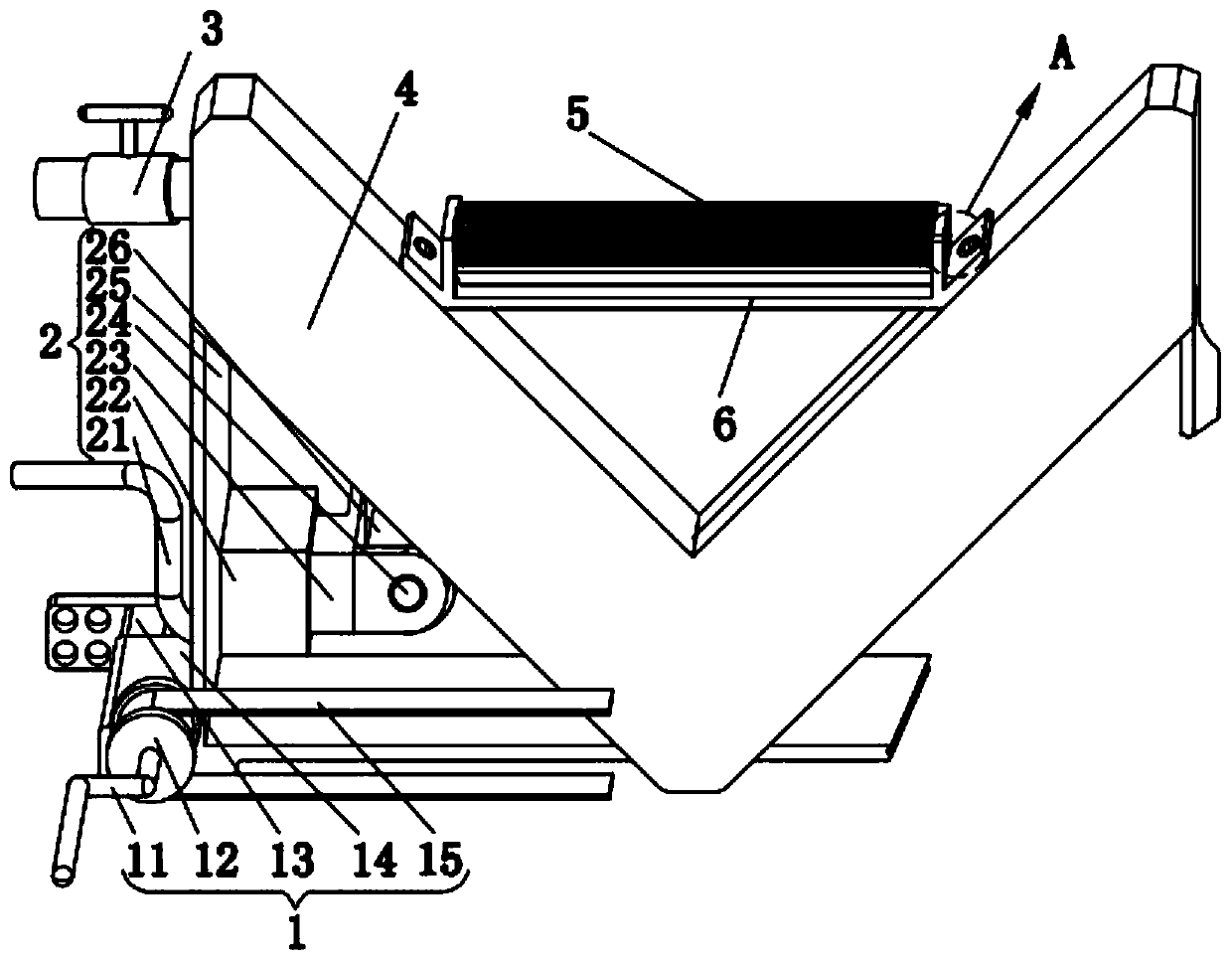

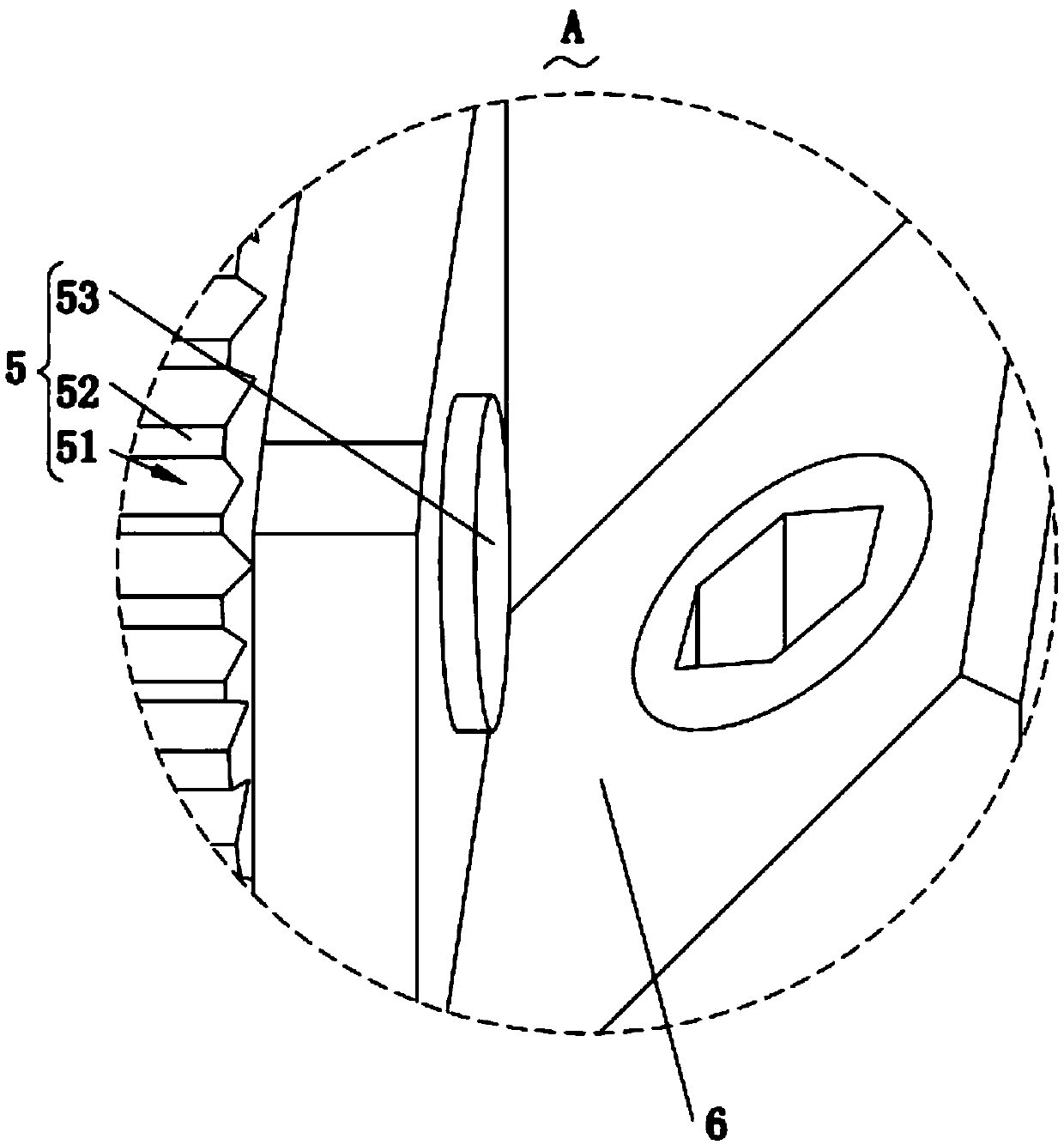

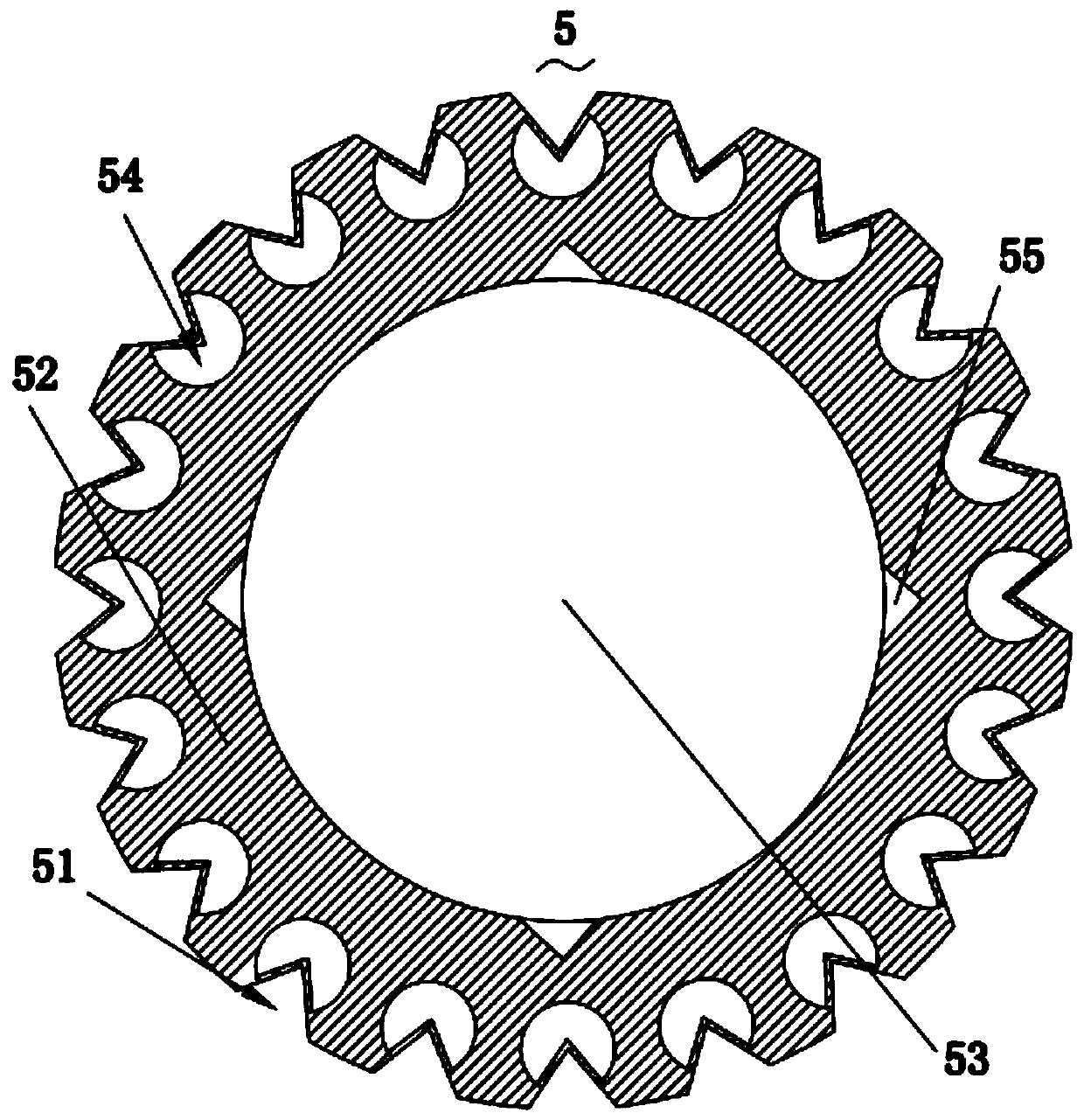

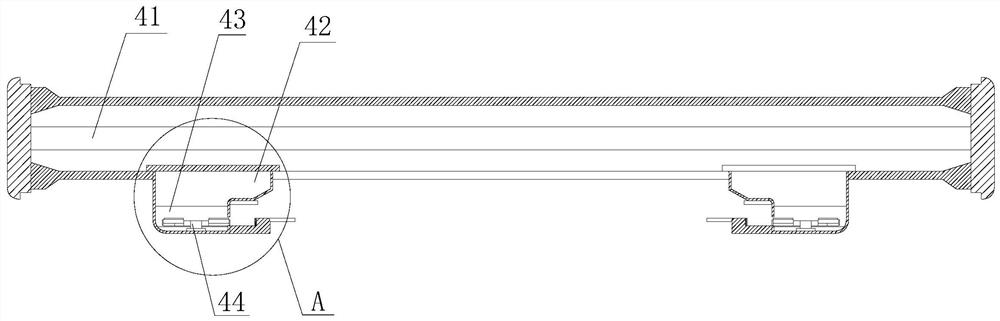

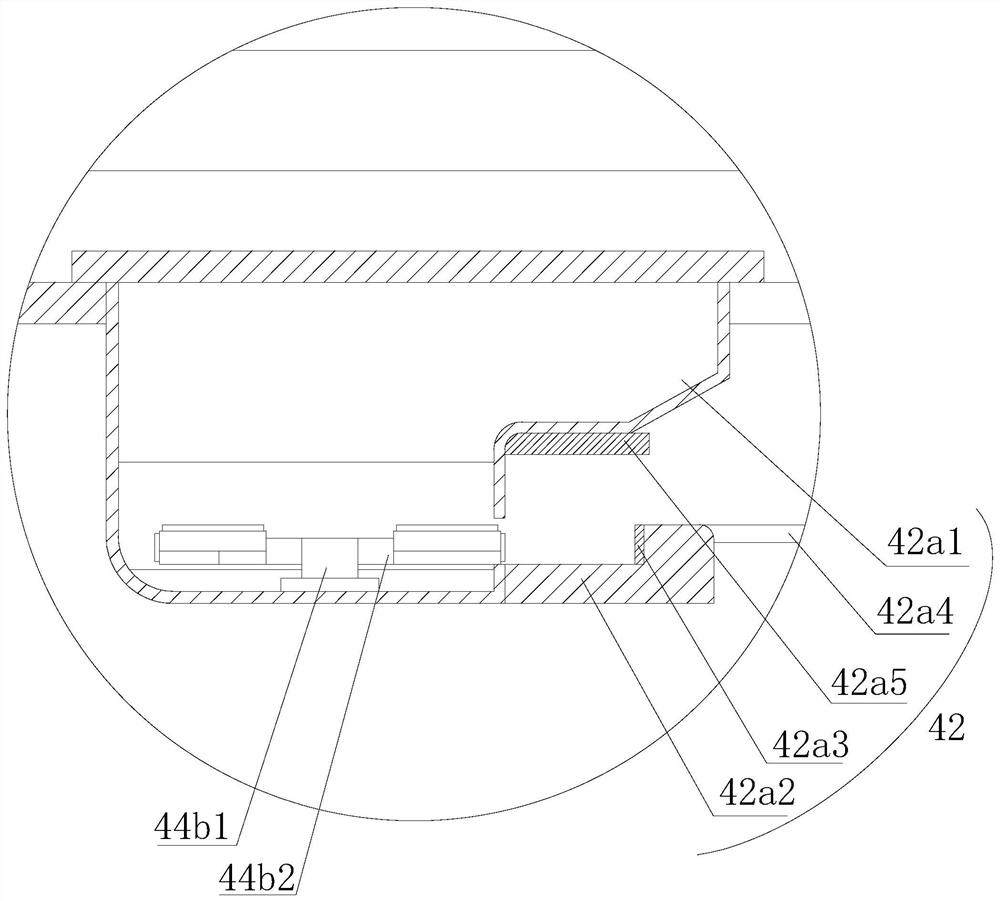

Paper feeding system used for printing machine

The invention provides a paper feeding system used for a printing machine. The paper feeding system comprises a paper feeding device and an ash removal device. The paper feeding device comprises a rack (1), a double-axis motor (2), a pair of chain boxes (3), a pair of chains (4), a stacking plate (5) and one or one set of paper rubbing wheels (6). The paper feeding system used for the printing machine has the advantage that through the system, the situation that particles fall on a paper board, and consequentially the printing quality is affected can be effectively avoided.

Owner:HUBEI HOUDONG PRINTING & PACKAGING

Continuous ink supply device for printer

ActiveCN114290815AEasy to operateTroubleshoot print progress delaysPrintingComputer printingProcess engineering

The continuous ink supply device for the printer comprises an ink supply box, a main ink tank is arranged on the lower portion of the ink supply box, and a liquid level sensor is arranged in the main ink tank; an ink supplementing device is installed above a main ink tank in the ink supply box, the ink supplementing device can move back and forth relative to the ink supply box, the ink supplementing device comprises an installation frame, the installation frame is provided with a containing groove corresponding to the main ink tank in position, and the containing groove is used for containing an ink supplementing ink box. When the installation frame moves backwards to a limit position, an ink outlet of the ink supplementing ink box placed on the containing groove corresponds to an ink inlet of the main ink tank in position. The ink supply box is internally provided with a hole breaking device, and the hole breaking device is used for puncturing a sealing layer at an ink outlet of the ink supplementing ink box so that ink in the ink supplementing ink box can flow into the main ink tank. The ink supply device has the beneficial effects of guaranteeing continuous ink supply of the printing spray head, being convenient to operate, high in practicability and high in reliability.

Owner:BEIJING ZHONGDIAN YUANDE TECH CO LTD

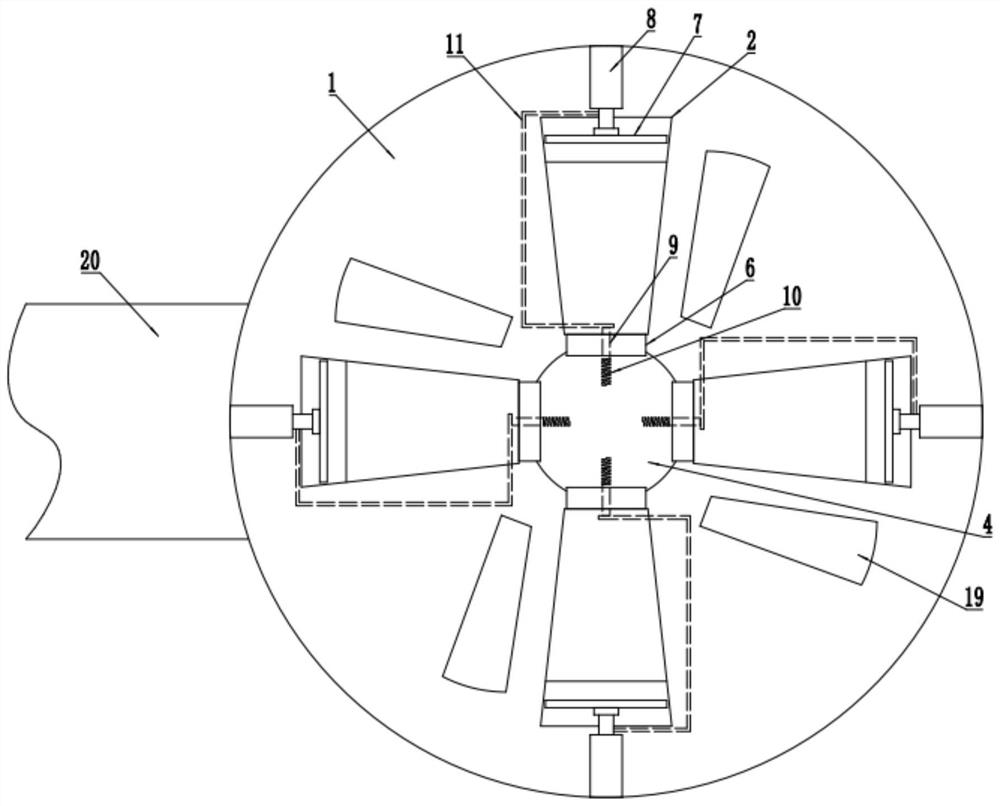

Environment-protecting paper cup printing device

PendingCN113478957AEfficient automatic printing job functionAccurate automatic printing job functionRotary pressesElectrical and Electronics engineeringBevel gear

One or more embodiments of the invention provide an environment-protecting paper cup printing device. The environment-protecting paper cup printing device comprises a supporting plate, wherein the upper end of the supporting plate is provided with a top cover in a covered mode, and the top cover is sequentially provided with a feeding port, a blowing part and a printing part at intervals in the circumferential direction. Paper cups are sequentially stacked in a cup falling channel in a side lying mode, a conical tooth disc is driven by a motor to rotate, and then the supporting plate is driven to rotate synchronously; feeding is carried out downwards in sequence through the feeding port, the paper cups are clamped through clamping grooves, and then an electric push rod stretches out to push a rotating plate, so that one end of each paper cup abuts against the rotating plate, and the other end of each paper cup abuts against a bevel gear; and meanwhile, due to the fact that the electric push rod pushes a connecting rod together, an auxiliary shaft is pushed to retract into the conical tooth disc, then the conical tooth disc is driven by the motor to rotate independently, and bevel gears are driven to synchronously mesh and rotate so as to drive the paper cups in the clamping grooves to axially rotate, so that the paper cups below the blowing part axially rotate and are blown and cleaned, the paper cups below the printing part also rotate and are printed, and then the paper cups are driven by revolution of the supporting plate to move to a discharging port to fall.

Owner:安庆市来客纸品有限公司

Silk-screen printing device and method for curved surface

InactiveCN112829440AAvoid compromising print qualityScreen printersPrinting press partsScreen printingPolymer science

The invention relates to the technical field of silk-screen printing devices, in particular to silk-screen printing device and method for a curved surface. The silk-screen printing device for the curved surface comprises a silk-screen printing base, wherein clamping seats are fixedly connected to the two sides of the center of the top of the silk-screen printing base, a clamping groove is formed in the side, close to the center of the silk-screen printing base, of each clamping seat, pressing plates are connected into the clamping grooves, a silk screen printing plate is fixedly connected to the side, away from the clamping grooves, of the pressing plates, push-pull type electromagnets are fixedly connected to the tops of the pressing plates, fixing supports are fixedly connected to the back faces of the centers of the tops of the clamping seats, a scraper rail frame is installed on the portions, above the silk-screen printing base, of the outer walls of the fixing supports. and the outer wall of the scraper rail frame is connected with a sliding seat. By arranging the silk-screen printing base, the scraper rail frame, the sliding seat, silk-screen printing scraper heads and the silk-screen printing plate, the problems that an existing silk-screen printing machine can only conduct printing on the surfaces of objects with flat surfaces or slight curved surfaces, cannot conduct printing on the surfaces of objects with large-curvature surfaces and is small in application range are solved.

Owner:陈布东

Automatic code spraying device and use method thereof

InactiveCN113415077AImprove cleanlinessGuaranteed neatnessOther printing apparatusEngineeringMechanical engineering

The invention discloses an automatic code spraying device and a using method thereof. The automatic code spraying device comprises a supporting frame, a guide roller frame, guide rollers, a code spraying machine, a cleaning structure, a material supplementing structure and an arranging structure, the guide roller frame is transversely installed in the middle of the supporting frame, a first rubber scraper is erected between two sliding buckles, and the first rubber scraper moves along the bottom side of a code spraying machine. According to the automatic code spraying device, redundant ink at the bottom of the code spraying machine can be scraped and cleaned, it can be guaranteed that in the next cleaning process, a spray head of the code spraying machine is neat, the situation of ink overflowing is avoided, neatness and regularity of printing are guaranteed, and neatness of a blade face is guaranteed; the ink box is arranged on the top side of the code spraying machine, and a floating ball is arranged in the ink box and can float along with the liquid level of the ink; and in the ink reducing process, electrode balls on the bottom sides of limiting plates descend, when the ink amount is small, the two electrode balls make contact, the ink box is powered on, an alarm can be given, maintenance personnel are reminded to supplement materials in time, it is guaranteed that the ink is sufficient in the printing process, and a better printing effect is achieved.

Owner:王军艳

Reactive 3D printer

InactiveCN111572023AProblems that affect cloggingAvoid compromising print qualityAdditive manufacturing apparatus3D object support structuresMulti materialComputer printing

The invention discloses a reactive 3D printer. The reactive 3D printer comprises a bottom plate, the bottom end of a supporting rod is arranged on one side of the upper wall surface of the bottom plate, the center position of the upper wall surface of a supporting frame is arranged on the lower wall surface of one end of the supporting rod, a driving device is arranged at one end of the supportingframe, one end of a fixing frame is arranged at the bottom end of the driving device, a through hole is formed in the center position of the upper wall surface of the fixing frame, and a printing device is arranged in the through hole formed in the upper wall surface of the fixing frame. According to the 3D printer, single material printing or multi-material splicing printing can be conducted, and meanwhile the problems of poor printing quality and nozzle blockage caused by material mixing can be avoided.

Owner:XIAN KUNLUN IND GRP

A kind of intermittent flat screen printing machine with back side cleaning

ActiveCN110281641BAvoid displacementAvoid compromising print qualityScreen printersPrinting press partsPrinting pressSilk-screen printer

The invention discloses an intermittent flat screen printing machine with edge cleaning of the back material. The structure includes a main body of the printing machine, a control panel, a working panel, a device for cleaning the back material, a moving frame, an ink return knife and an ink scraper. Beneficial effects: the present invention uses the electrostatic plate and the flat plate to fix the label under the action of the electrostatic plate when the printed label passes through the back material side cleaning device to prevent the occurrence of displacement. Position phenomenon, using the bottom scraping mechanism in the process of rotating movement, through the scraping bar to do rotating scraping on the back of the label edge under the action of rotating movement, so as to avoid a large number of spots on the back of the label after the printing is completed. The printing material thus affects the printing quality. The arc-shaped cylinder is placed above and close to the bottom scraping mechanism, and the printing material scraped by the bottom scraping mechanism is wiped when it is in contact with the rubbing cotton, and it is installed movable through the partition , which can make the cotton rubbing be utilized to the maximum degree during the rotary motion of the bottom scraping mechanism.

Owner:NANAN FUQUAN MASCH TECH CO LTD

An Automatic Inking Mechanism of Printing Machine Based on Floating Ball Seal

InactiveCN106827803BAvoid affecting printing qualityAvoid affecting service lifePrinting press partsEngineeringPrinting press

The invention discloses a printer automatic-ink-adding mechanism based on a floating ball meal. By utilizing a safe ink chamber arranged in an ink bucket, a printing roller can always run under the situation that the safety ink amount is reserved. When a floating ball located in the safe ink chamber exceeds the detection range of a position sensor, an ink pump receives a sensor signal to automatically add ink, so that the ink bucket retains the buffer ink amount of added ink, and the adverse influence on the printing roller due to non-timely ink adding for the ink bucket is avoided.

Owner:浙江青联文具科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com