Patents

Literature

99results about How to "Large space for activities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

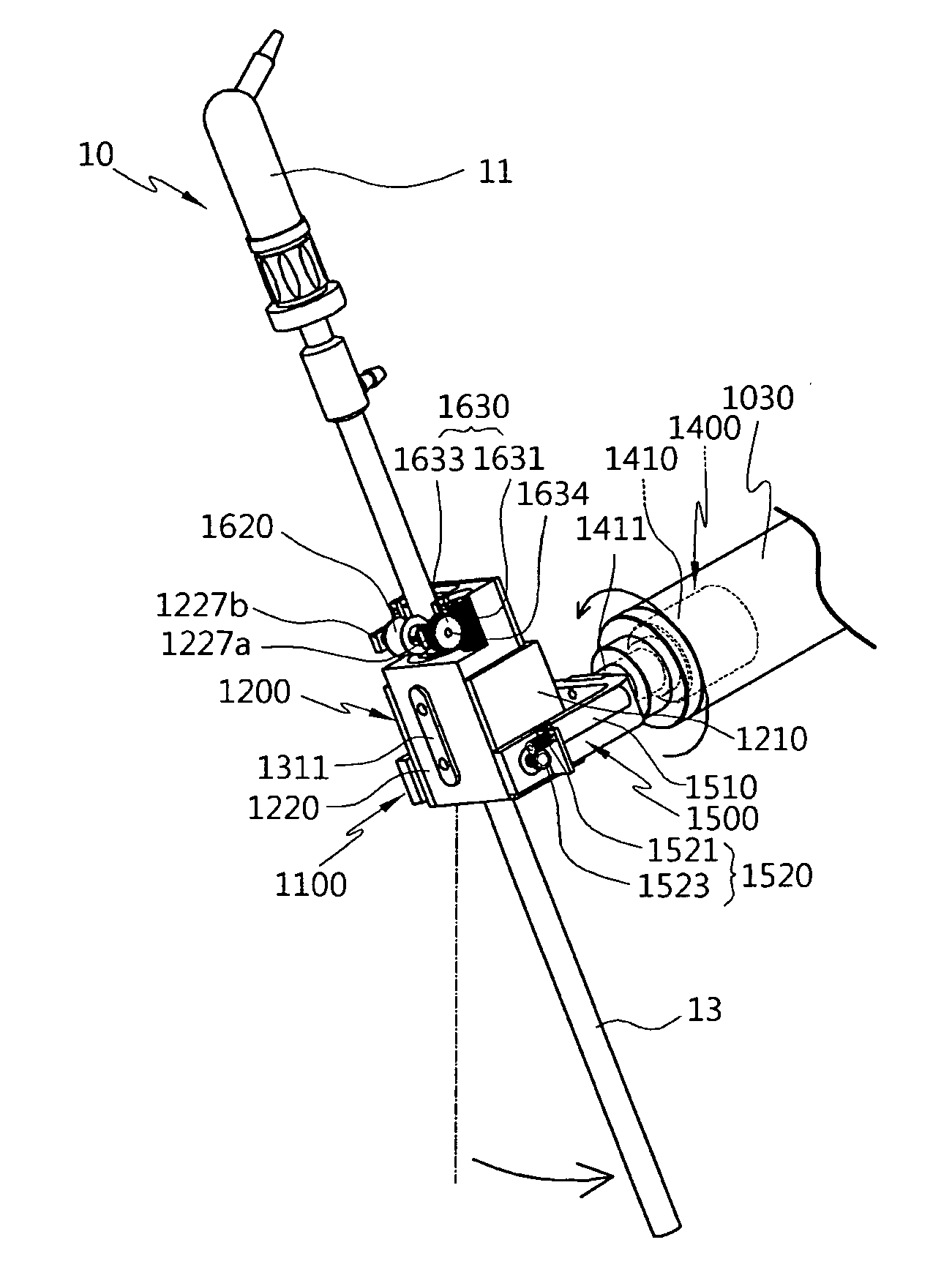

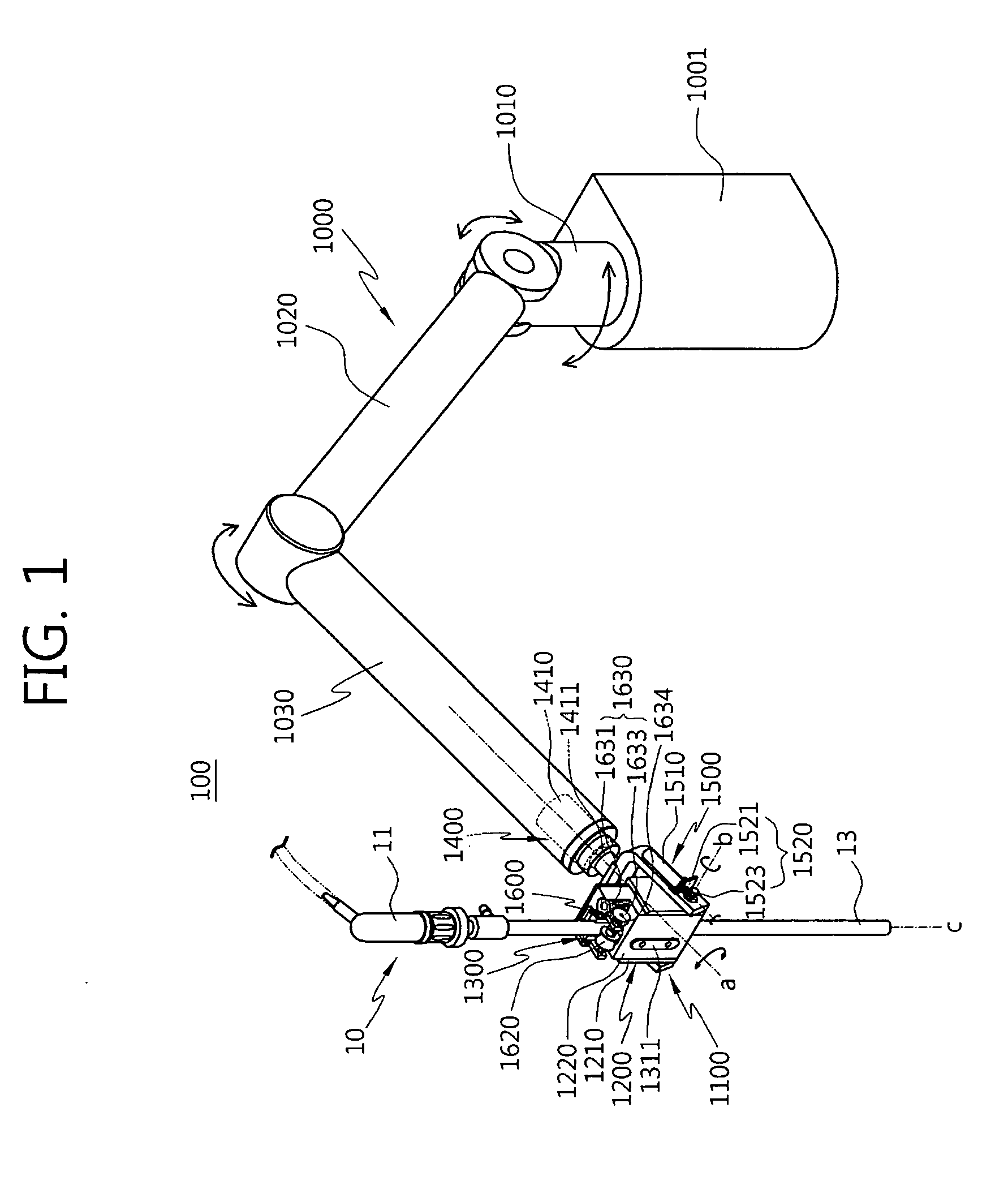

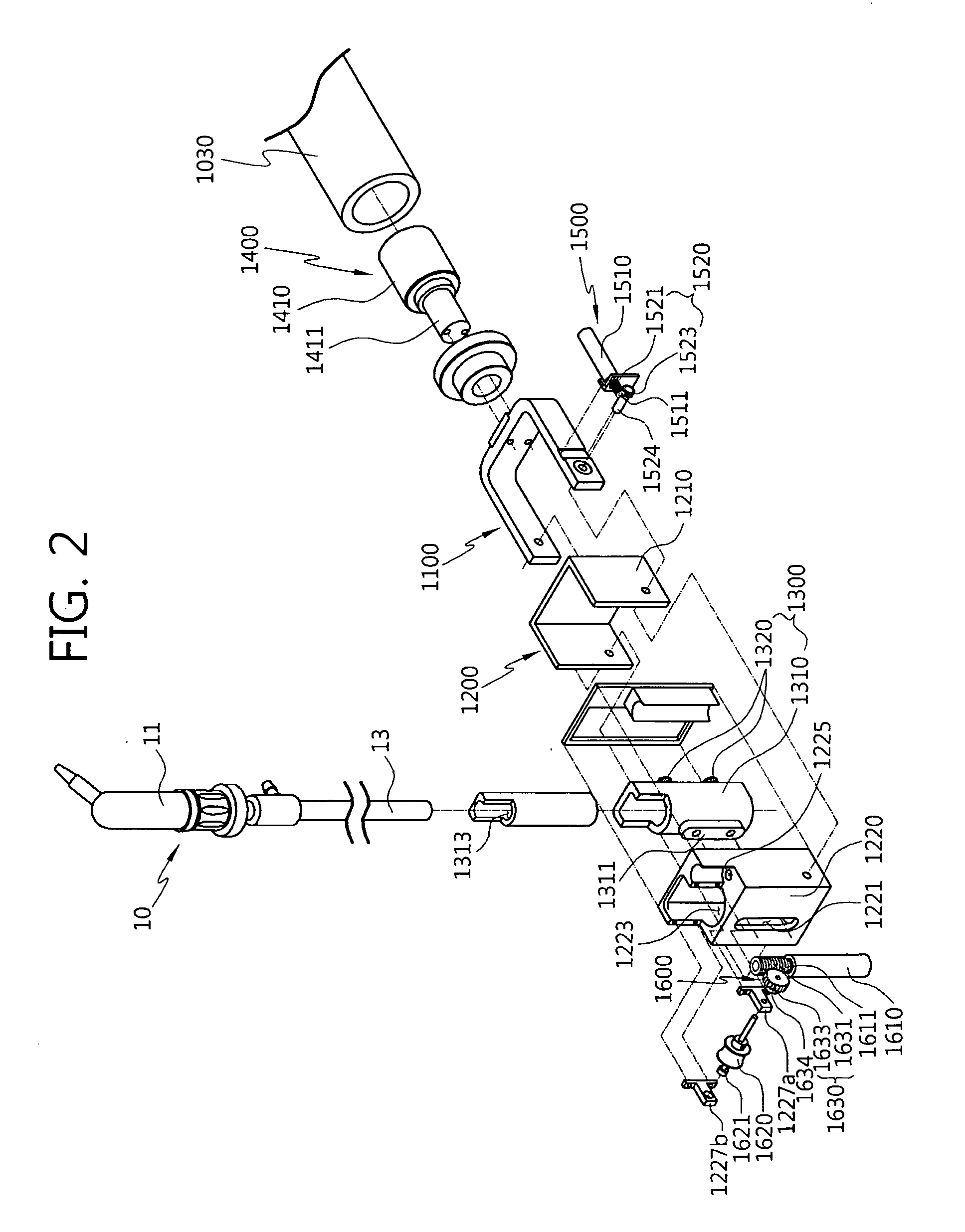

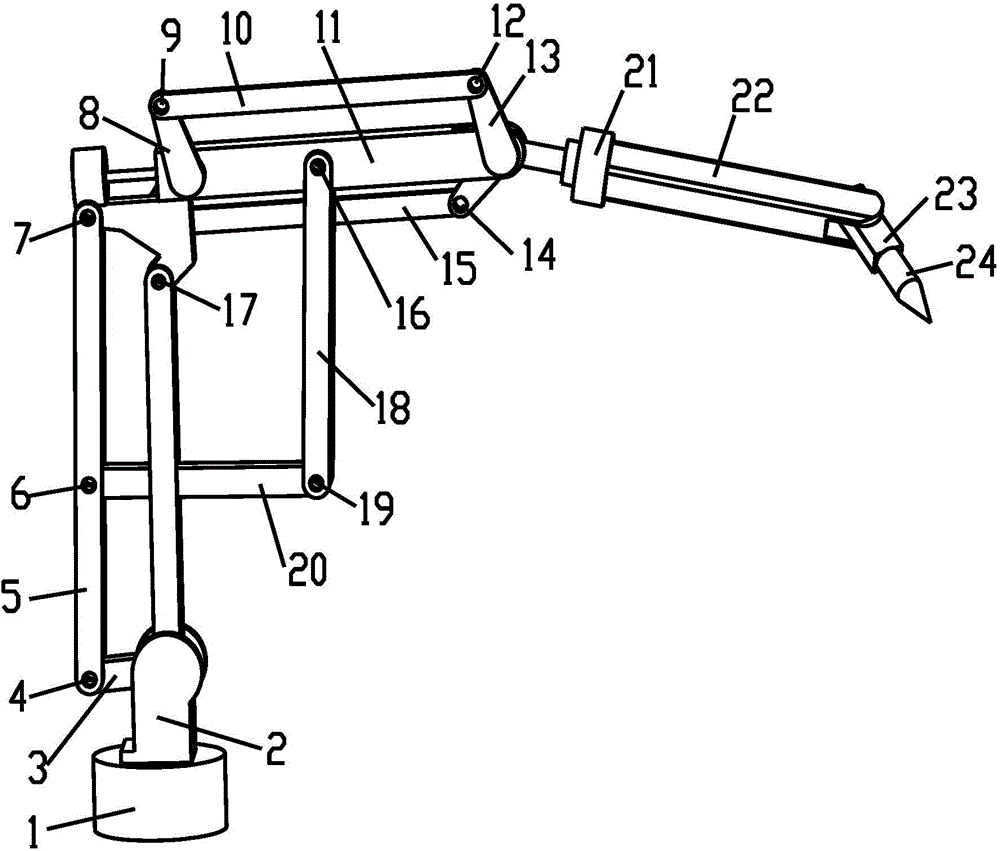

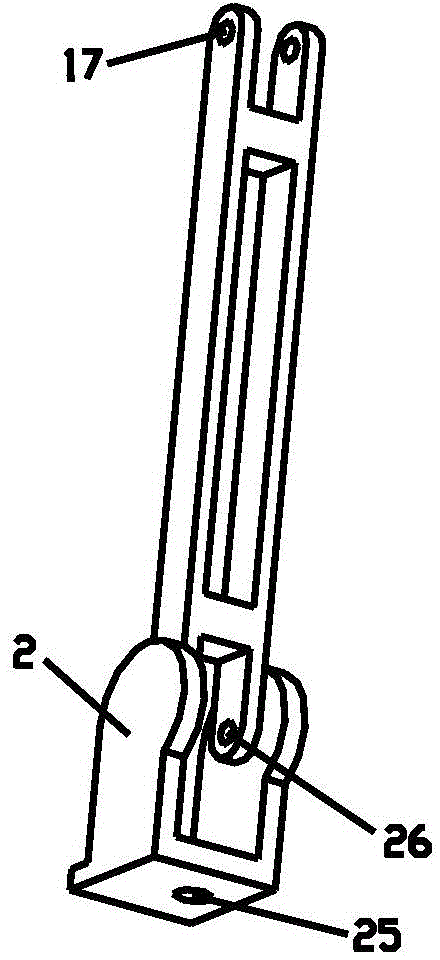

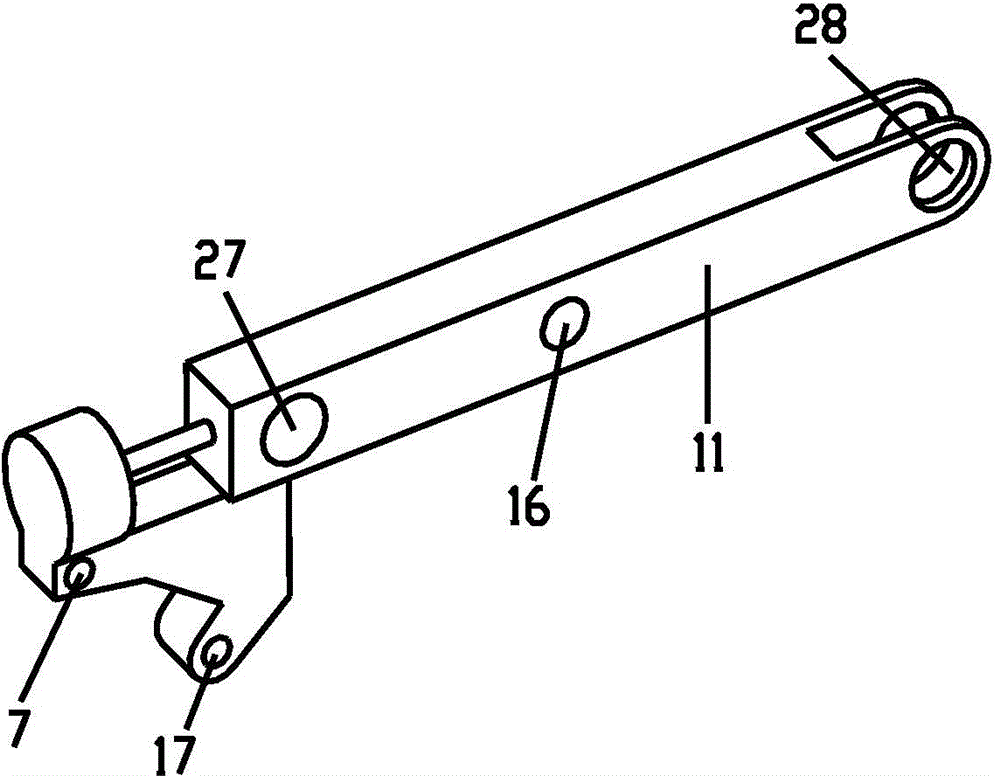

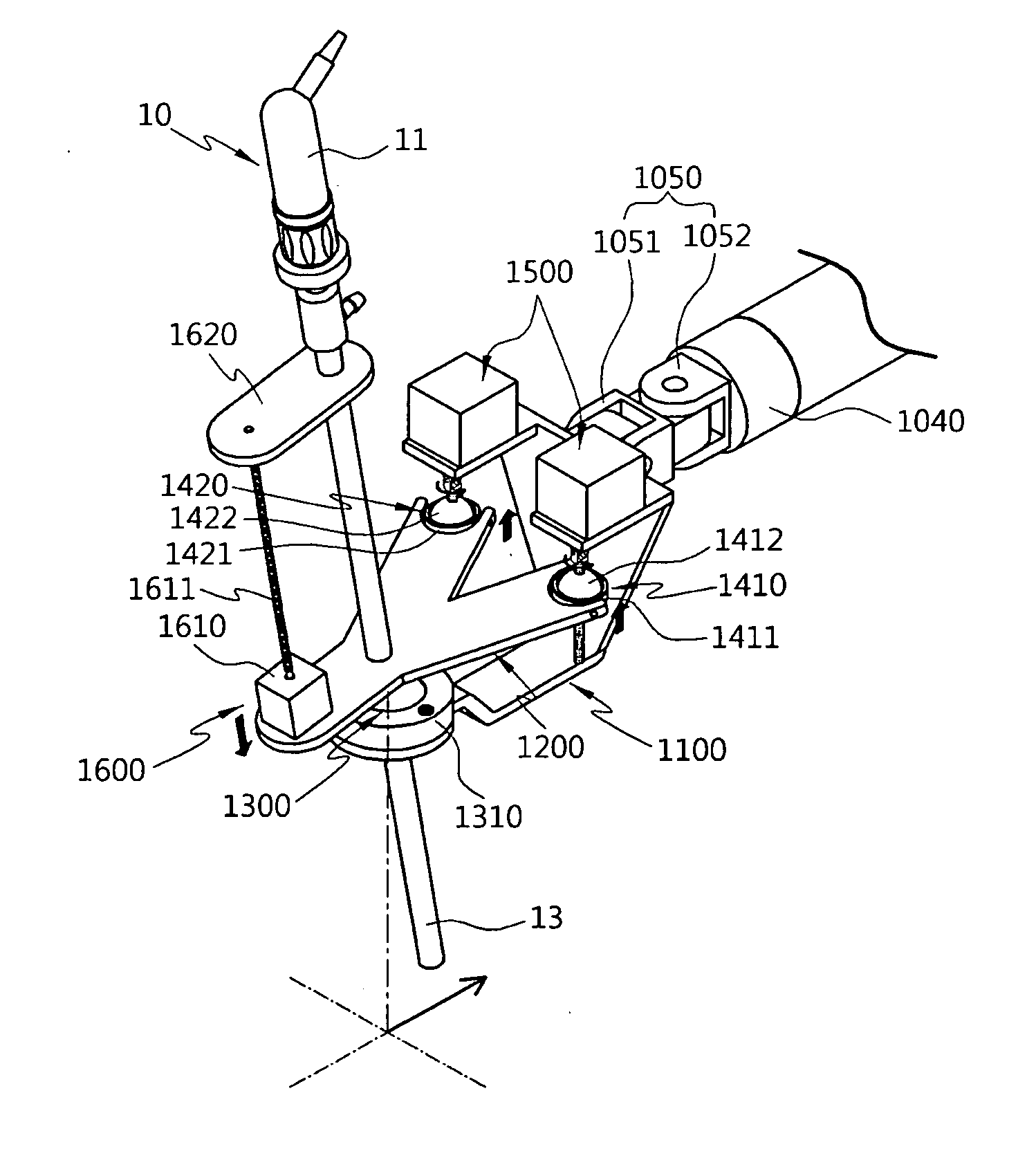

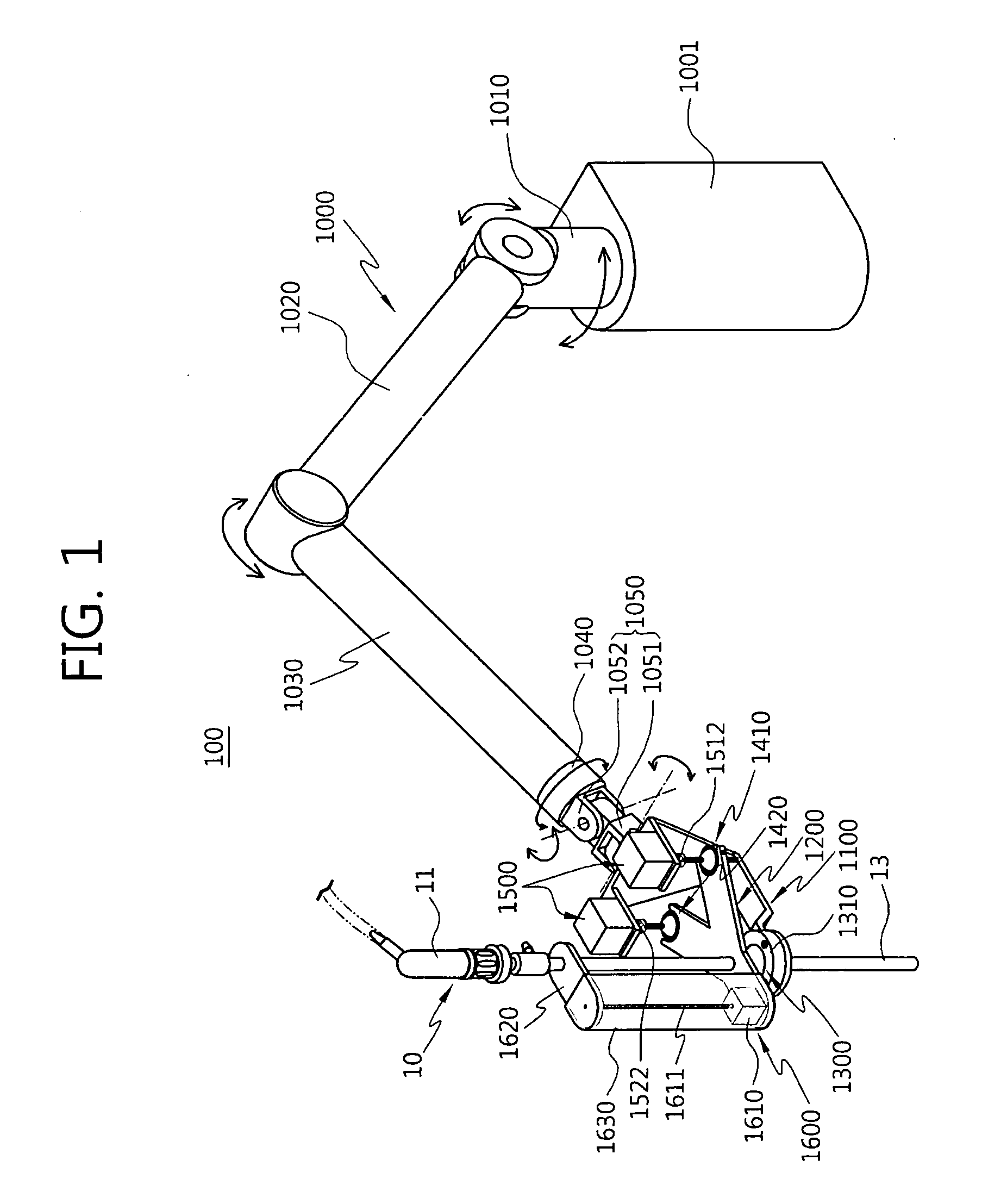

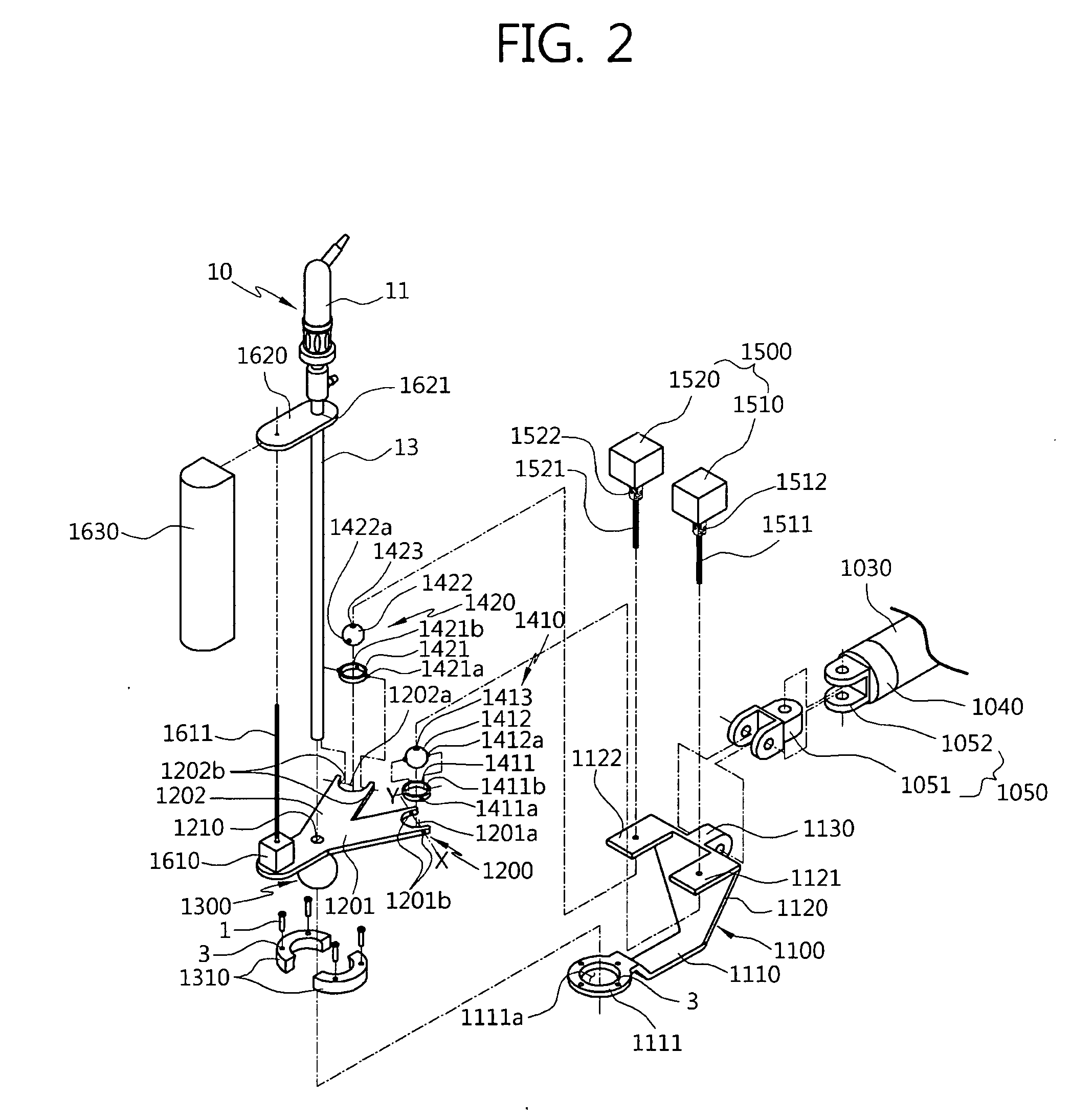

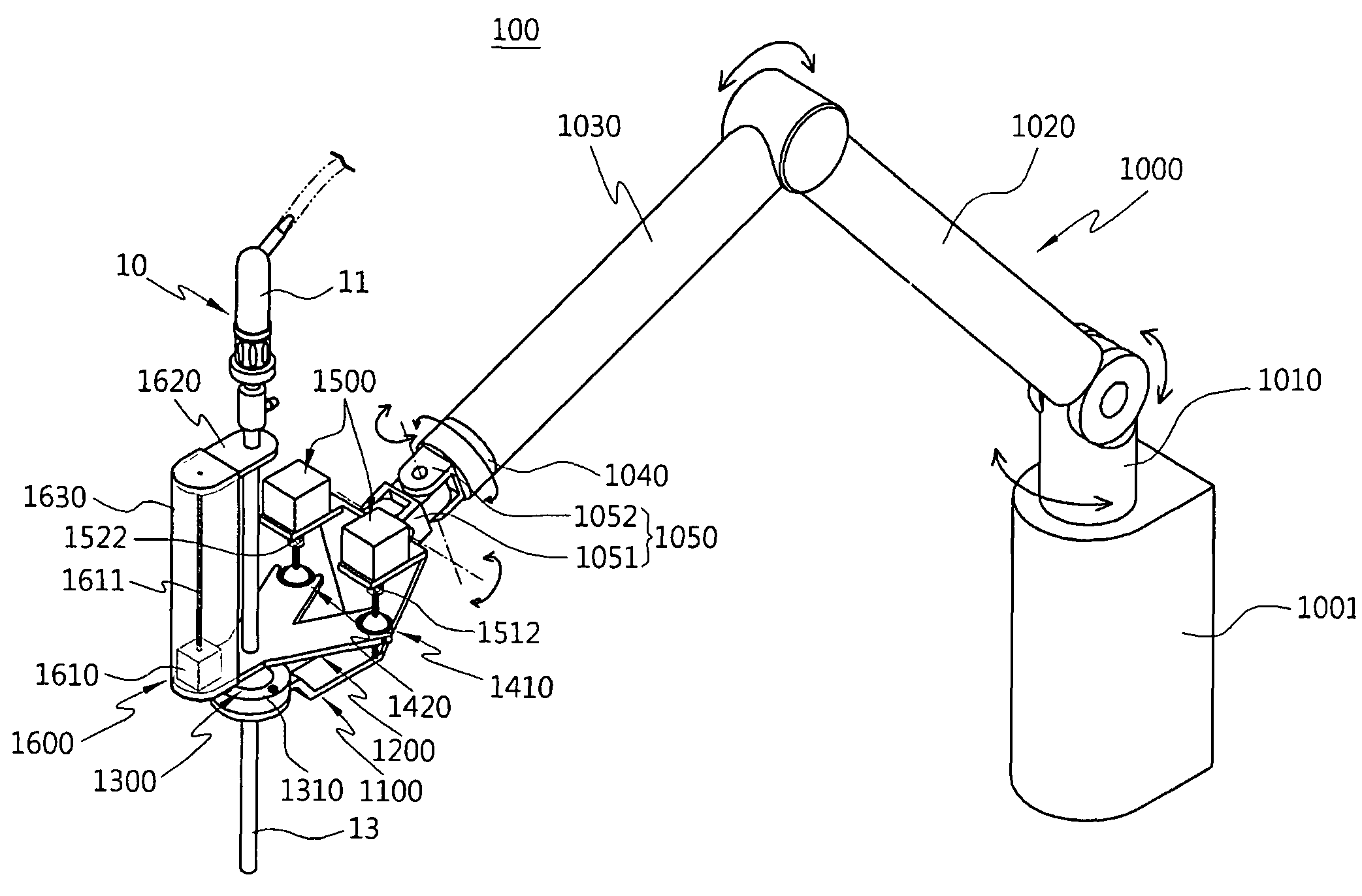

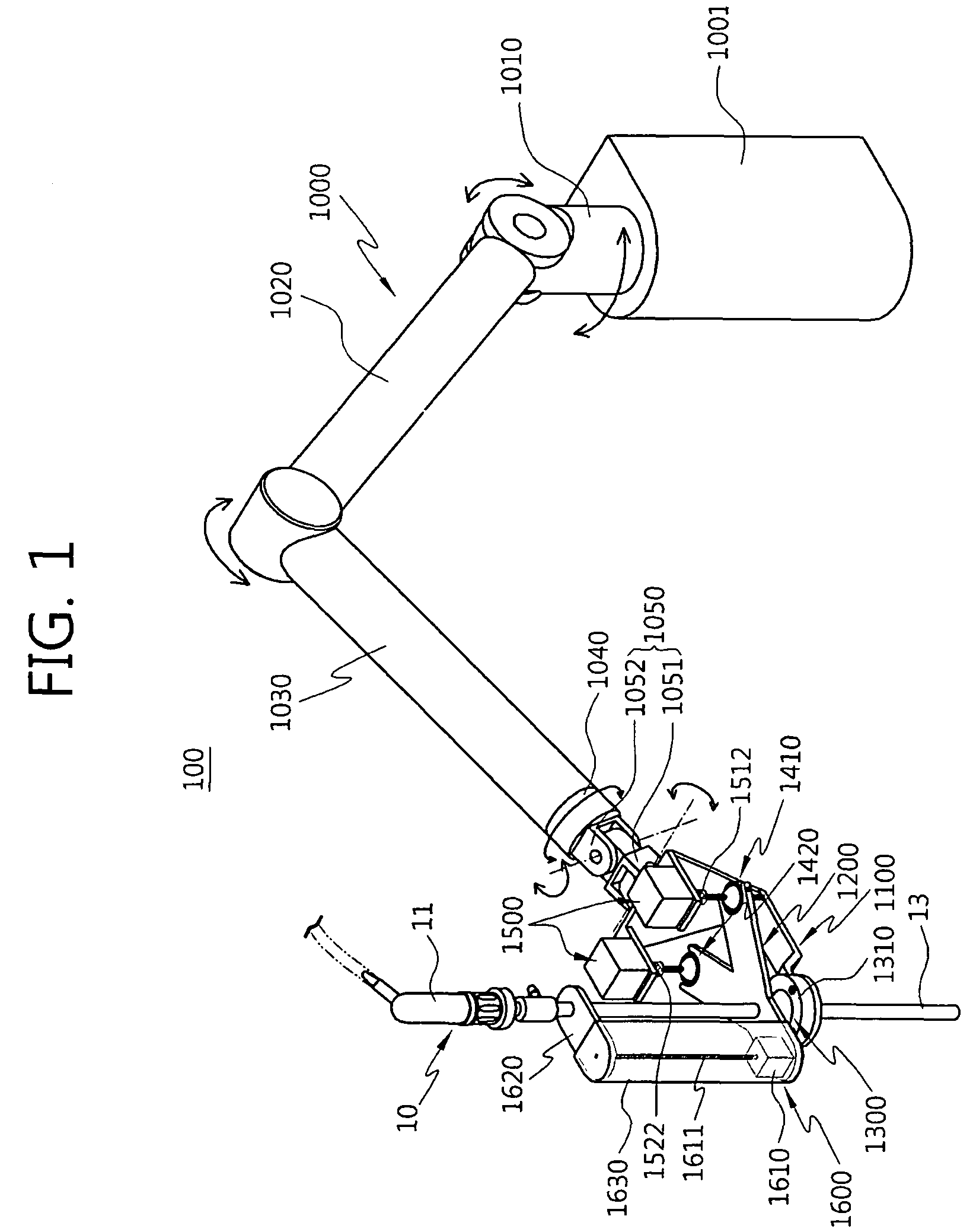

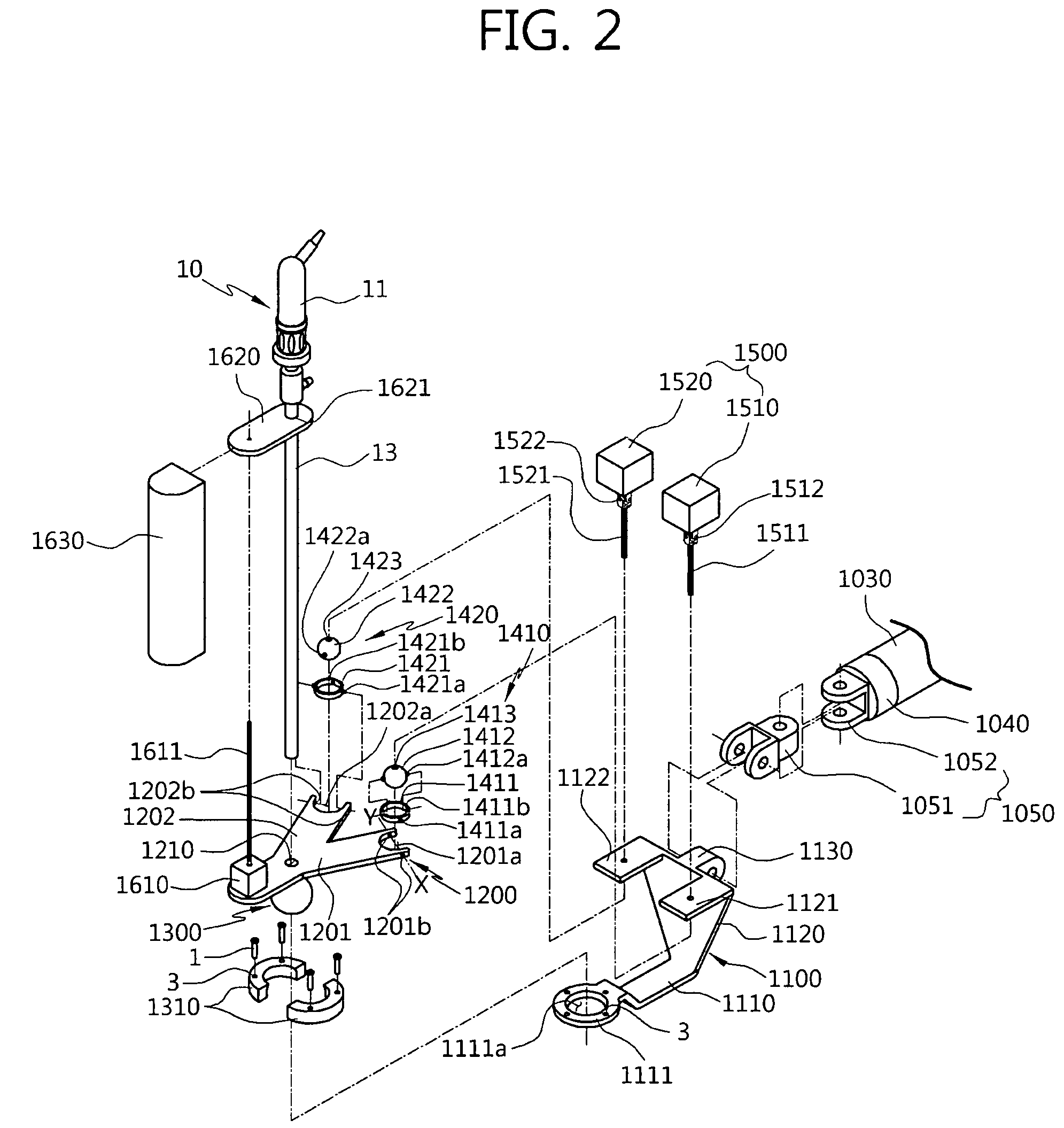

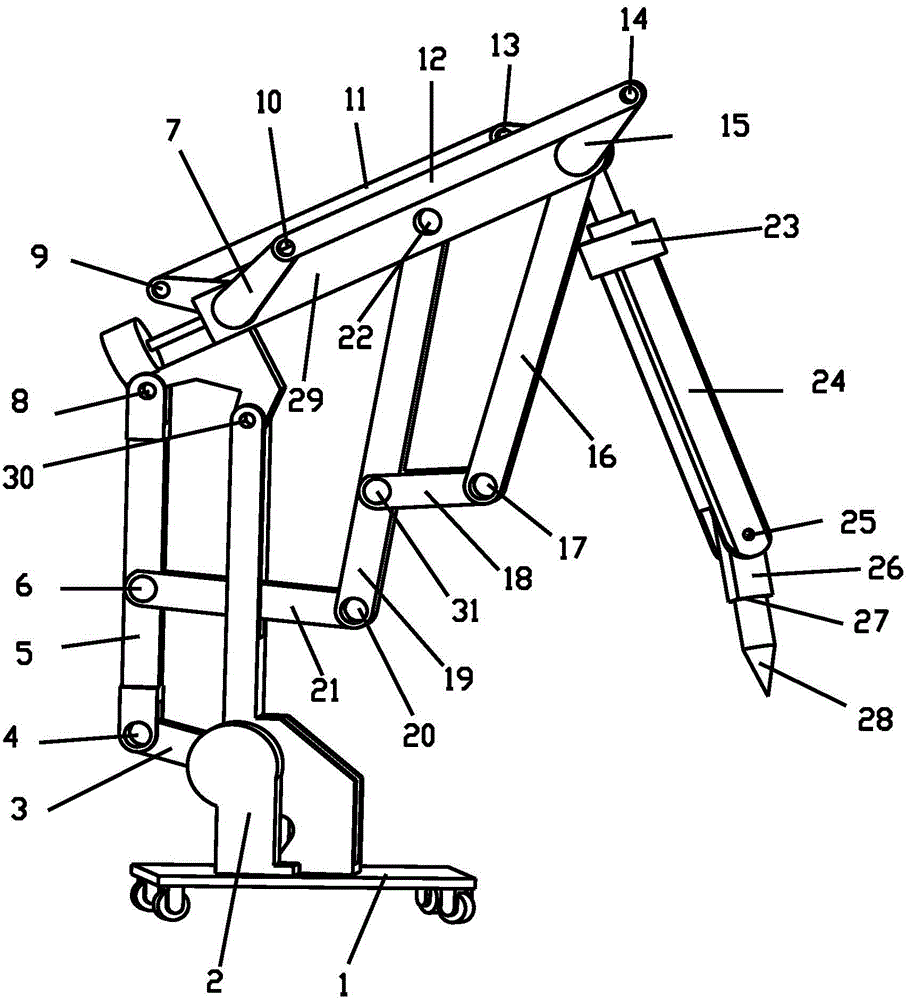

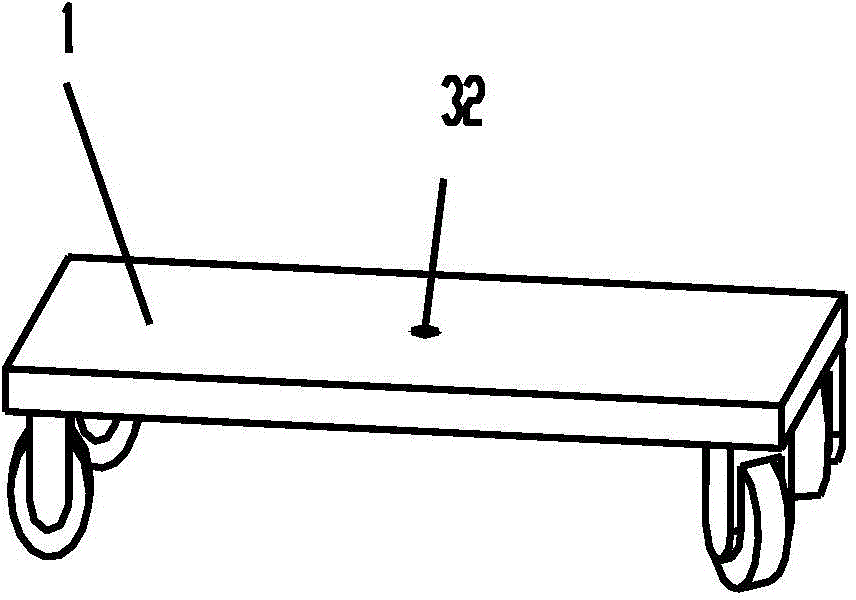

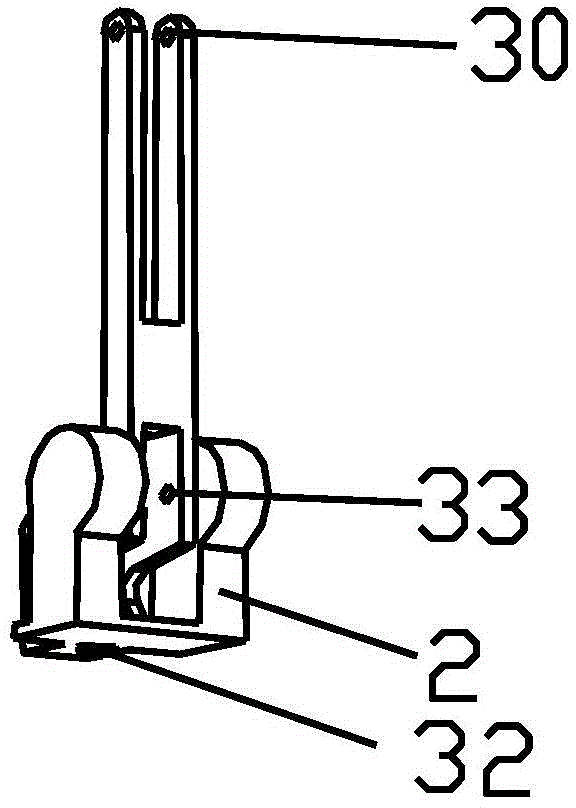

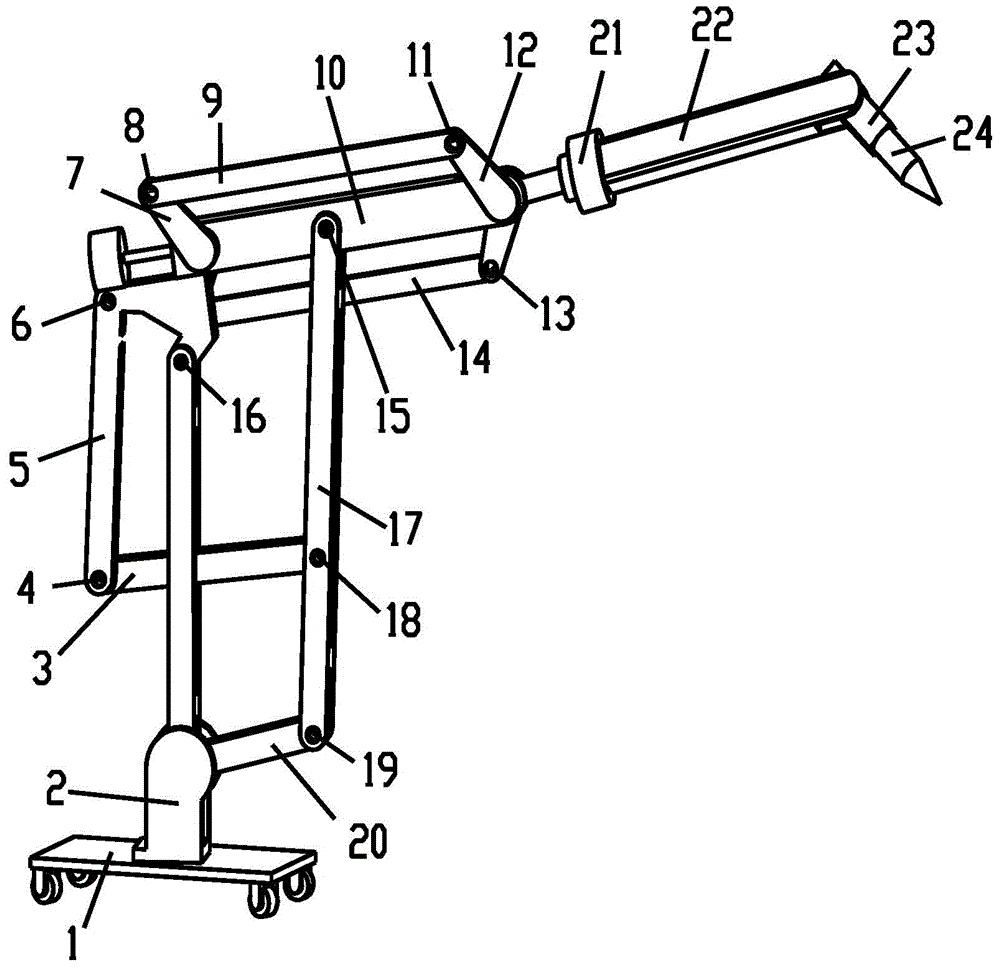

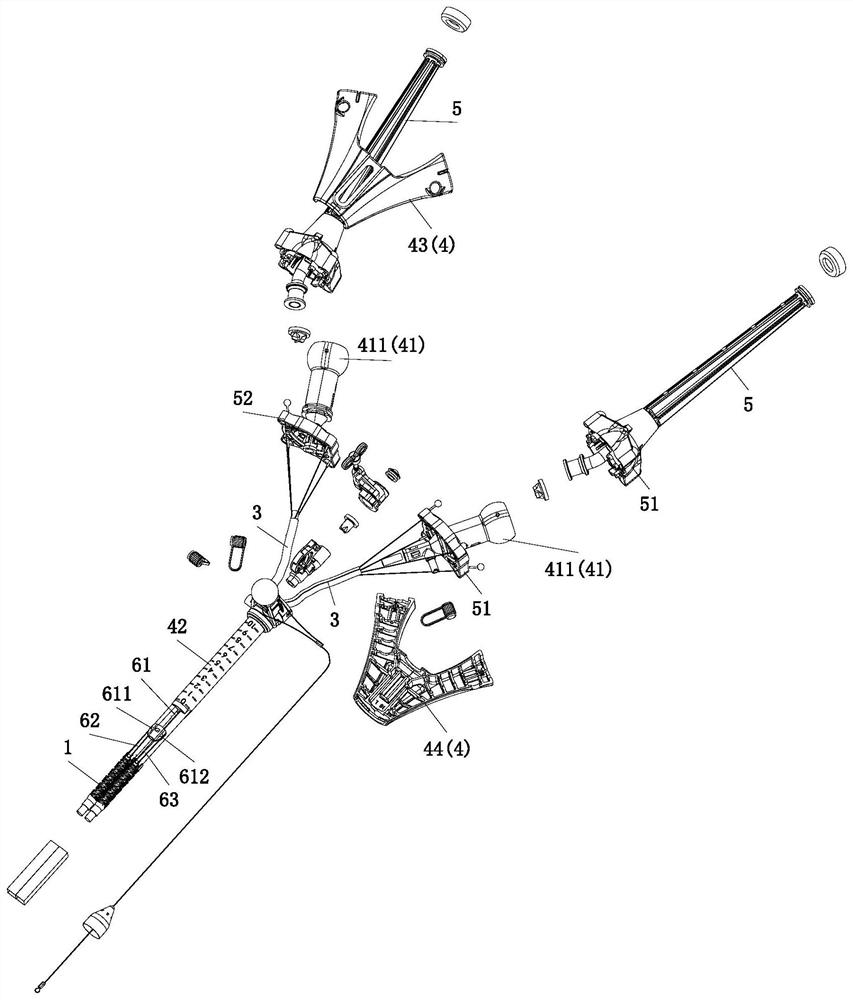

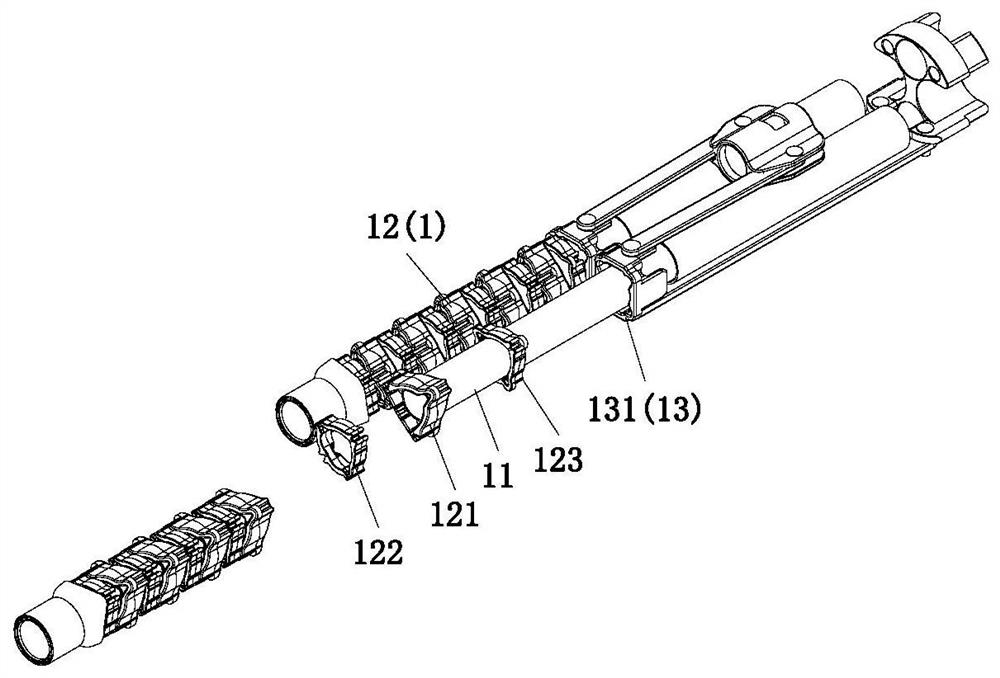

Endoscope manipulator for minimally invasive surgery

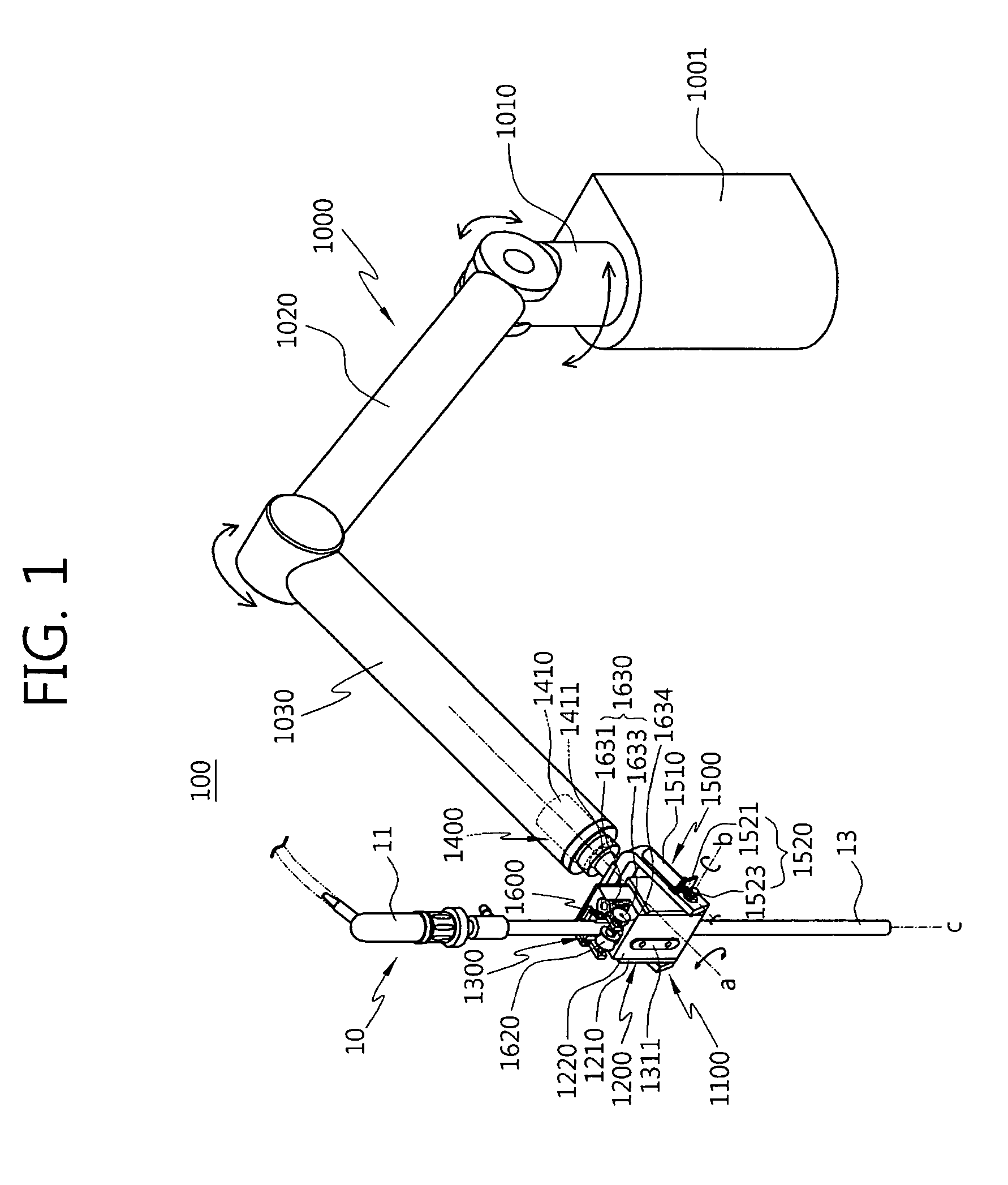

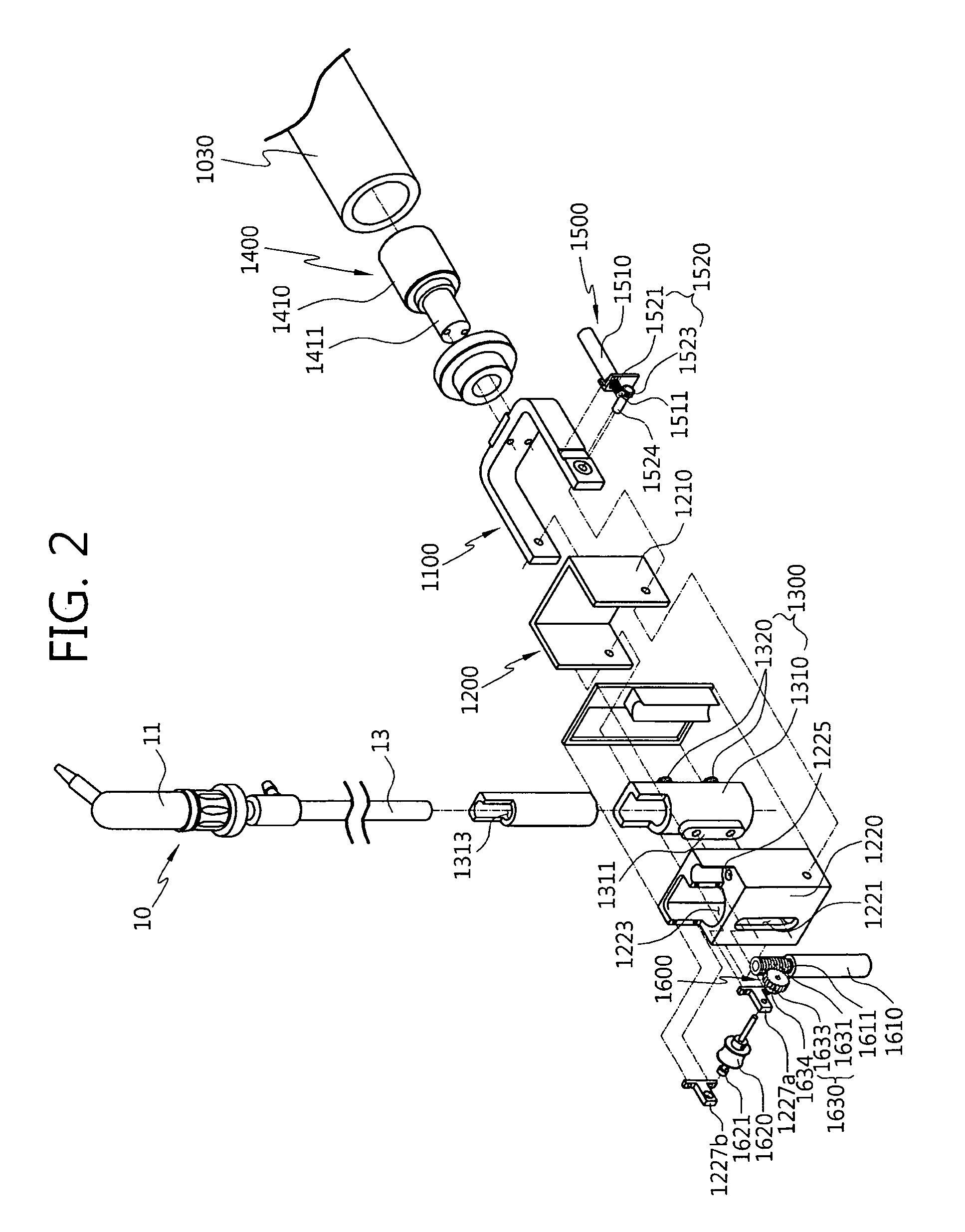

InactiveUS20100274078A1Large space for activitiesEndoscopesSurgical instrument supportLess invasive surgeryThree degrees of freedom

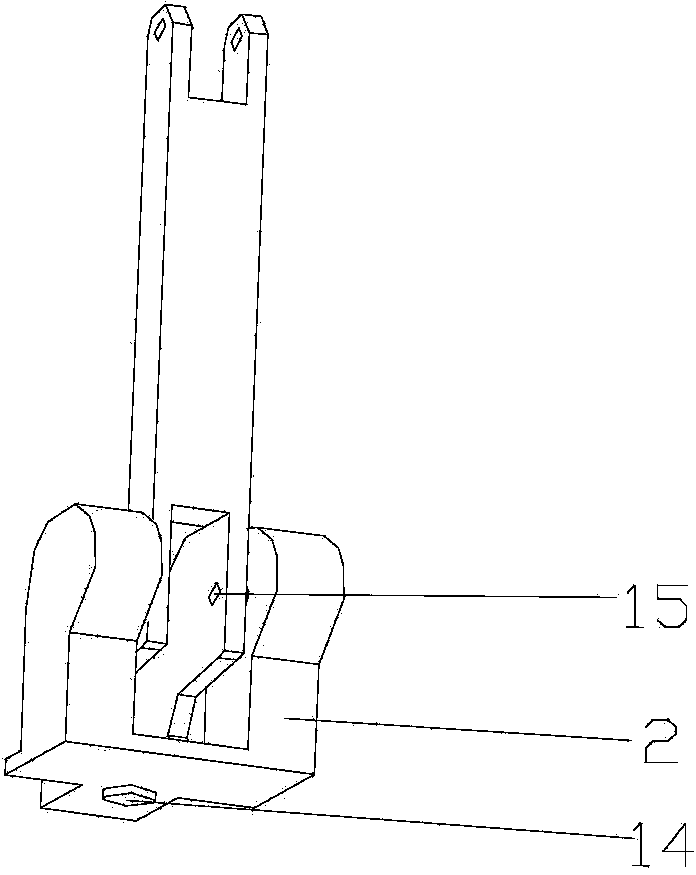

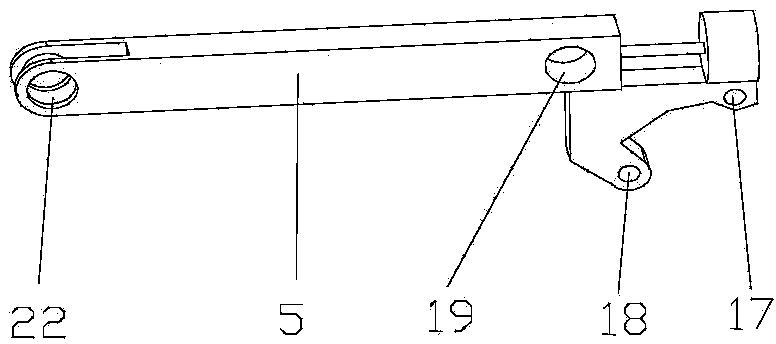

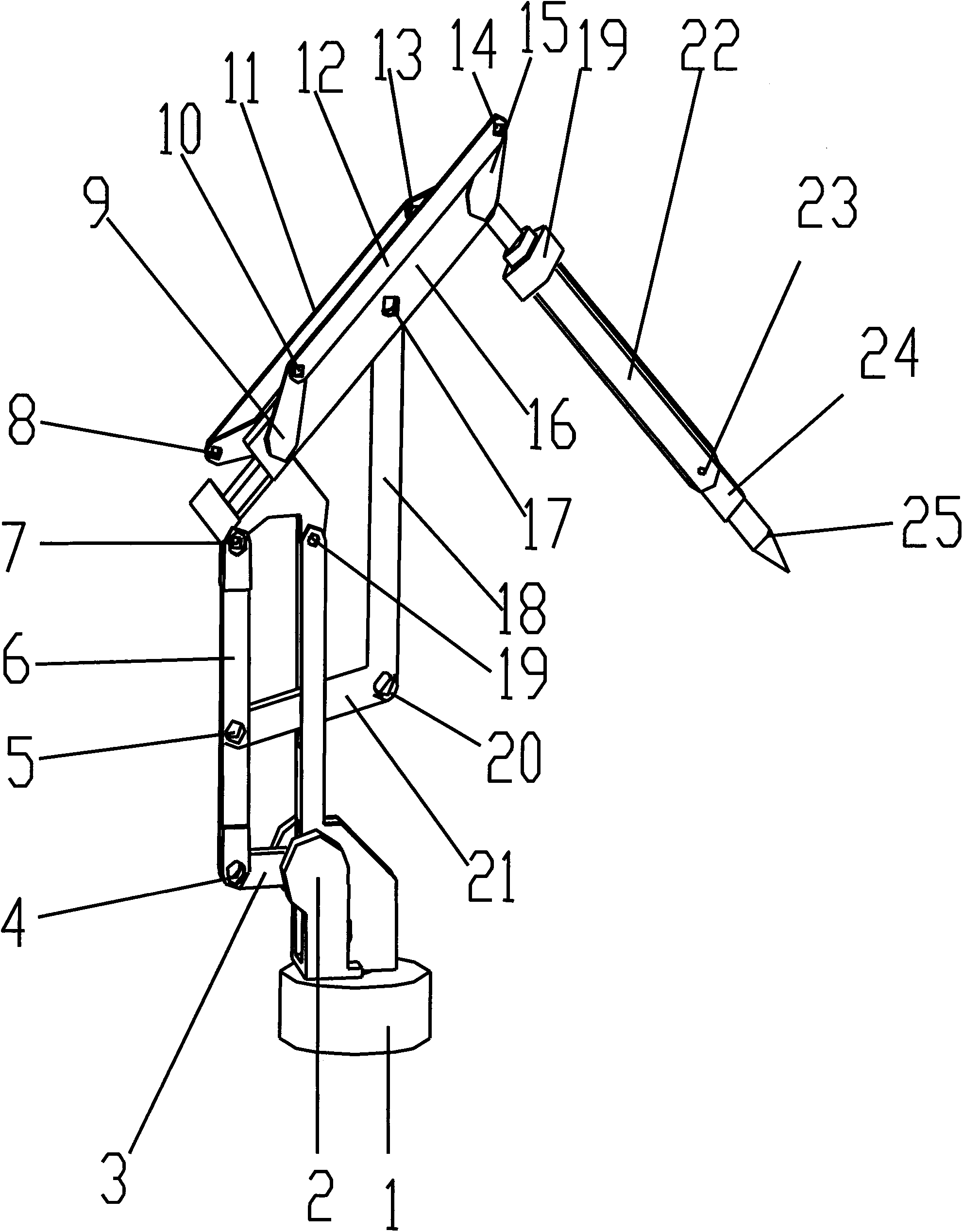

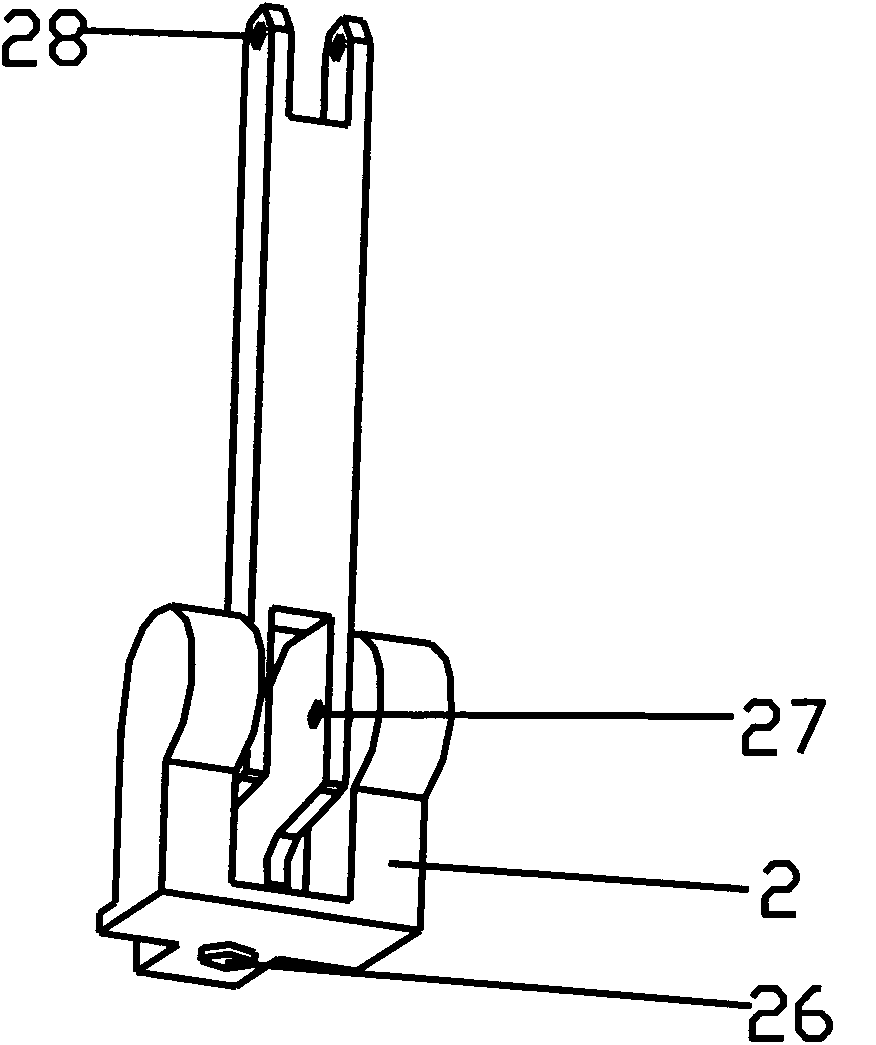

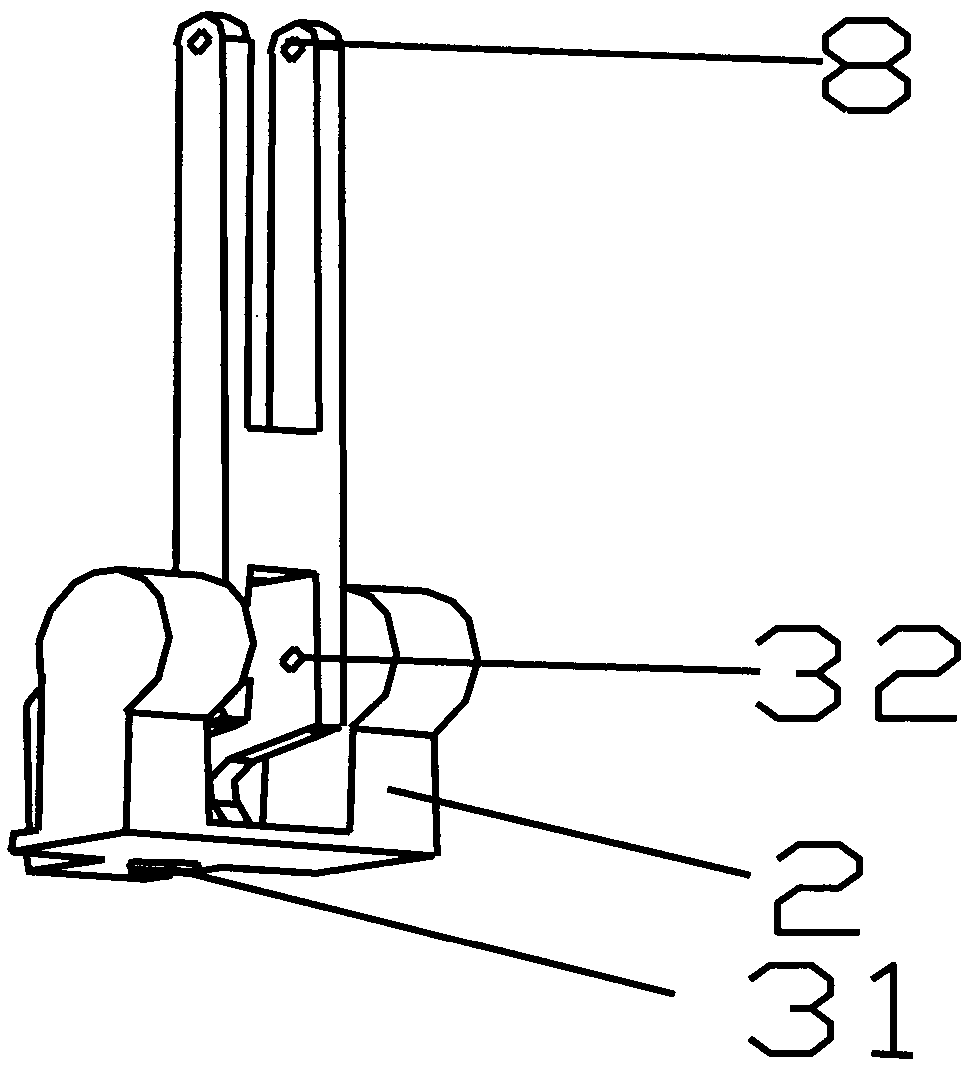

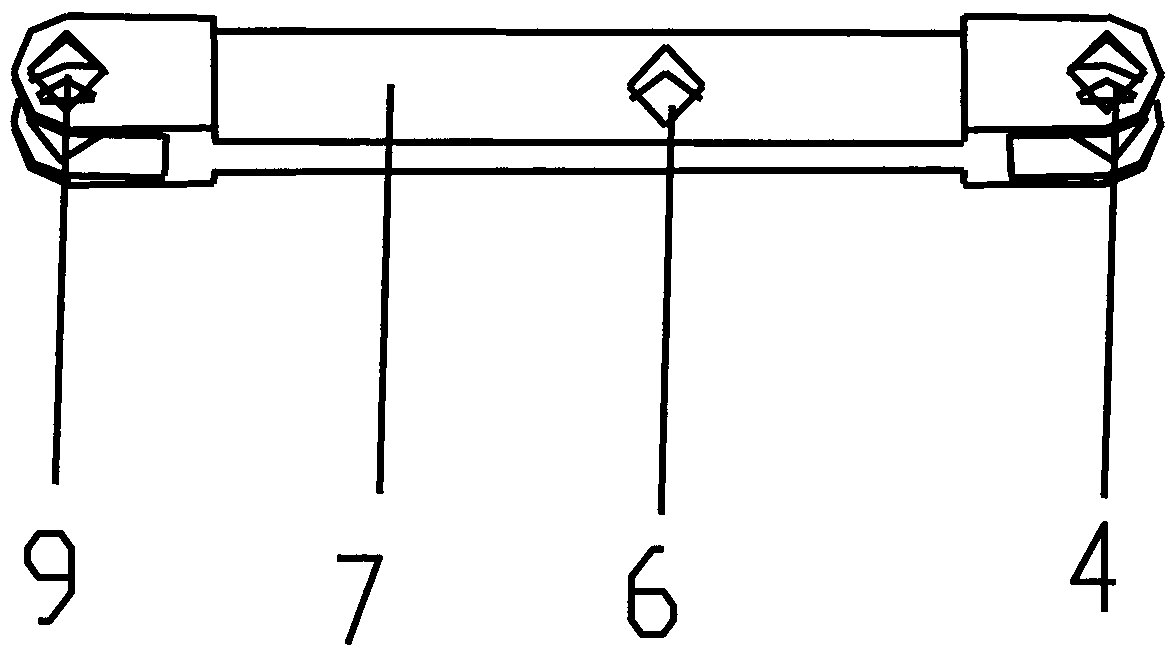

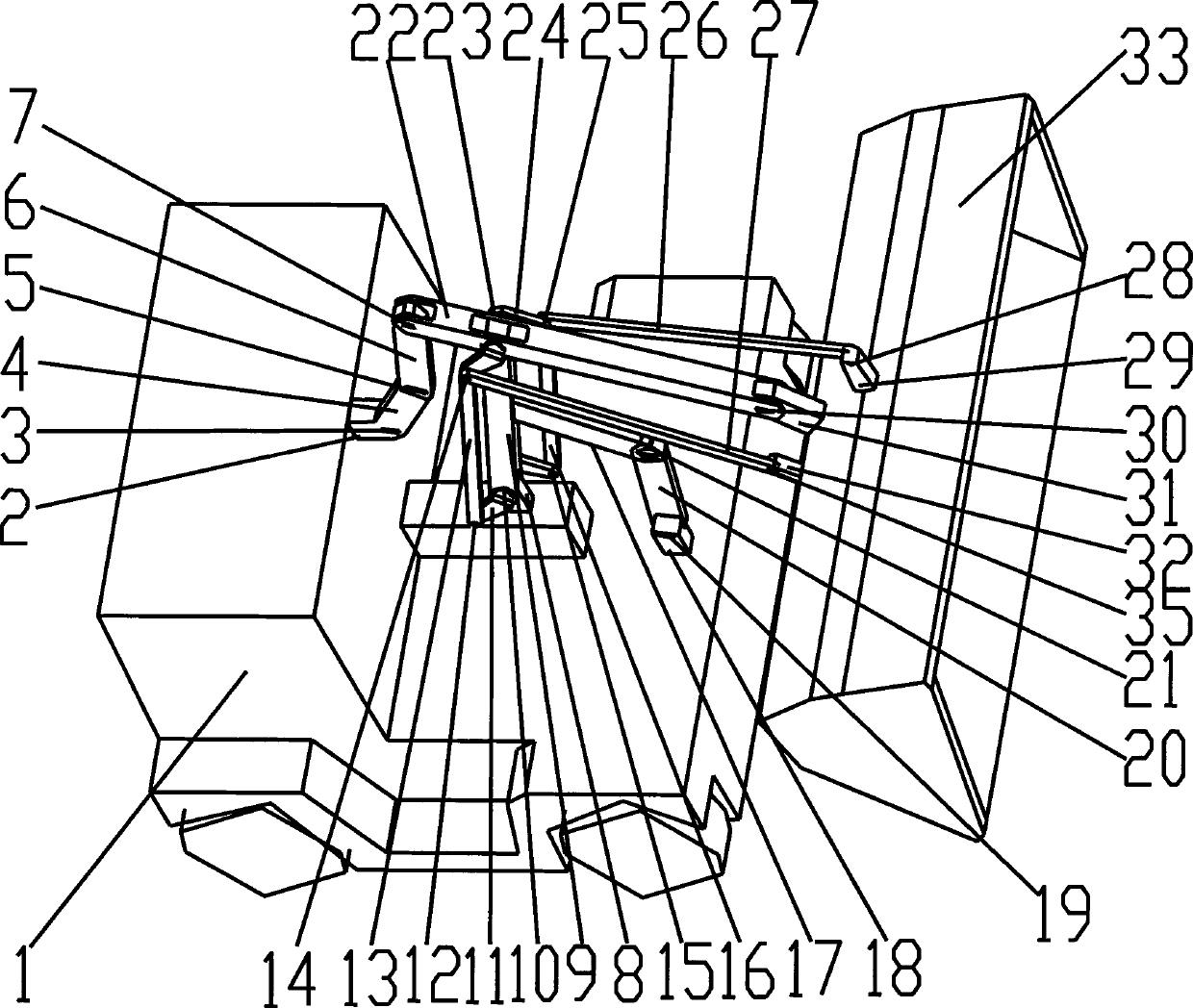

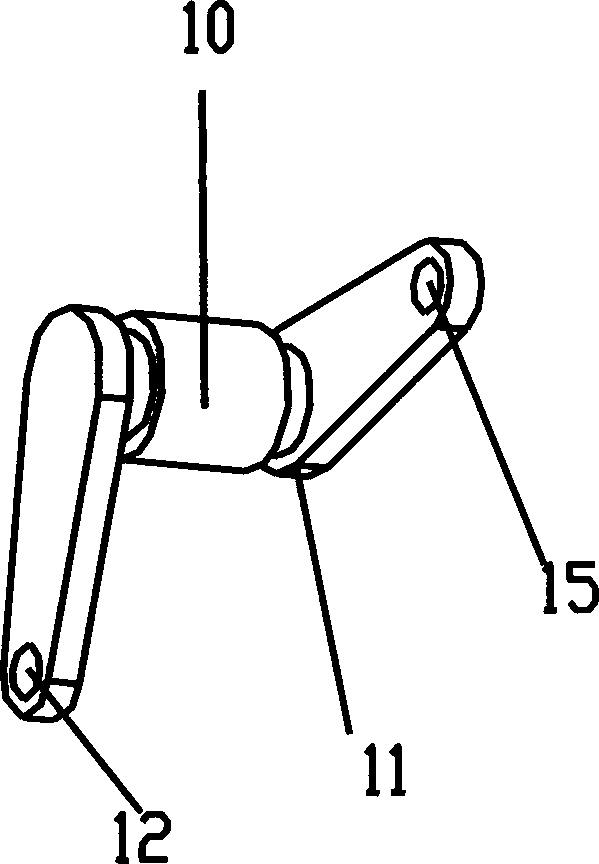

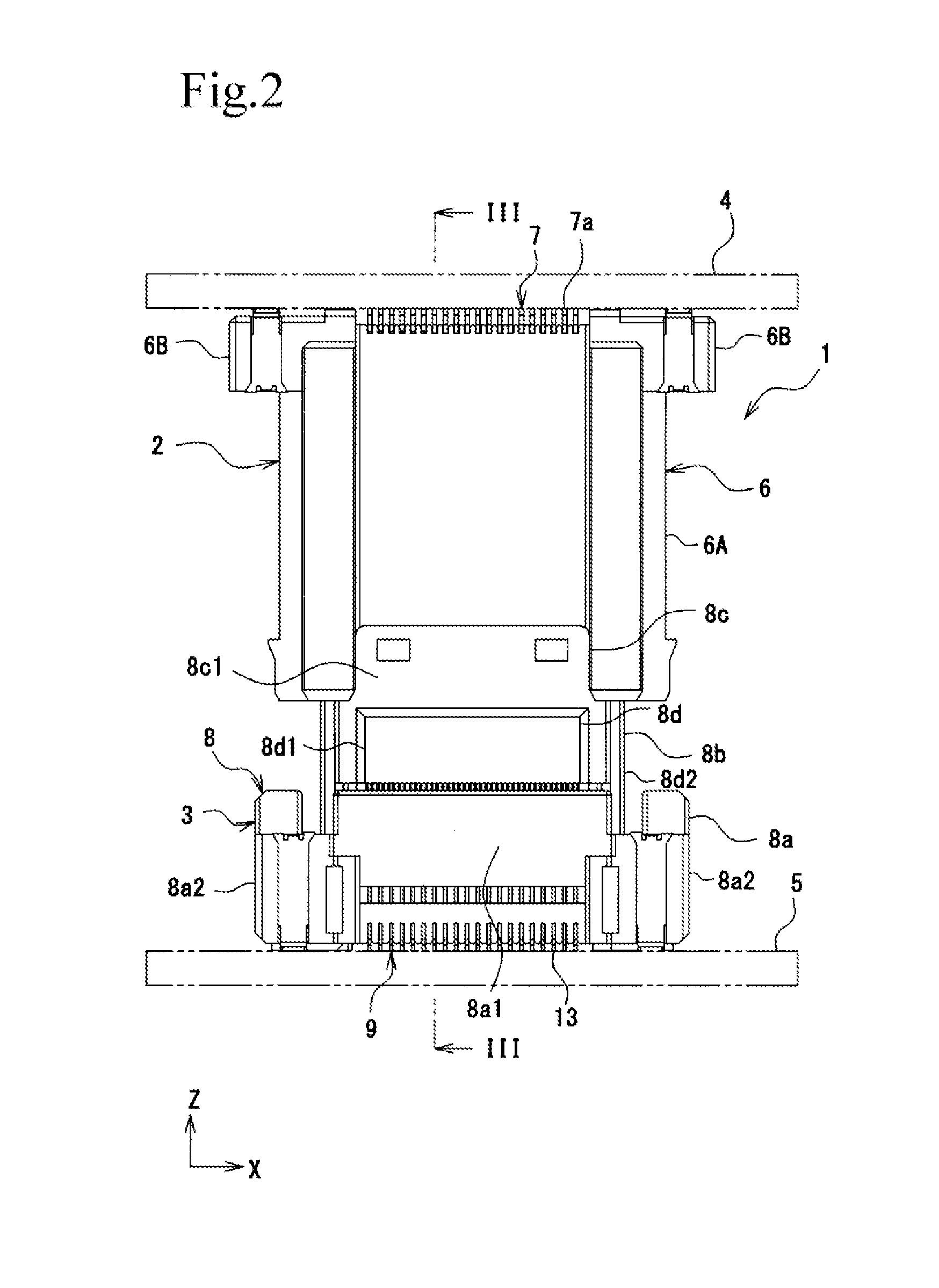

According to endoscope manipulator for MIS capable of overcoming disadvantages of multiaxial endoscope manipulator including conventional robot arm and providing compact and light-weight structure to obtain maximum activity space for medical staff, multi-joint arm is configured so that movement of all joints from base link to tip link is manually locked-unlocked by user and not controlled by motors. Endoscope mounted on end of multi-joint arm is manipulated using motors to enable movement of three-degrees of freedom, thereby accomplishing compact and light-weight endoscope manipulator. Tube of endoscope can be press-fitted onto tip of multi-joint arm, and three-axis movement function for vertical, lateral and forward / backward conveyance of endoscope is implemented in tip of multi-joint arm. Since external manual joints are not moved during operation, disturbance or restriction to activities of medical staff can be minimized. One-click button function of readily and rapidly attaching / detaching endoscope to / from endoscope manipulator can increase convenience of use.

Owner:NAT CANCER CENT

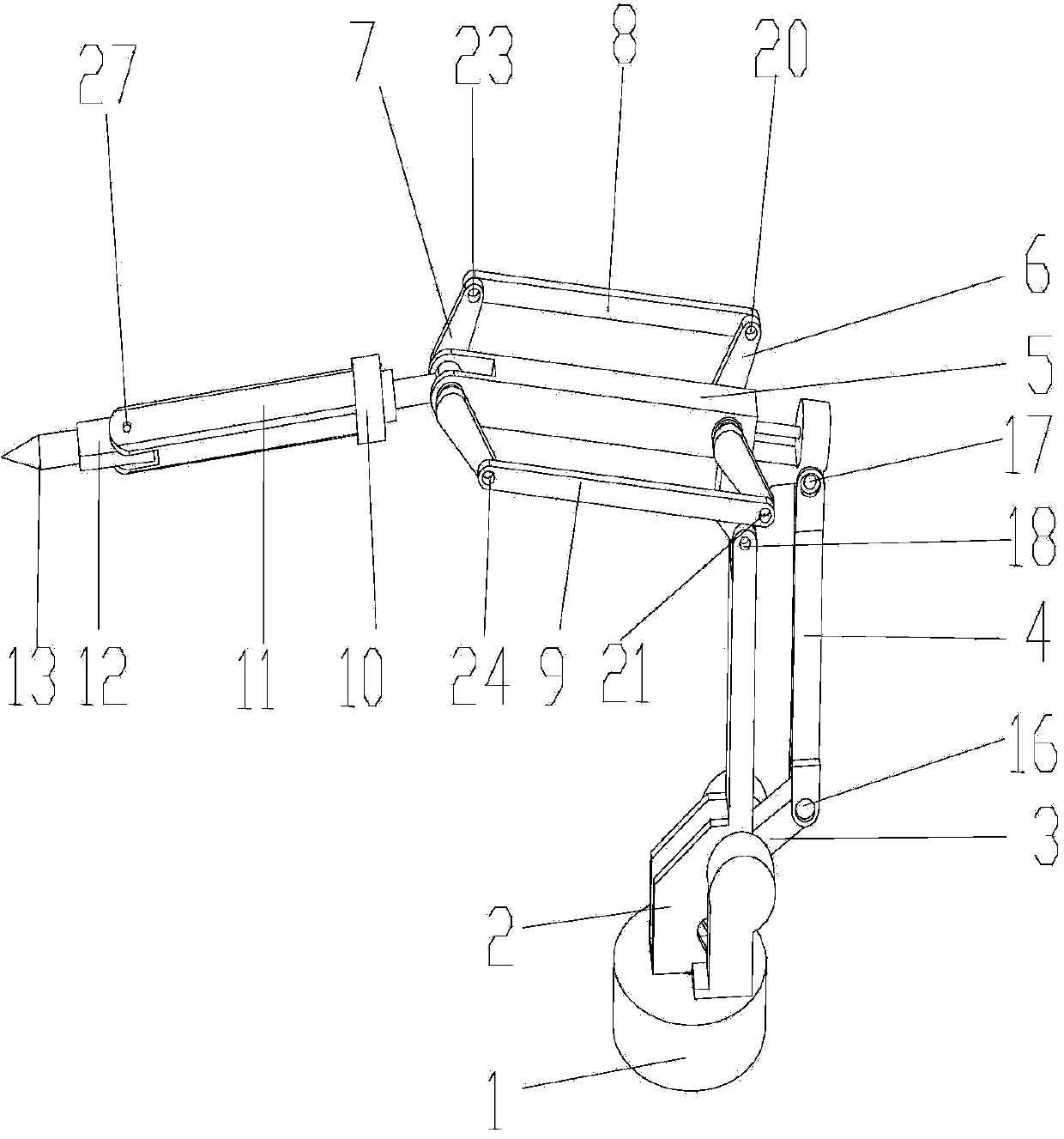

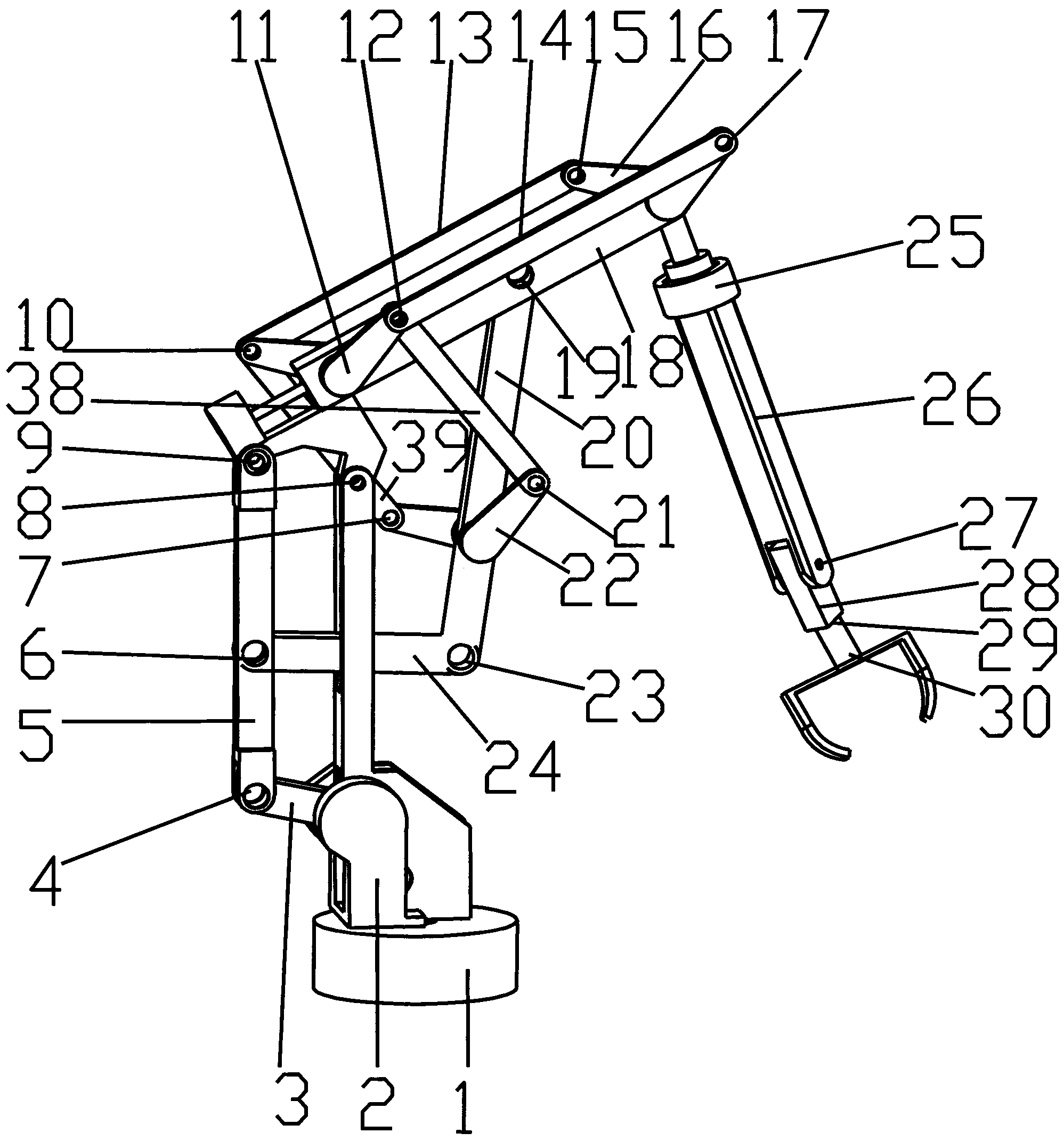

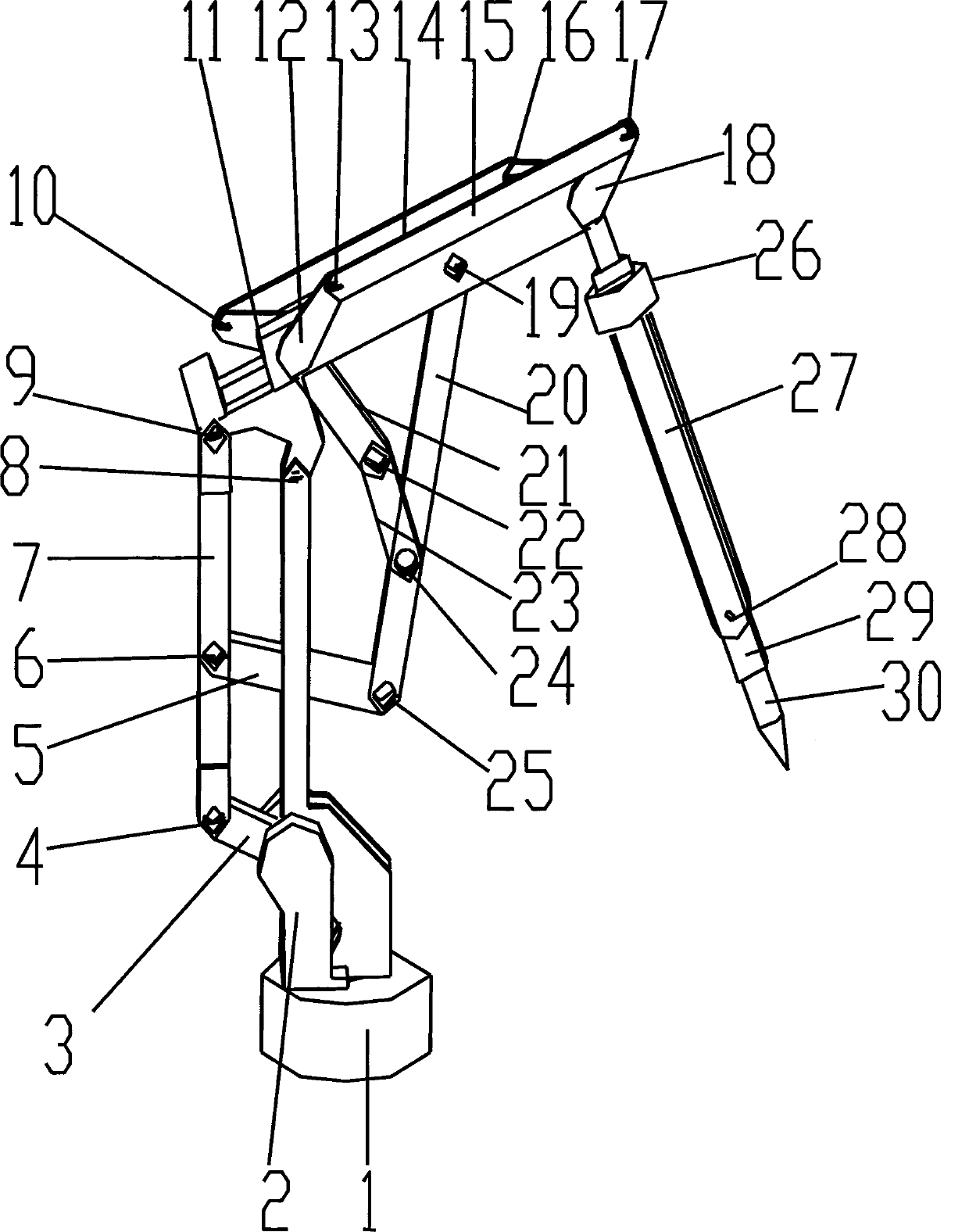

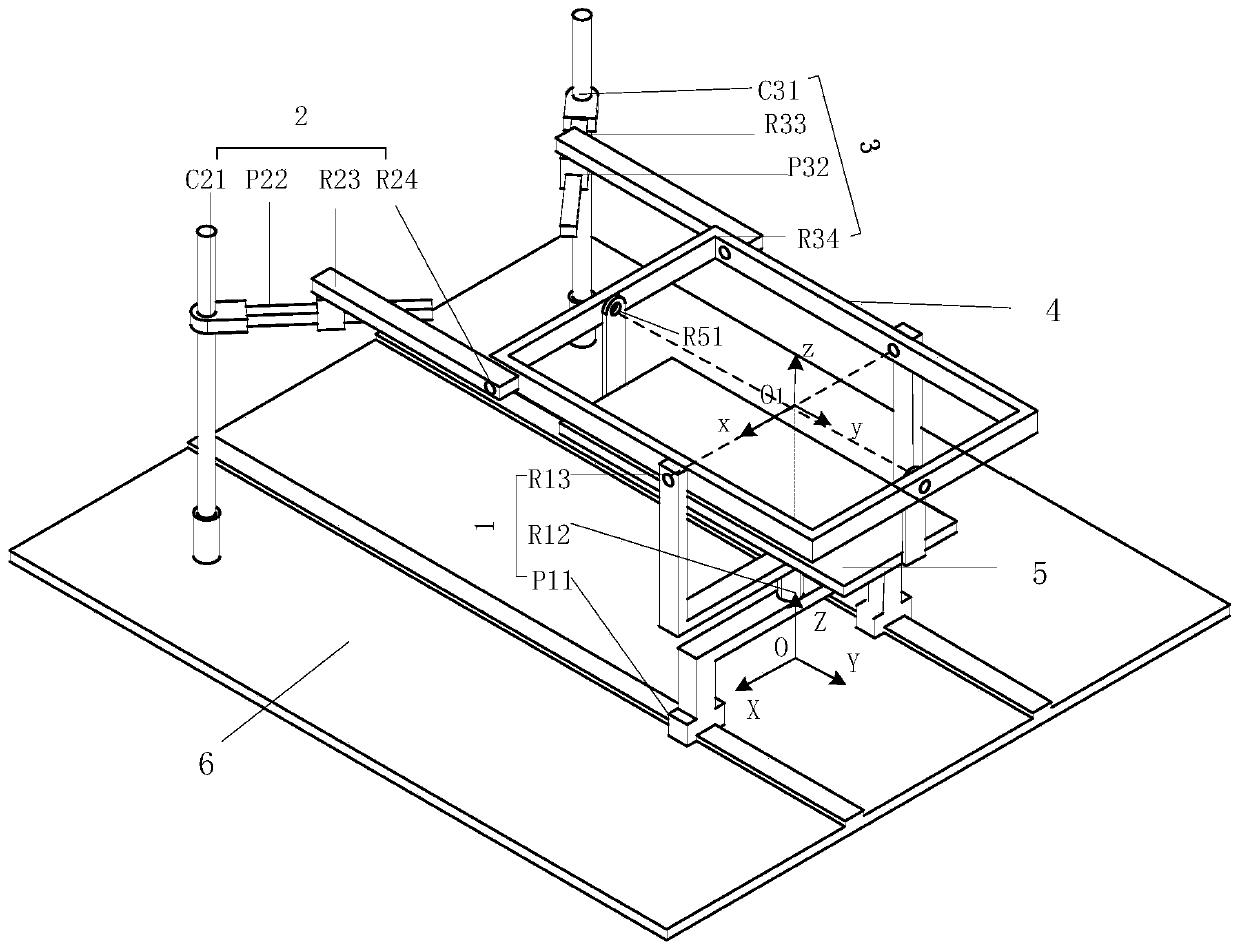

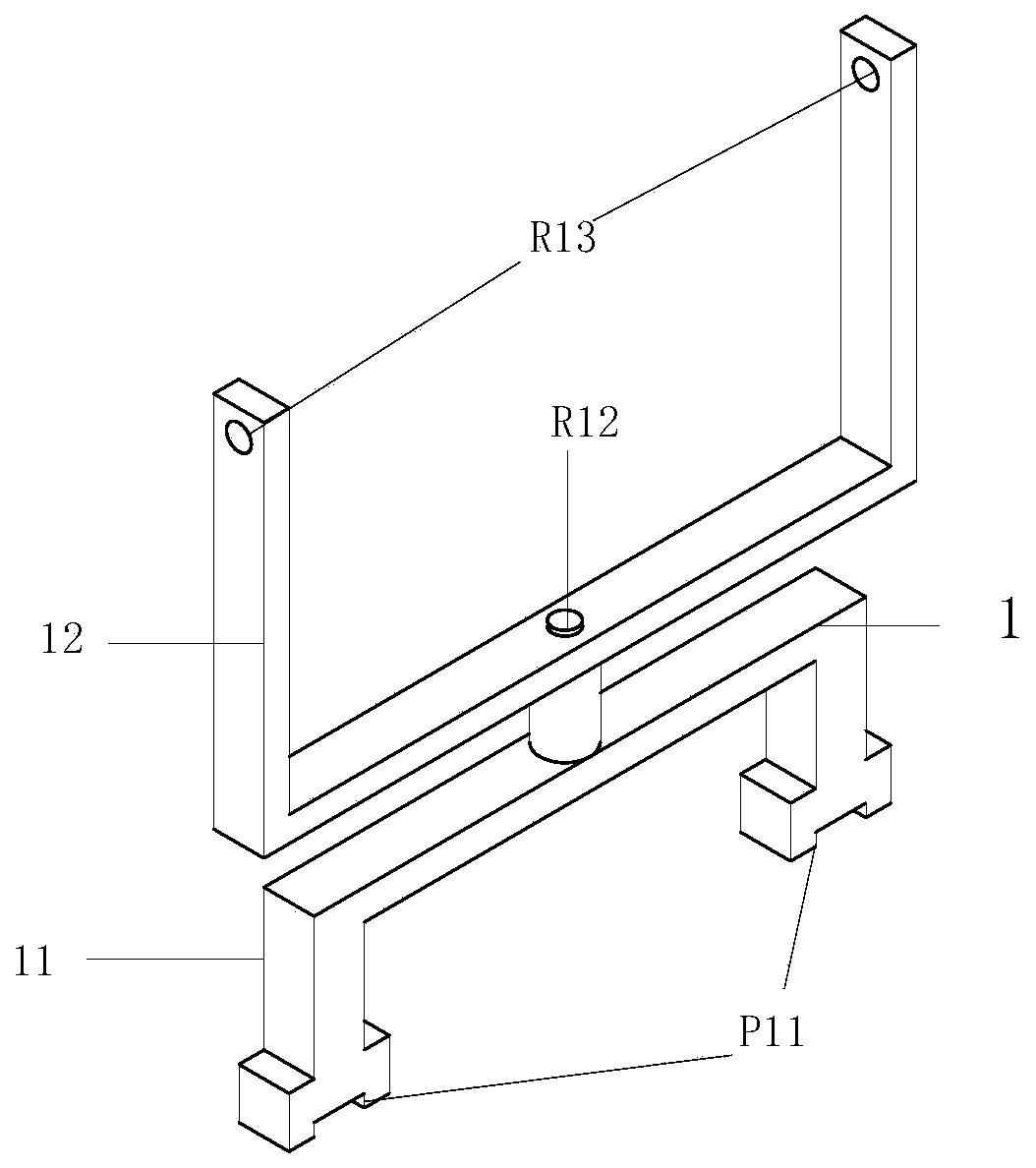

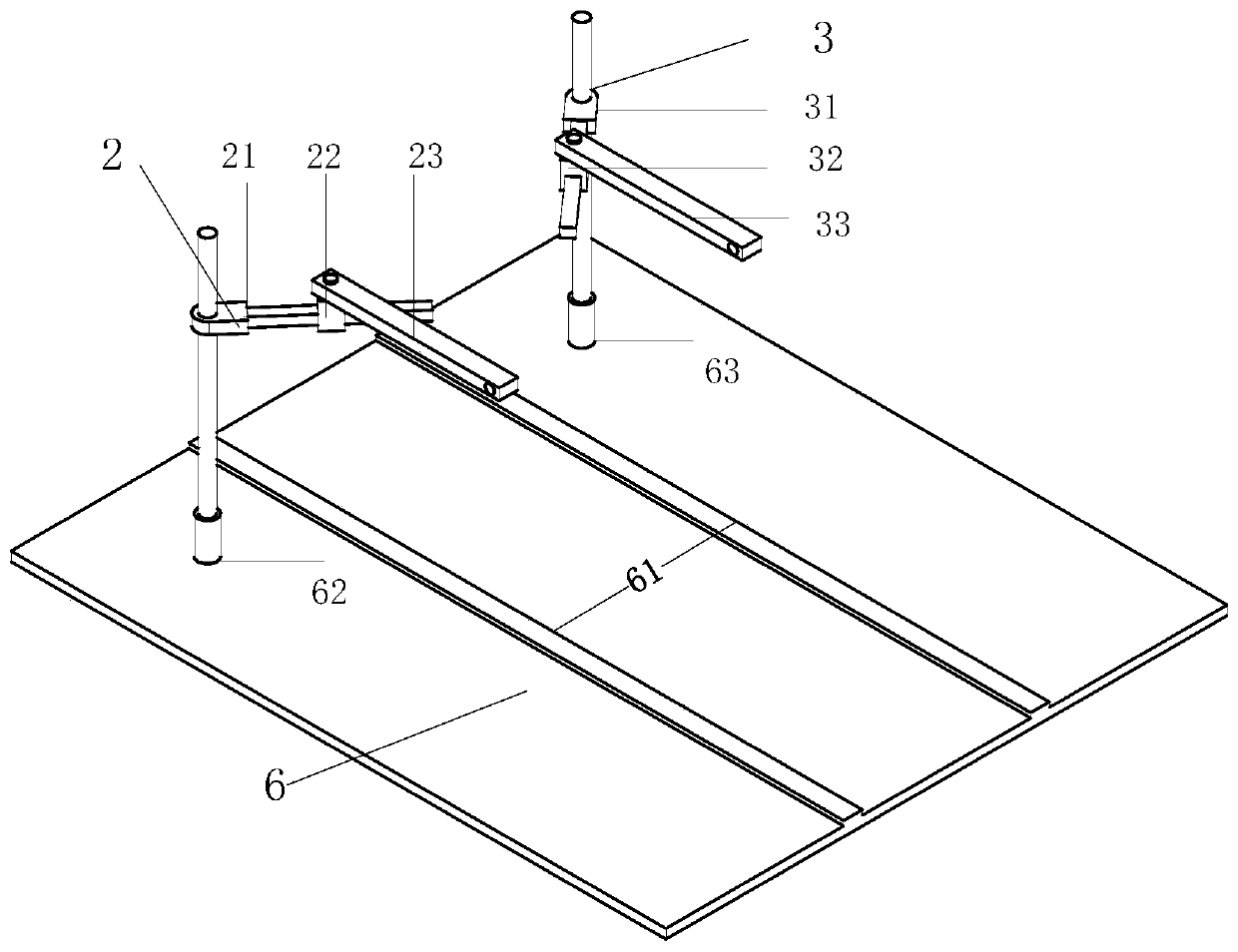

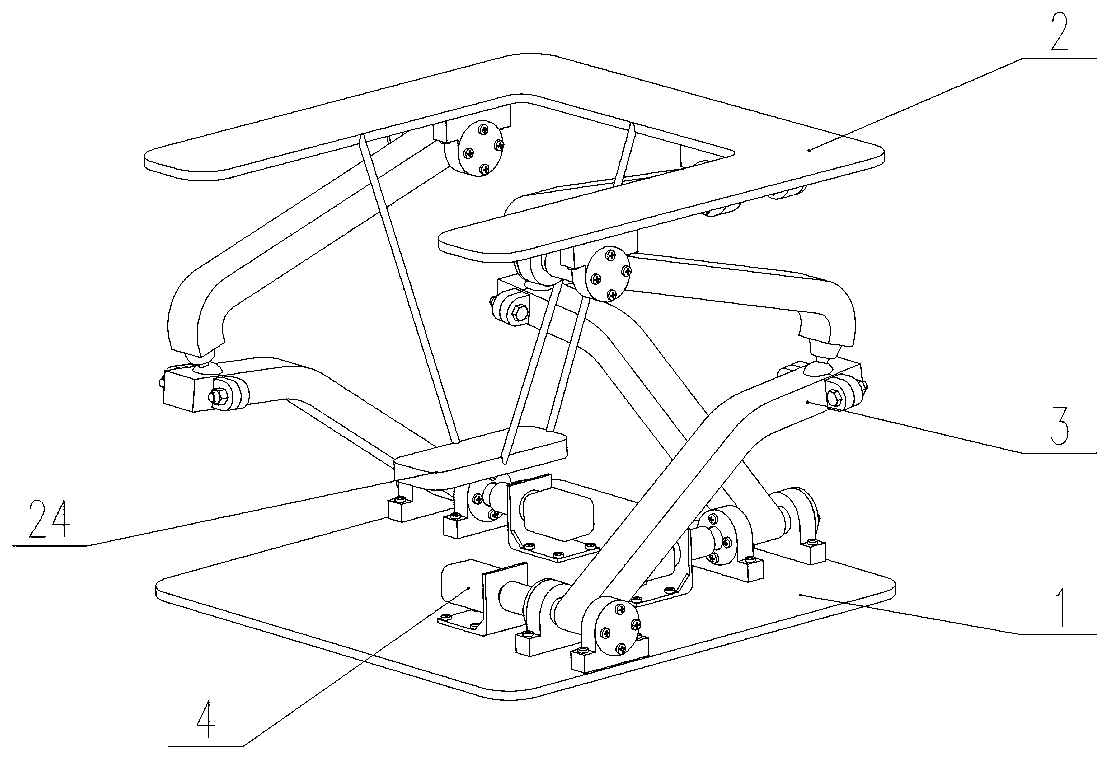

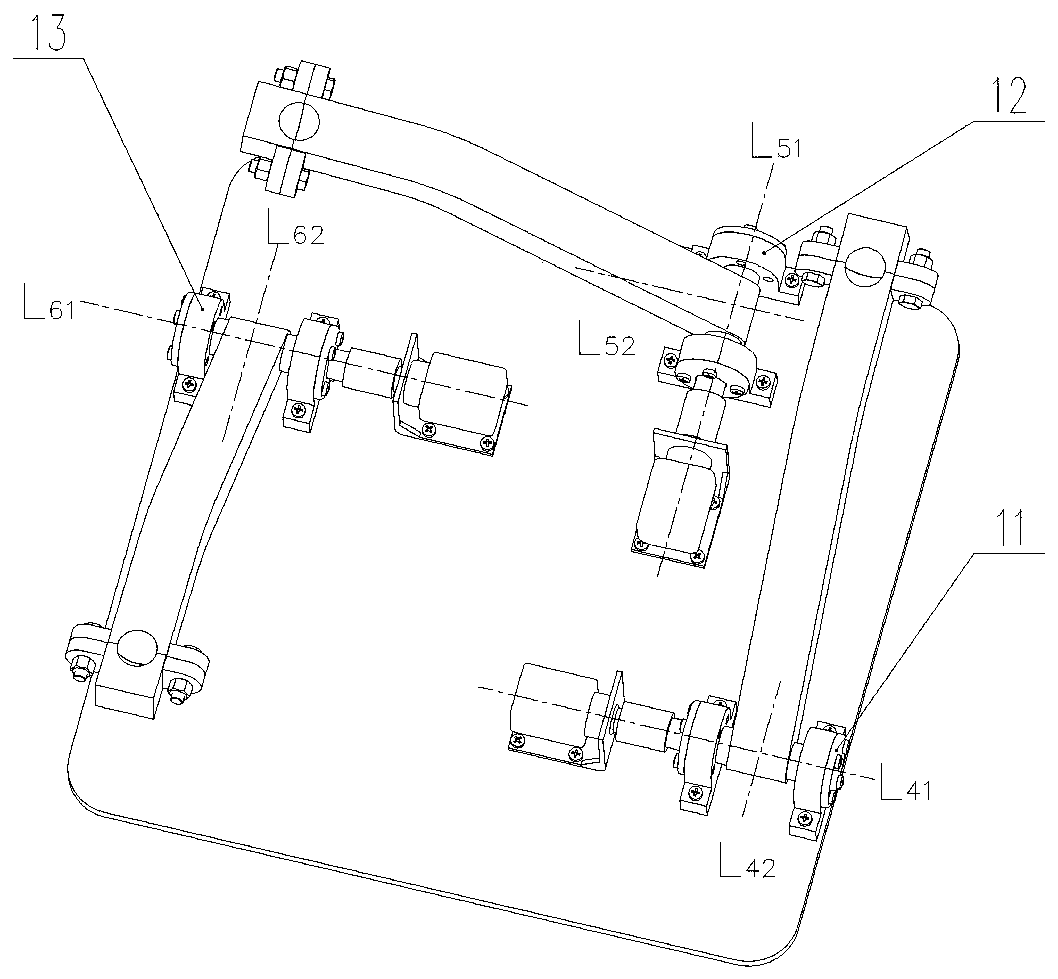

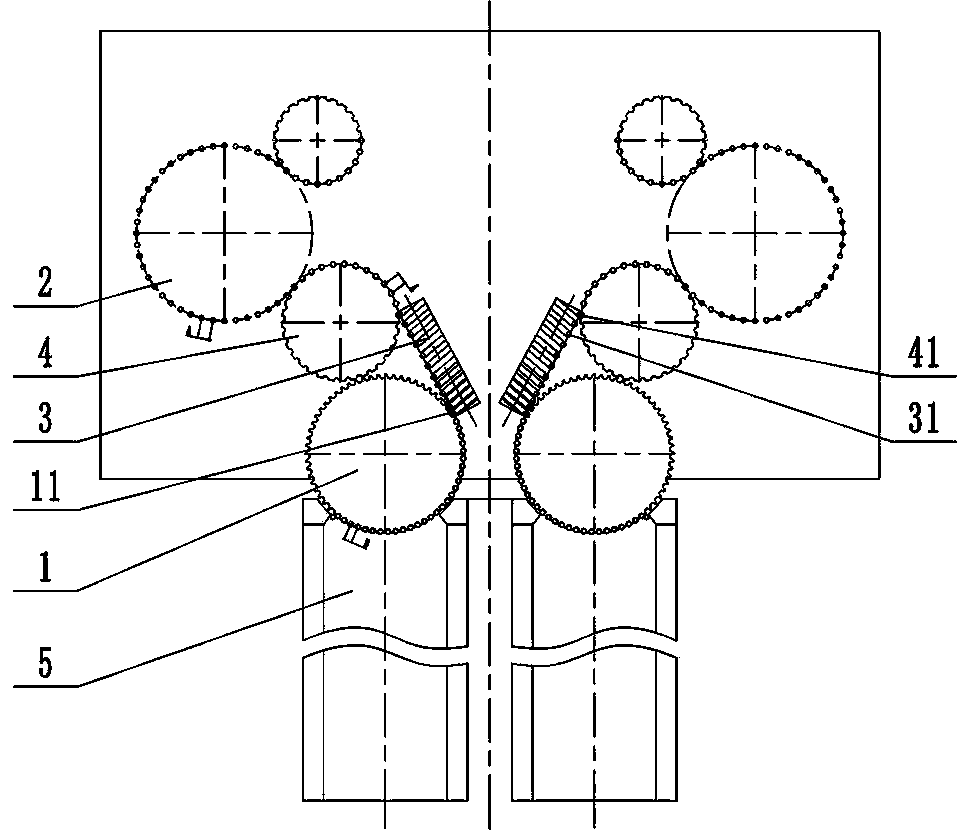

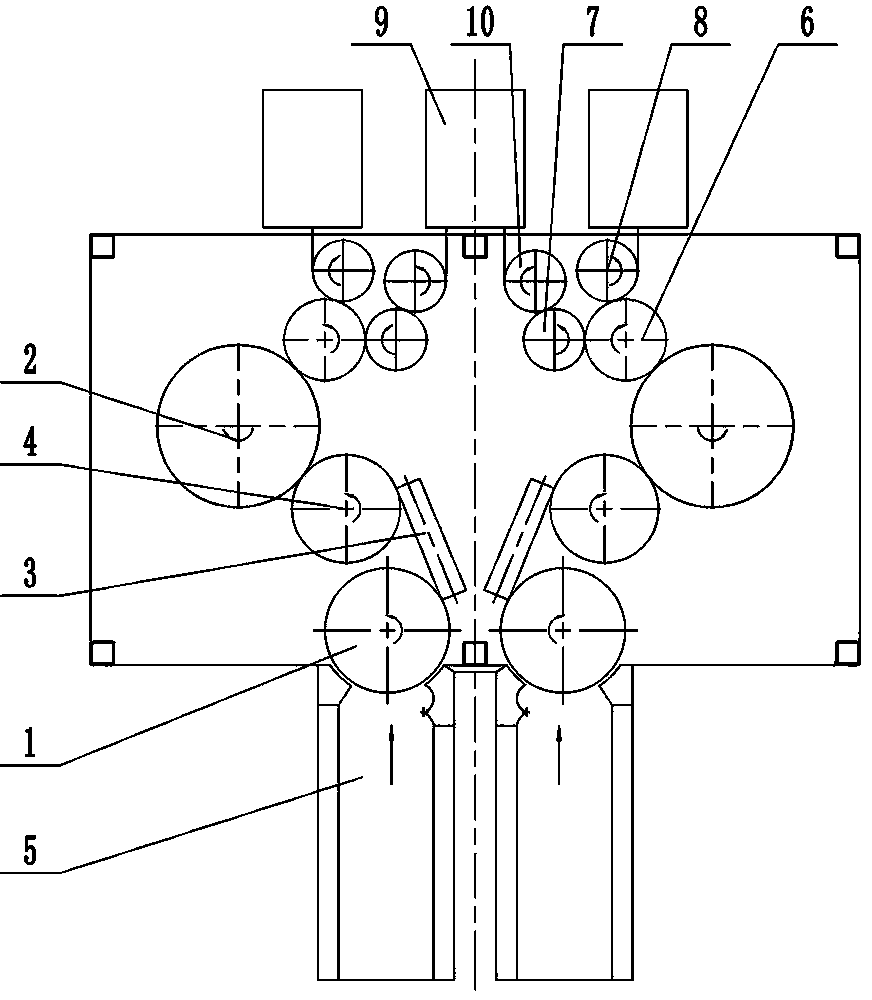

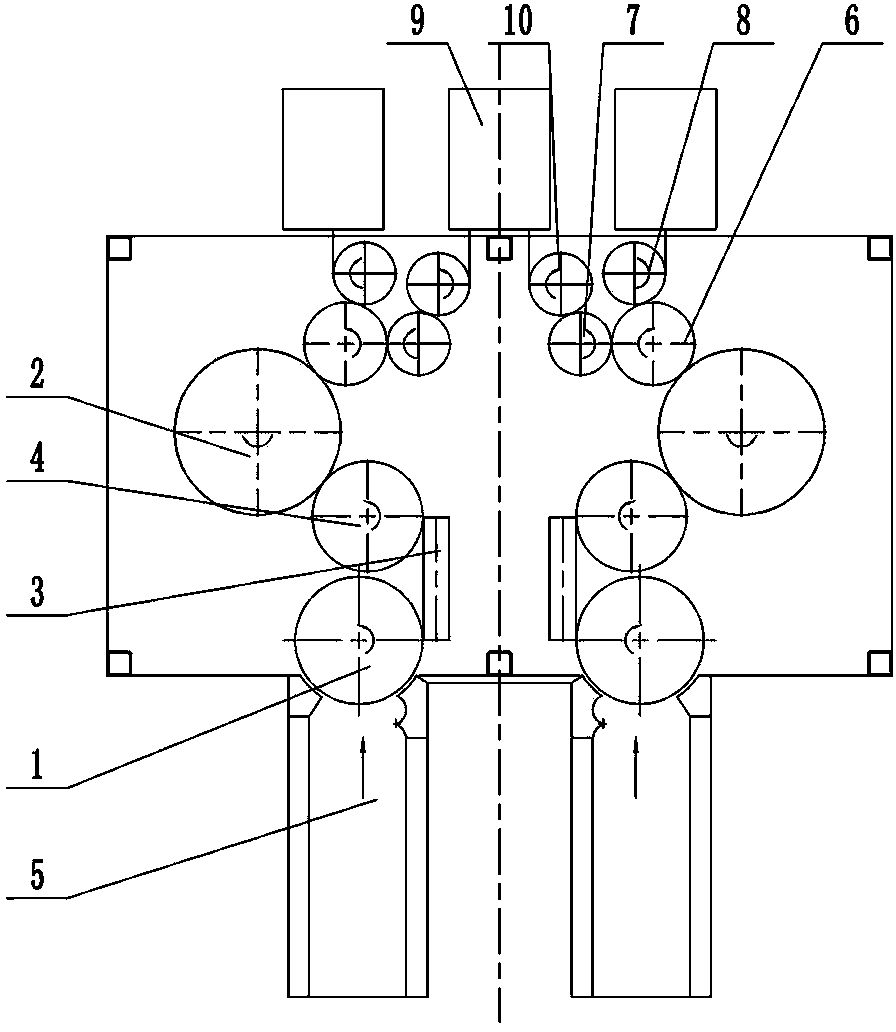

Controllable mechanism type fine-adjusting welding robot with multiple degrees of spatial freedom

ActiveCN103737578AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesControl engineeringMachine

A controllable mechanism type fine-adjusting welding robot with multiple degrees of spatial freedom comprises three controllable fine-adjusting four-rod mechanism closed-loop subchains connected in parallel and an execution mechanism subchain in series connection. The four-rod mechanism closed-loop subchains can control a first connecting rod to move in the plane where the four-rod mechanism closed-loop subchains are located, and the spatial movement of a platform can be achieved through the movement of parallel connecting rods and a machine body. The spatial movement of a tail end executor can be controlled through the resultant movement of the three closed-loop subchains and the machine body, the movement inertia of the tail end executor is small, dynamics performance is good, reliability is high, the mechanism has the advantages of being compact in structure and easy to control, the connecting rods are used for control, rod pieces can be made into light rods, the work space of the mechanism is large, the gravity of the mechanism moves backwards, the mechanism is kept balanced, and the mechanism can act on more occasions.

Owner:GUANGXI UNIV

Controllable multi-degree of freedom welding robot

InactiveCN103707289AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopEngineering

A controllable multi-degree of freedom welding robot comprises four controllable four-link-mechanism closed-loop executing mechanism subchains which are in parallel connection and an executing main chain in series connection. A main chain connecting rod can be controlled by the controllable four-link-mechanism closed-loop executing mechanism subchain to move within the surface with the controllable four-link-mechanism closed-loop executing mechanism subchains. The spatial motion of a moving platform can be achieved by the motion of a first connecting rod and a body. According to this arrangement, the spatial motion of an end effector can be achieved, motion inertia is small, dynamics performance is good and reliability is high. The controllable multi-degree of freedom welding robot has the advantages of being compact in structure and easy to control. The rods can be made as light rods, work spaces for mechanisms are large, gravity centers of the mechanisms are moved backwards to keep balance. The controllable multi-degree of freedom welding robot can be widely used.

Owner:GUANGXI UNIV

Multi-degree of freedom parallel mechanism type spot welding robot

InactiveCN104096998AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopDegrees of freedom

The invention discloses a multi-degree of freedom parallel mechanism type spot welding robot. A frame, a body, a first connecting rod, a second connecting rod, a third connecting rod, a fourth connecting rod, a fifth connecting rod, a sixth connecting rod, a seventh connecting rod, an eighth connecting rod, a ninth connecting rod, a tenth connecting rod, an eleventh connecting rod, a twelfth connecting rod and an end effector are connected into four controlled four-link mechanism closed loop actuator subchains which are connected in parallel and an actuator main chain which is connected in series; the subchains control the connecting rods of the main chain to move in the plane in which the subchains are positioned; the spatial motion of a platform is realized through the movement of the first connecting rod and the body. According to the spot welding robot, the control is realized through resultant motion of the four closed loop subchains and the body, the spatial motion of the end effector is realized through the connection between the multiple connecting rods and the body, the effector is higher in flexibility, and the work space is larger than that of the conventional robot; moreover, the connecting rods with hinges can be made into light rods, so that the whole mechanism is higher in dynamic performance and easy to control.

Owner:GUANGXI UNIV

Endoscope manipulator for minimally invasive surgery

Endoscope manipulator for MIS can overcome disadvantages of multiaxial endoscope manipulator including conventional robot arm and provide compact and lightweight structure to obtain maximum activity space for medical staff. According to the endoscope manipulator for MIS, multi-joint arm is configured so that movement of all of the joints from base link to tip link is manually locked and unlocked by user and not controlled by motors. Additionally, endoscope mounted on an end of multi-joint arm is manipulated using motors to enable movement of three degrees of freedom, thereby accomplishing compact and lightweight endoscope manipulator. Additionally, tube of endoscope can be press-fitted onto tip part of multi-joint arm, and triaxial movement function for vertical, horizontal and forward / backward conveyance of endoscope is implemented in the tip part of multi-joint arm. Therefore, since external manual joints are not moved during operation, Disturbance or restriction to activities of medical staff can be minimized.

Owner:NAT CANCER CENT

Multi-degree-of-freedom palletizing robot

InactiveCN103707288AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorStacking articlesEngineeringMulti degree of freedom

The invention discloses a multi-degree-of-freedom palletizing robot. The palletizing robot comprises a plurality of parallel mechanism closed-loop executing mechanism branch chains and a serial executing mechanism main chain. The mechanism closed-loop branch chains can be used for controlling a main chain connecting rod to move in a plane where a four-rod mechanism closed-loop branch chain is positioned, and spatial movement of a movable platform can be realized via movement of a plurality of parallel connecting rod branch chains and a machine body. Control is realized via composite motion of four closed-loop branch chains and the machine body, and a plurality of connecting rods are connected with the machine body, thereby realizing spatial movement of a tail end executer, small motion inertia of the tail end executer, high dynamics performance and high reliability. The mechanism has the advantages of compact structure and easiness in controlling. Rod pieces can be designed as light rods, the working space of the mechanism is large, and the gravity center of the mechanism is moved backward, thereby keeping the mechanism in a balanced state, and allowing the palletizing robot to be applied to more occasions.

Owner:GUANGXI UNIV

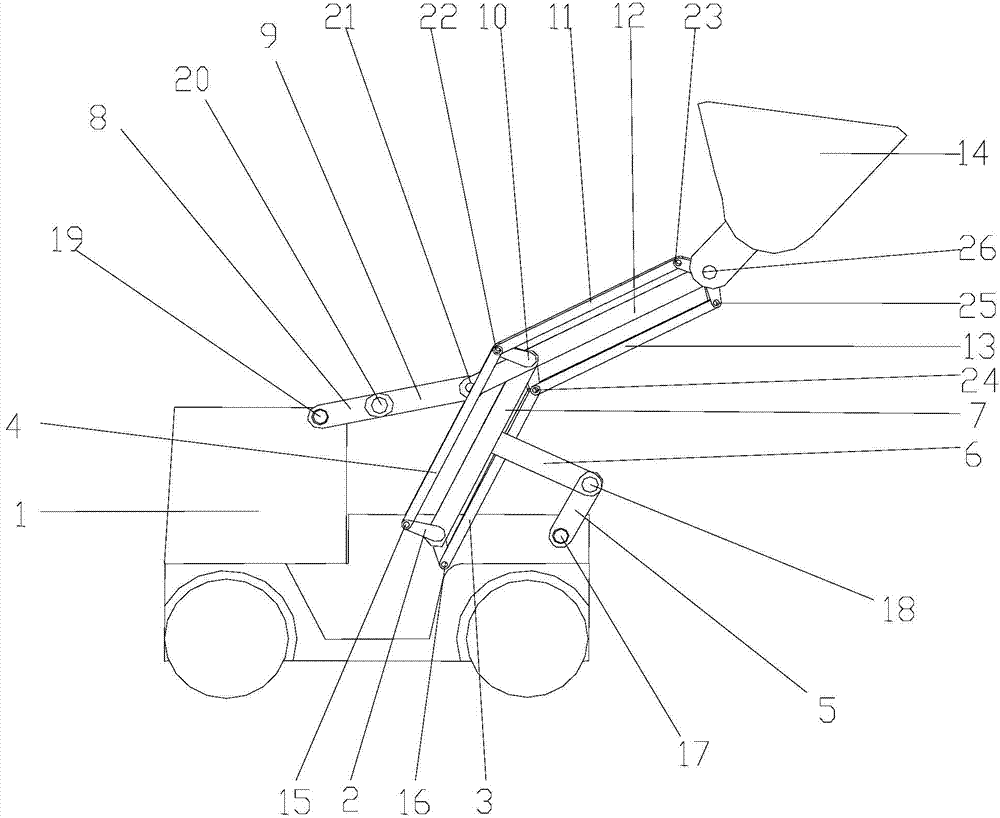

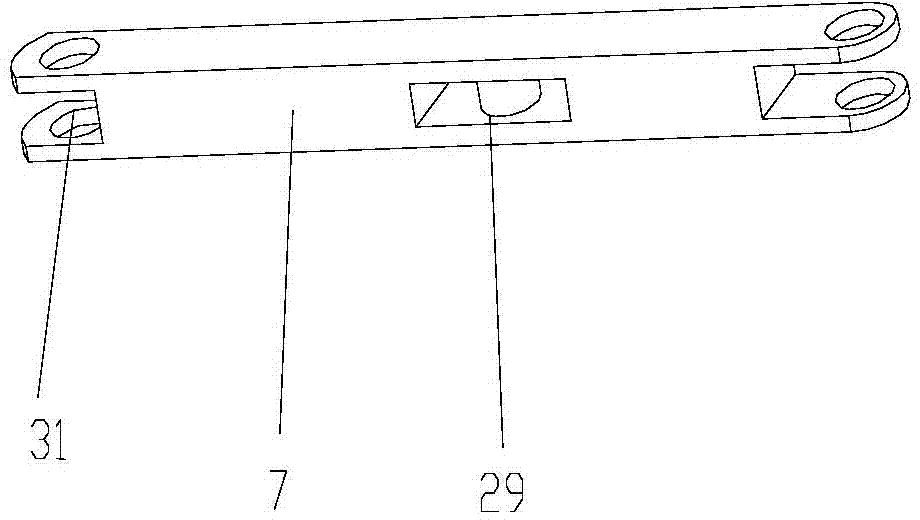

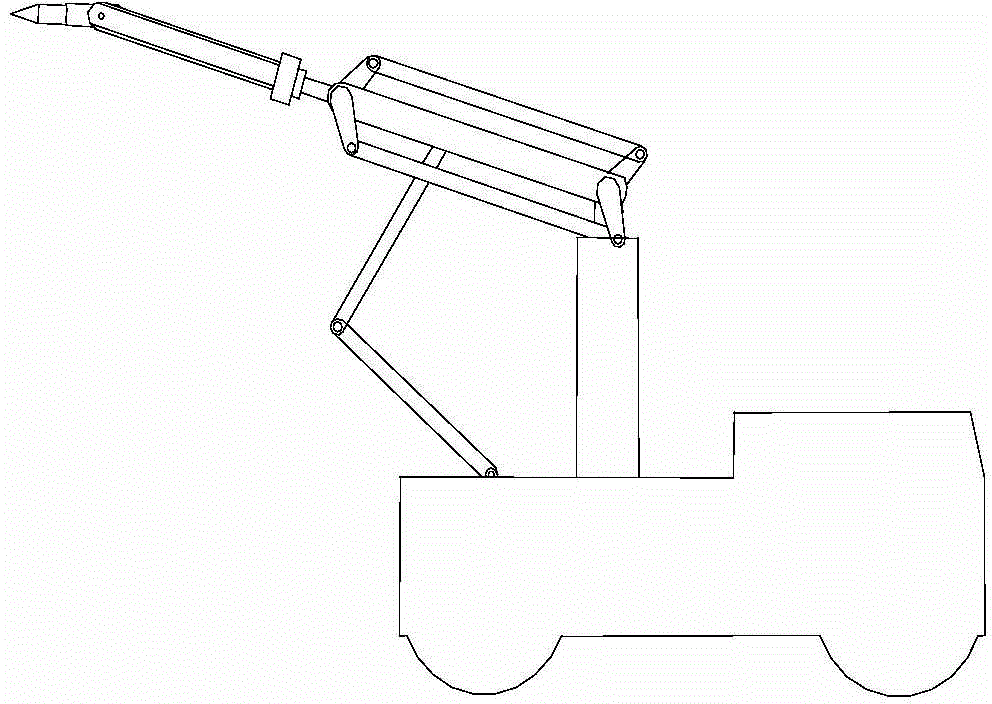

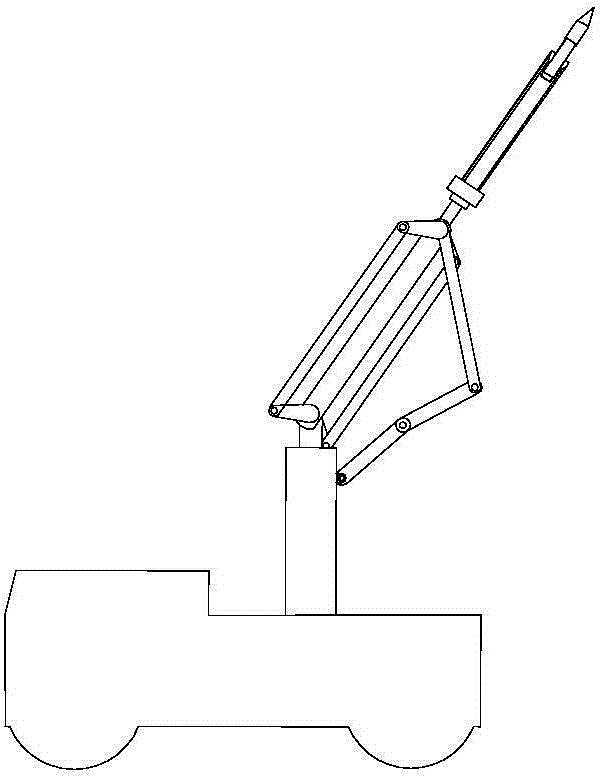

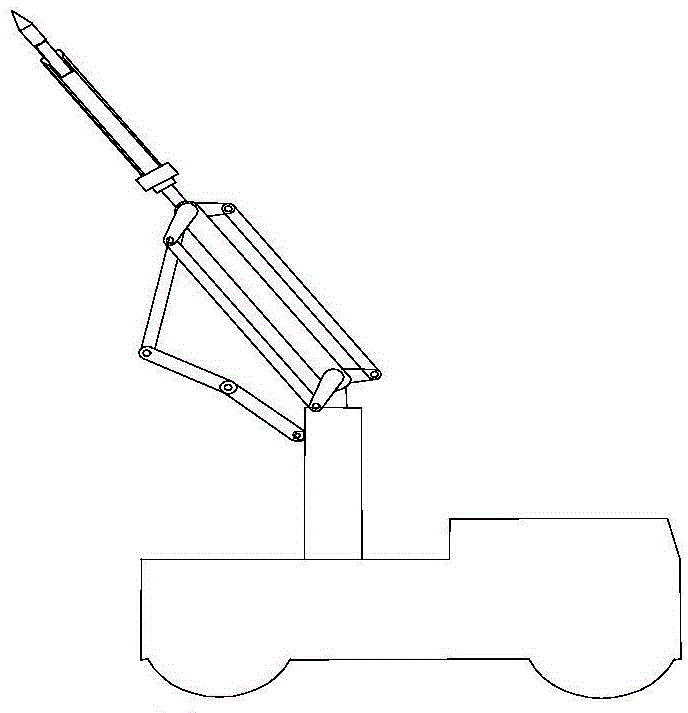

Controllable symmetrical-and-parallel mechanism type loader

InactiveCN103726532AIncrease stiffnessIncrease workspaceMechanical machines/dredgersMechanical reliabilityClosed loop

A controllable symmetrical-and-parallel mechanism type loader comprises a main actuator chain with a closed-loop subchain and two parallel actuator subchains. The main actuator chain with the closed-loop subchain can control plane motion of a bucket space of a plane where main arm bars are located, and the actuator subchains perform controllable regulation on the bucket and control motions of turning up and down and the like of the bucket. The controllable symmetrical-and-parallel mechanism type loader has the advantages that plane control can be realized through the synthetic motions of the main actuator chain with the closed-loop subchain, and the spatial motion of the bucket is realized through connection of the actuator subchains; the bucket space is good in dynamics performance, large in working space, good in balance performance, high in mechanical reliability, compact in mechanism and simple to control; the member bars can be made into light bars acting on more occasions; the loader is driven fully electrically and free of emissions and noise pollution.

Owner:GUANGXI UNIV

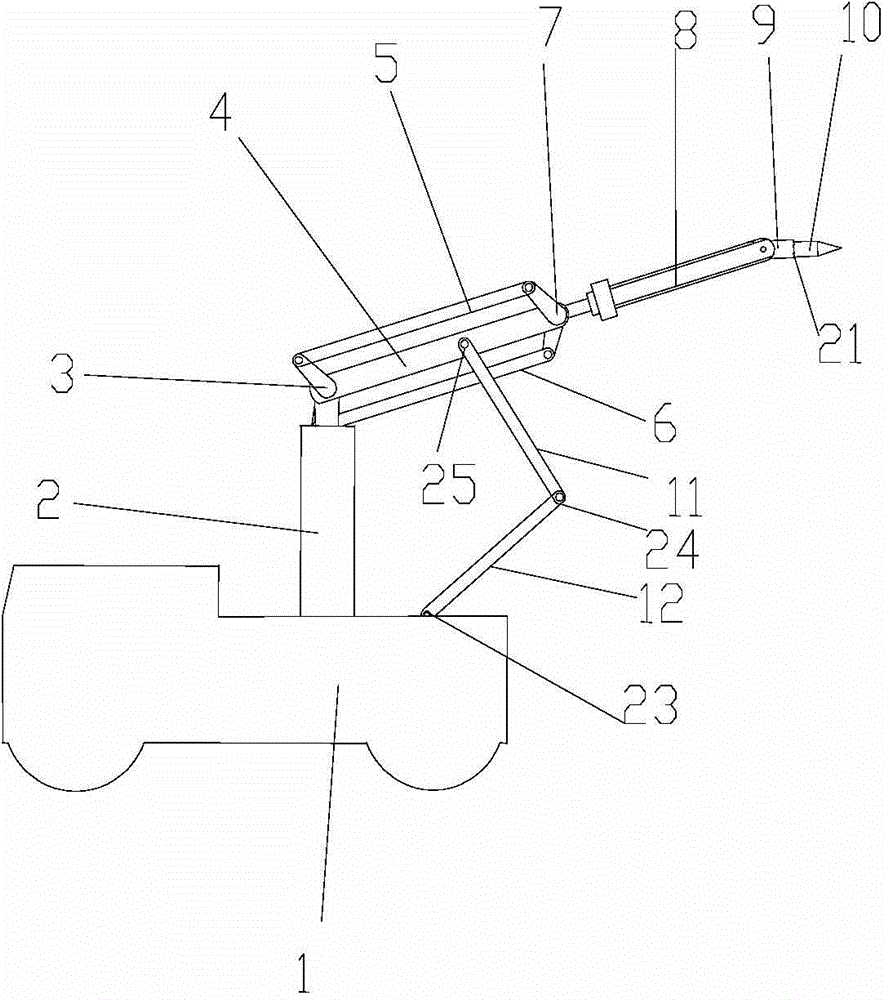

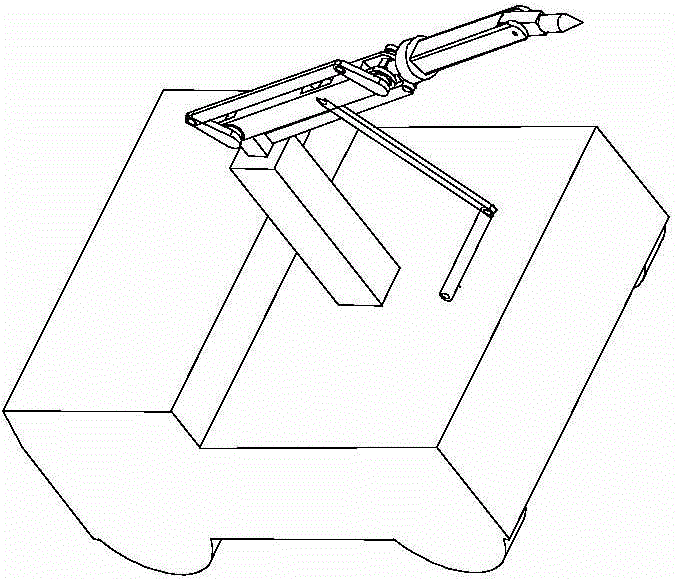

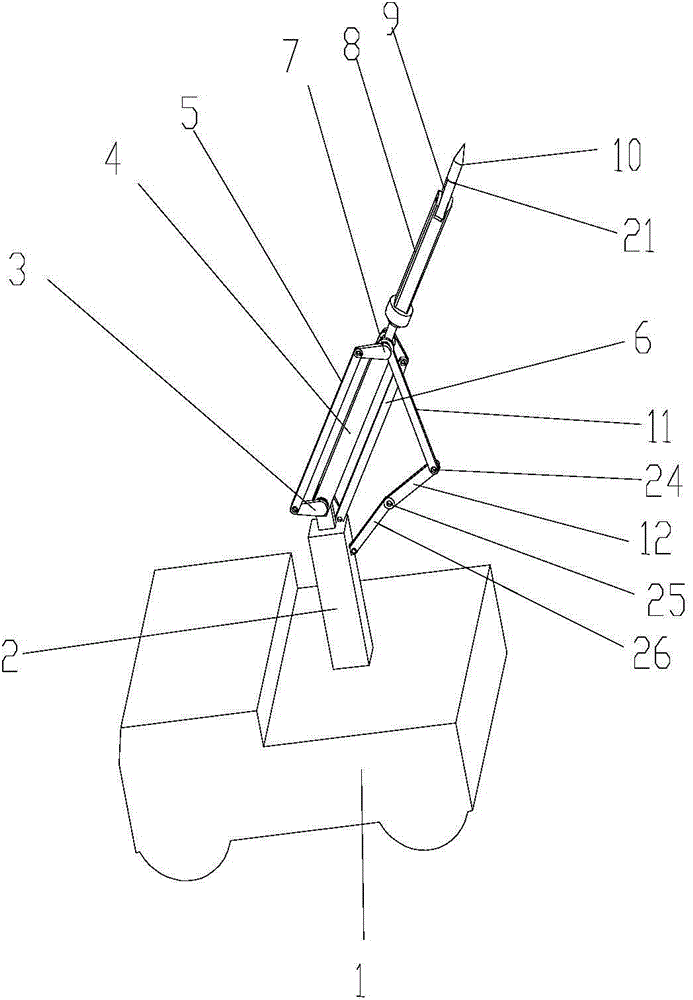

Multi-degree-of-freedom controllable mechanism type moving welding robot

InactiveCN104552248AAvoid dead center positionImprove balanceProgramme-controlled manipulatorWelding/cutting auxillary devicesMulti degree of freedomEngineering

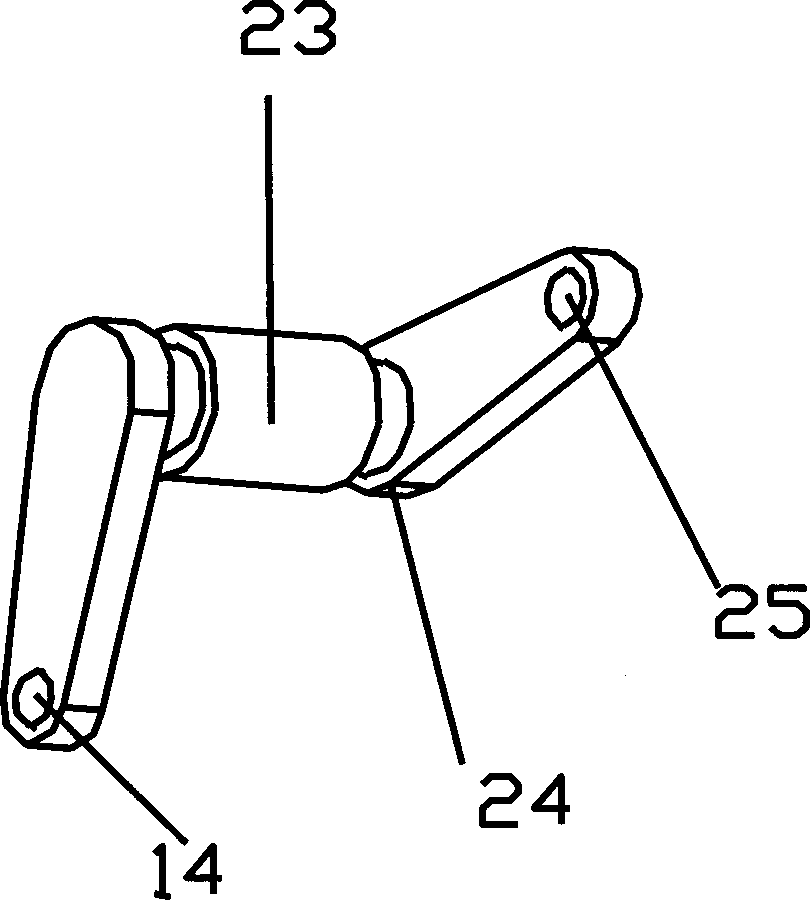

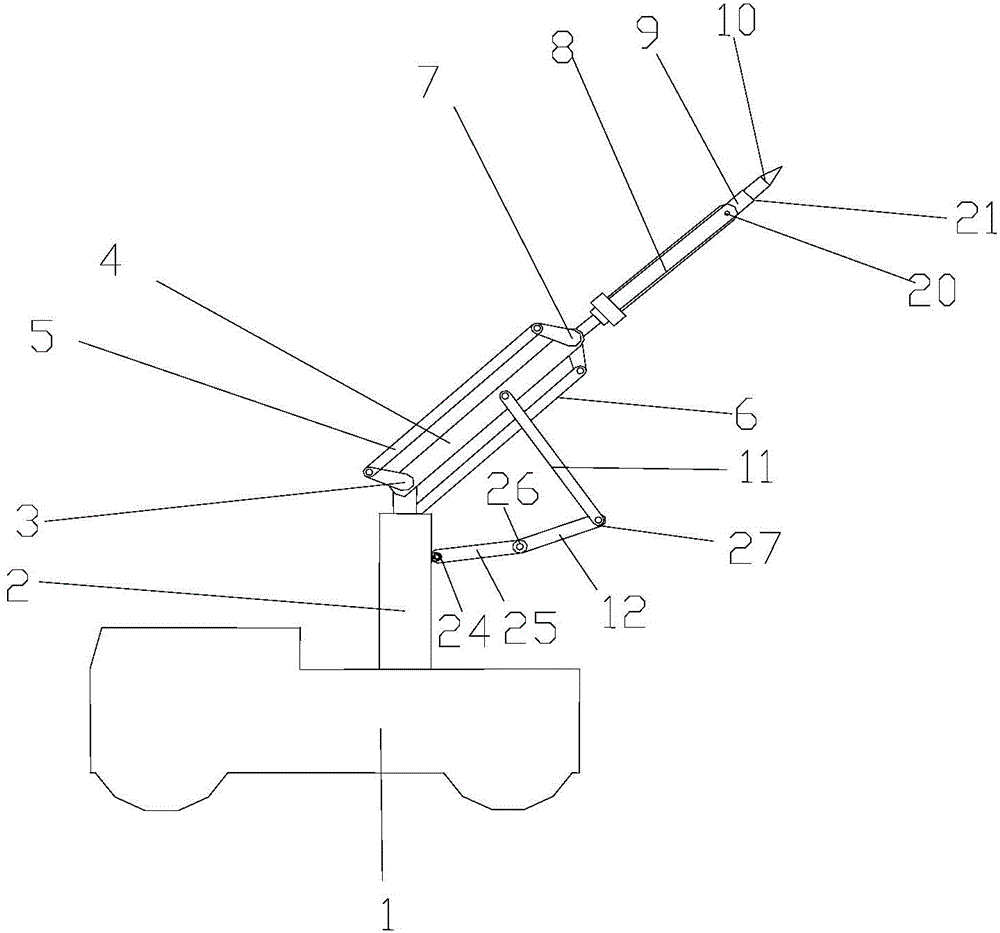

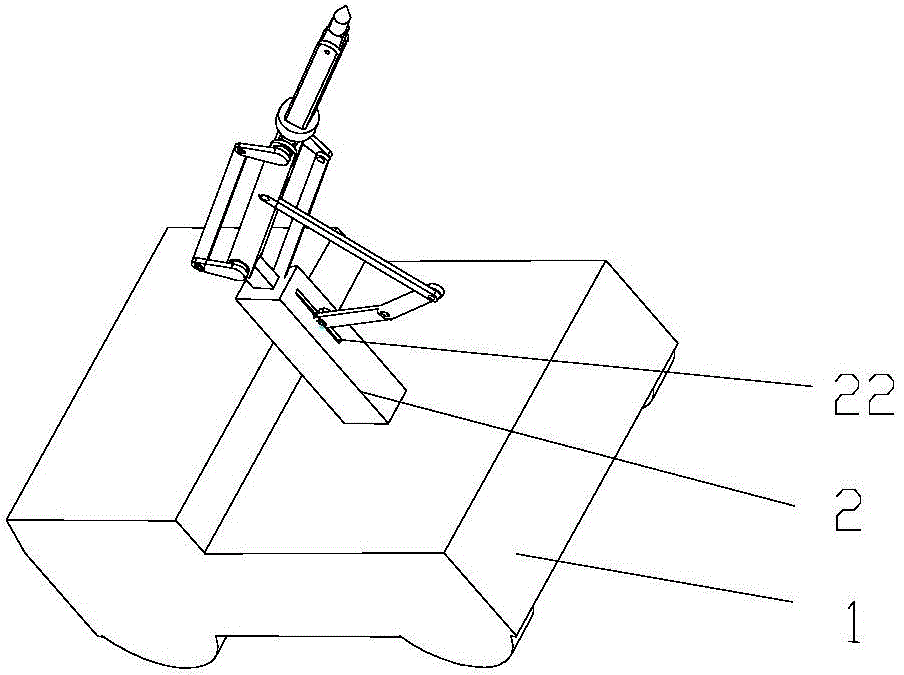

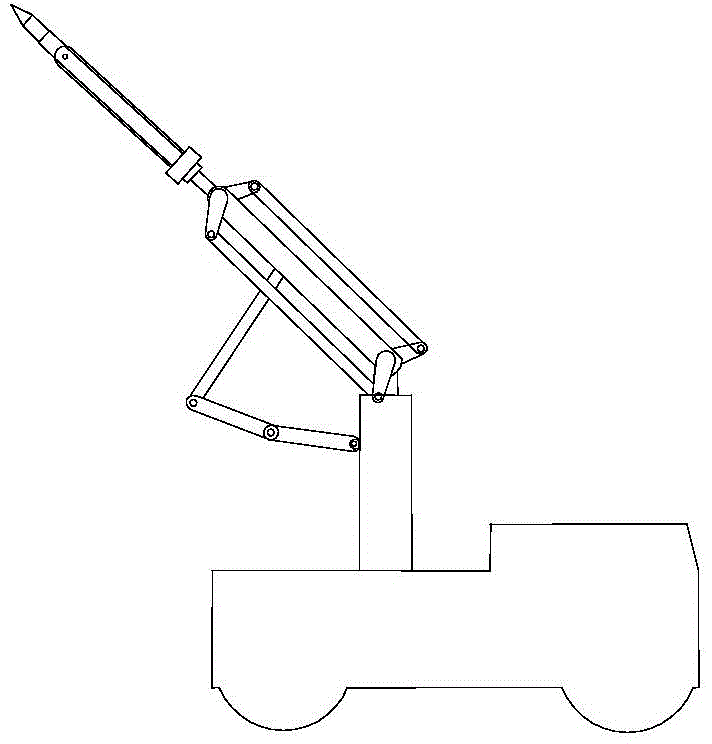

The invention discloses a multi-degree-of-freedom controllable mechanism type moving welding robot. One end of a stand column is connected with a vehicle body; the other end of the stand column is respectively connected with one end of a main arm and the first connection end of a first rocker arm; the second connection end of the first rocker arm is connected with one end of a first connecting rod; the other end of the first connecting rod is connected with the second connection end of a second rocker arm; the first connection end of the second rocker arm is connected with the other end of the main arm; the third connection end of the second rocker arm is connected with one end of a second connecting rod; the other end of the second connecting rod is connected with the third connection end of the first rocker arm; one end of a third connecting rod is connected with the fourth connection end of the second rocker arm; the other end of the third connecting rod is connected with one end of a fourth connecting rod; the other end of the fourth connecting rod is connected with a tail end welding executor; one end of a sliding block is connected with the stand column via a moving pair; the other end of the sliding block is connected with a fifth connecting rod; the fifth connecting rod, a sixth connecting rod, a seventh connecting rod and the third connection end of the main arm are successively connected. The multi-degree-of-freedom controllable mechanism type moving welding robot has the advantages of large working space, high rigidity, high bearing capability and high execution precision.

Owner:GUANGXI UNIV

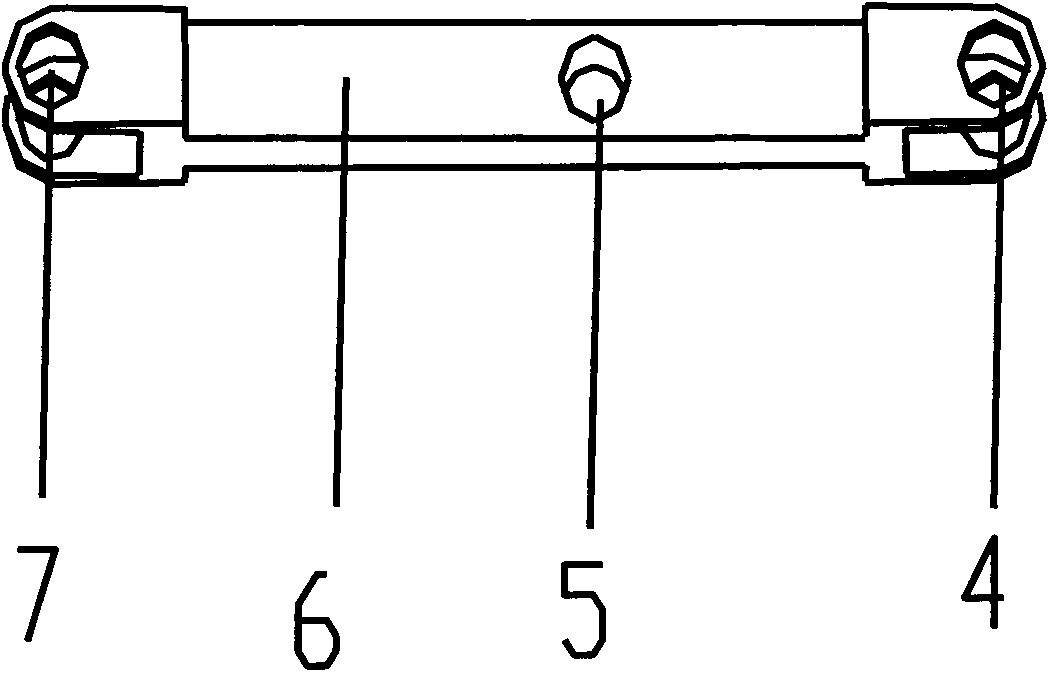

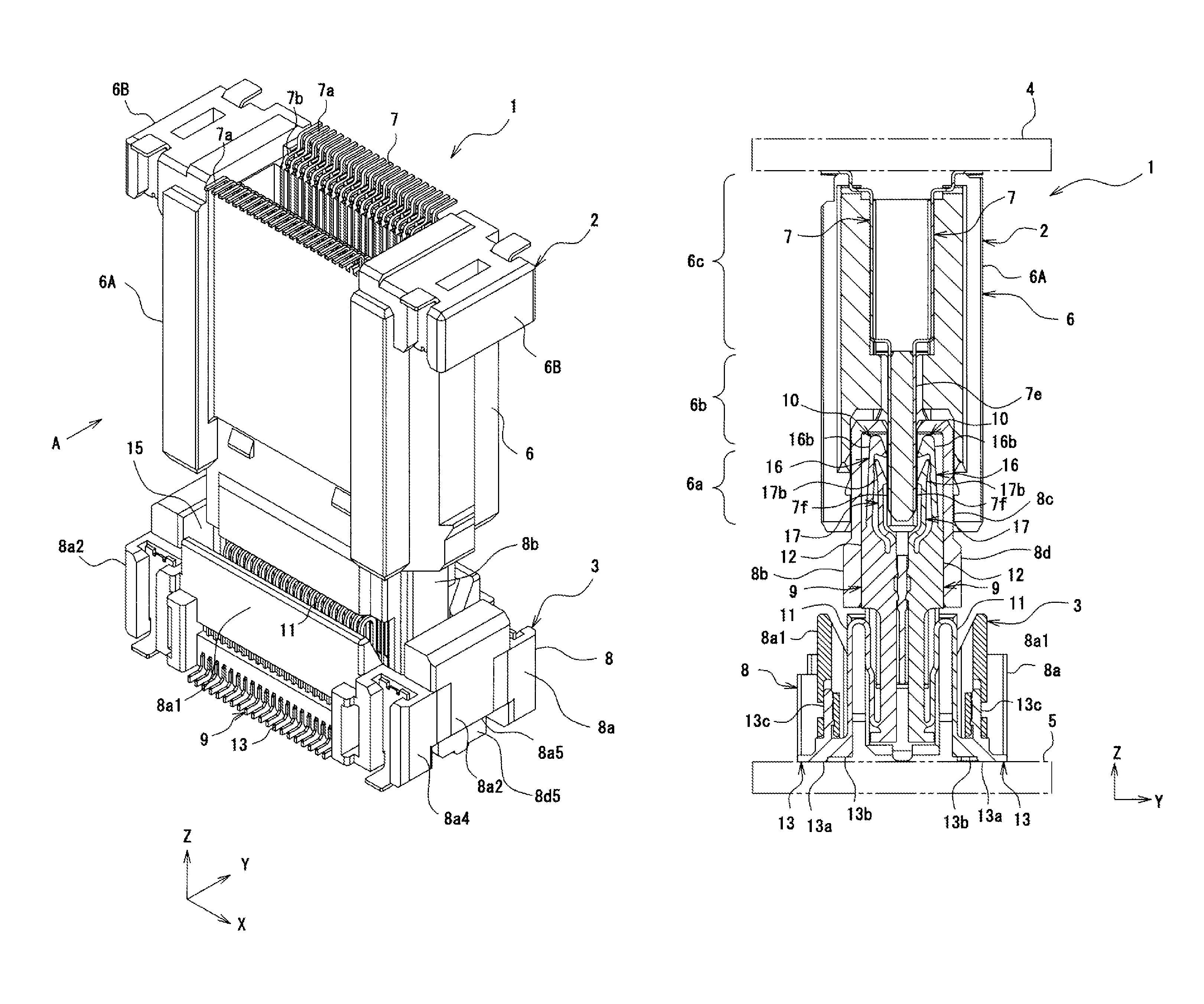

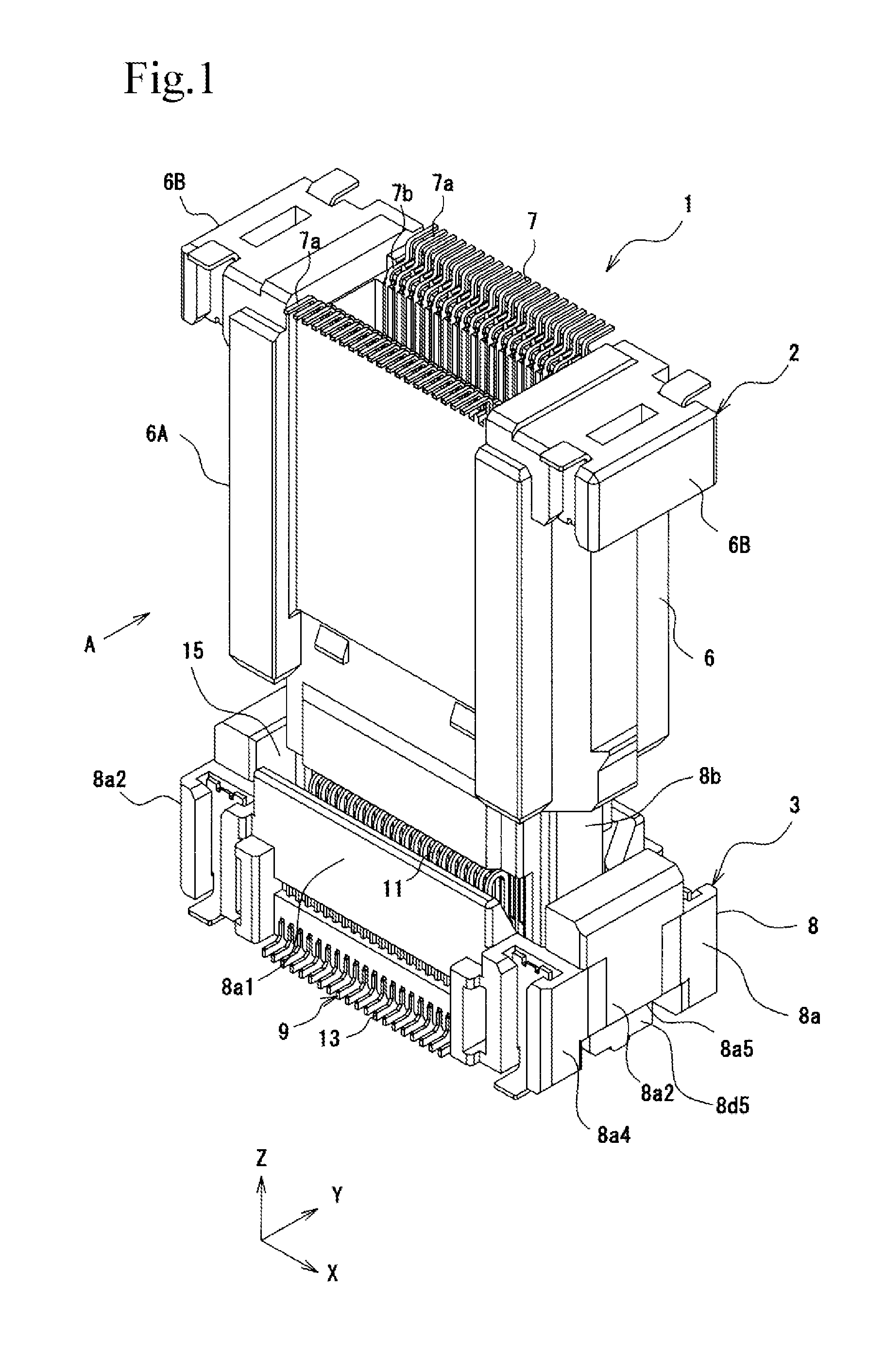

Connector Terminal and Electrical Connector

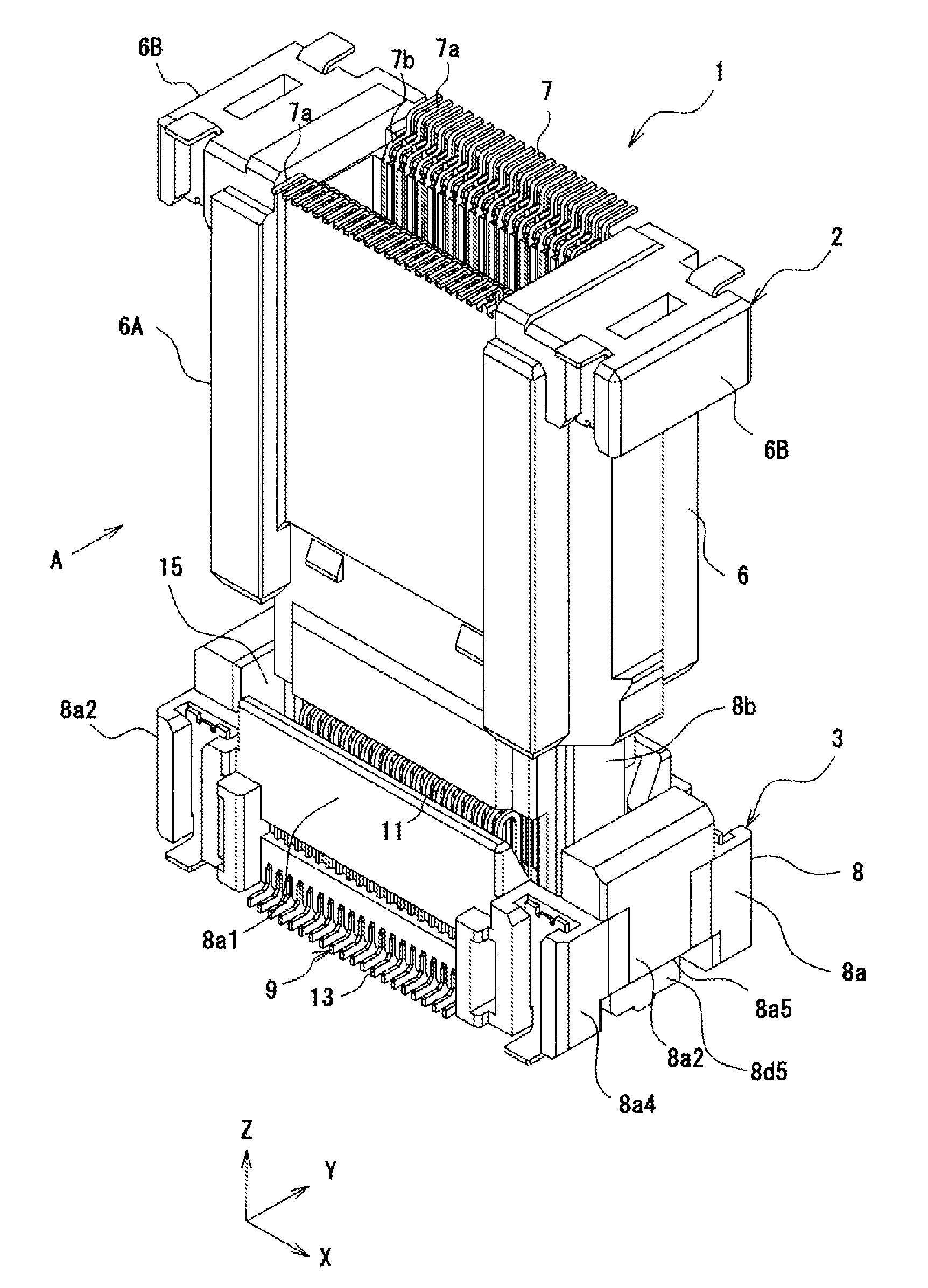

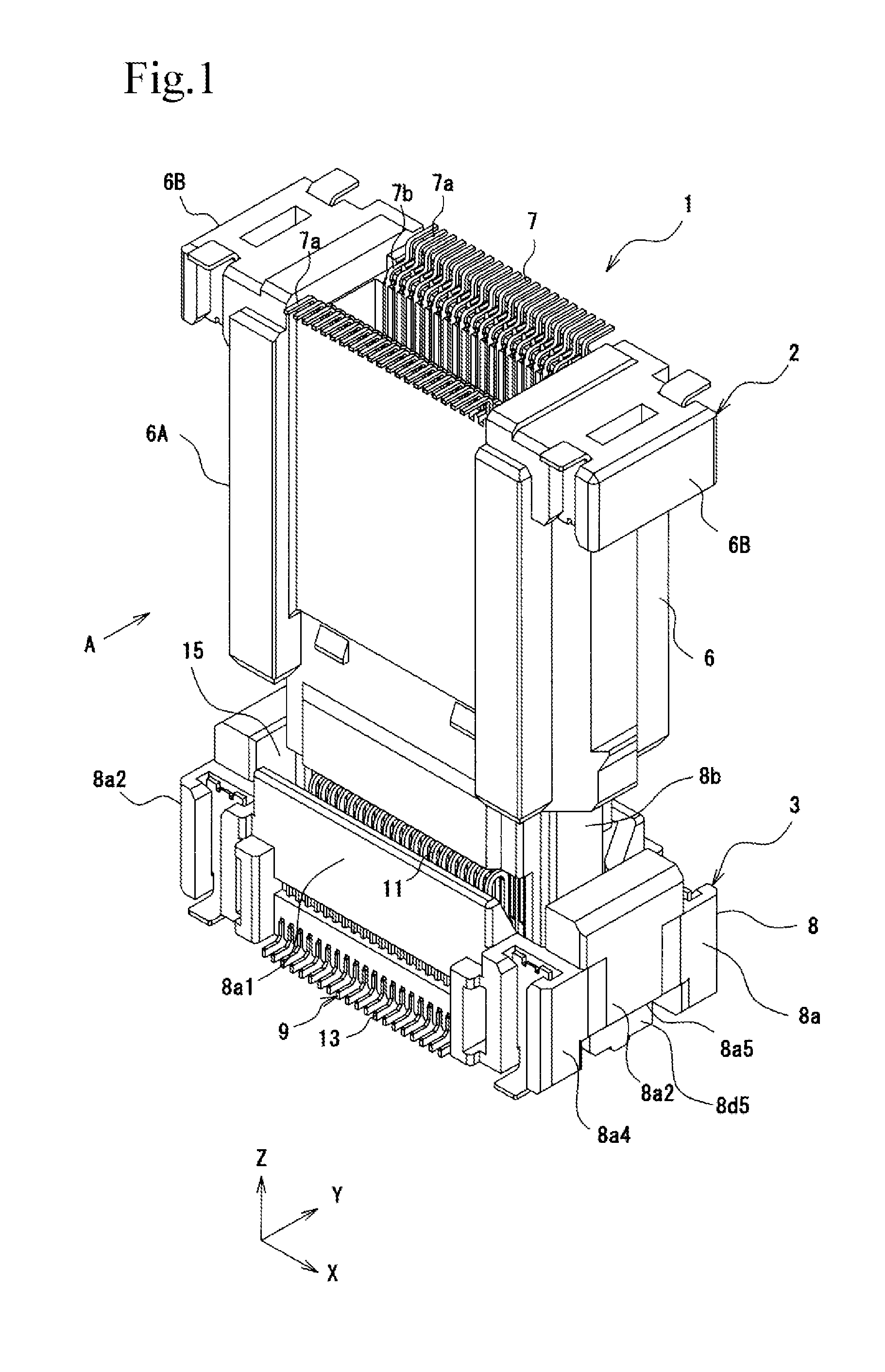

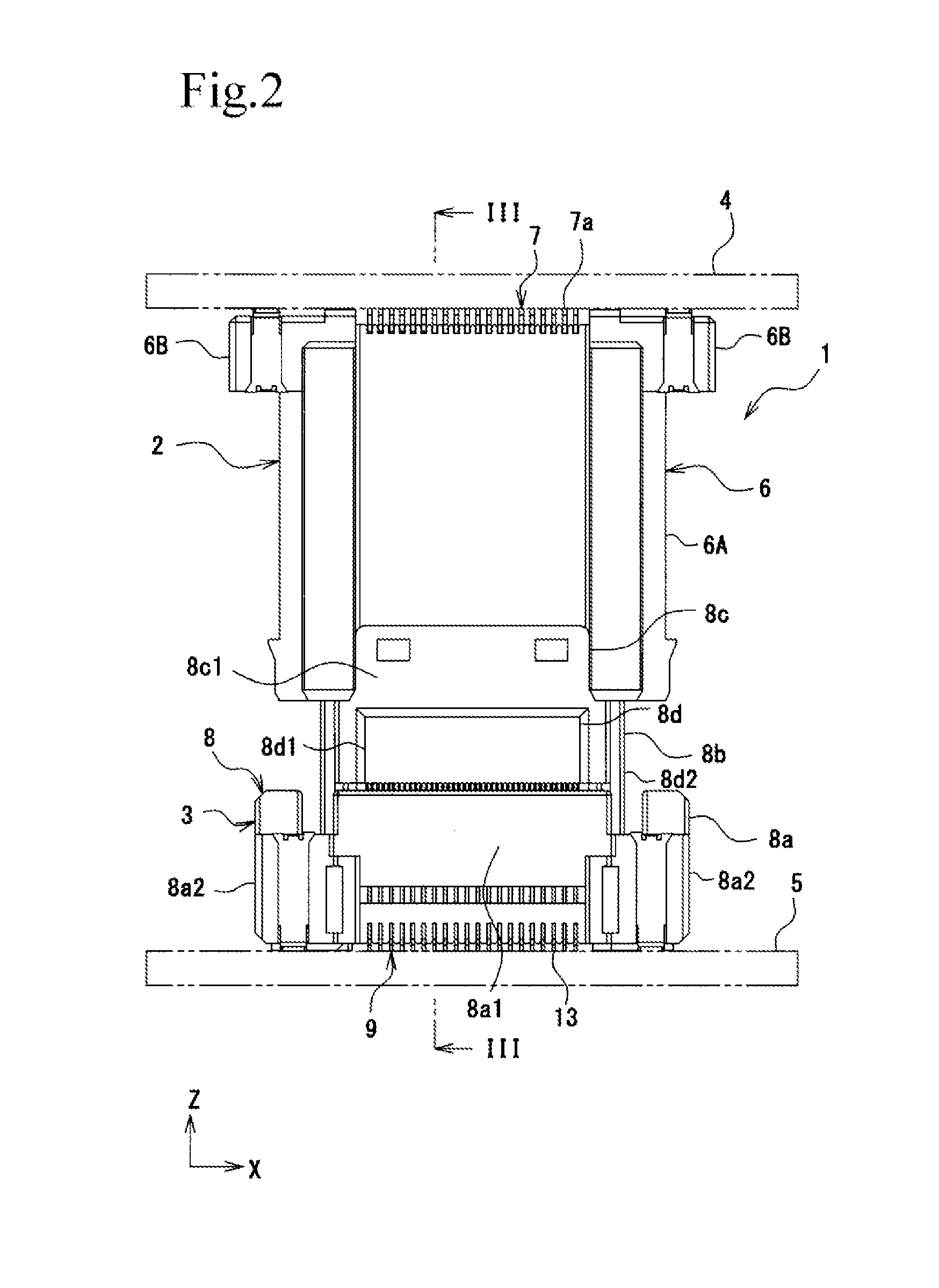

ActiveUS20150132999A1High densityElectrical size reductionCoupling device detailsTwo-part coupling devicesElectrical connectorMechanical engineering

A socket terminal includes a movable portion that includes a first extension that extends from a position near a fixed housing in an insertion / extraction direction of a plug connector, a hairpin portion that is continuous with the first extension, and a second extension that is continuous with the hairpin portion and that extends in the insertion / extraction direction toward a movable housing. The movable portion elastically supports the movable housing in such a way that the movable housing is displaceable relative to the fixed housing. The second extension of the movable portion includes a spring portion that is bent in such a way that the width of a gap between the second extension and a base at one end portion of the second extension continuous with the hairpin portion is larger than that at the other end portion of the second extension continuous with the base.

Owner:IRISO ELECTRONICS CO LTD

Multi-degree-of-freedom parallel-mechanism type controllable welding robot

ActiveCN103722553AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopMulti degree of freedom

A multi-degree-of-freedom parallel-mechanism type controllable welding robot comprises multiple parallel-mechanism closed-loop actuator subchains and a serially-connected main actuator chain, the mechanism closed-loop subchains can control main chain connecting bars to move in a plane of the four-bar mechanism closed-loop subchains, and spatial movement of a moving platform can be realized by movement of multiple parallel connecting bar subchains and a body. Control is realized through resultant movement of the four closed-loop subchains and the body, spatial movement of an end actuator is realized through connection of multiple connecting bars and the body, the end actuator is small in movement inertia, good in dynamics performance and high in reliability, the robot has the advantages of compact structure and simplicity in control, the bars can be made to light bars, the robot is large in working space, center of gravity of the robot shifts backwards to keep the robot in balance, and the robot can act to more situations.

Owner:GUANGXI UNIV

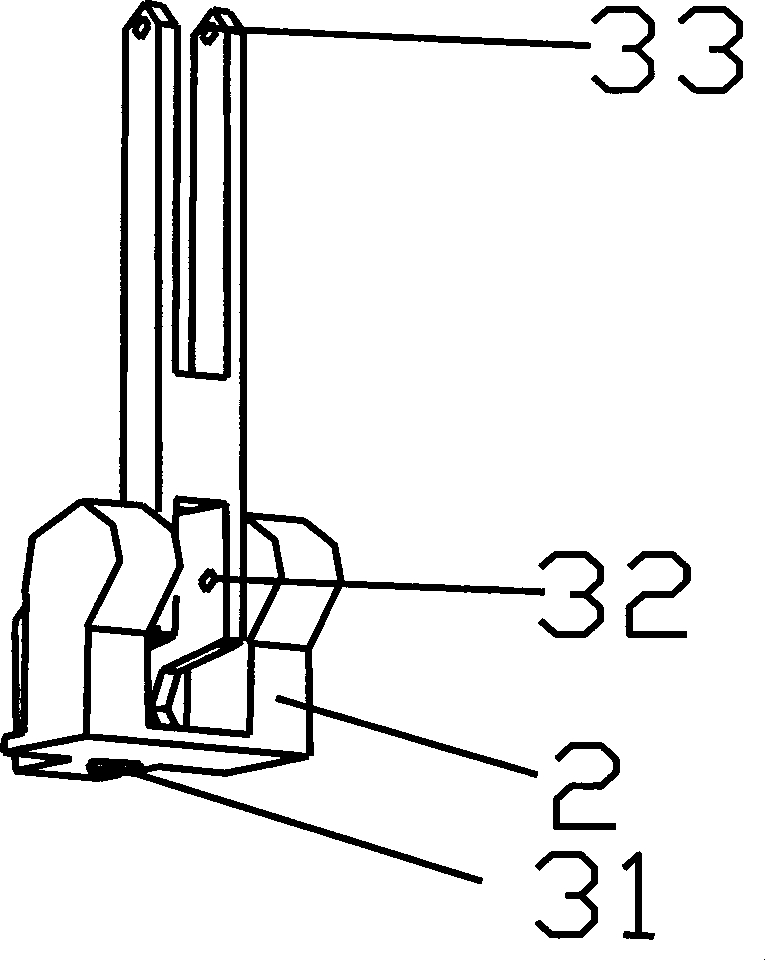

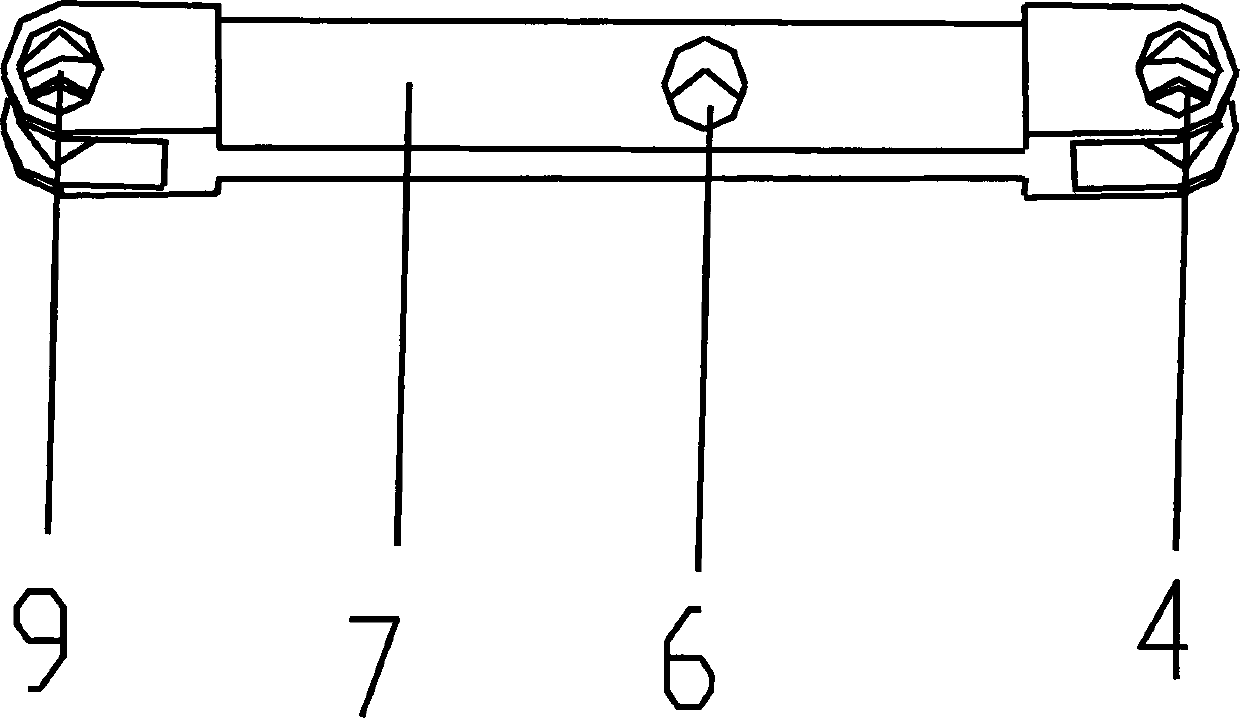

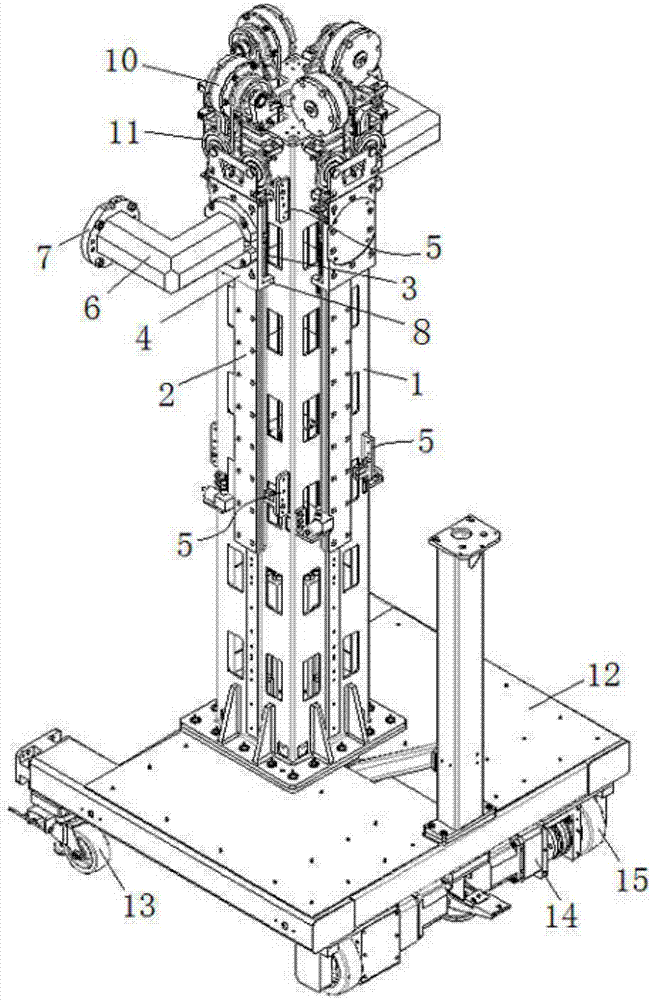

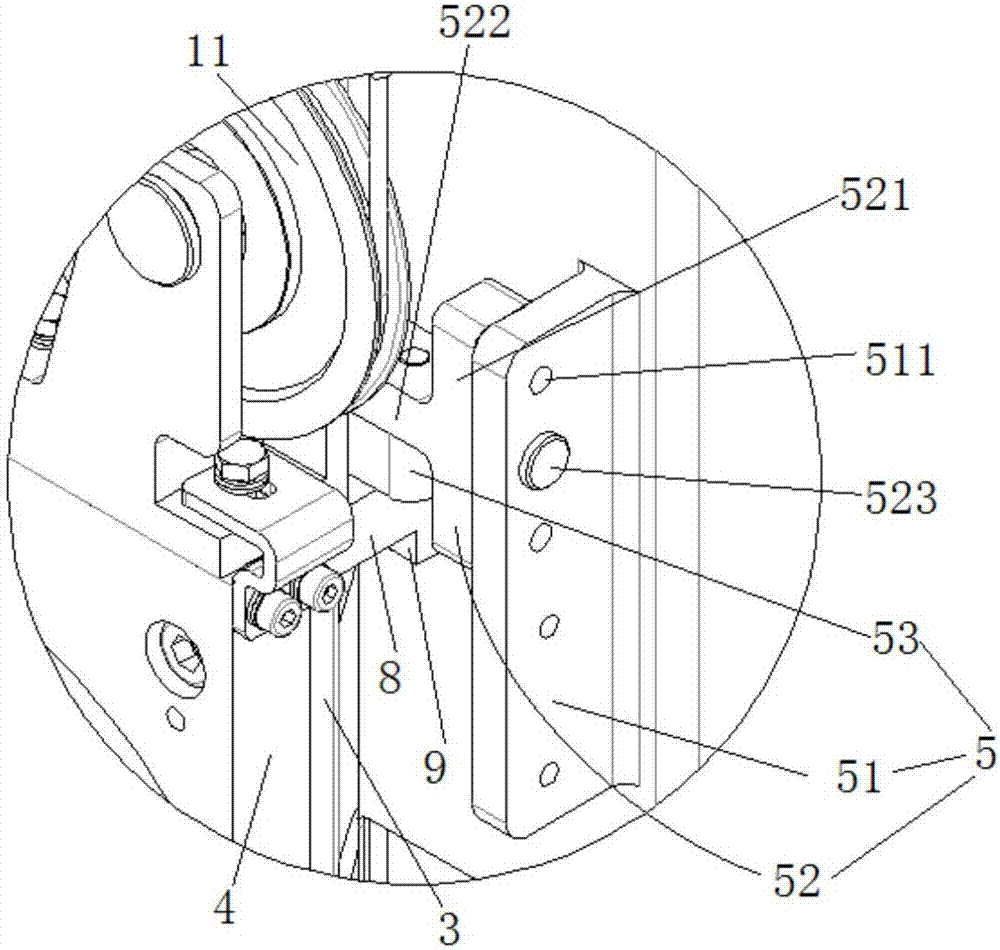

Mechanical arm connecting device for surgical robot and surgical robot

ActiveCN107260308AWide range of activitiesLarge space for activitiesSurgical manipulatorsSurgical robotsSurgical robotEngineering

The invention relates to a surgical robot and a mechanical arm connecting device for the surgical robot. The mechanical arm connecting device comprises a first pipe section and a second pipe section. The center axis of the first pipe section is perpendicular to the center axis of the second pipe section. A first flange plate is arranged at one end of the first pipe section, the other end of the first pipe section is perpendicularly connected with one end of the second pipe section, and a second flange plate is arranged at the other end of the second pipe section. The first flange plate is connected with a stand column of the surgical robot. The second flange plate is connected with a mechanical arm of the surgical robot. The mechanical arm connecting device allows the mechanical arm to move forwards, leftwards and rightwards within a wider range and larger space, and facilitates positioning of the mechanical arm before surgery, so that larger surgical space can be obtained. Mechanical arms can be installed on all four sides of the stand column, both independent use of one mechanical arm and simultaneous use of two, three or four mechanical arms can be achieved, and surgical requirements with different installation demands are met through various combinations of mechanical arms in different positions.

Owner:CHENGDU BORNS MEDICAL ROBOTICS INC

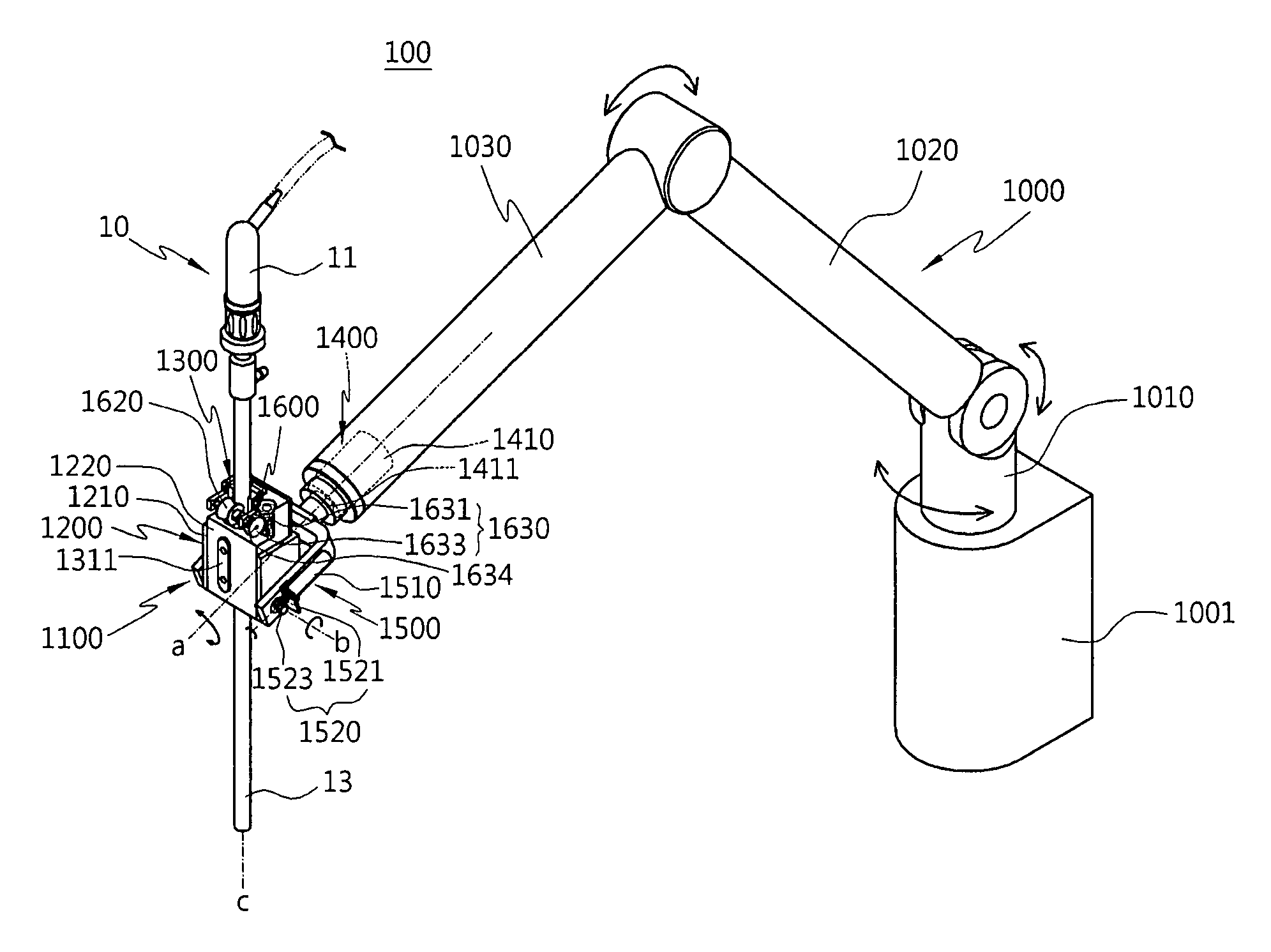

Endoscope manipulator for minimally invasive surgery

InactiveUS8425403B2Large space for activitiesSurgeryEndoscopesLess invasive surgeryThree degrees of freedom

Endoscope manipulator for MIS can overcome disadvantages of multiaxial endoscope manipulator including conventional robot arm and provide compact and lightweight structure to obtain maximum activity space for medical staff. According to the endoscope manipulator for MIS, multi-joint arm is configured so that movement of all of the joints from base link to tip link is manually locked and unlocked by user and not controlled by motors. Additionally, endoscope mounted on an end of multi-joint arm is manipulated using motors to enable movement of three degrees of freedom, thereby accomplishing compact and lightweight endoscope manipulator. Additionally, tube of endoscope can be press-fitted onto tip part of multi-joint arm, and triaxial movement function for vertical, horizontal and forward / backward conveyance of endoscope is implemented in the tip part of multi-joint arm. Therefore, since external manual joints are not moved during operation, Disturbance or restriction to activities of medical staff can be minimized.

Owner:NAT CANCER CENT

Large-working-space multi-degree-of-freedom controllable mechanism-type shovel-loading integrated transport car

ActiveCN103693340ASimple loading and transportation processReduce workloadRefuse vehiclesNoise pollutionSpatial movement

The invention relates to a large-working-space multi-degree-of-freedom controllable mechanism-type shovel-loading integrated transport car, which comprises two actuation mechanism subchains which are connected with each other in parallel. Two main arm rods can be controlled by the two parallelly connected actuating mechanism subchains to make plane motion in a bucket space of the plane on which the two main arm rods stay, a bucket is controllably adjusted by the actuation mechanism subchains, and the bucket is controlled by the actuation mechanism subchains to turn upwards and downwards. The plane control is realized through the synthesis motion of an actuation mechanism chain comprising a closed-loop subchain, the space motion of the bucket is realized through the connection with the two symmetric and parallelly connected subchains, the dynamics performance of the bucket space is good, the working space is large, the balance property is good, the mechanism reliability is high, the advantages such as compact structure and simplicity in control can be realized, a rod piece can be made into a light rod, so that the transport car can run forwards and backwards, can unload the material forwards and backwards, can be applied to more fields, is completely driven by the electric power and has no emission and noise pollution.

Owner:GUANGXI UNIV

Method for performing welding construction by use of multi-DOF (Degree Of Freedom) controllable rocking arm type connecting rod mechanism

InactiveCN104646881AAvoid dead center positionIncrease stiffnessProgramme-controlled manipulatorWelding/cutting auxillary devicesEngineeringMulti degree of freedom

The invention relates to a method for performing welding construction by use of a multi-DOF (Degree Of Degree) controllable rocking arm type connecting rod mechanism. The method comprises the following steps of: constructing an execution main chain by use of an upright column, a main arm, a first rocking arm, a second rocking arm, a first connecting rod, a second connecting rod, a third connecting rod and a fourth connecting rod; constructing an execution sub-chain by use of a fifth connecting rod, a sixth connecting rod, an upright column and a main arm; during a welding operation, driving the main arm by use of a motor so as to enable the main arm to perform rotating motion, supporting the main arm by use of the fifth connecting rod and the sixth connecting rod, and performing motion synthesizing on the fifth and sixth connecting rods and the main arm; driving the second rocking arm by use of the motor so as to enable the second rocking arm to perform rocking arm type control on the third connecting rod; driving the third connecting rod and the fourth connecting rod to perform rotating motion by use of the motor so as to enable the connecting rod mechanism to finish the welding operation. The method has the advantages of large operating space, high rigidity, high bearing capacity and high execution accuracy.

Owner:GUANGXI UNIV

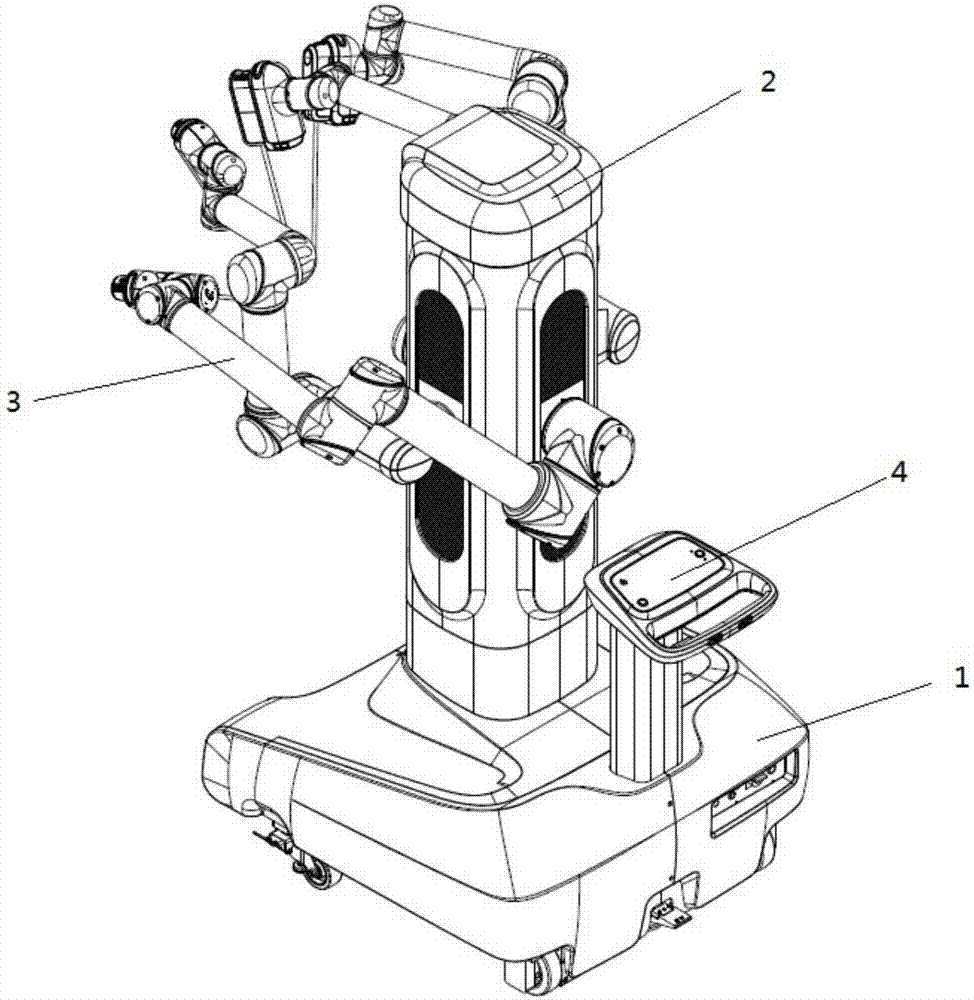

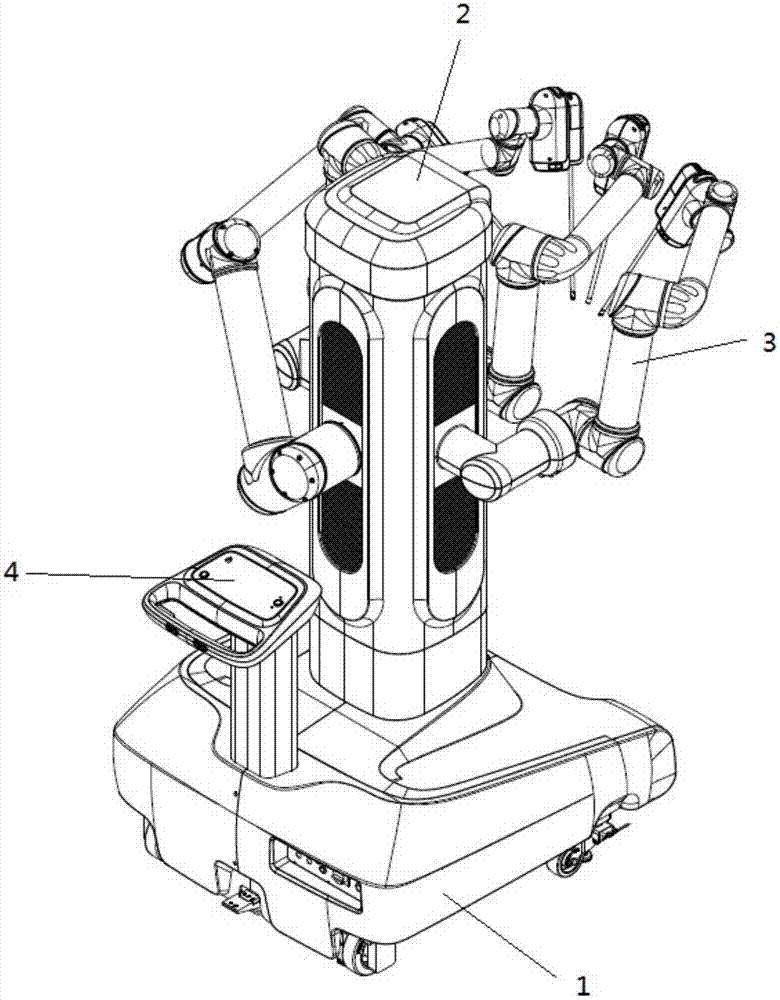

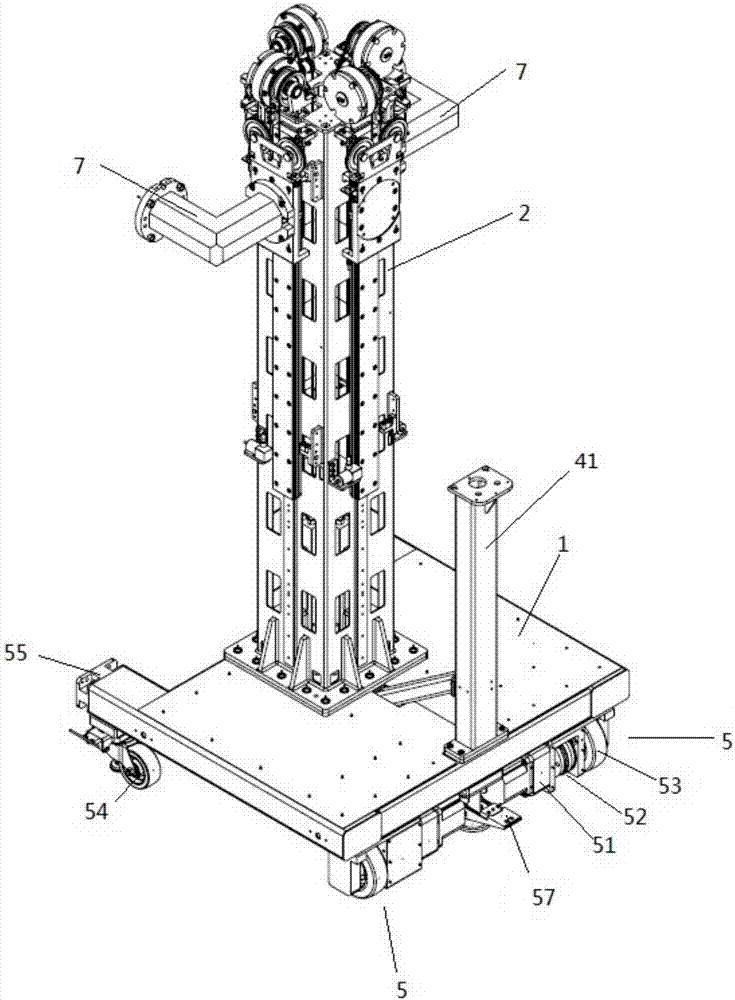

Surgical cart

The invention discloses a surgical cart. The surgical cart is characterized by comprising a standing column. Vertical guide rails are arranged on the outer walls of the standing column. A slider is slidably arranged on each vertical guide rail. A base for mounting a mechanical arm is fixedly arranged on each slider. Limit devices for controlling the corresponding base to move in stroke limit are respectively arranged at the top and the bottom of each outer wall of the standing column. Each limit device comprises a first support plate and a buffer device, wherein the first support plate is arranged on the corresponding outer wall of the standing column, and the buffer device is arranged on one side of the first support plate and used for absorbing impact. The surgical cart has the advantages that mechanical arms can be controlled to move in stroke limit, and the surgical cart is good in safety and stability.

Owner:CHENGDU BORNS MEDICAL ROBOTICS INC

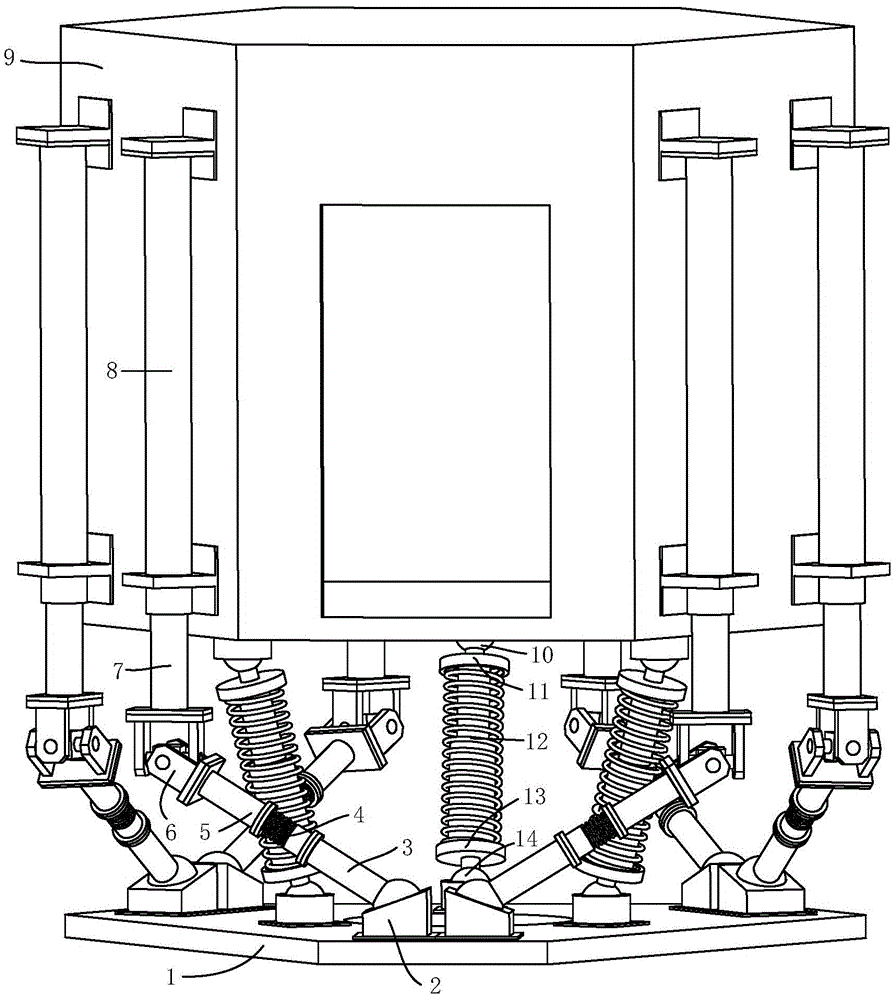

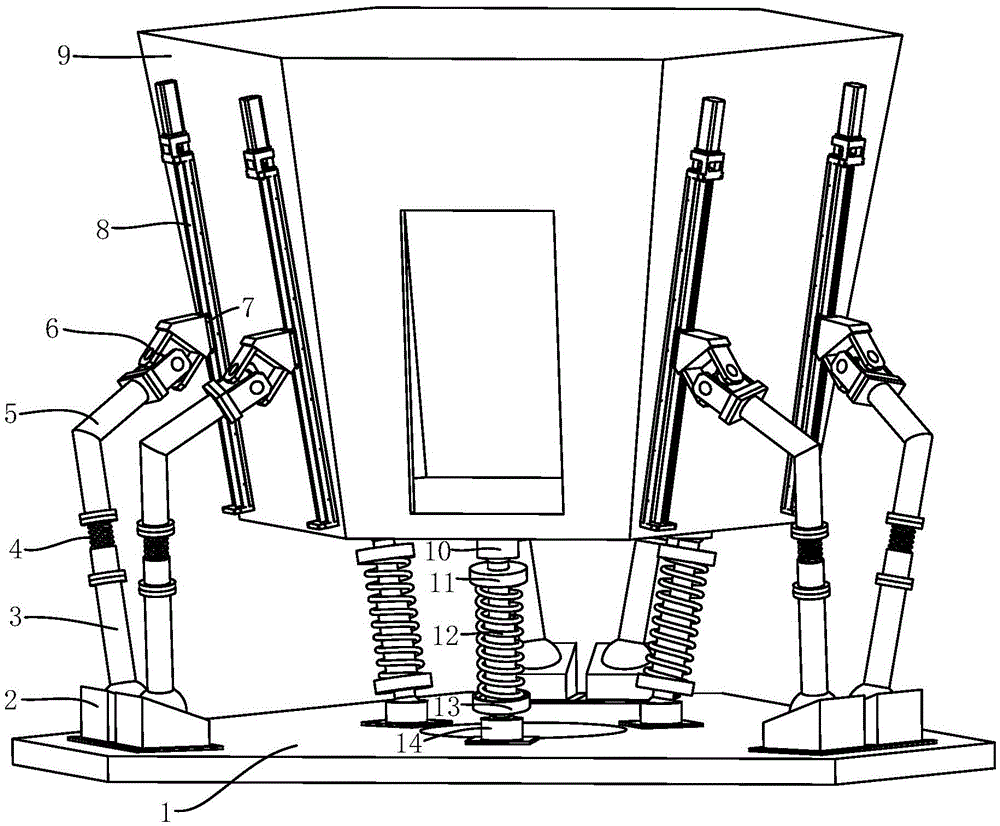

Six-degree-of-freedom parallel stabilizing and vibration-isolating cabin

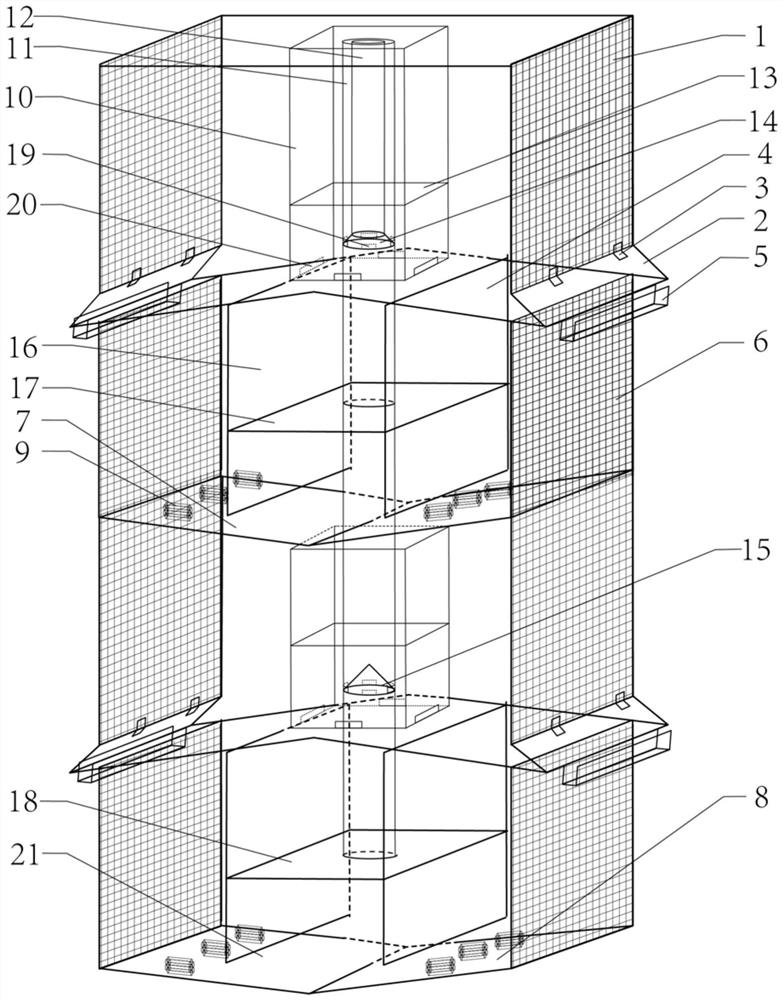

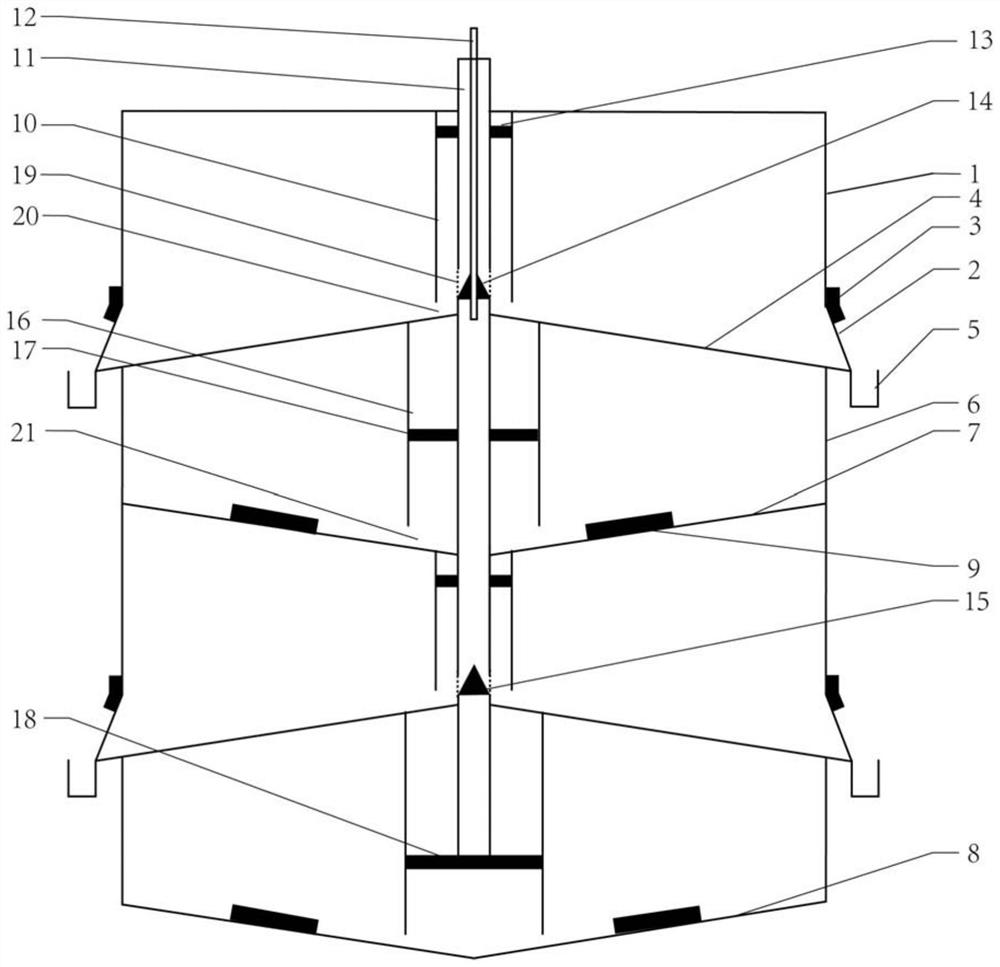

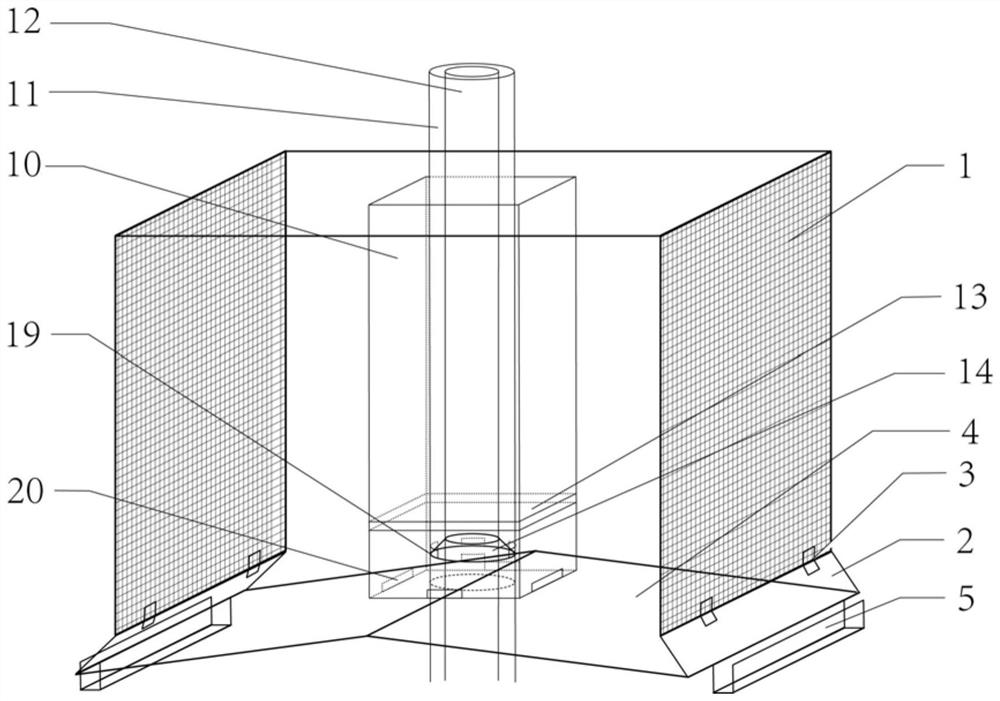

ActiveCN105570378ALarge load capacityLarge space for activitiesNon-rotating vibration suppressionStands/trestlesDegrees of freedomEngineering

A six-degree-of-freedom parallel stabilizing and vibration-isolating cabin mainly comprises a base, six vibration-isolating branches, assisting bearing branches, a cabin body and six linear driving units fixedly connected onto the cabin body, wherein each of the six vibration-isolating branches comprises a spherical hinge, a first connecting rod, a vibration isolator, a second connecting rod and a universal hinge, one end of the first connecting rod is connected with the base by the aid of the spherical hinge, the other end of the connecting rod is connected with one end of the vibration isolator, the other end of the vibration isolator is connected with one end of the second connecting rod, and the other end of the second connecting rod is connected with one end of a moving rod of each of the six linear driving units by the aid of the universal hinge; the cabin body adopts a hexagonal prism structure, every two linear driving units form a group, driving directions are parallel, and the six linear driving units are uniformly and fixedly connected onto spaced side surfaces of the hexagonal prism; each of the assisting bearing branches comprises spherical hinges and an assisting part, and two ends of the branch are connected with the bottom of the cabin and the base by the aid of the spherical hinges. The six-degree-of-freedom parallel stabilizing and vibration-isolating cabin is low in overall height and high in bearing capacity and has very good stabilizing and vibration-isolating effects.

Owner:YANSHAN UNIV

Welding construction method through utilizing six-degree-of-freedom five-rod moving type connecting rod mechanism

ActiveCN104476054AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesSix degrees of freedomArchitectural engineering

The invention relates to a welding construction method through a six-degree-of-freedom five-rod moving type connecting rod mechanism. According to the welding construction method through the six-degree-of-freedom five-rod moving type connecting rod mechanism, an execution main chain is formed by a vertical column, a main arm, a first rocker arm, a second rocker arm, a first connecting rod, a second connecting rod, a third connecting rod and a fourth connecting rod; an execution sub-chain is formed by a fifth connecting rod, a sixth connecting rod, a seventh connecting rod, the vertical column and the main arm; during the welding operation, the main arm is driven by a motor to enable the main arm to perform rotational movement, the fifth connecting rod, the sixth connecting rod and the seventh connecting rod support the main arm, and the fifth connecting rod, the sixth connecting rod, the seventh connecting rod and the main arm perform motion synthesis; the motor drives the second rocker arm to enable the second rocker arm to control the third connecting rod in a rocker arm mode; the motor drives the third connecting rod and the fourth connecting rod to perform rotational motion to enable the connecting rod mechanism to achieve the welding operation. The welding construction method through the six-degree-of-freedom five-rod moving type connecting rod mechanism has the advantages of being large in working space, high in rigidity, strong in bearing capability and high in execution accuracy.

Owner:GUANGXI UNIV

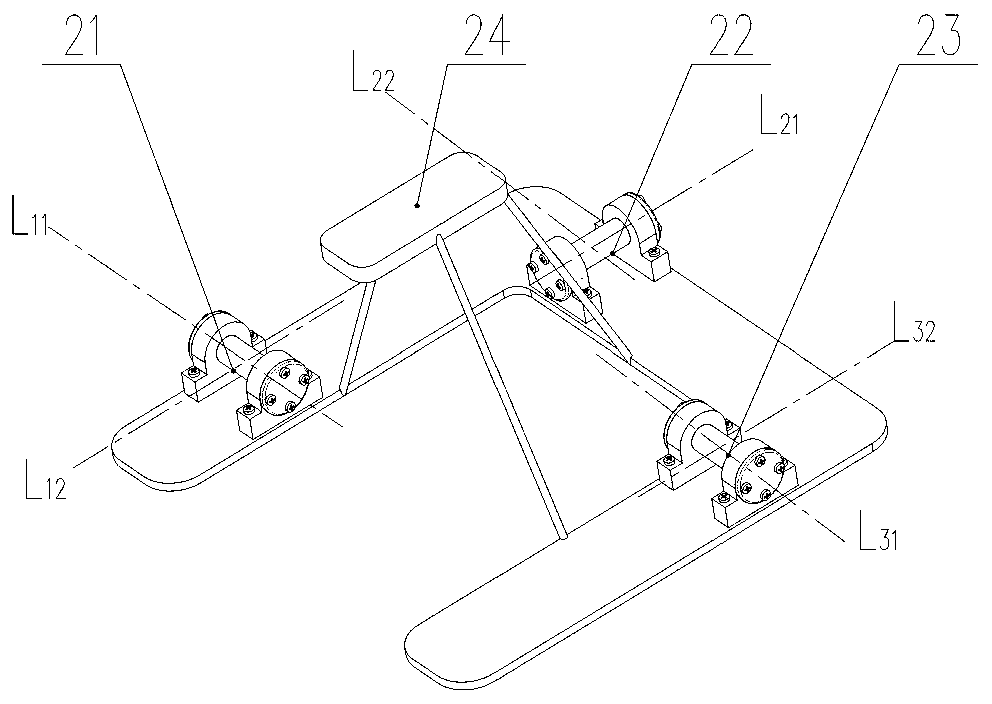

Three-turn-one-shift decoupling ankle joint rehabilitation robot

The invention relates to a three-turn-one-shift decoupling ankle rehabilitation robot which comprises a machine body, a driving mechanism and a monitoring system. The machine body consists of a symmetrical series-parallel mechanism and comprises a base, a movable platform, a foot pedal and three branches for connecting the base and the movable platform, preferably, the first branch of the three branches is a PRR branch, the second branch and the third branch are CPRR branches and are symmetrically distributed relative to the bottom of the base; the pedal and the movable platform are connectedin series to form a local branch, and the whole mechanism is a 3R1T mechanism; preferably, the mechanism contained in the robot is a decoupling mechanism in kinematics, and can independently achieve dorsiflexion / phalangeal flexion, varus / valgus and pronation / supination in ankle joint movement by controlling different branches. The three-turn-one-shift decoupling ankle rehabilitation robot has a wide application range, can be used not only for ankle rehabilitation training, but also for implanting corresponding massage components on the pedals, and can also be used for family health care.

Owner:YANSHAN UNIV

Endoscope manipulator for minimally invasive surgery

InactiveUS8460175B2Large space for activitiesEndoscopesSurgical instrument supportLess invasive surgeryThree degrees of freedom

According to endoscope manipulator for MIS capable of overcoming disadvantages of multiaxial endoscope manipulator including conventional robot arm and providing compact and light-weight structure to obtain maximum activity space for medical staff, multi-joint arm is configured so that movement of all joints from base link to tip link is manually locked-unlocked by user and not controlled by motors. Endoscope mounted on end of multi-joint arm is manipulated using motors to enable movement of three-degrees of freedom, thereby accomplishing compact and light-weight endoscope manipulator. Tube of endoscope can be press-fitted onto tip of multi-joint arm, and three-axis movement function for vertical, lateral and forward / backward conveyance of endoscope is implemented in tip of multi-joint arm. Since external manual joints are not moved during operation, disturbance or restriction to activities of medical staff can be minimized. One-click button function of readily and rapidly attaching / detaching endoscope to / from endoscope manipulator can increase convenience of use.

Owner:NAT CANCER CENT

Parallel ankle rehabilitation robot

ActiveCN111513982AAchieve inversion/valgus movementPromote recoveryChiropractic devicesHuman bodyPhysical medicine and rehabilitation

The invention discloses a parallel ankle rehabilitation robot. The parallel ankle rehabilitation robot comprises a movable platform, a fixed platform, three movement branches and three driving devices. The top ends and the bottom ends of the movement branches are rotationally connected with the movable platform and the fixed platform correspondingly. Each of the fixed platform and the movable platform is provided with three revolute pairs which correspond to one another in position and are parallel relative to a first plane. A pedal on the movable platform is located below the first plane andis parallel to the first plane. Each movement branch comprises a first connecting rod, a second connecting rod and a first ball pair. The parallel ankle rehabilitation robot has two rotational degreesof freedom and one moving degree of freedom, can drive the ankle of a human body to realize pronation / supination and introversion / extroversion movements, and can adjust the initial position of self-rehabilitation to a certain extent according to the structural size of the ankle joint of a patient to ensure that the movement of a mechanism is matched with the movement property of the ankle joint of the human body, thereby ensuring the accuracy of rehabilitation.

Owner:YANSHAN UNIV

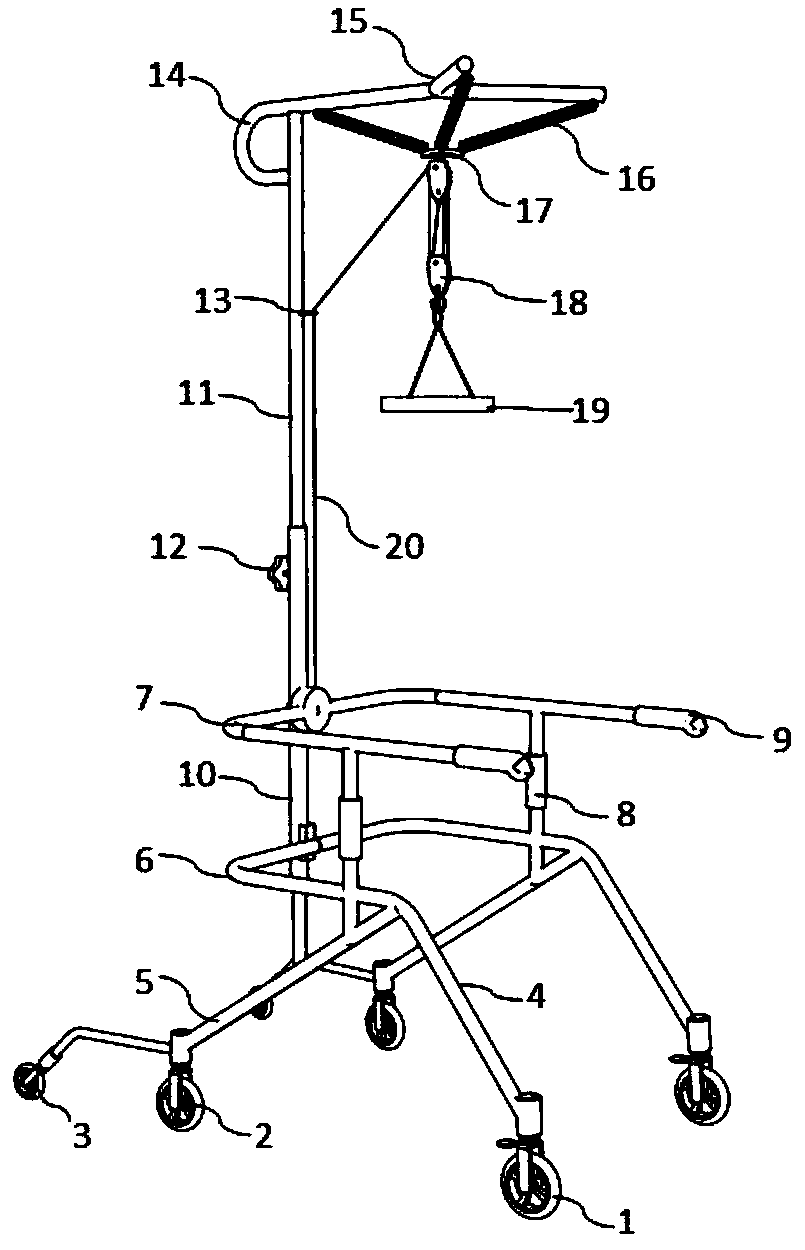

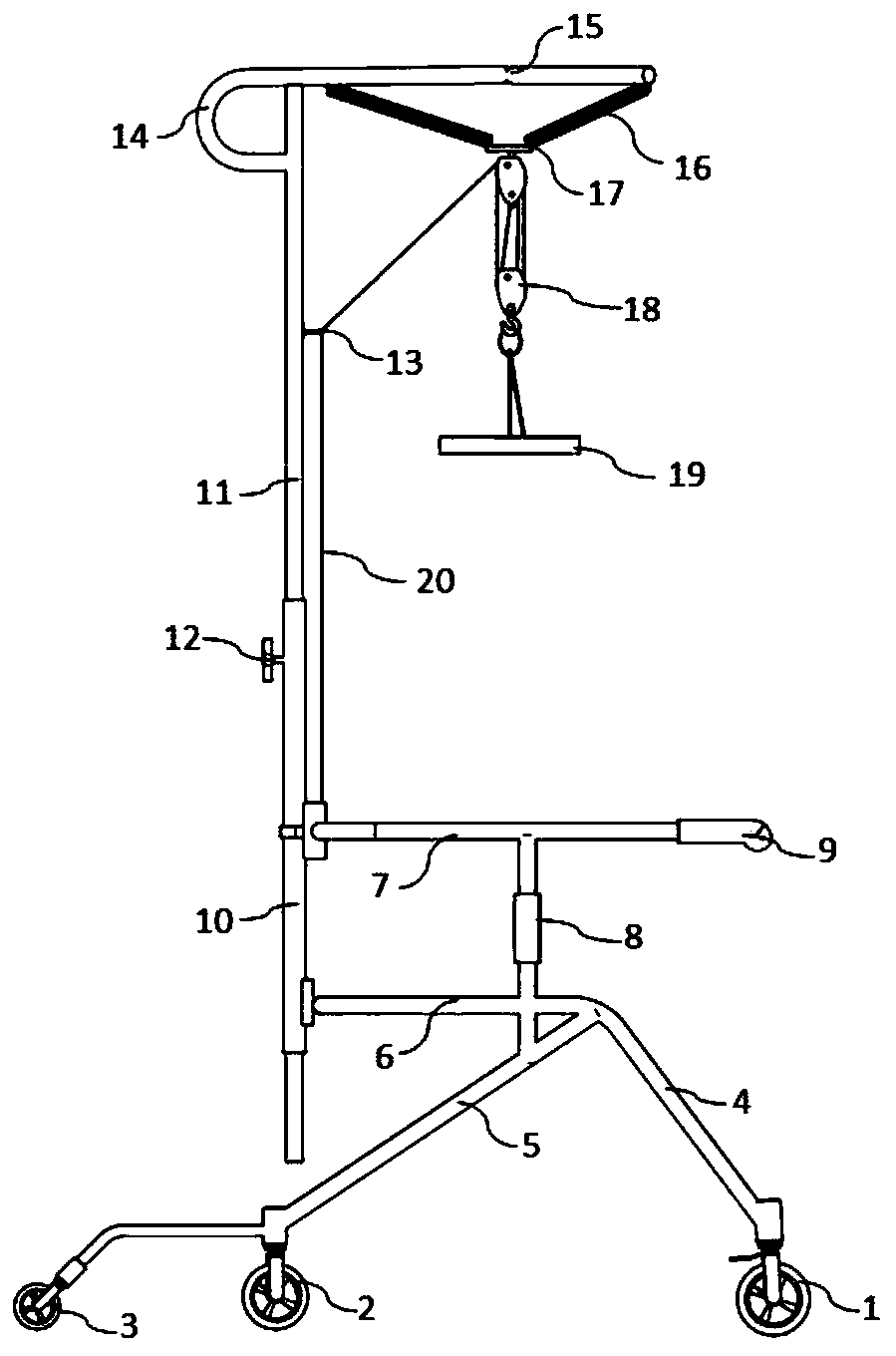

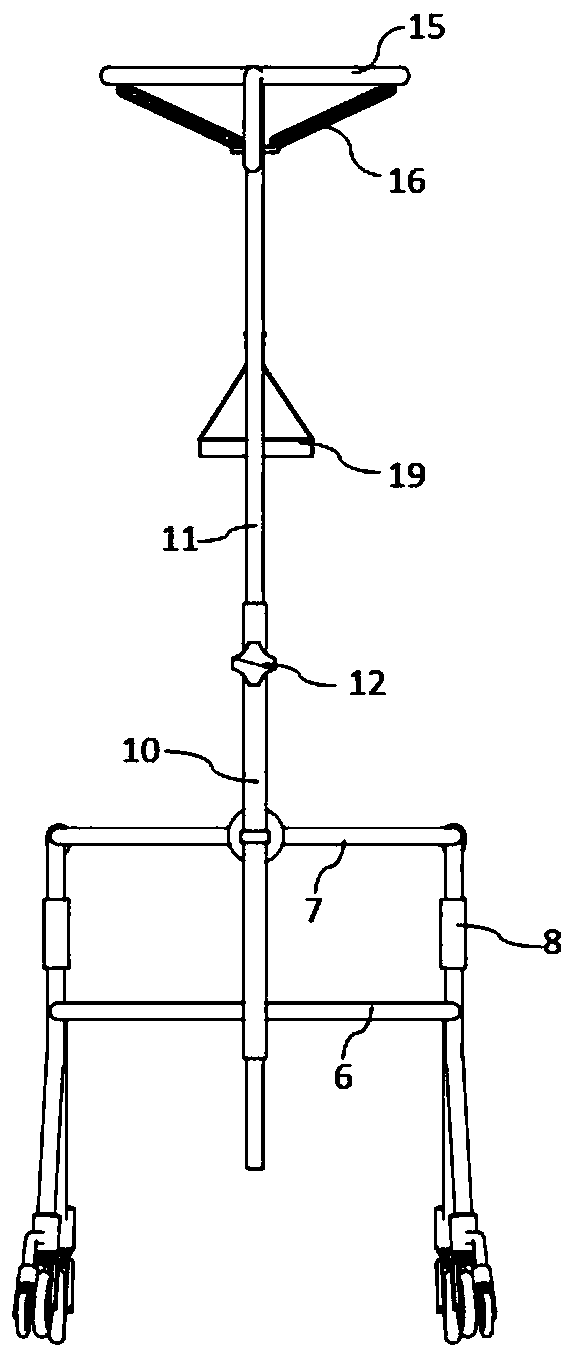

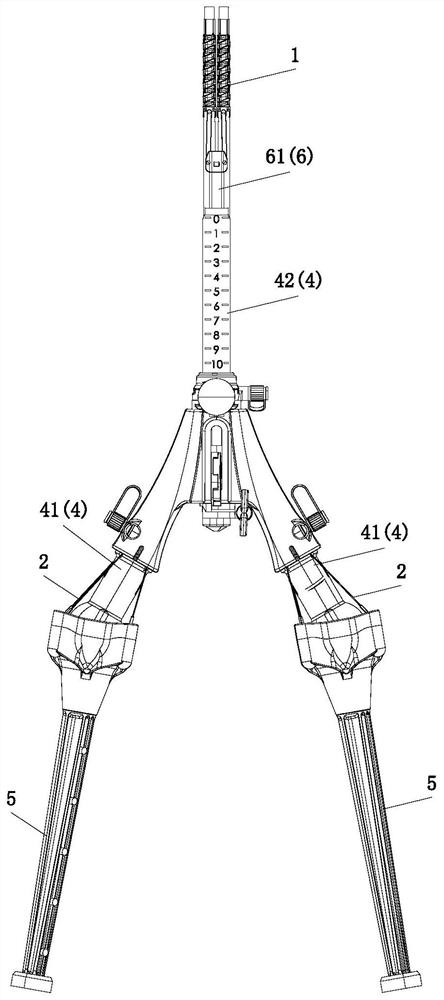

Walking type scoliosis traction device

PendingCN111035495AImprove life freedomNo security threatOperating tablesWalking aidsPhysical medicine and rehabilitationTraction cord

The invention relates to a walking type scoliosis traction device. A traction support is composed of a hand guided walking support, an adjustable supporting frame and a spring type gravity traction device. The hand guided walking support is composed of front wheels, rear wheels, rear protection wheels, a front wheel rod, a rear wheel rod, a bottom U-shaped rod, an upper U-shaped rod, a screwing type height adjusting rod and a handle. The adjustable supporting frame is composed of a bottom rod, an upper rod, a height adjusting nut, a ferrule, a top bent rod and a front fork. According to the device, a dragged person can also be subjected to traction treatment in an upright walking state, so that the large living freedom degree is kept, weights, sandbags and other heavy objects are not needed in the traction process, self gravity is used as traction force, the equilateral three-fork type high-precision spring combination enables the traction force to be flexible and stable, and a pulleyblock and a traction rope are convenient for a patient to self-adjust and remove the traction force, so that the simplicity, convenience and safety of traction operation are greatly improved.

Owner:NANJING CHILDRENS HOSPITAL

Wheeled mobile welding robot with plurality of closed-loop sub-chains

InactiveCN104552245ALarge working spaceHigh Motion RedundancyProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopEngineering

The invention provides a wheeled movable welding robot with a plurality of closed-loop sub-chains. The wheeled mobile welding robot comprises a plurality of parallel mechanism closed-loop executing mechanism sub-chains, a serial executing mechanism main chain and a moveable platform, wherein the mechanism closed-loop sub-chains are used for controlling a connecting rod of the main chain to move in a plane of a four-rod mechanism closed-loop sub-chain, and the space movement of the movable platform is realized by the movement of parallel connecting rod sub-chains, a robot body and the movable platform. The wheeled mobile welding robot has the advantages that the control is realized by the synthesis movement of the four closed-loop sub-chains and the robot body, and the space movement of a tail executer is realized by the connecting of the connecting rods, the robot body and the movable platform, the movement inertia of the tail executer is small, the dynamic property is good, and the reliability is high; the movement and operation functions of the mechanism are realized, and the robot has maximum working space and good movement redundancy, and can be applied to multiple occasions.

Owner:GUANGXI UNIV

Light inspection device and double-light inspection machine

ActiveCN104291108AImprove delivery efficiencyReduce and avoid bottle shortagesPackagingConveyor partsEngineeringBottle

The invention discloses a light inspection device and a double-light inspection machine. The light inspection device comprises a bottle conveying shifting wheel and a light inspection turnplate, wherein the slot pitch of the bottle conveying shifting wheel is smaller than that of the light inspection turnplate; a bottle conveying screw and an auxiliary shifting wheel are arranged between the bottle conveying shifting wheel and the light inspection turnplate; bottles on the bottle conveying shifting wheel orderly pass through the bottle conveying screw and the auxiliary shifting wheel and go into the light inspection turnplate. The double-light inspection machine comprises two light inspection devices which are arranged symmetrically. The light inspection device has the advantages of reducing and avoiding bottle missing and bottle breakage phenomena and improving the steady reliability the efficiency of bottle feeding.

Owner:TRUKING TECH LTD

Connector terminal and electrical connector

ActiveUS9246283B2Small sizeIncrease widthCoupling device detailsTwo-part coupling devicesEngineeringElectrical connector

A socket terminal includes a movable portion that includes a first extension that extends from a position near a fixed housing in an insertion / extraction direction of a plug connector, a hairpin portion that is continuous with the first extension, and a second extension that is continuous with the hairpin portion and that extends in the insertion / extraction direction toward a movable housing. The movable portion elastically supports the movable housing in such a way that the movable housing is displaceable relative to the fixed housing. The second extension of the movable portion includes a spring portion that is bent in such a way that the width of a gap between the second extension and a base at one end portion of the second extension continuous with the hairpin portion is larger than that at the other end portion of the second extension continuous with the base.

Owner:IRISO ELECTRONICS CO LTD

Ecological intercropping net cage for precious marine products

InactiveCN113439698ARealize the separation functionRealize the cleaning functionClimate change adaptationPisciculture and aquariaZoologySea urchin

The invention discloses an ecological intercropping net cage for precious marine products and belongs to the field of aquaculture. The ecological intercropping net cage comprises an upper-layer culture unit, a lower-layer culture unit, a multifunctional drainage system in the middle and a matched device, wherein the culture units are vertically distributed in a net cage purse net; each culture unit comprises an upper-layer sea urchin area and a lower-layer sea cucumber area, and the sea urchin areas and the sea cucumber areas are alternately arranged two by two to form a relatively independent intercropping system; and the upper-layer sea urchin areas and the lower-layer sea cucumber areas are separated by polyethylene nets with meshes, and excrement generated by sea urchin falls into the sea cucumber areas from the meshes to serve as young sea cucumber bait. The multifunctional drainage system is located in the middle of the net cage surrounding net, penetrates through the whole culture net cage, and is used for feeding baits in the sea urchin areas and cleaning sea urchin excrement which is not eaten up by sea cucumbers, excrement generated by the sea cucumbers and other metabolites in the sea cucumber areas. The problems of sea urchin winter ingestion and excrement cleaning can be solved, and winter growth of sea cucumbers is facilitated; and the ecological intercropping net cage uses common culture materials, is low in price, simple and time-saving to operate, capable of realizing large-scale intensive production and suitable for large-scale popularization.

Owner:DALIAN OCEAN UNIV

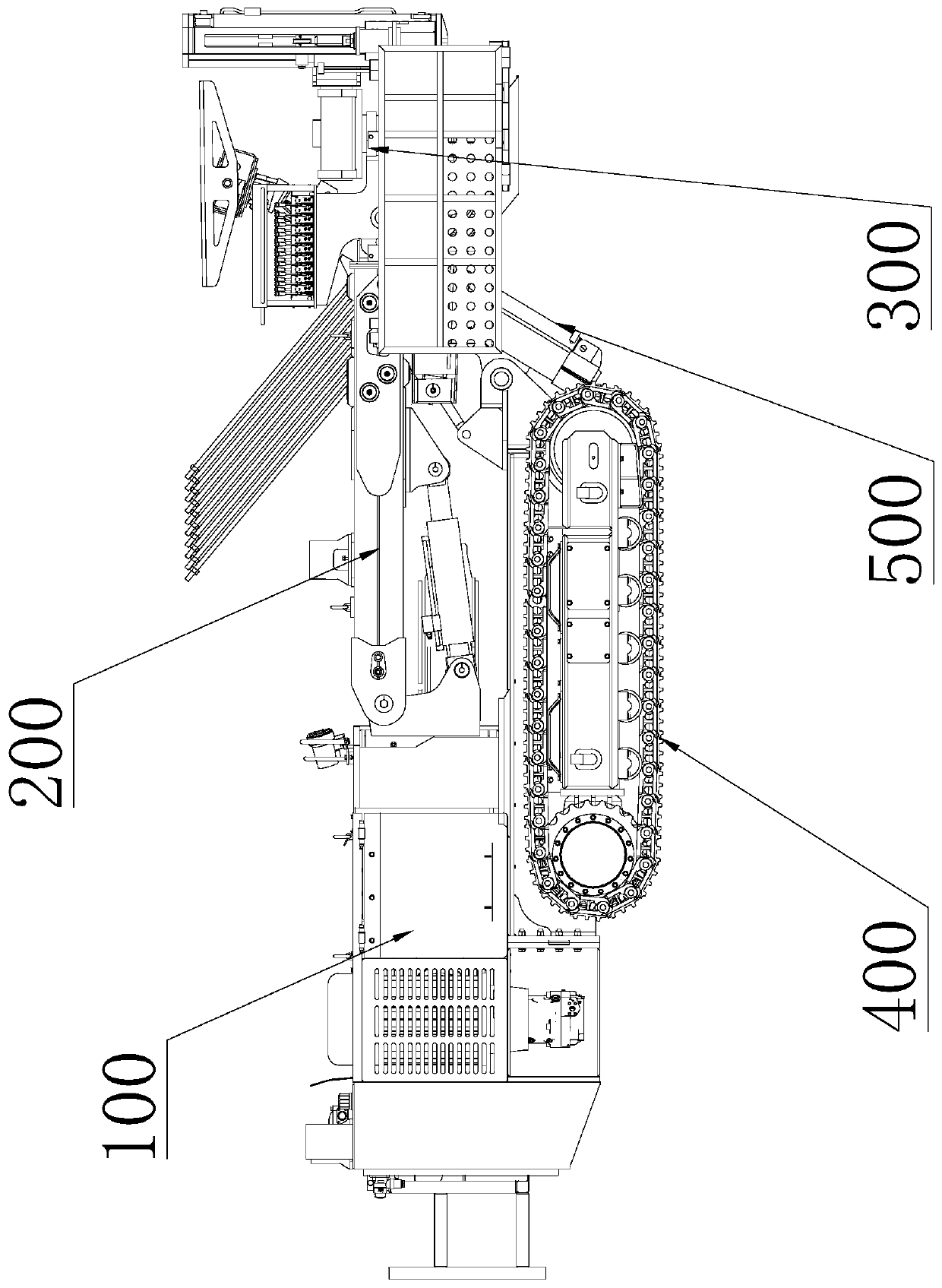

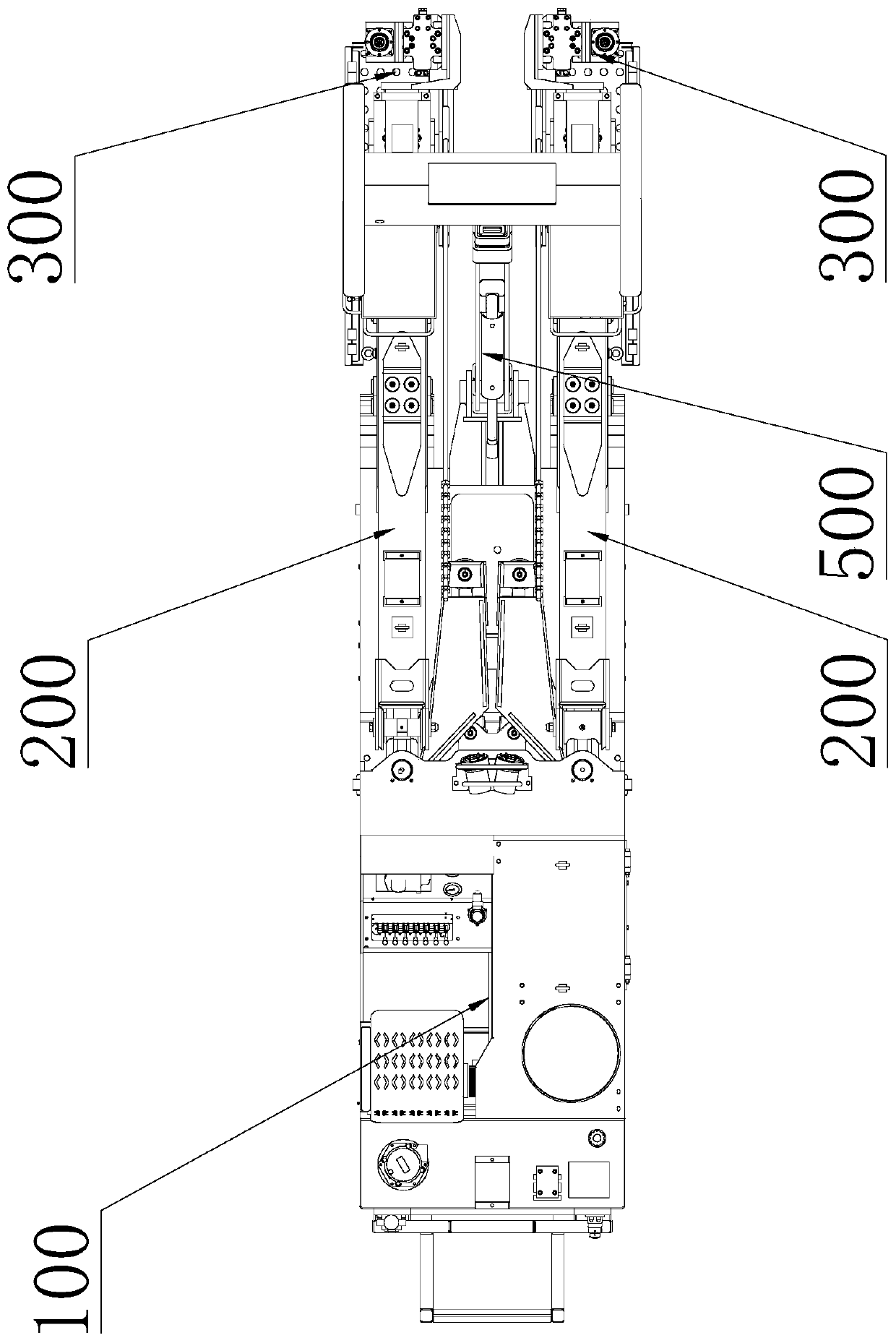

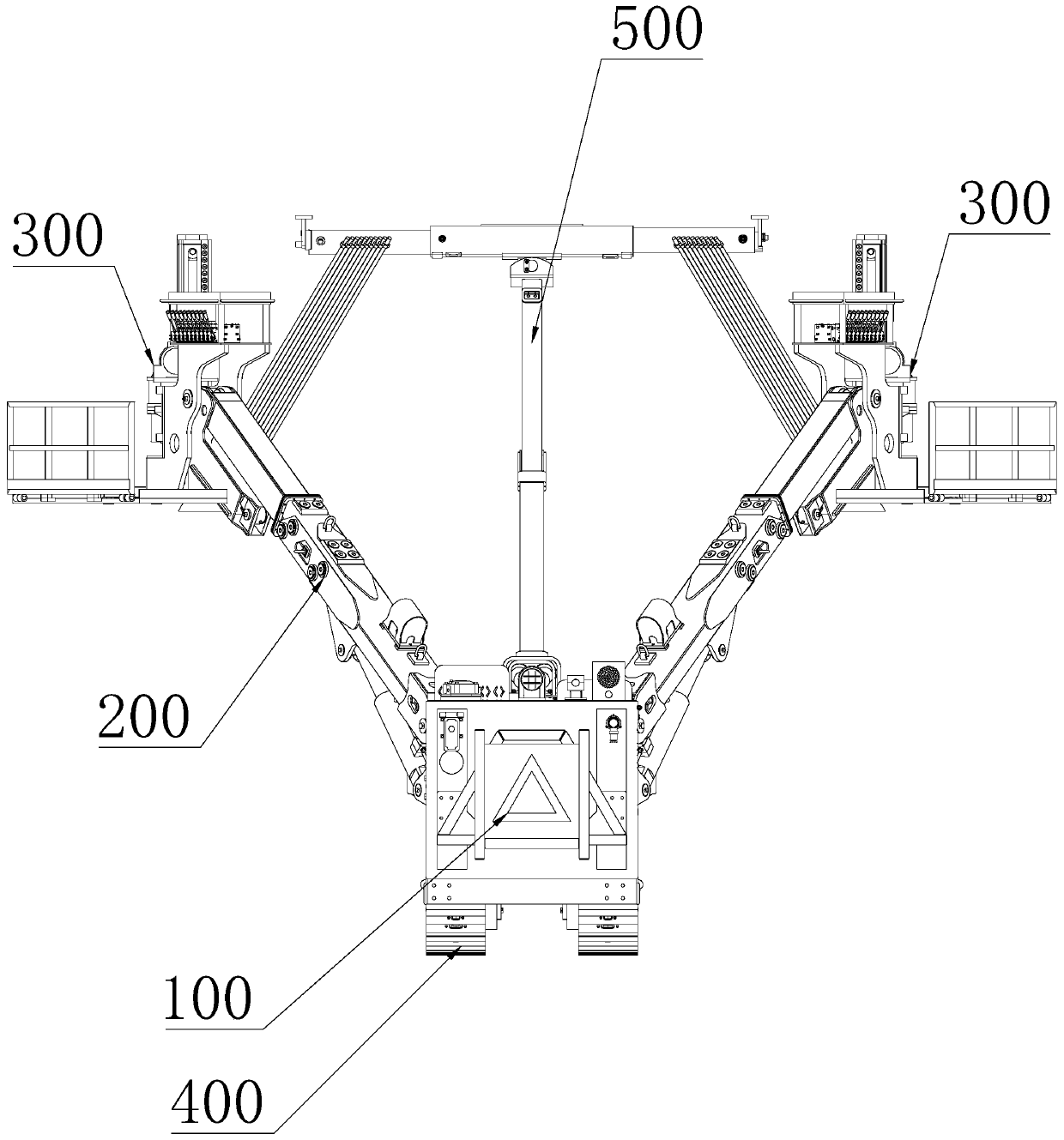

Mine anchor roddrill carriage

PendingCN110219684ASimple structureReasonable settingDerricks/mastsAnchoring boltsEngineeringActuator

The invention discloses a mine anchor roddrill carriage which comprises a machine body and a walking mechanism. Themine anchor roddrill carriageis characterized in that at least one mechanical arm ismounted on the machine body, the mechanical arm comprises a working arm composed ofat least twosections of sub-arms, any adjacent twosections of sub-arms are slidably matchedin the length direction ofthe sub-arms, and the working arm is internally provided with a telescopic cylinder;an anchoring actuator is installed at the front end of the first-section sub-arm of the working arm, the front endof the first-section sub-arm is connected to abearing seat of the anchoring actuator through a mounting part, the anchoring actuator includes the bearing seat, anda propulsion mechanism is installed at the front end of the bearing seat; and the mounting part is installed at the rear end of the bearing seat, and working platforms and anchor rod bins are disposed at the positions, on the two sides of the propulsion mechanism, of the bearing seat correspondingly. According to the mine anchor roddrill carriage, the structure of the mechanical arm is simpler and more reliable, so that the cost of the whole vehicle is lower and the structure is more reliable.

Owner:江西鑫通机械制造有限公司

Multi-degree-of-freedom controllable parallel type mobile robot

InactiveCN104476536ALarge working spaceHigh Motion RedundancyProgramme-controlled manipulatorClosed loopMulti degree of freedom

The invention relates to a multi-degree-of-freedom controllable parallel type movable spot welding robot. The multi-degree-of-freedom controllable parallel type movable spot welding robot comprises a movable platform, four parallel controllable four-bar mechanism closed-loop actuator subchains and a serial actuator main chain. The controllable four-bar mechanism closed-loop actuator subchains controls main-chained connecting bars to move within a plane where the four-bar mechanism closed-loop subchains are located, and spatial motion of the movable platform can be realized through motions of a first connecting bar, a machine body and the movable platform. A moving function is realized through the movable platform; the robot is controlled through the synthetic motion of the four four-bar mechanism closed-loop actuator subchains and the machine body; the spatial motion of an end actuator is realized through a plurality of connecting bars and the machine body; the end actuator is small in movement inertia, good in dynamics performance and high in precision. Through the structure, the robot has motion redundancy of almost infinite work space and height, has moving and operating functions at the same time, and can act on more occasions.

Owner:GUANGXI UNIV

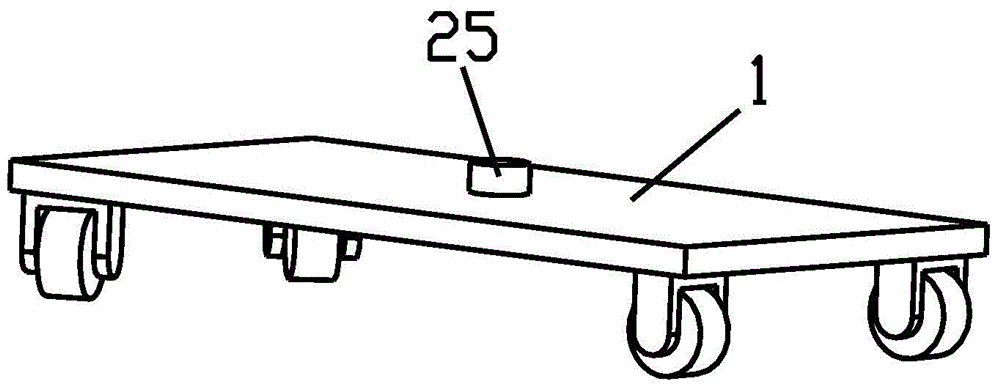

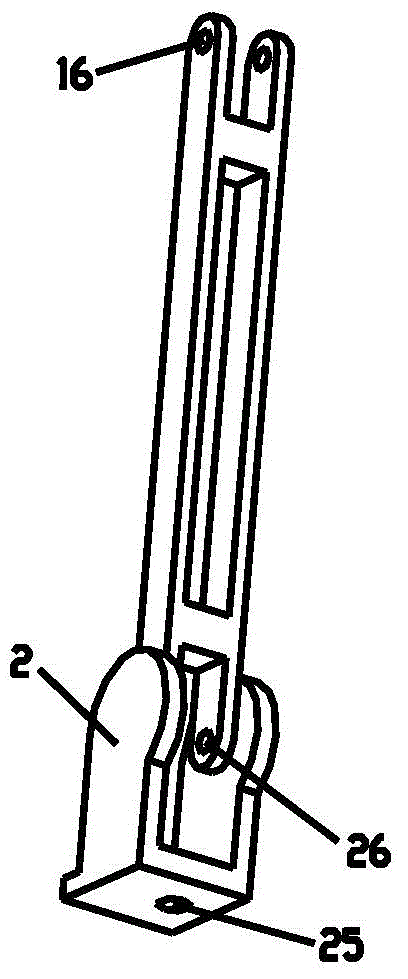

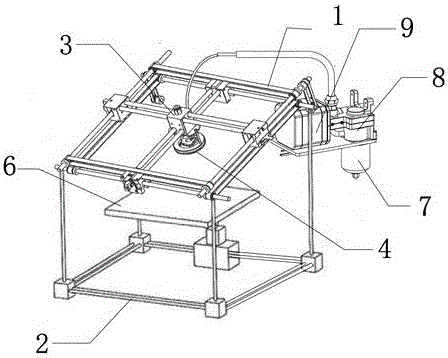

3D printing bone platform

InactiveCN106215233ALarge space for activitiesLarge adjustment spaceAdditive manufacturing apparatusTissue regenerationBiological bodyBiocompatibility Testing

The invention discloses a 3D printing bone platform and belongs to the field of 3D printing. The 3D printing bone platform comprises an upper bracket and a lower bracket which are movably connected with each other, wherein the upper bracket is of square shape; the bottom of the lower bracket is of square shape; the lower bracket comprises four support rods along the vertical direction; the vertex of the upper bracket is connected with the vertex of the bottom of the lower bracket through the support rods; the support rods are moveably connected with the upper bracket; the upper bracket can be overturned around the joint point; a print head is arranged on the upper bracket; a fusing device is fixedly arranged above the lower bracket; the fusing device is connected with the print head through a sampling pipe. The 3D printing bone platform provided by the invention has excellent biocompatibility and can supply growth cavity to the tissue cells; the print bone transplanted into the biological body can survive and be integrally fused with the transplant receptor; the printing precision is ultrahigh; the platform can correct at any time and accurately control the flow, so that the artificial bone completely matched with the original bone system can be acquired.

Owner:成都测迪森生物科技有限公司

Surgical auxiliary instrument

ActiveCN112603394AIncrease local degrees of freedomImprove maneuverabilitySurgeryBiomedical engineeringOperative aid

The application discloses a surgical auxiliary instrument comprising a control unit, the control unit comprises a flexible joint unit and a plurality of pull wires, and the flexible joint unit comprises a flexible pipe and a joint assembly; the joint assembly comprises a plurality of first annular joints and a plurality of second annular joints which are arranged on the outer side of the flexible pipe in a sleeving mode at intervals, and receding notches formed by every two adjacent first annular joints and the corresponding second annular joint between the two adjacent first annular joints are formed in a staggered mode in the extending direction of the flexible joint unit. Each first annular joint is provided with a plurality of threading holes, and each second annular joint is provided with first limiting clamping grooves which are the same as the first annular joints in number and matched with the threading holes in a one-to-one alignment mode. The first end of each pull wire sequentially penetrates through the corresponding threading hole in each first annular joint and is fixedly connected with the extending end of the flexible joint unit, and the first limiting clamping groove in each second annular joint is connected with the corresponding pull wire in a limiting and clamping mode. The surgical auxiliary instrument has the advantages of being convenient to operate, safe, reliable and the like.

Owner:APEIRON SURGICAL CO LTD

Three-dimensional comprehensive cultivation method for stichopus japonicus and oyster

InactiveCN111096257AImprove the growing environmentLarge space for activitiesSeawater treatmentWater contaminantsStichopusOyster

The invention relates to a three-dimensional comprehensive cultivation method for stichopus japonicus and oyster. The method adopts a seabed comprehensive cultivation device with a specific structureto carry out three-dimensional comprehensive cultivation of stichopus japonicus and oyster, mainly comprises that: 1) stichopus japonicus is cultivated on a bottom of water in a bottom sowing mode, and oysters are cultivated in water in a hanging cultivation mode; 2) spines participate in the three-dimensional comprehensive culture of oysters, and large seaweeds are not introduced; 3) stichopus japonicus participate in the three-dimensional comprehensive culture of oysters, and the hanging culture mode adopted for the oysters comprises a shed frame type, an extended rope type and a floating raft type; and 4) inorganic nutrient salts and organic matters in the culture seawater are removed by utilizing a three-dimensional comprehensive cultivation system for stichopus japonicus and oyster and converted into biomass of oyster and stichopus japonicus. The method fully utilizes and transforms water nutrients to achieve a purpose of environmental regulation and repair, and realizes sustainable development of artificial cultivation of sea stichopus japonicus.

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com