Patents

Literature

61results about How to "Avoid dead center position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controllable mechanism type fine-adjusting welding robot with multiple degrees of spatial freedom

ActiveCN103737578AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesControl engineeringMachine

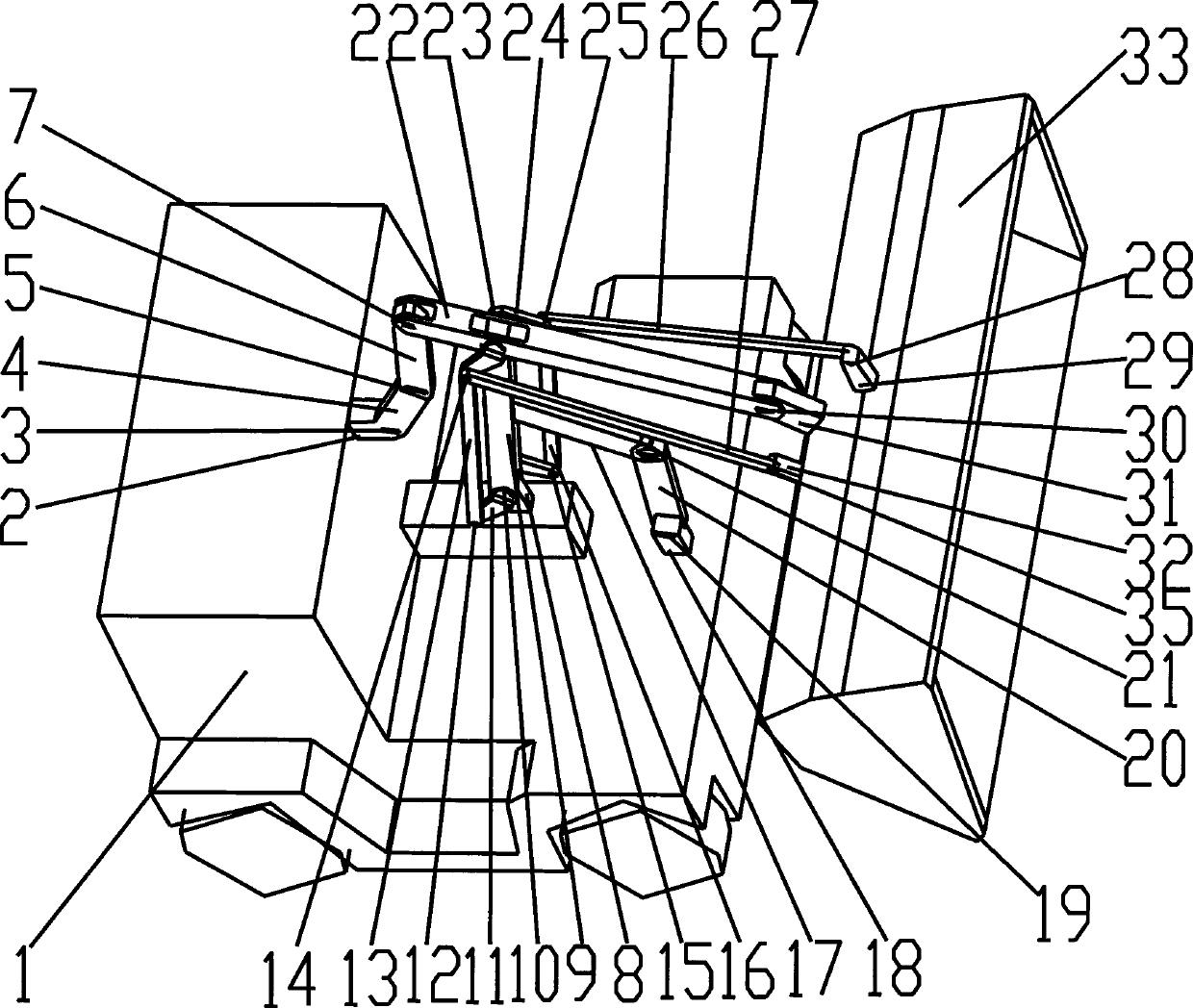

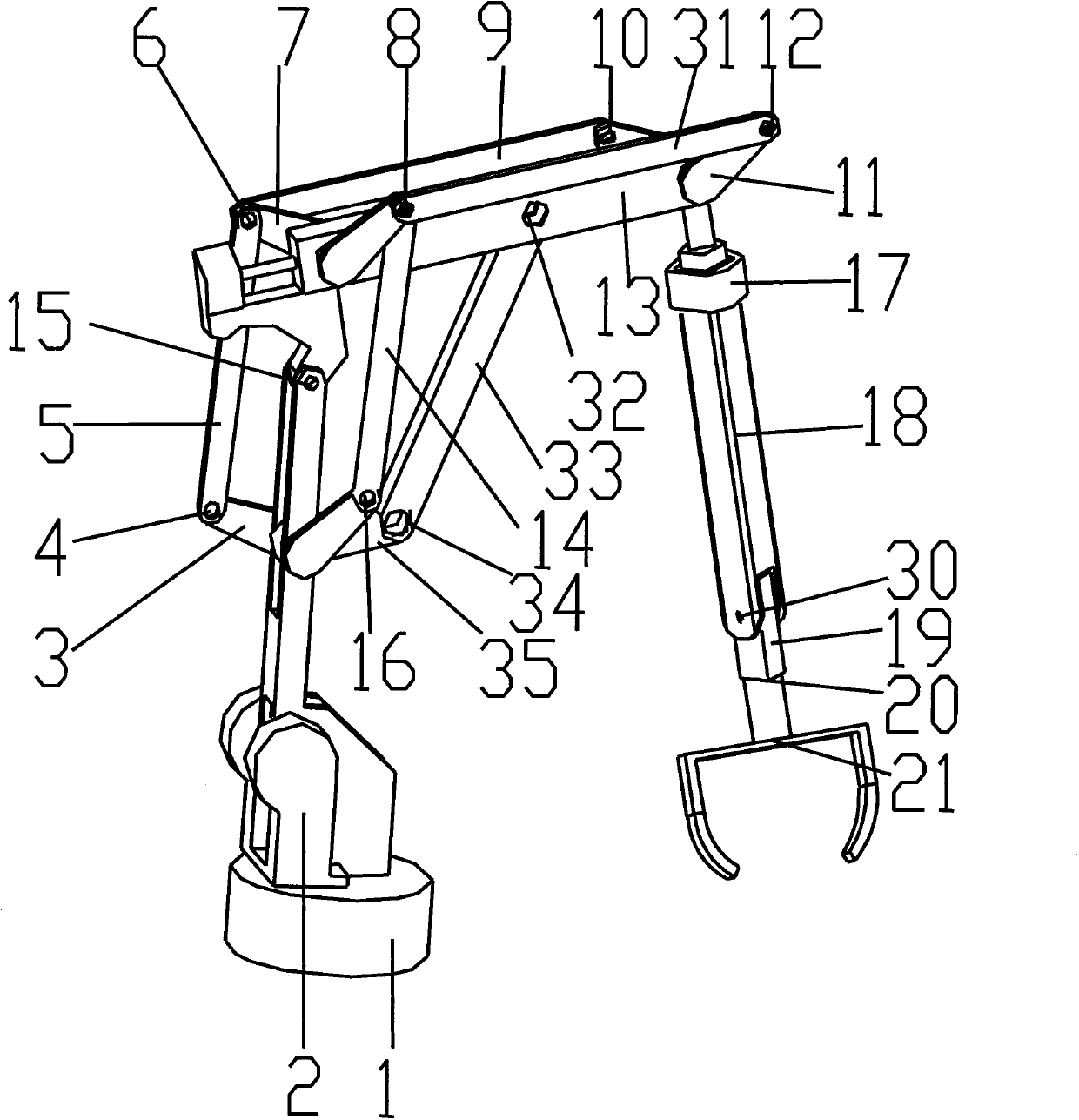

A controllable mechanism type fine-adjusting welding robot with multiple degrees of spatial freedom comprises three controllable fine-adjusting four-rod mechanism closed-loop subchains connected in parallel and an execution mechanism subchain in series connection. The four-rod mechanism closed-loop subchains can control a first connecting rod to move in the plane where the four-rod mechanism closed-loop subchains are located, and the spatial movement of a platform can be achieved through the movement of parallel connecting rods and a machine body. The spatial movement of a tail end executor can be controlled through the resultant movement of the three closed-loop subchains and the machine body, the movement inertia of the tail end executor is small, dynamics performance is good, reliability is high, the mechanism has the advantages of being compact in structure and easy to control, the connecting rods are used for control, rod pieces can be made into light rods, the work space of the mechanism is large, the gravity of the mechanism moves backwards, the mechanism is kept balanced, and the mechanism can act on more occasions.

Owner:GUANGXI UNIV

Controllable multi-degree of freedom welding robot

InactiveCN103707289AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopEngineering

A controllable multi-degree of freedom welding robot comprises four controllable four-link-mechanism closed-loop executing mechanism subchains which are in parallel connection and an executing main chain in series connection. A main chain connecting rod can be controlled by the controllable four-link-mechanism closed-loop executing mechanism subchain to move within the surface with the controllable four-link-mechanism closed-loop executing mechanism subchains. The spatial motion of a moving platform can be achieved by the motion of a first connecting rod and a body. According to this arrangement, the spatial motion of an end effector can be achieved, motion inertia is small, dynamics performance is good and reliability is high. The controllable multi-degree of freedom welding robot has the advantages of being compact in structure and easy to control. The rods can be made as light rods, work spaces for mechanisms are large, gravity centers of the mechanisms are moved backwards to keep balance. The controllable multi-degree of freedom welding robot can be widely used.

Owner:GUANGXI UNIV

Multi-degree of freedom parallel mechanism type spot welding robot

InactiveCN104096998AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopDegrees of freedom

The invention discloses a multi-degree of freedom parallel mechanism type spot welding robot. A frame, a body, a first connecting rod, a second connecting rod, a third connecting rod, a fourth connecting rod, a fifth connecting rod, a sixth connecting rod, a seventh connecting rod, an eighth connecting rod, a ninth connecting rod, a tenth connecting rod, an eleventh connecting rod, a twelfth connecting rod and an end effector are connected into four controlled four-link mechanism closed loop actuator subchains which are connected in parallel and an actuator main chain which is connected in series; the subchains control the connecting rods of the main chain to move in the plane in which the subchains are positioned; the spatial motion of a platform is realized through the movement of the first connecting rod and the body. According to the spot welding robot, the control is realized through resultant motion of the four closed loop subchains and the body, the spatial motion of the end effector is realized through the connection between the multiple connecting rods and the body, the effector is higher in flexibility, and the work space is larger than that of the conventional robot; moreover, the connecting rods with hinges can be made into light rods, so that the whole mechanism is higher in dynamic performance and easy to control.

Owner:GUANGXI UNIV

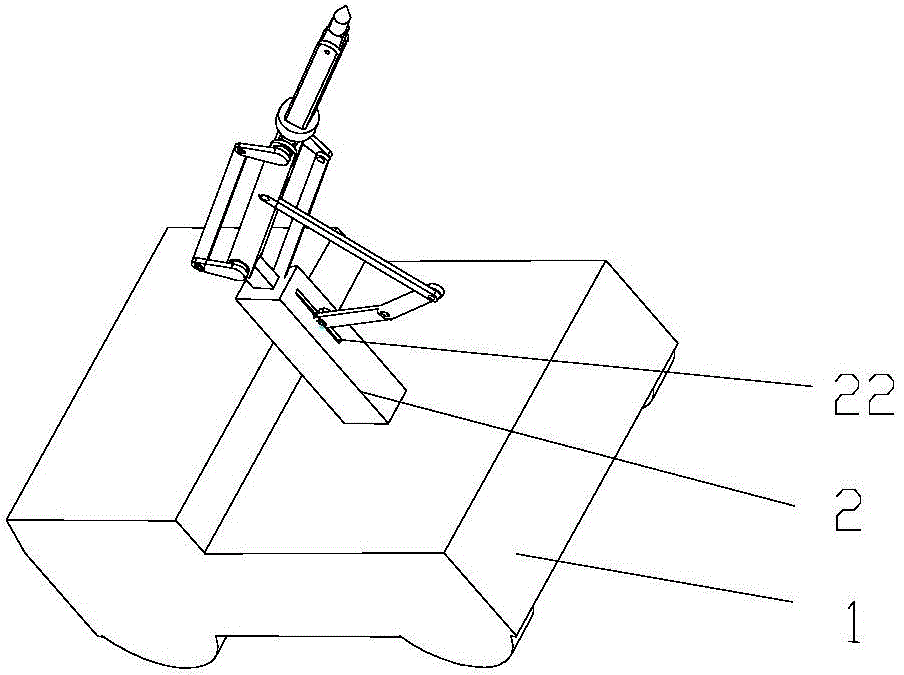

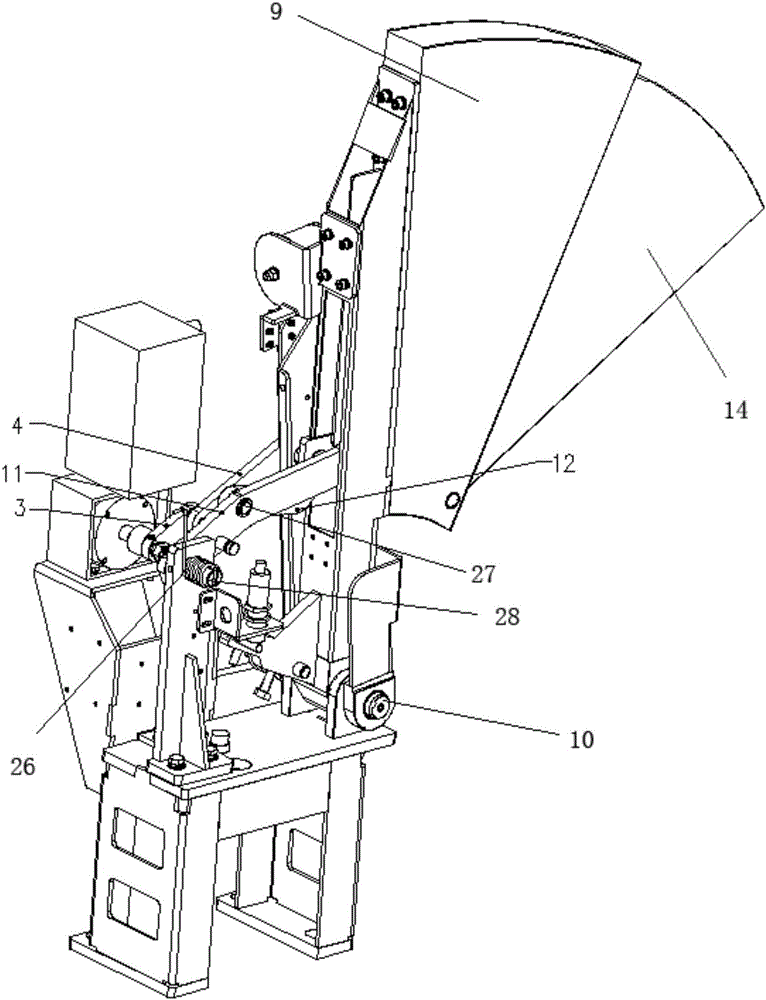

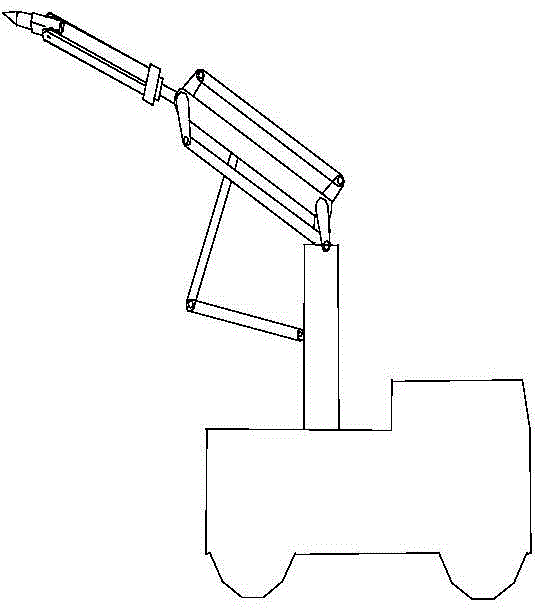

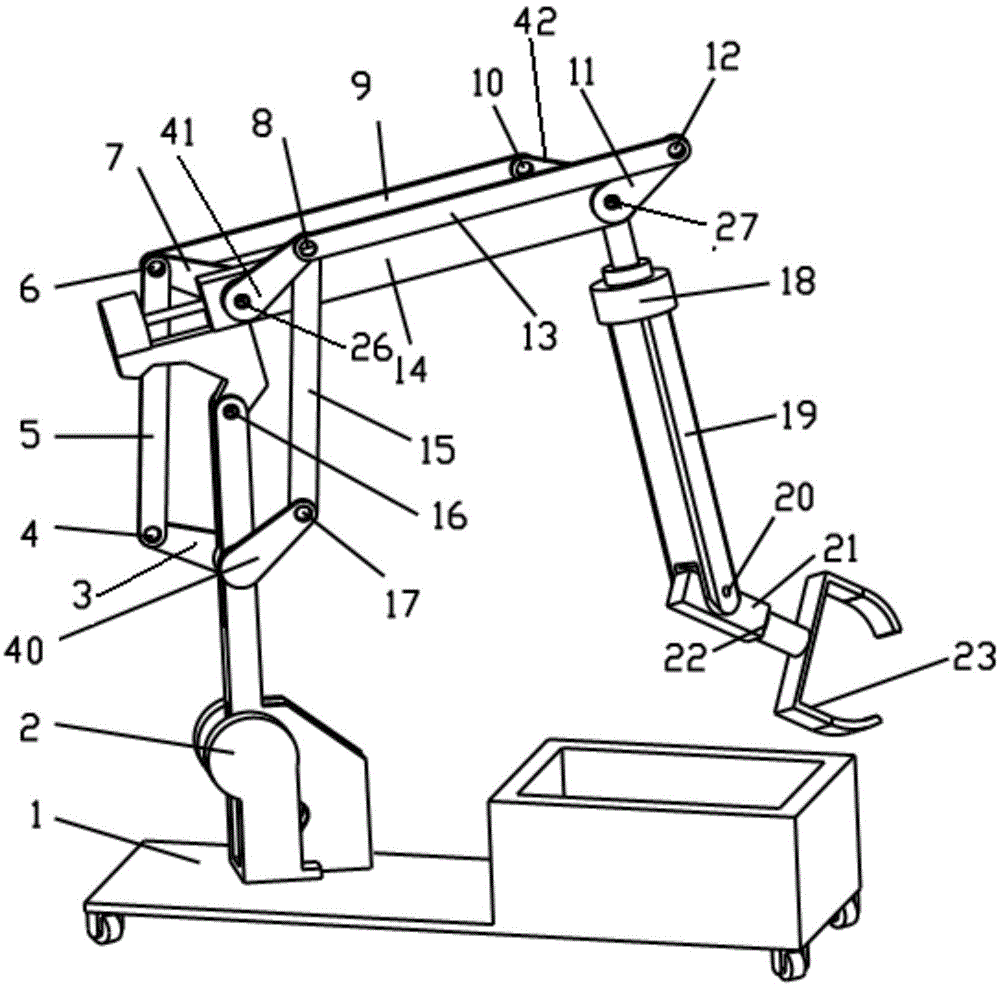

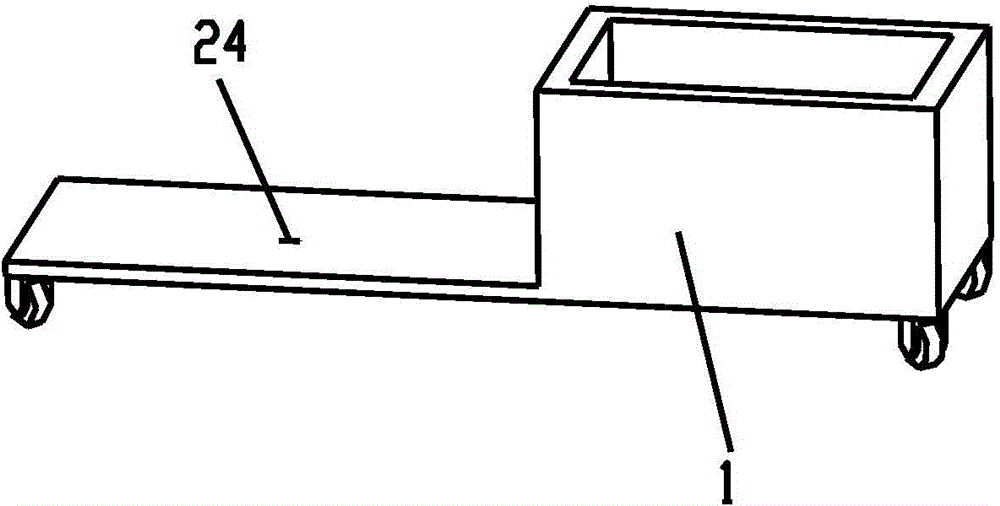

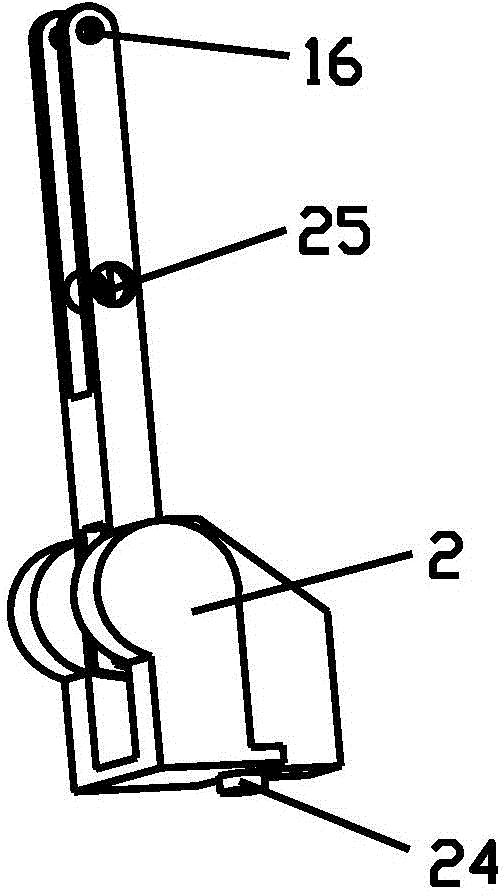

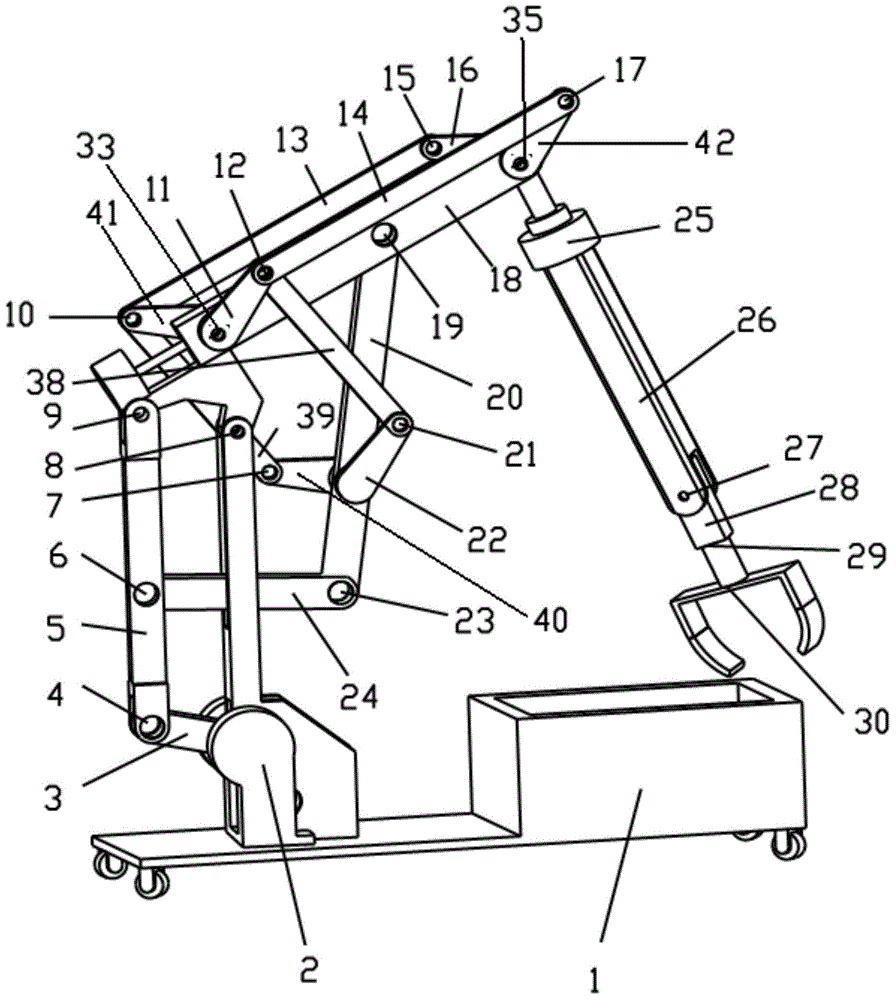

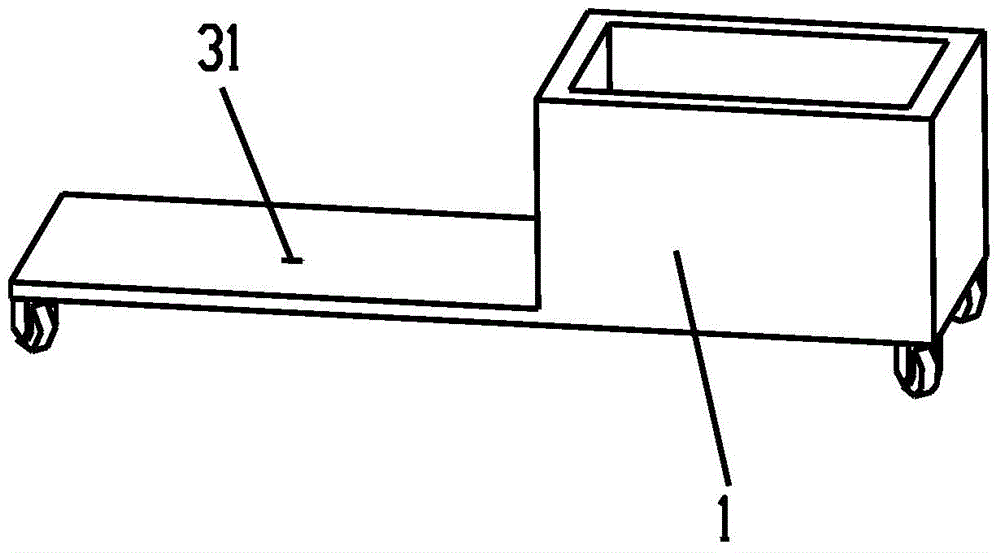

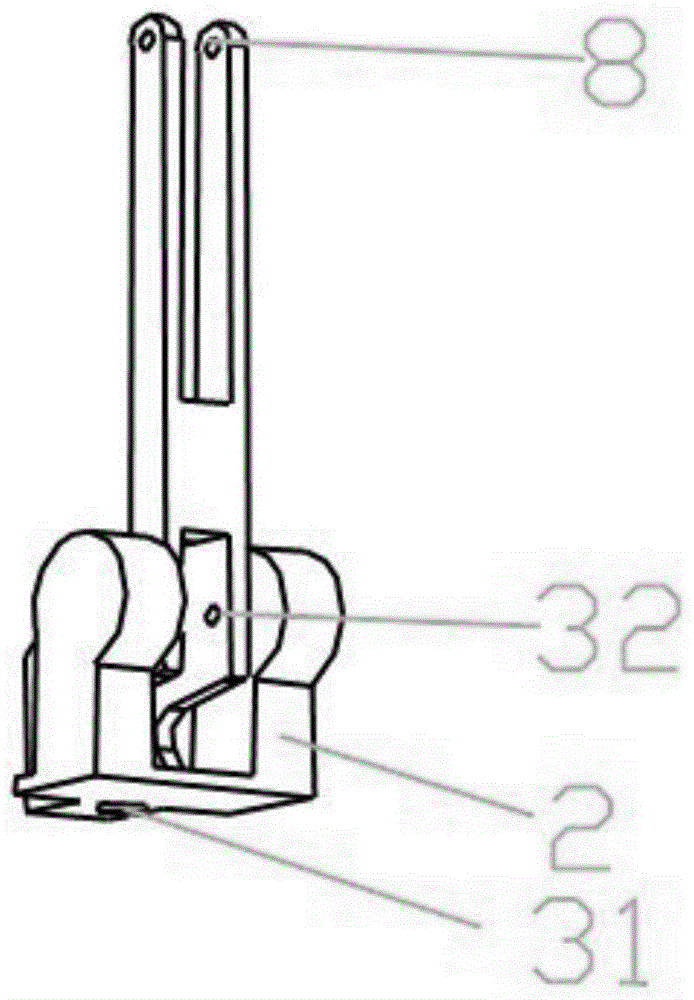

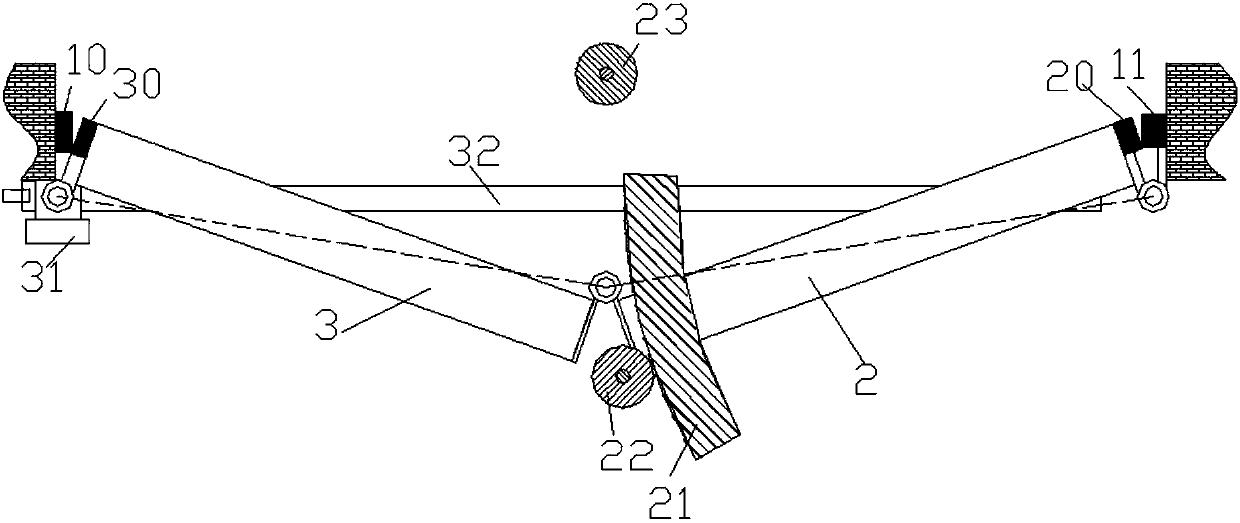

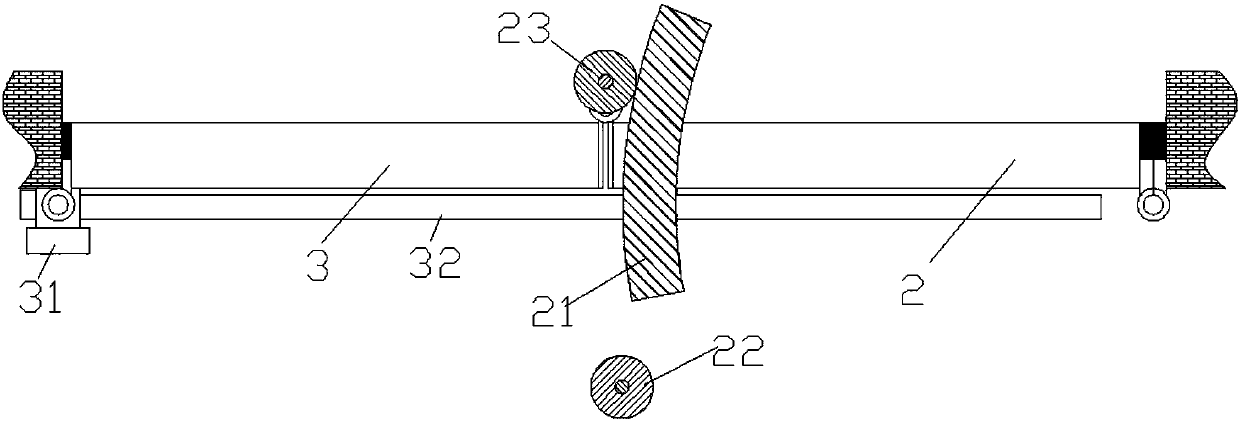

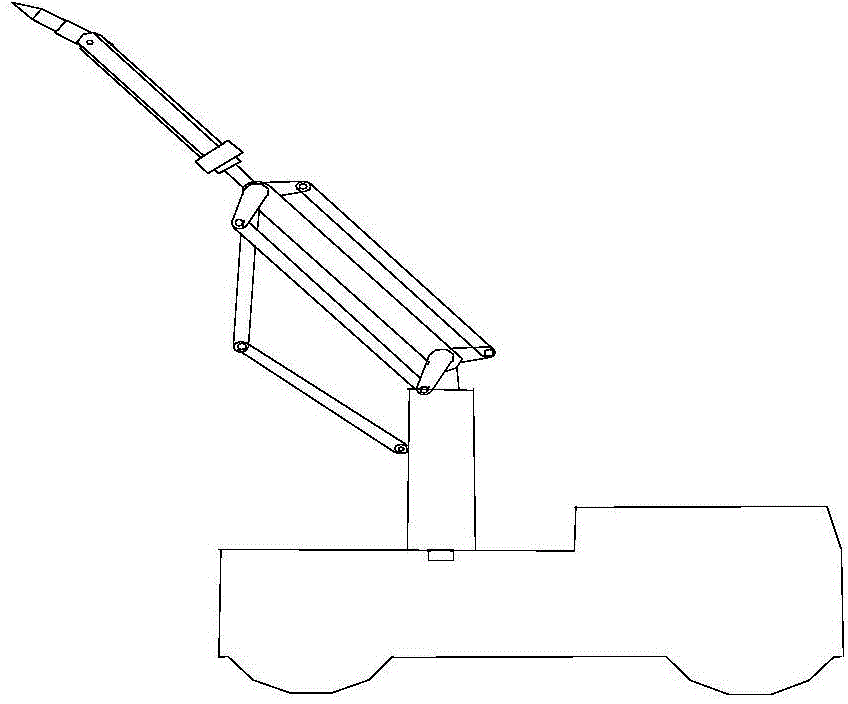

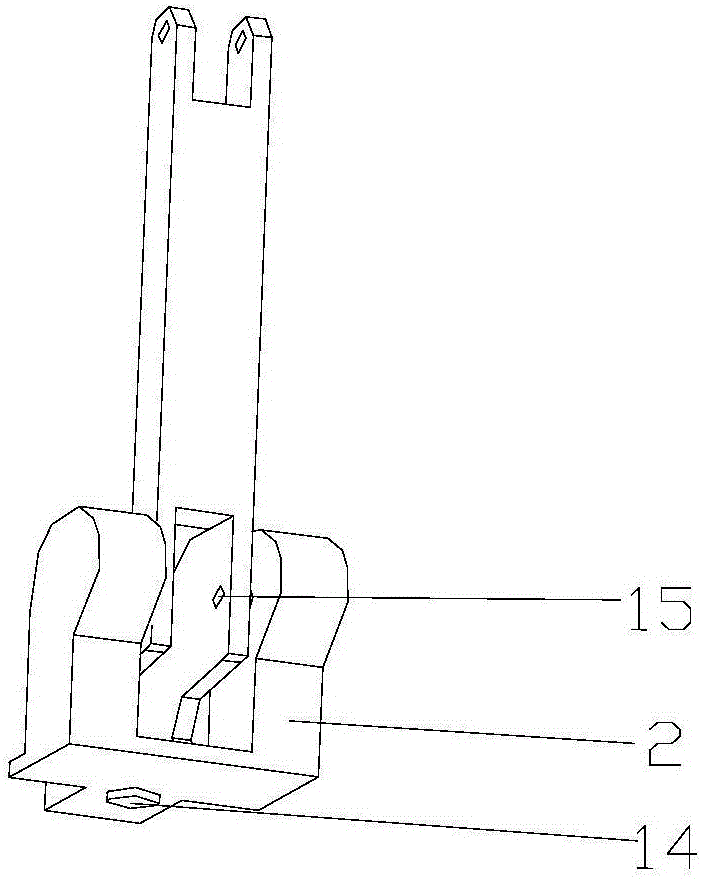

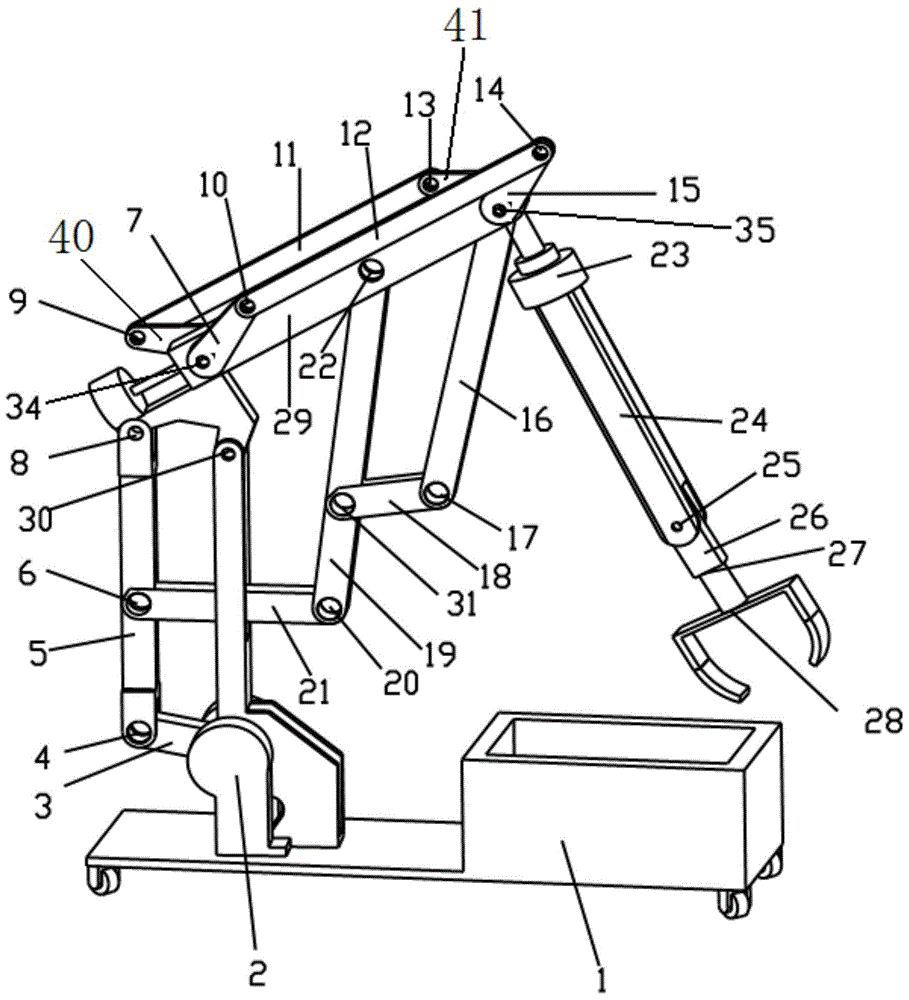

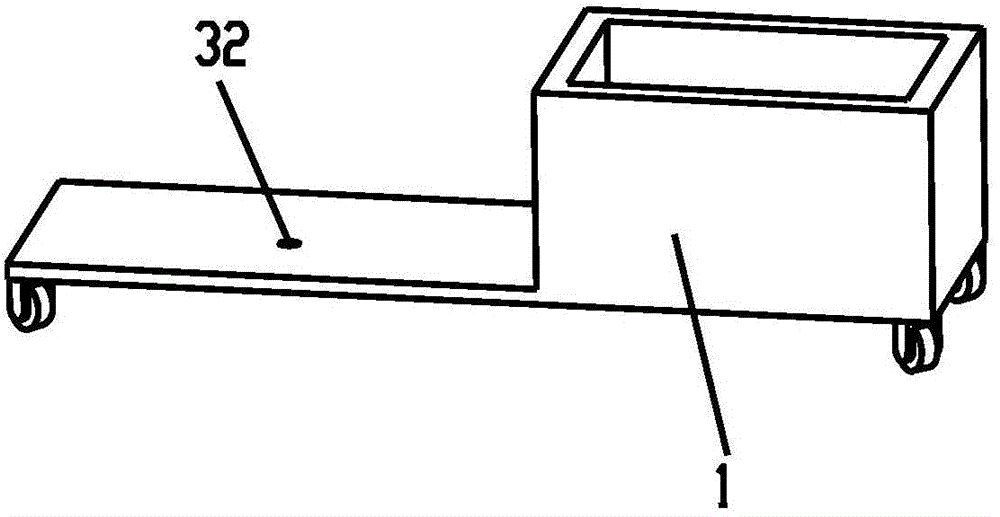

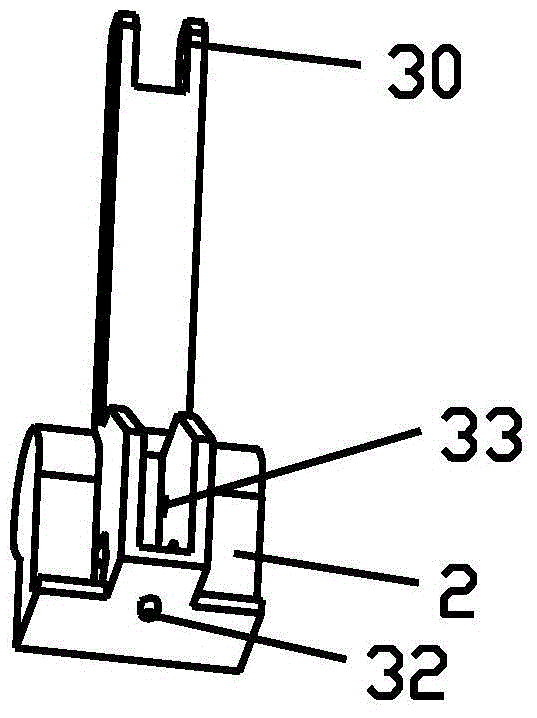

Controllable symmetrical-and-parallel mechanism type loader

InactiveCN103726532AIncrease stiffnessIncrease workspaceMechanical machines/dredgersMechanical reliabilityClosed loop

A controllable symmetrical-and-parallel mechanism type loader comprises a main actuator chain with a closed-loop subchain and two parallel actuator subchains. The main actuator chain with the closed-loop subchain can control plane motion of a bucket space of a plane where main arm bars are located, and the actuator subchains perform controllable regulation on the bucket and control motions of turning up and down and the like of the bucket. The controllable symmetrical-and-parallel mechanism type loader has the advantages that plane control can be realized through the synthetic motions of the main actuator chain with the closed-loop subchain, and the spatial motion of the bucket is realized through connection of the actuator subchains; the bucket space is good in dynamics performance, large in working space, good in balance performance, high in mechanical reliability, compact in mechanism and simple to control; the member bars can be made into light bars acting on more occasions; the loader is driven fully electrically and free of emissions and noise pollution.

Owner:GUANGXI UNIV

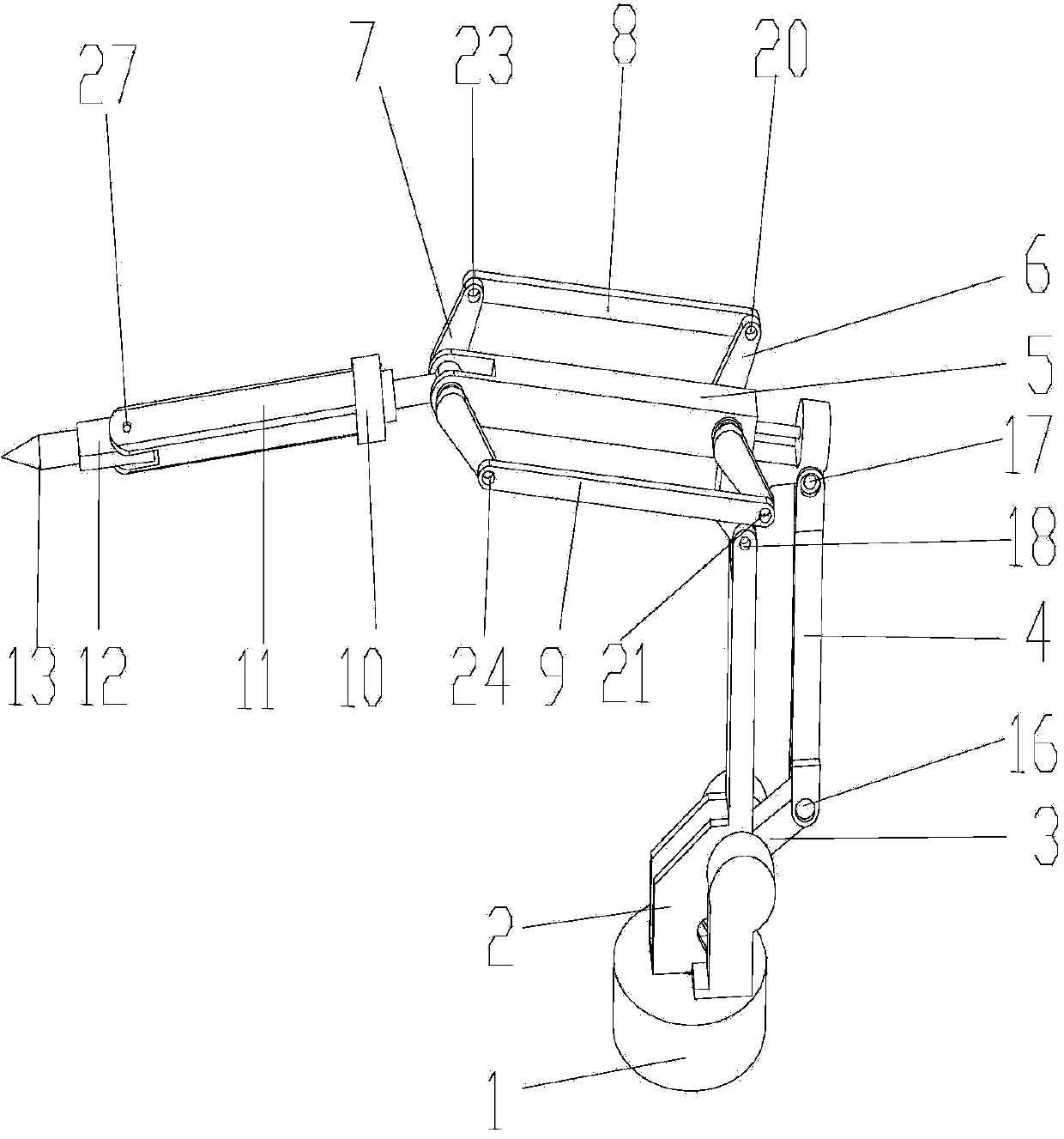

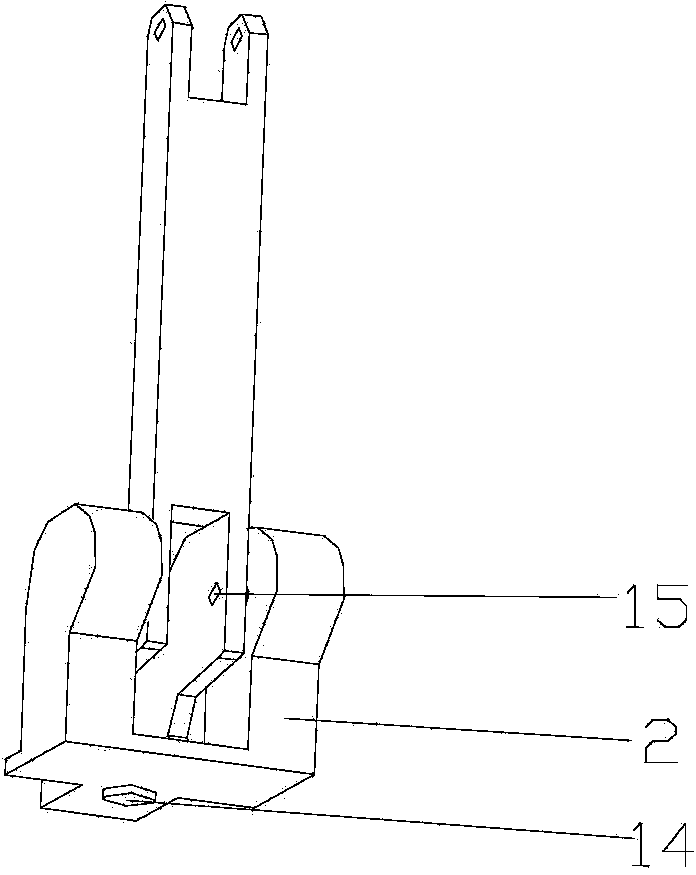

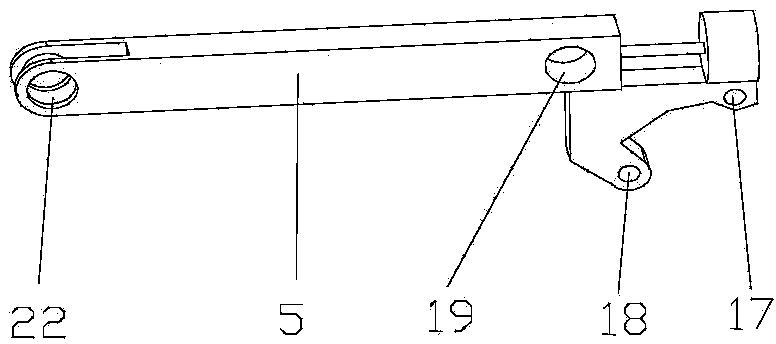

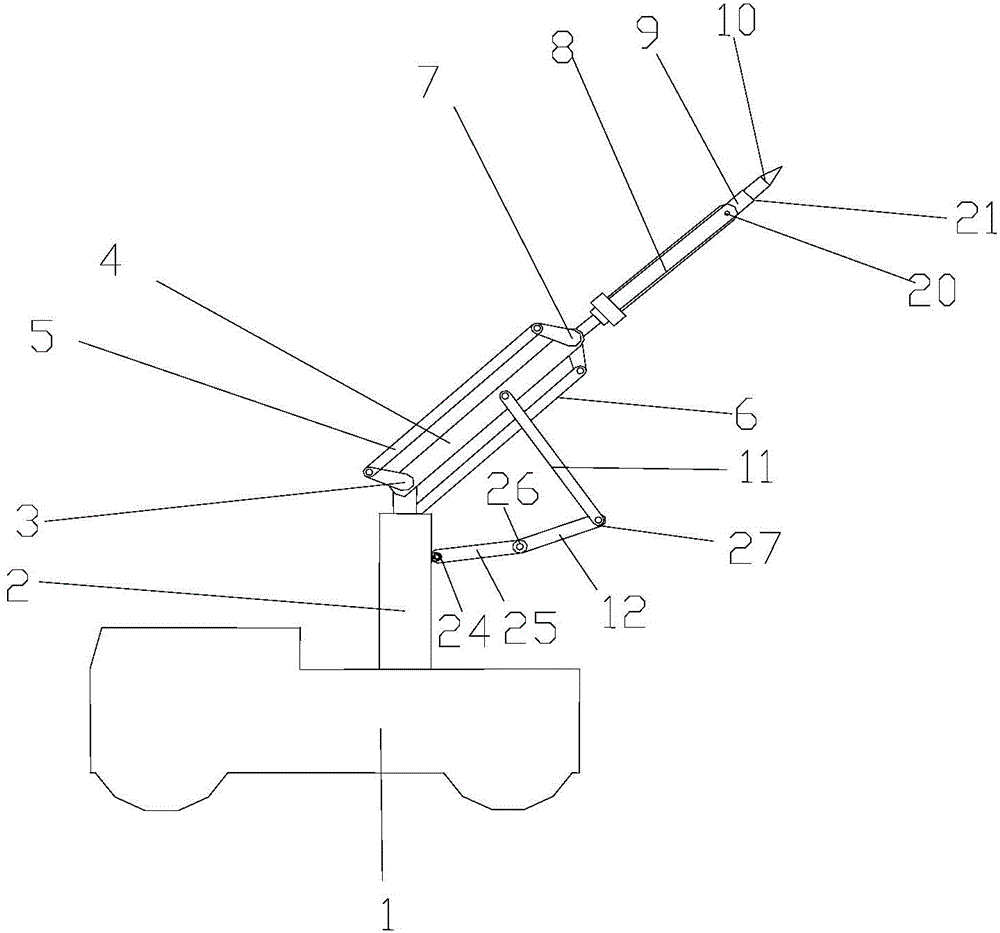

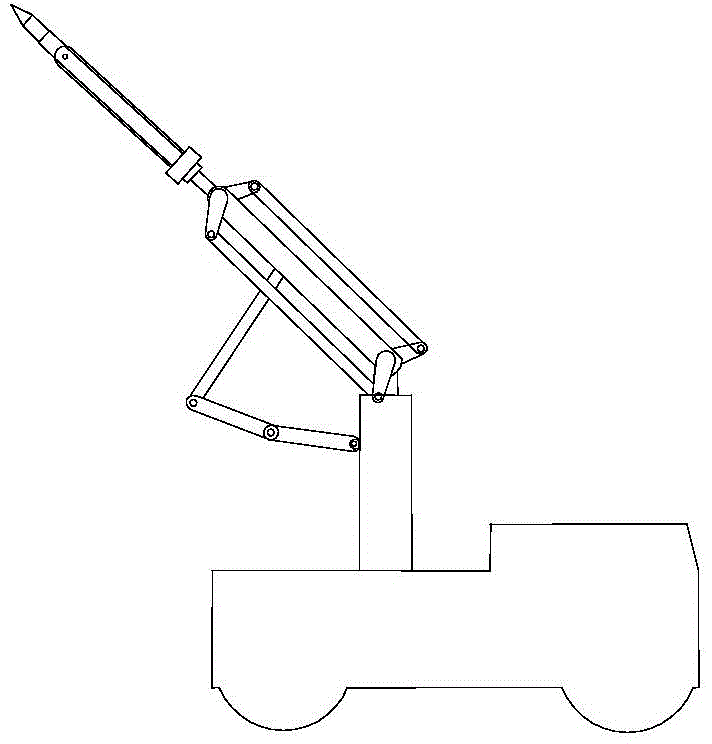

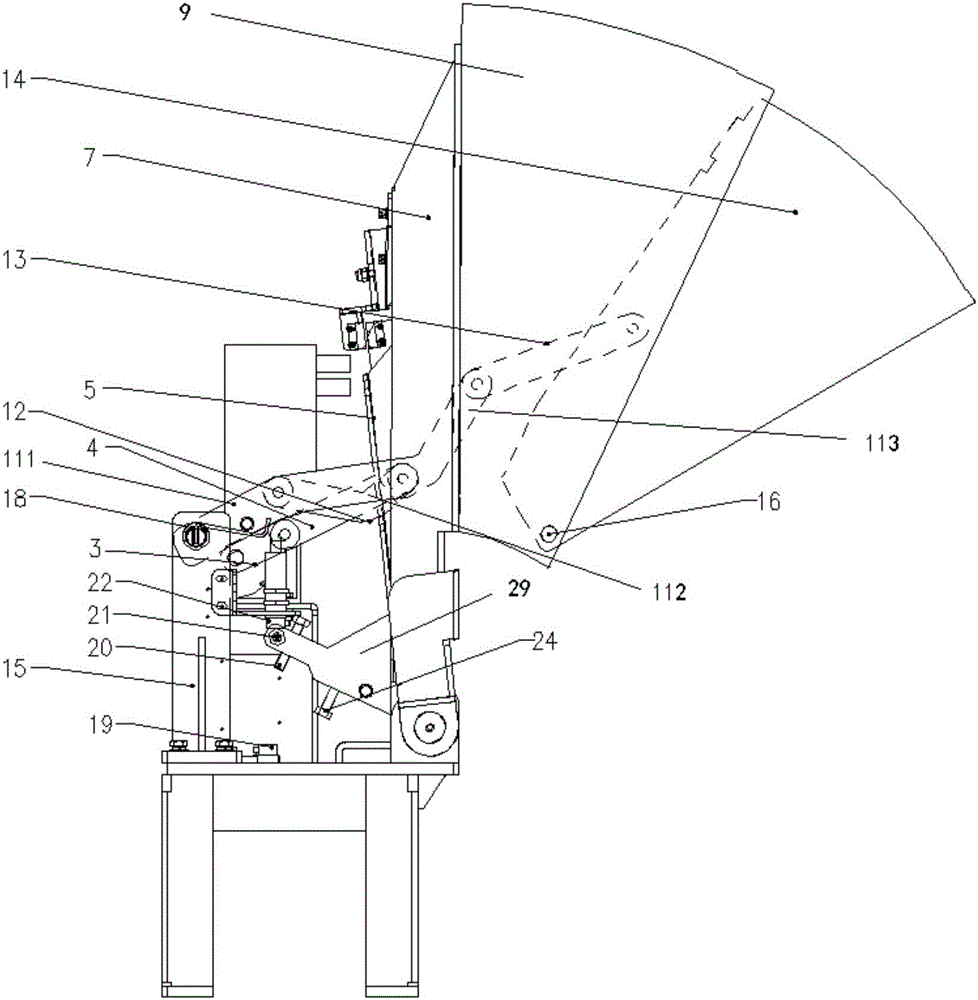

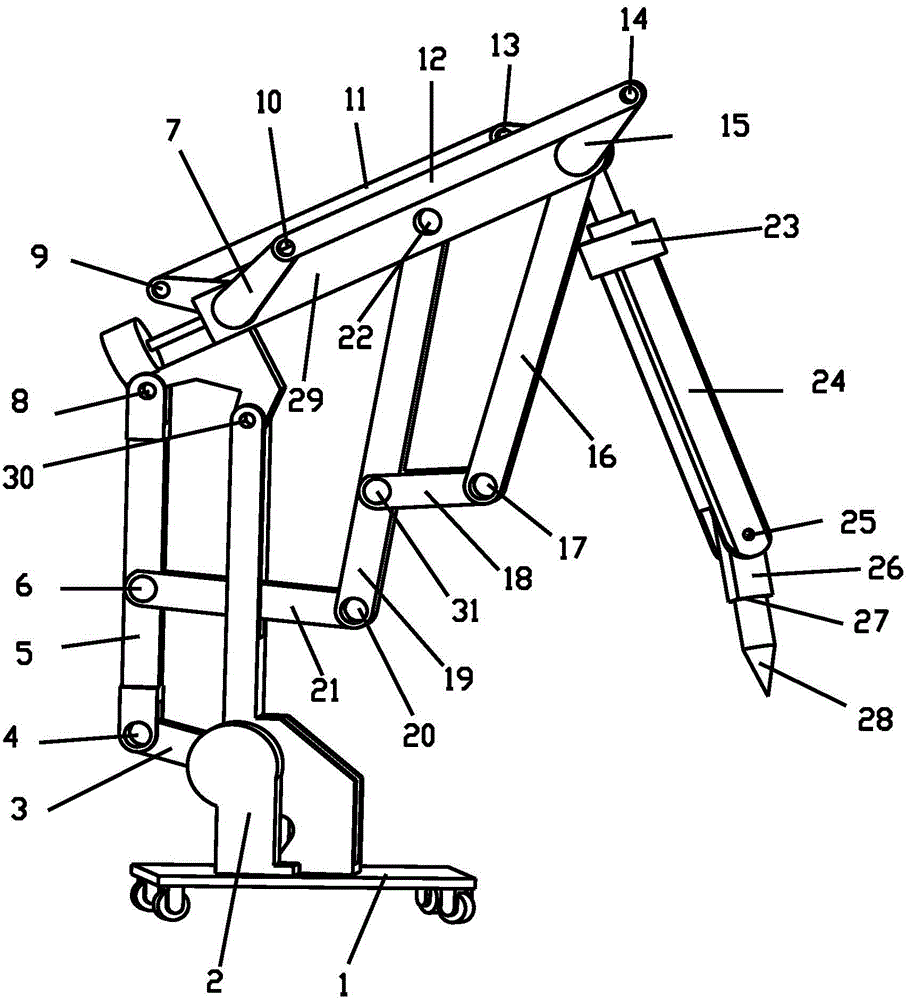

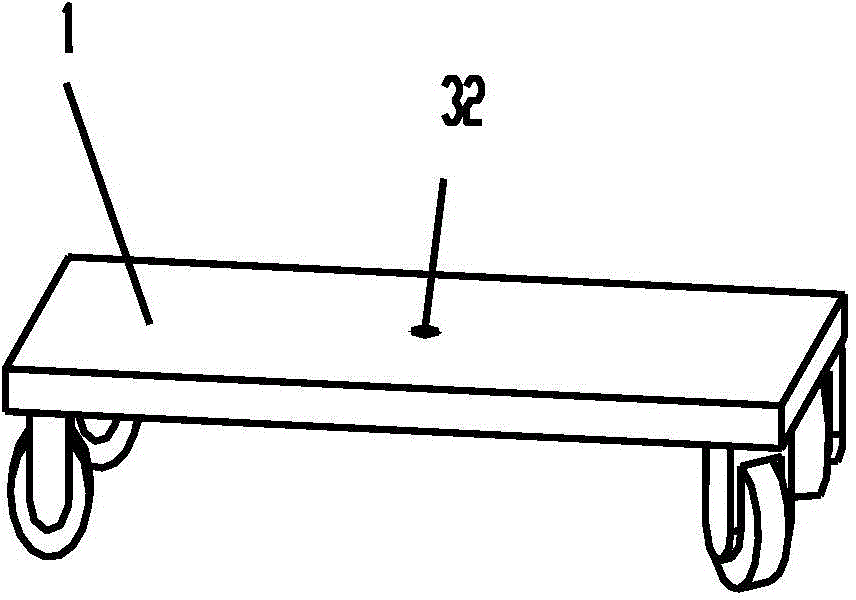

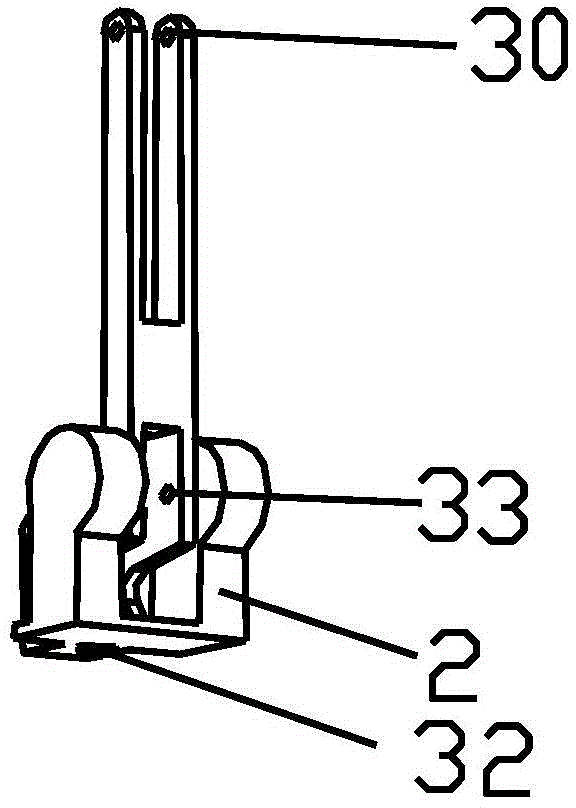

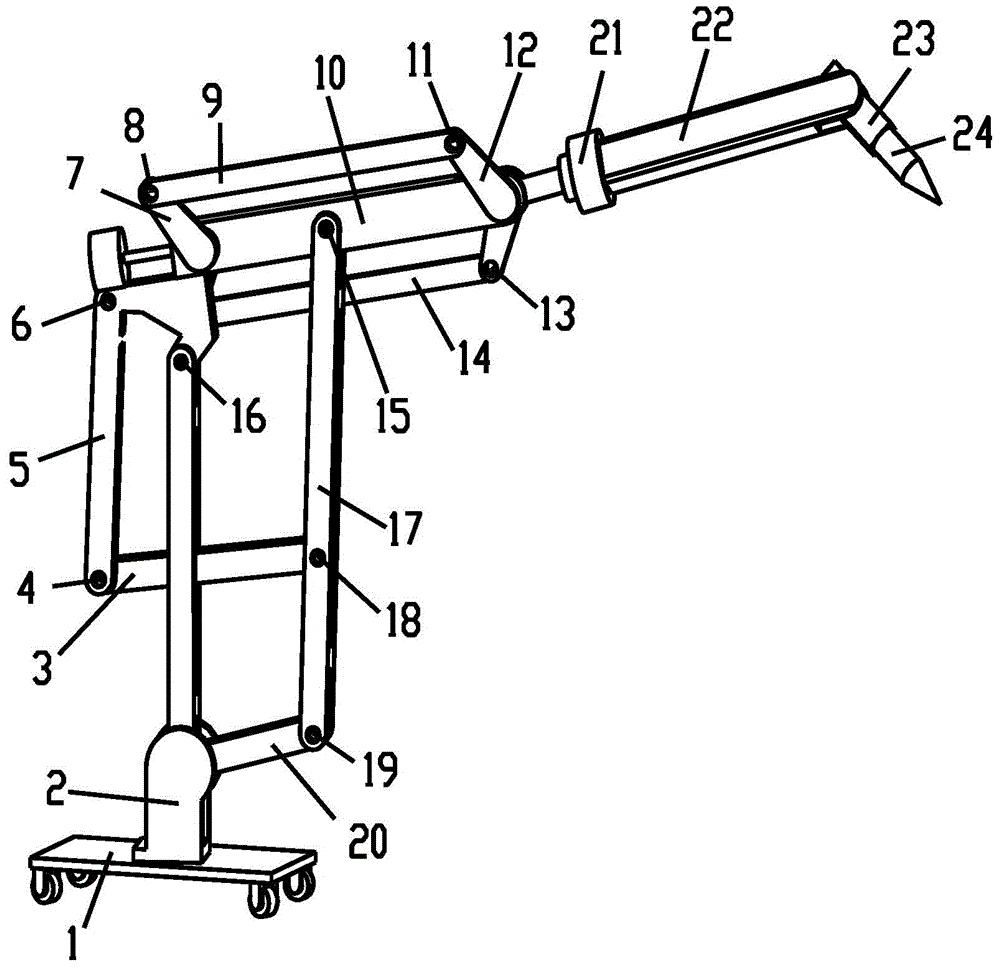

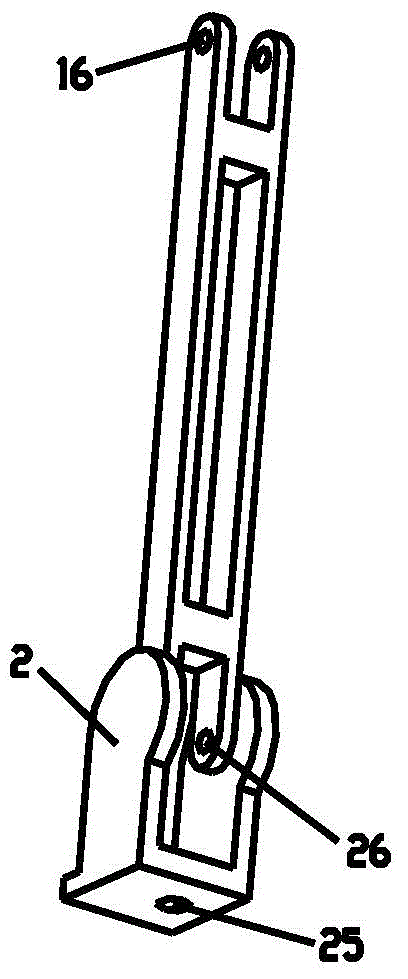

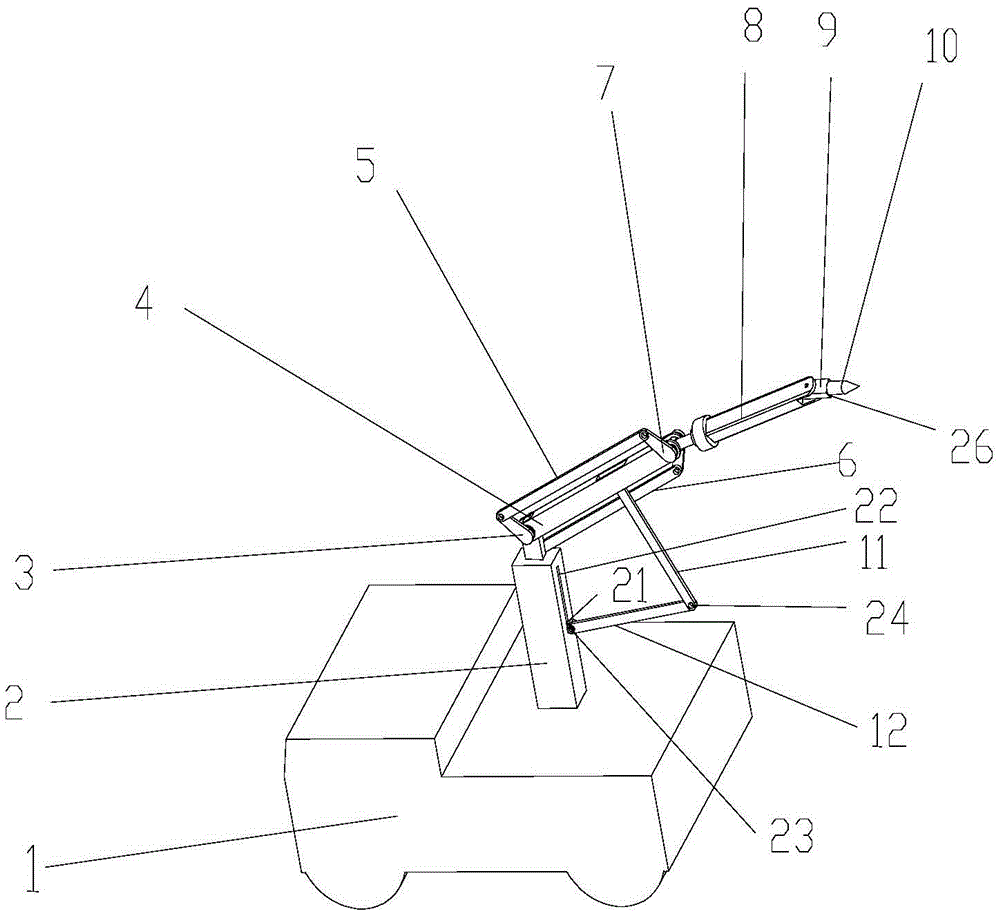

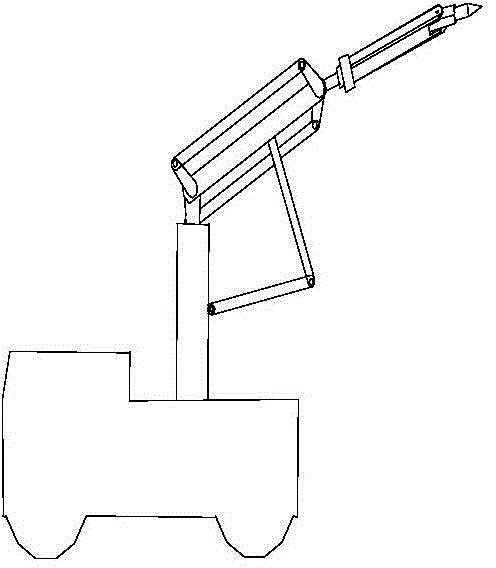

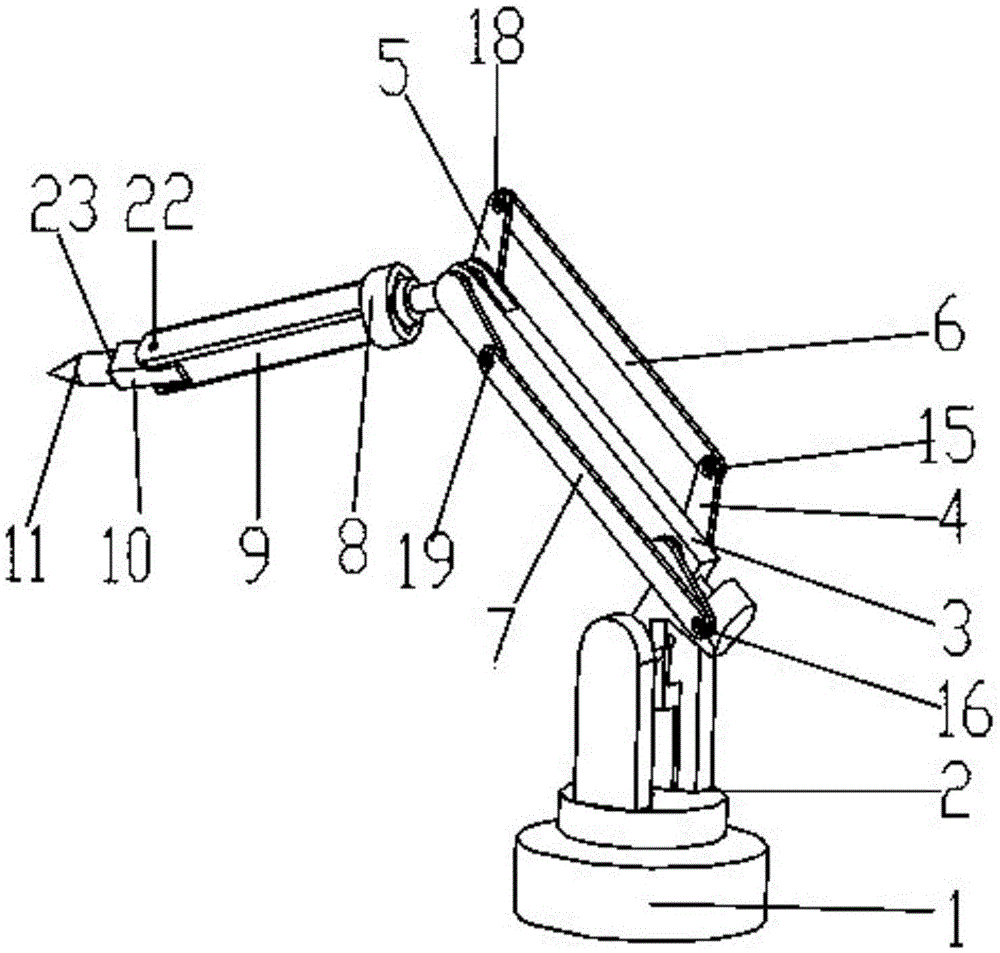

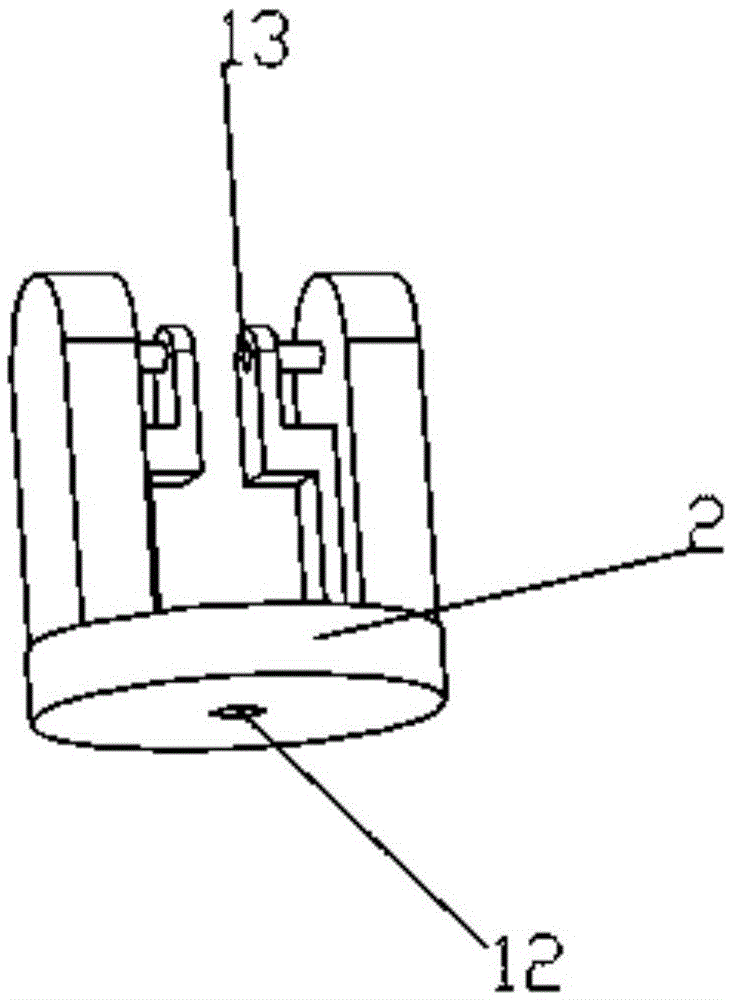

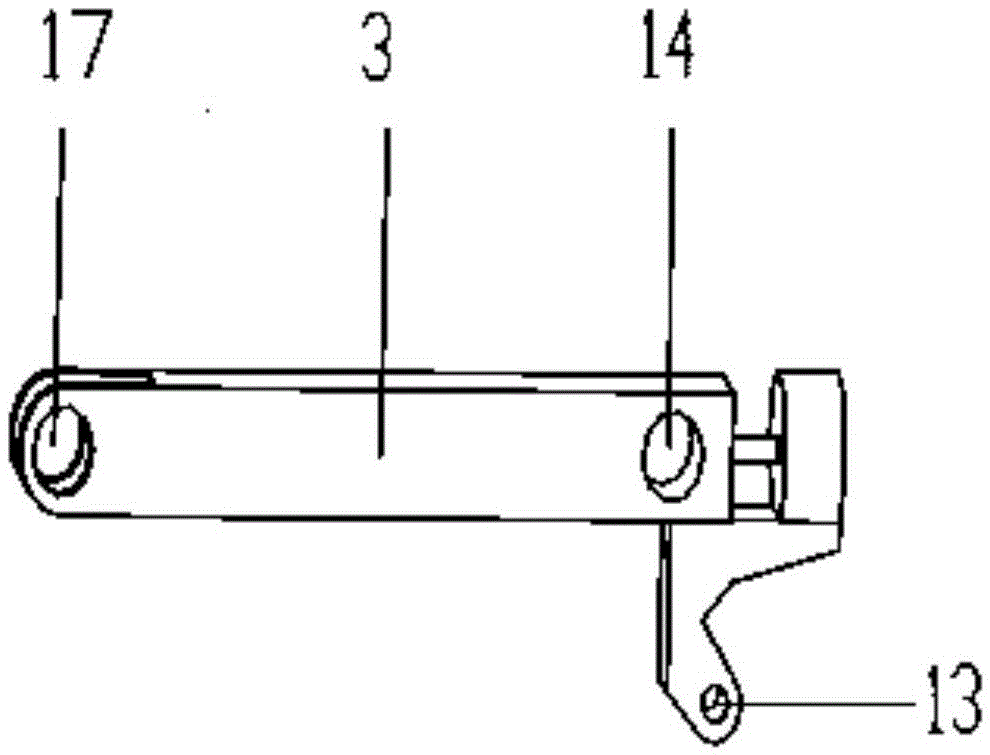

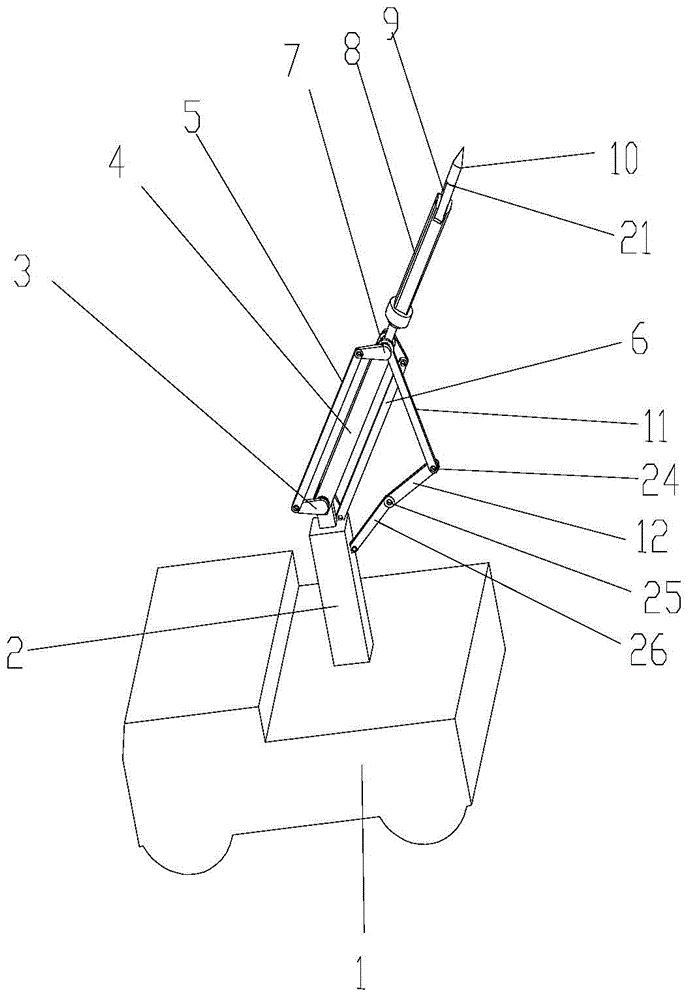

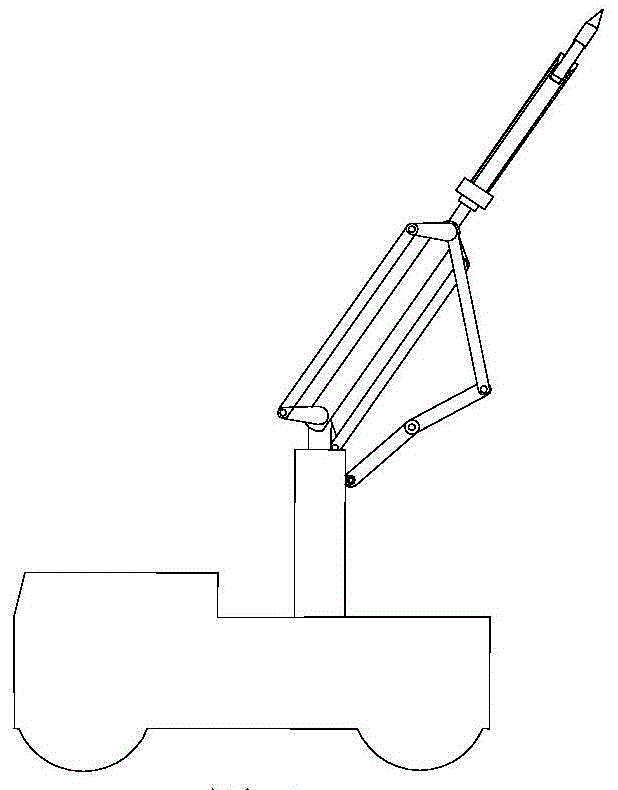

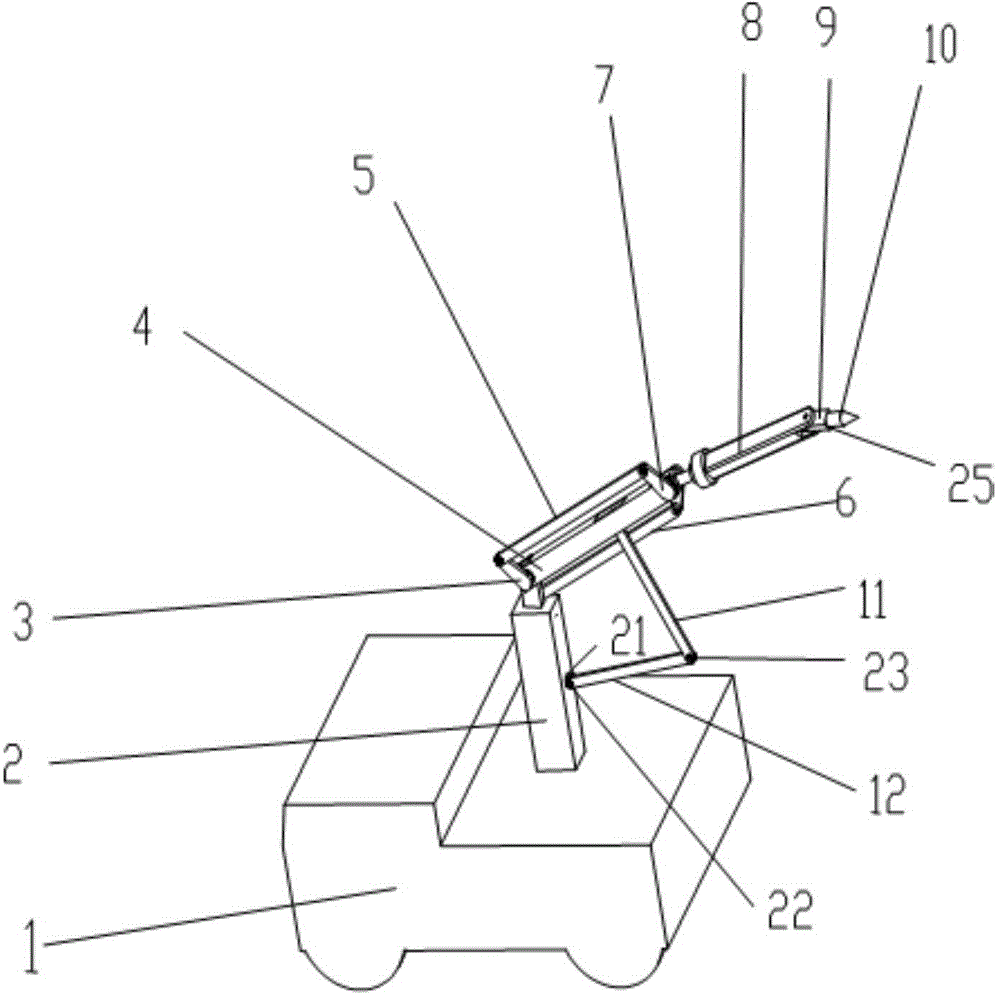

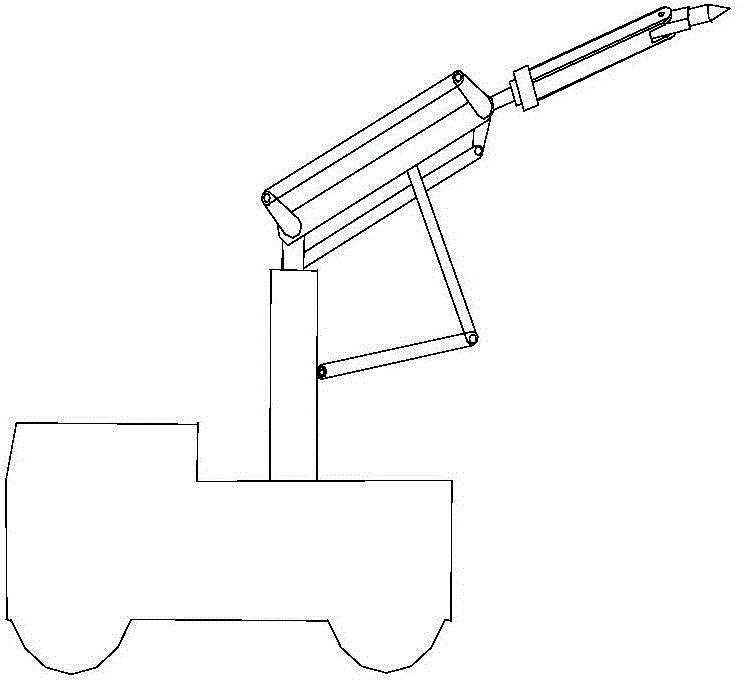

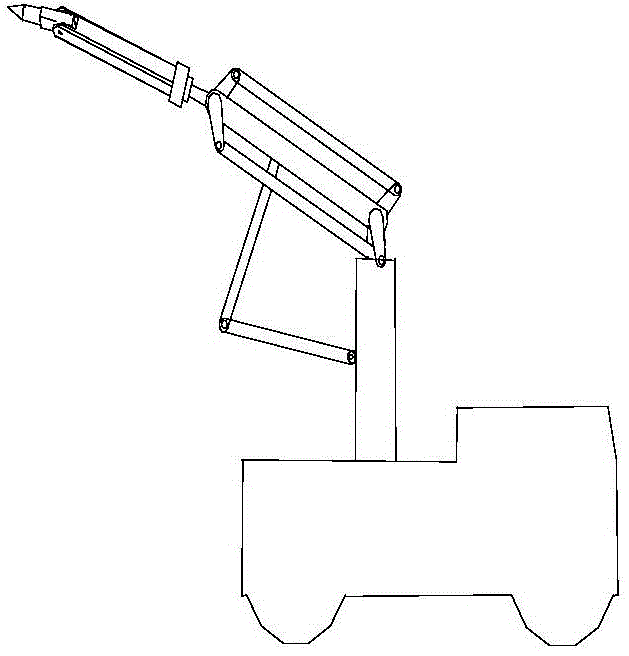

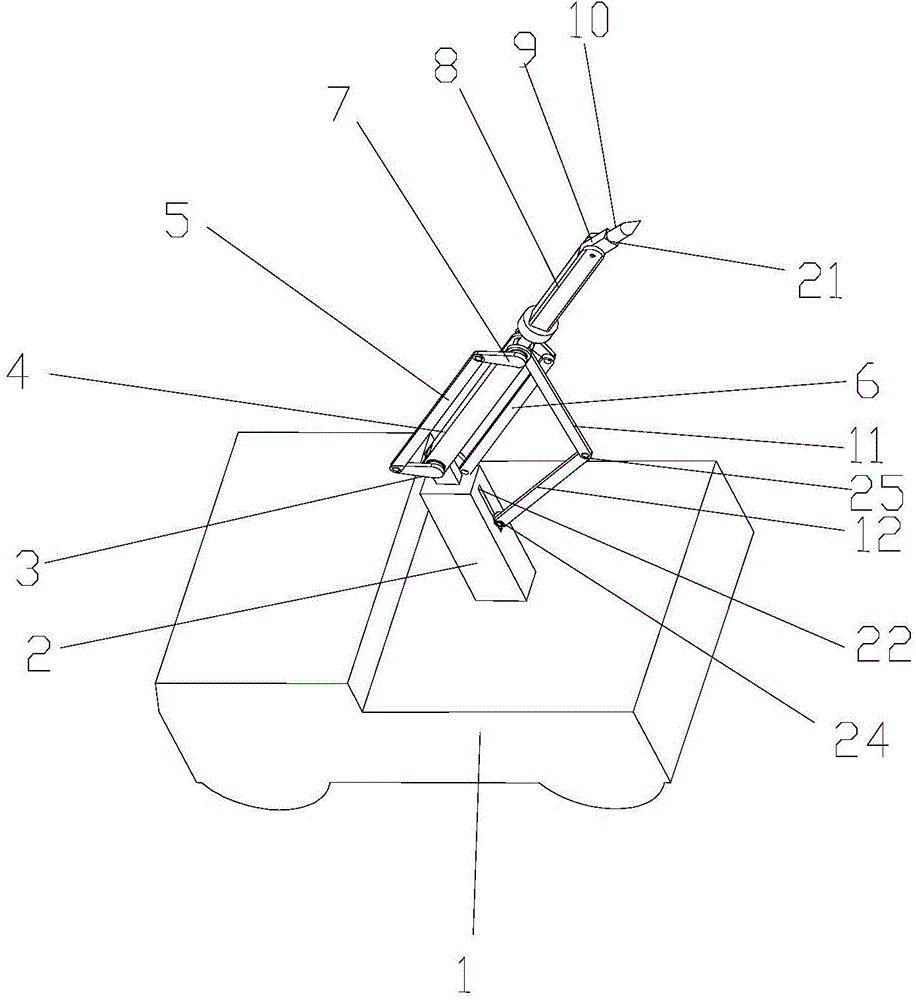

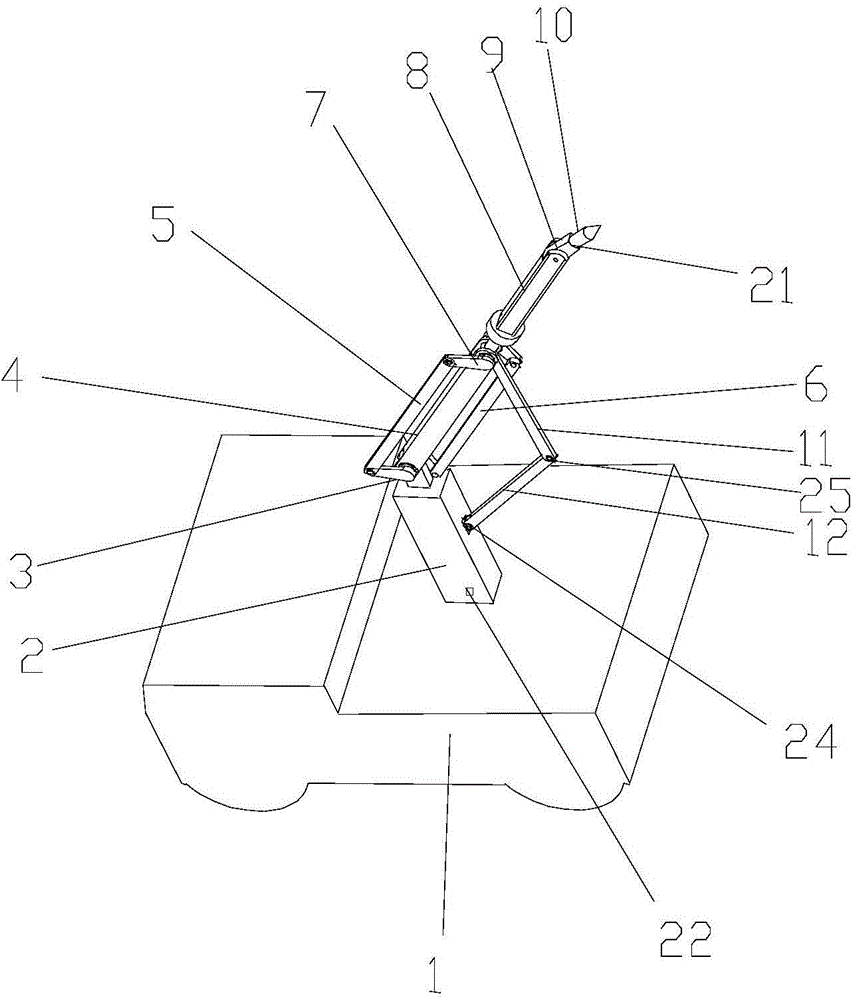

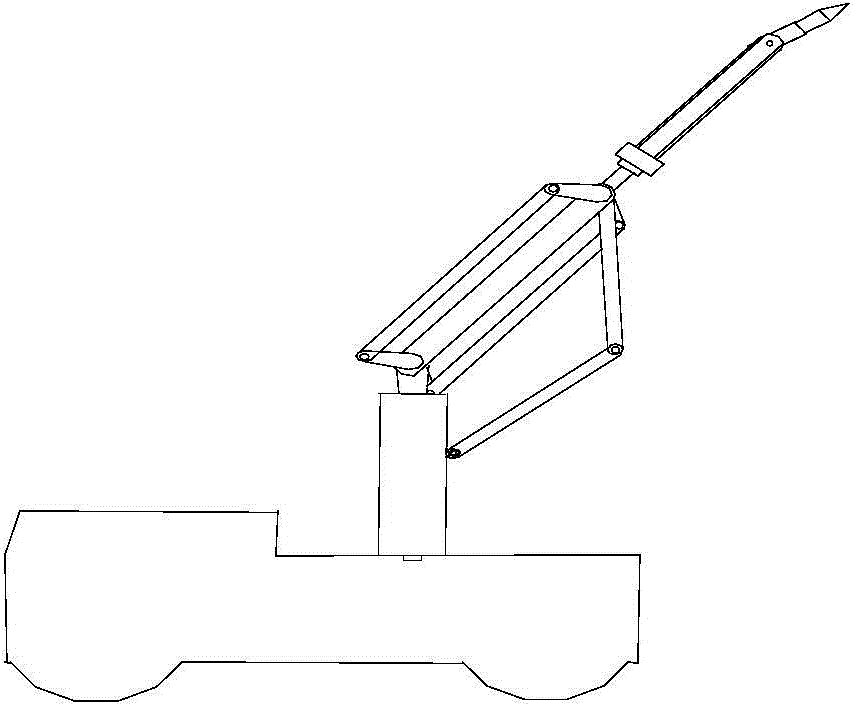

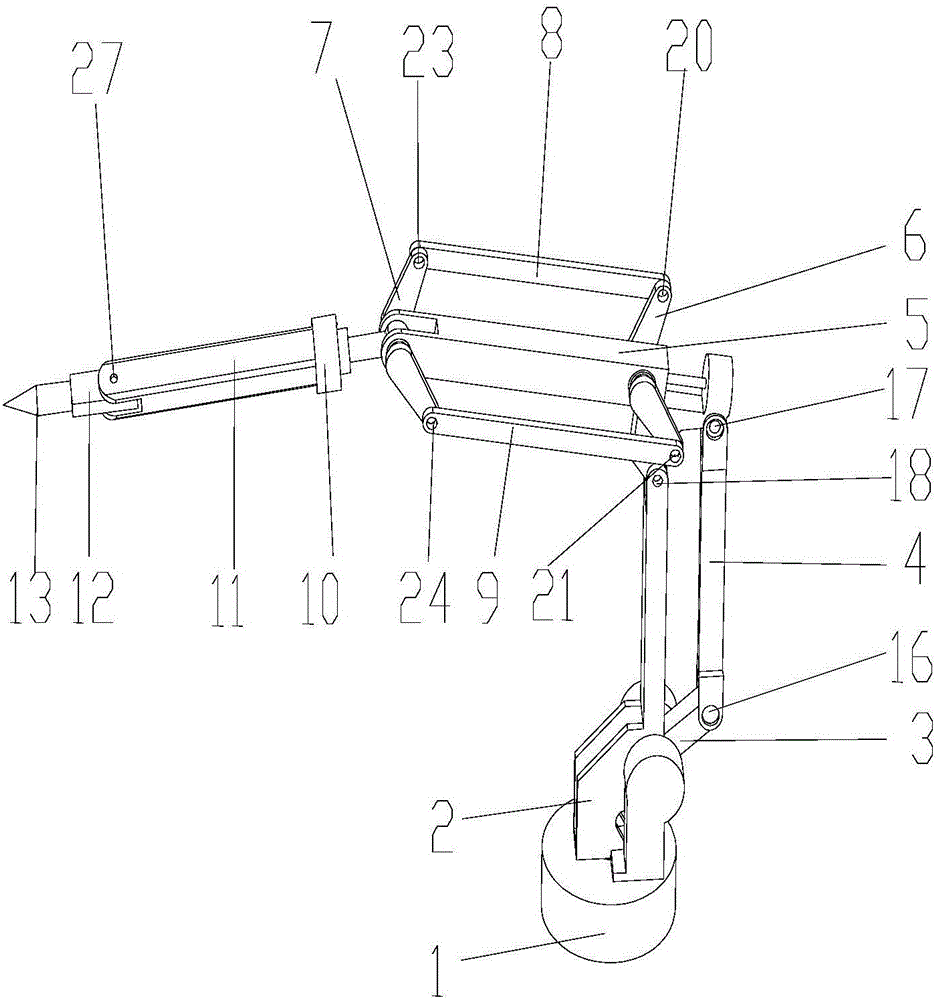

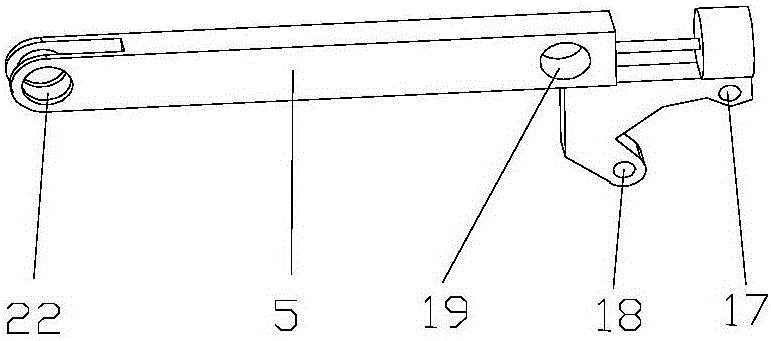

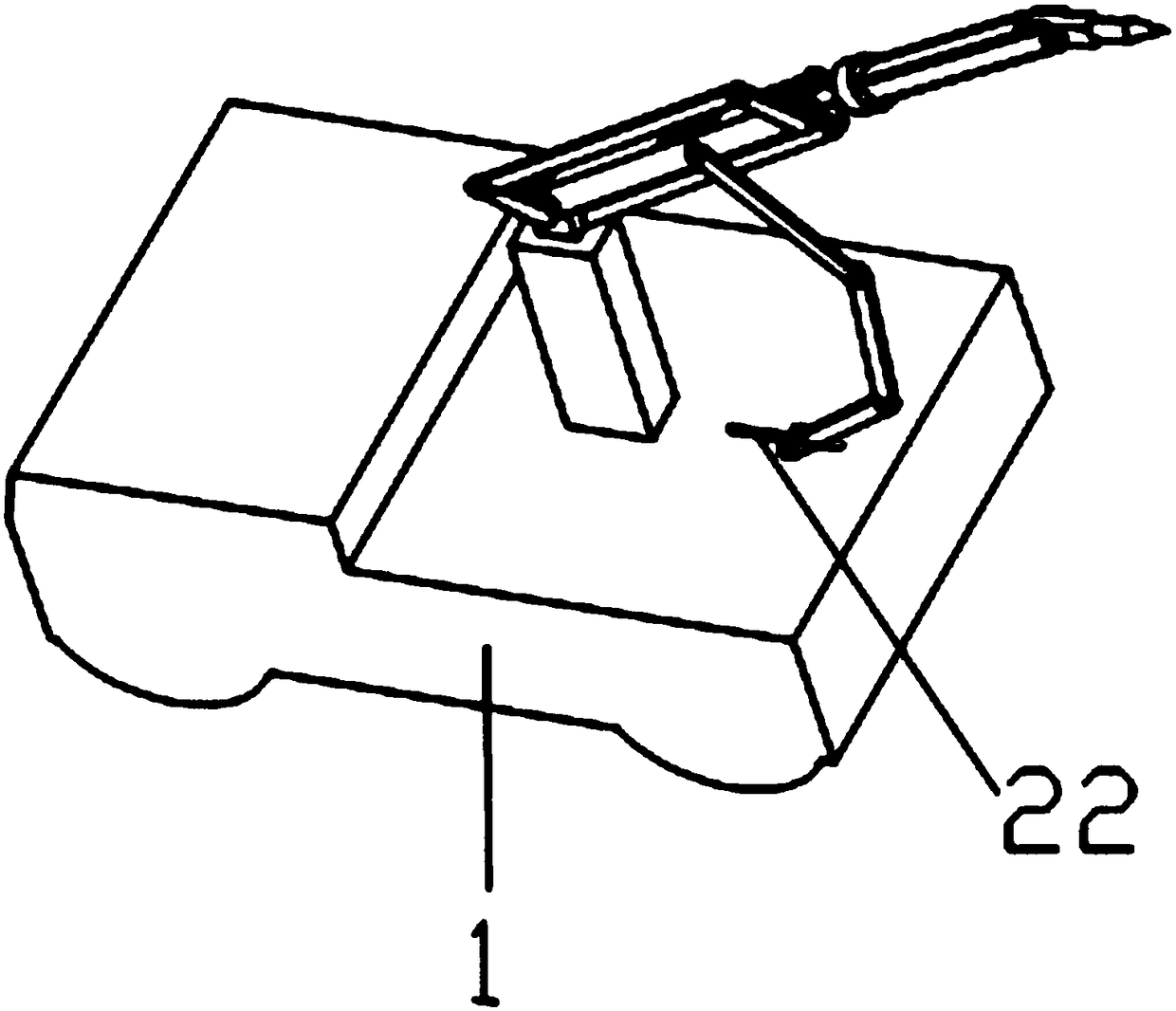

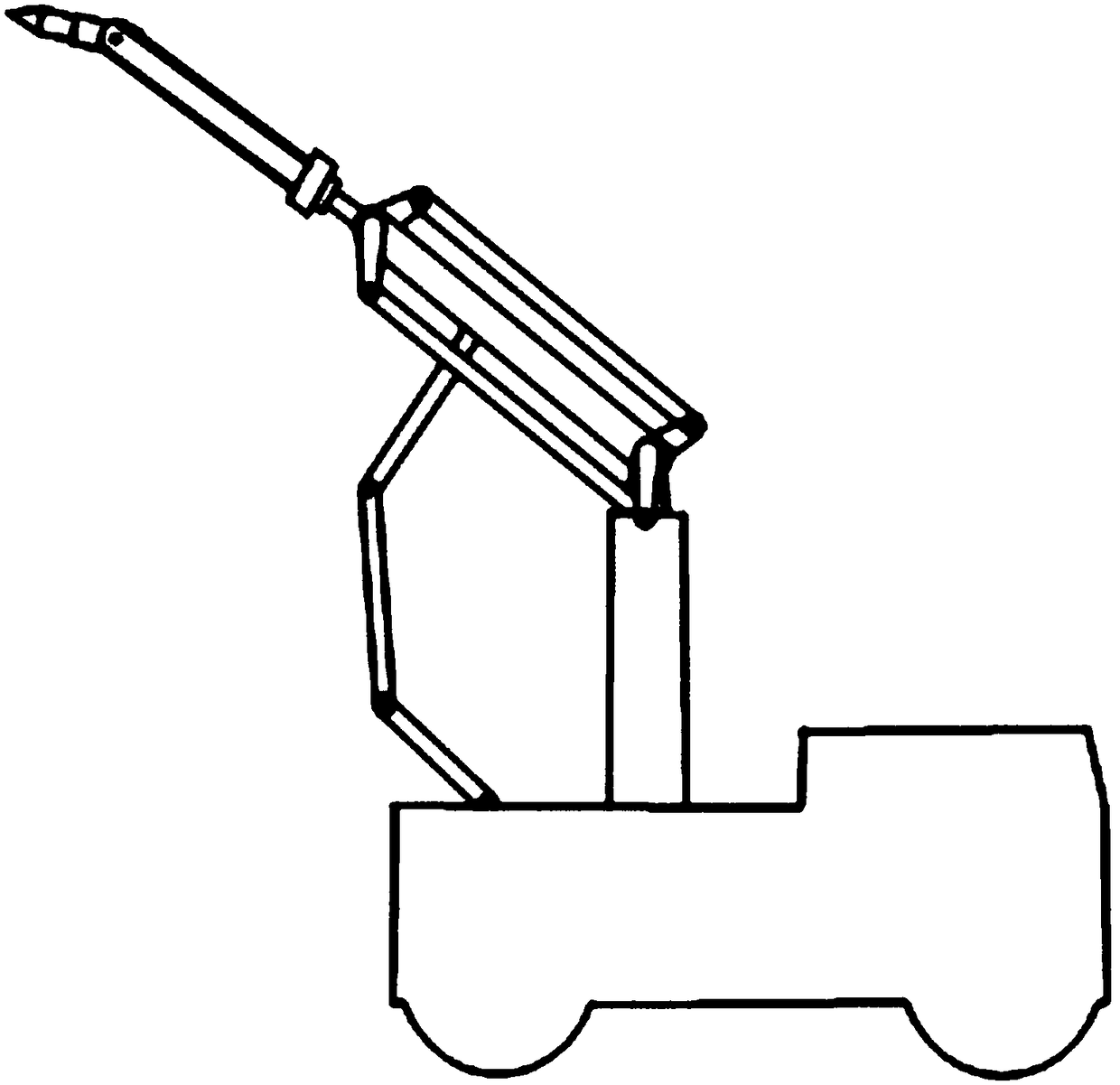

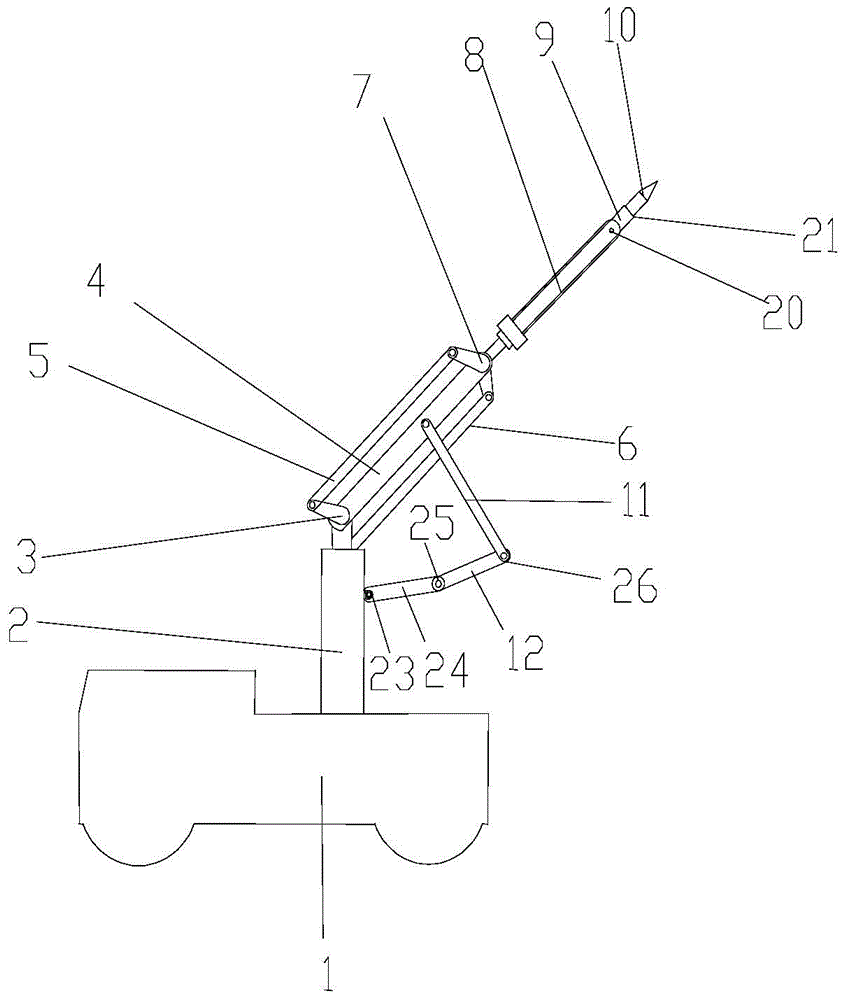

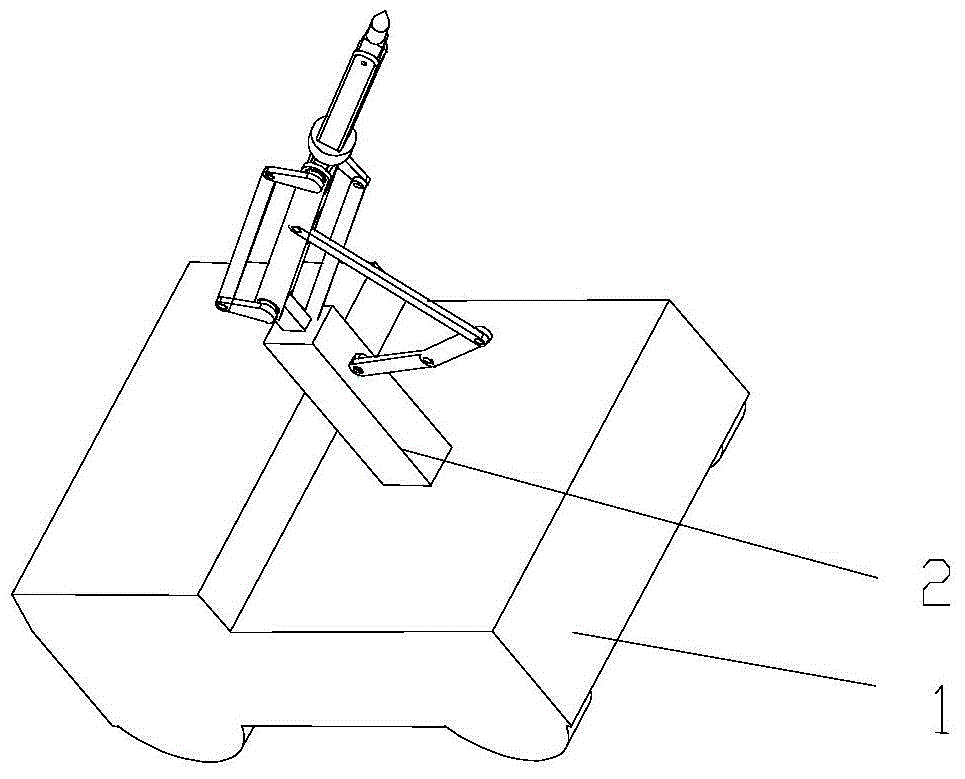

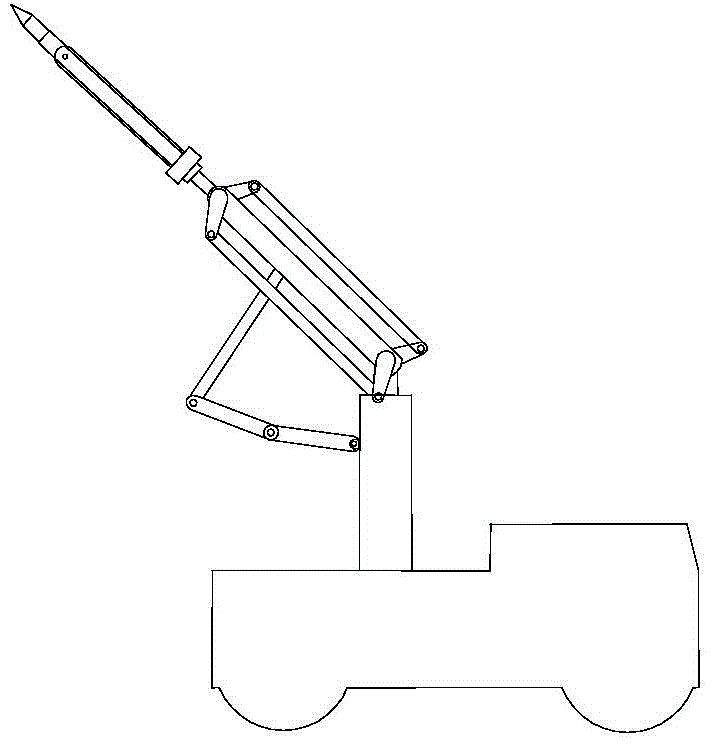

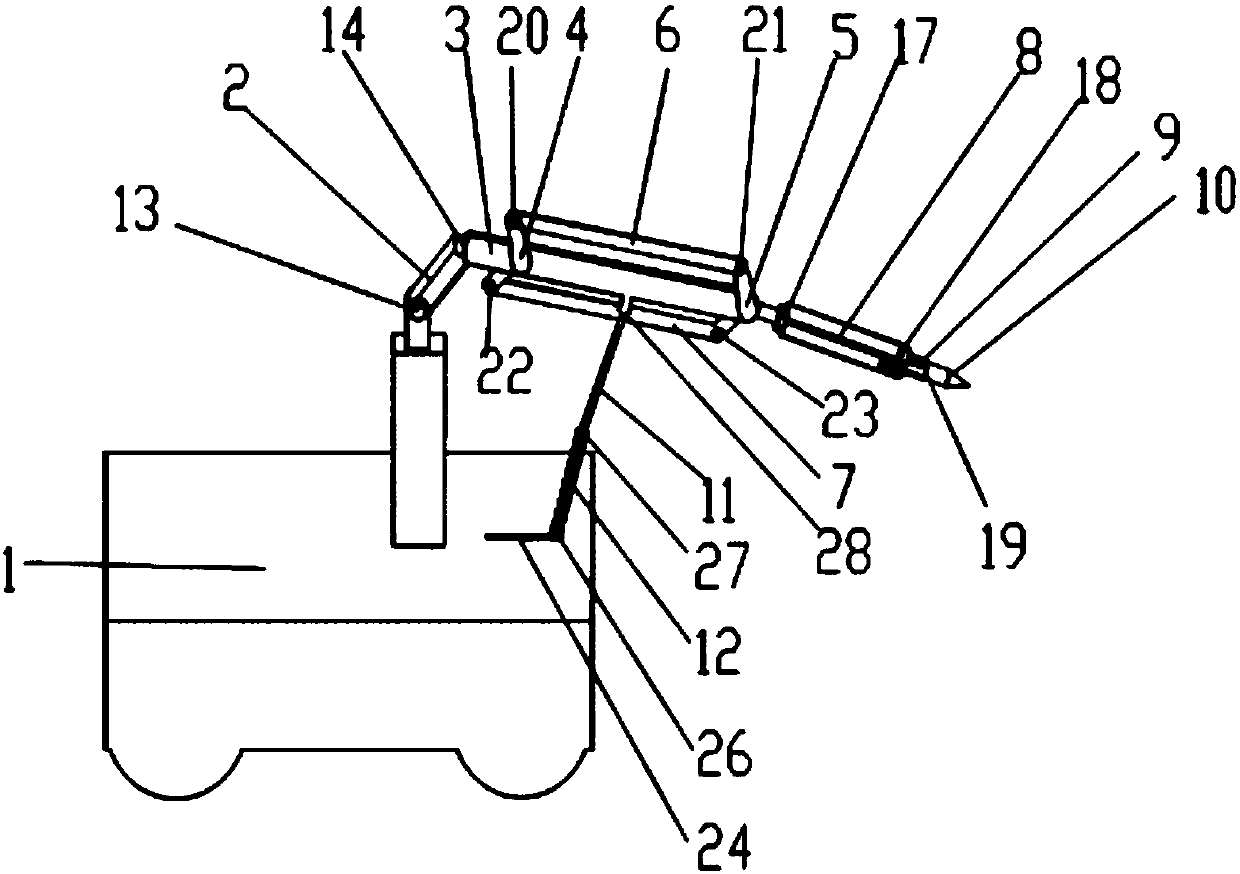

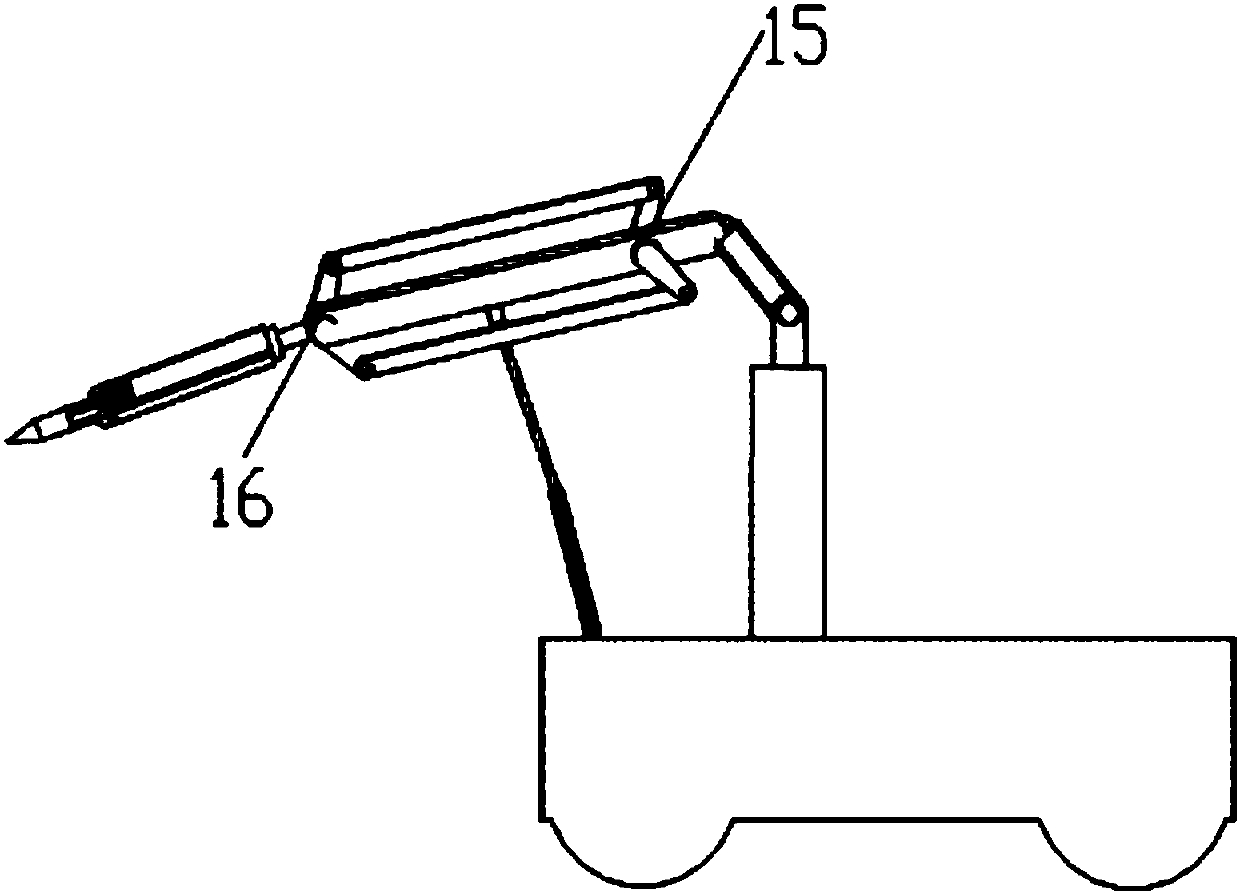

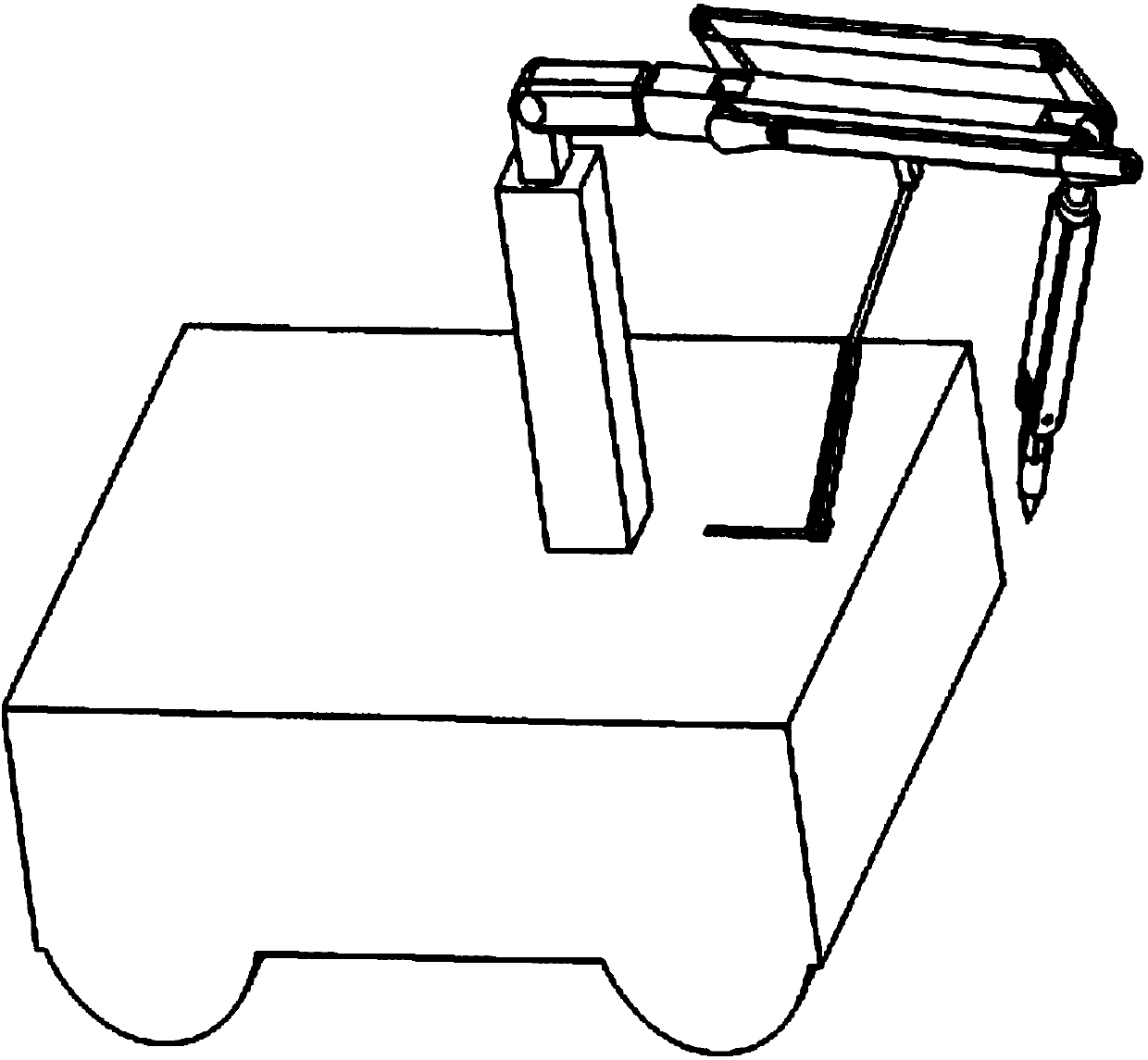

Multi-degree-of-freedom controllable mechanism type moving welding robot

InactiveCN104552248AAvoid dead center positionImprove balanceProgramme-controlled manipulatorWelding/cutting auxillary devicesMulti degree of freedomEngineering

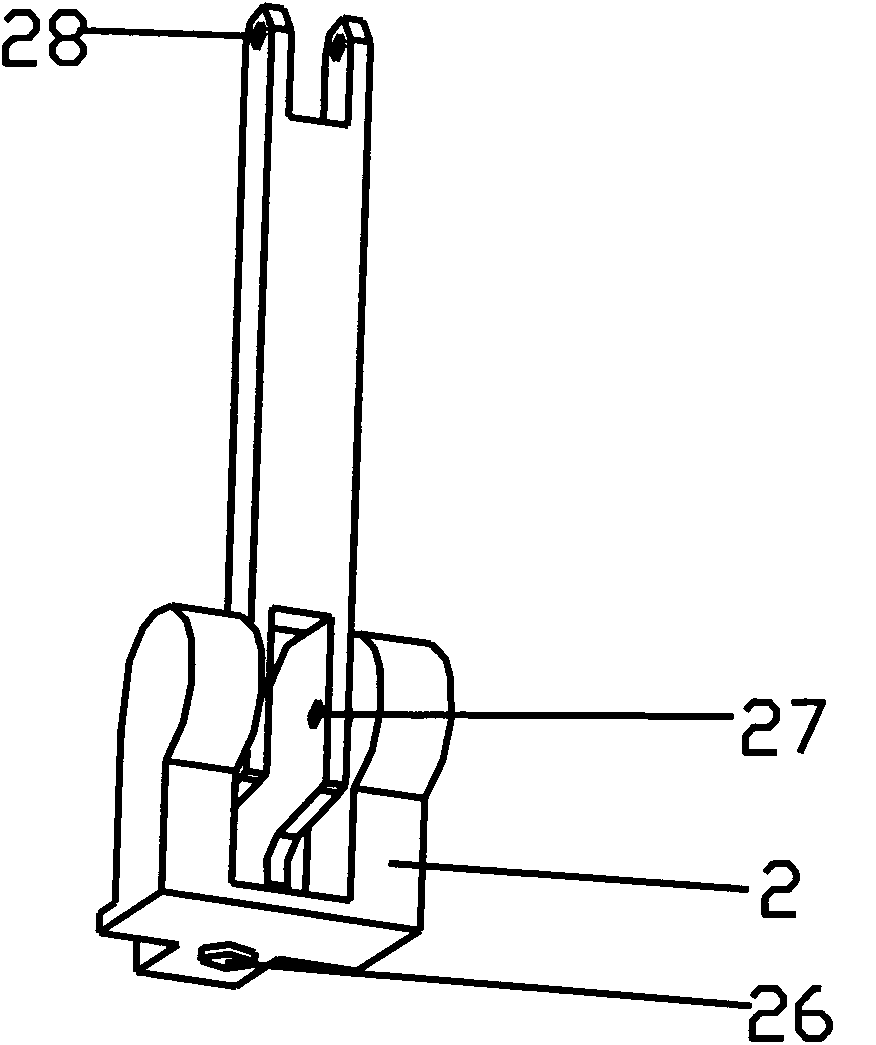

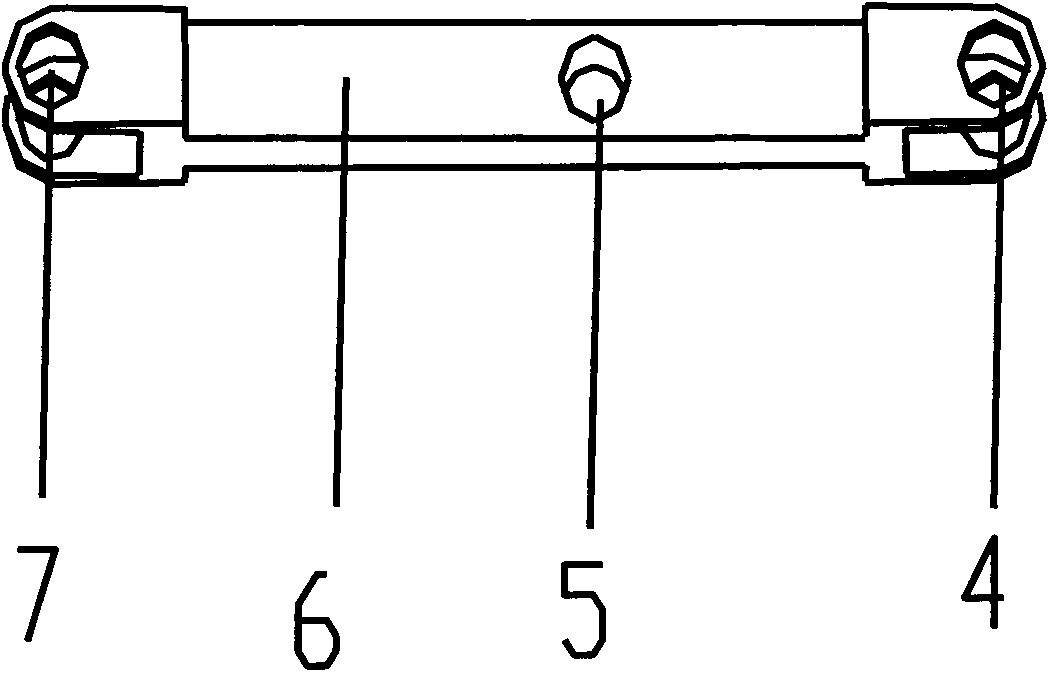

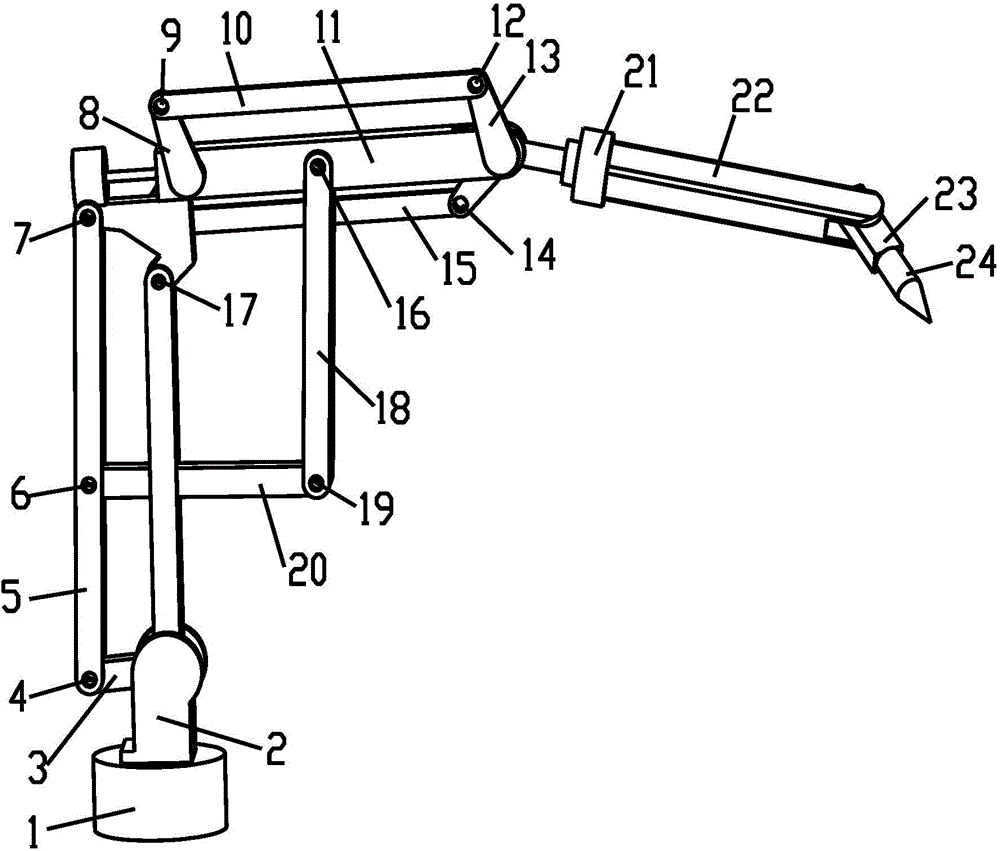

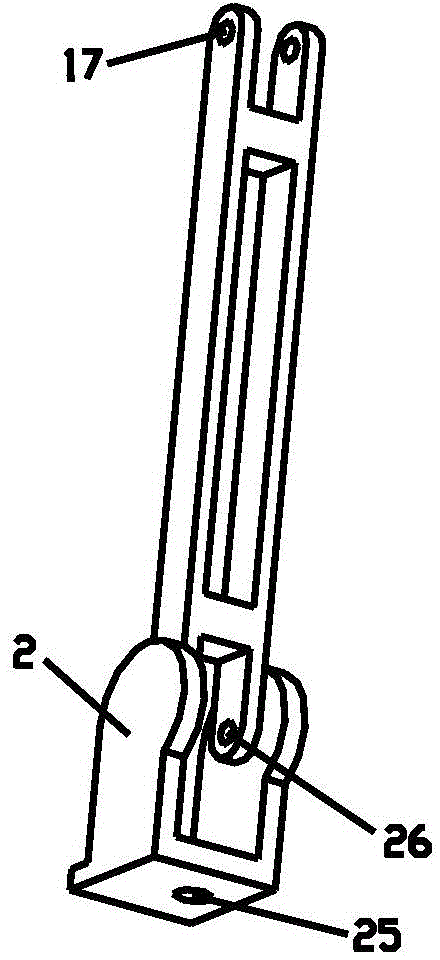

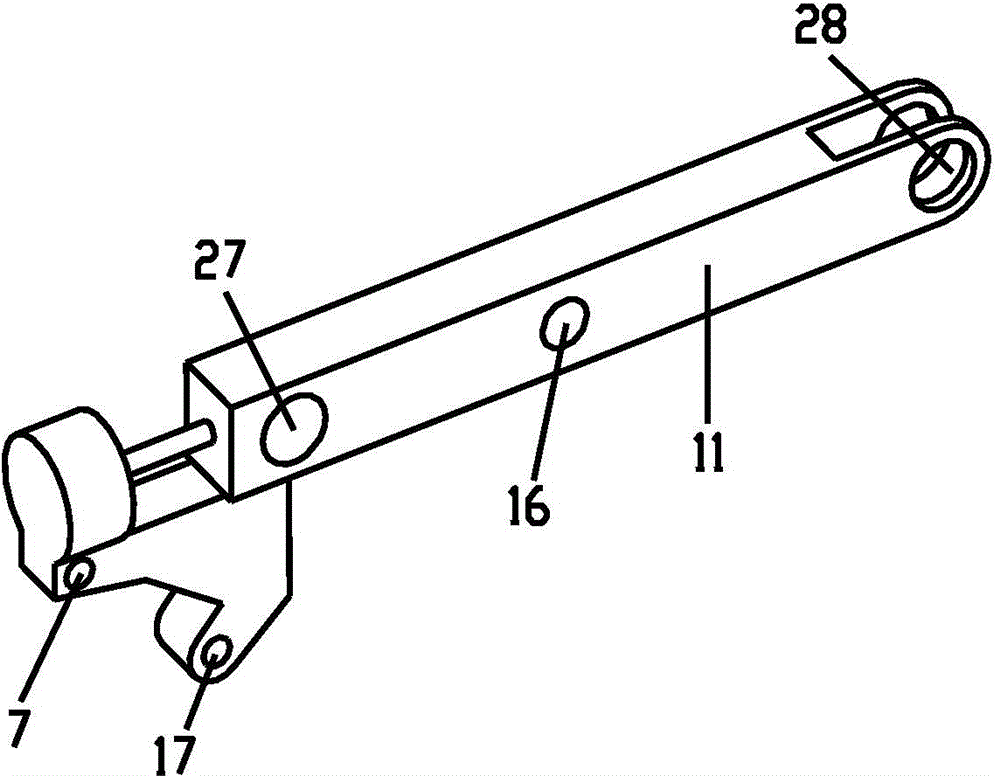

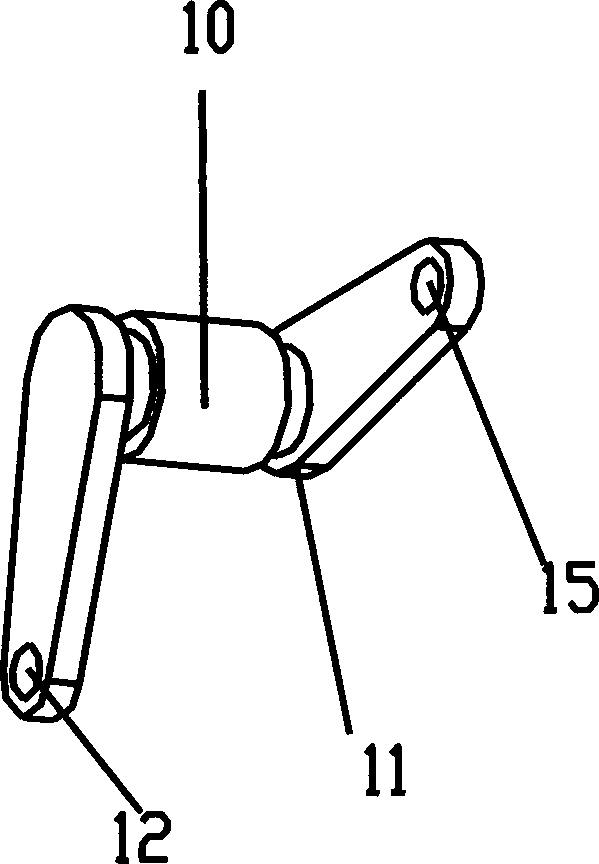

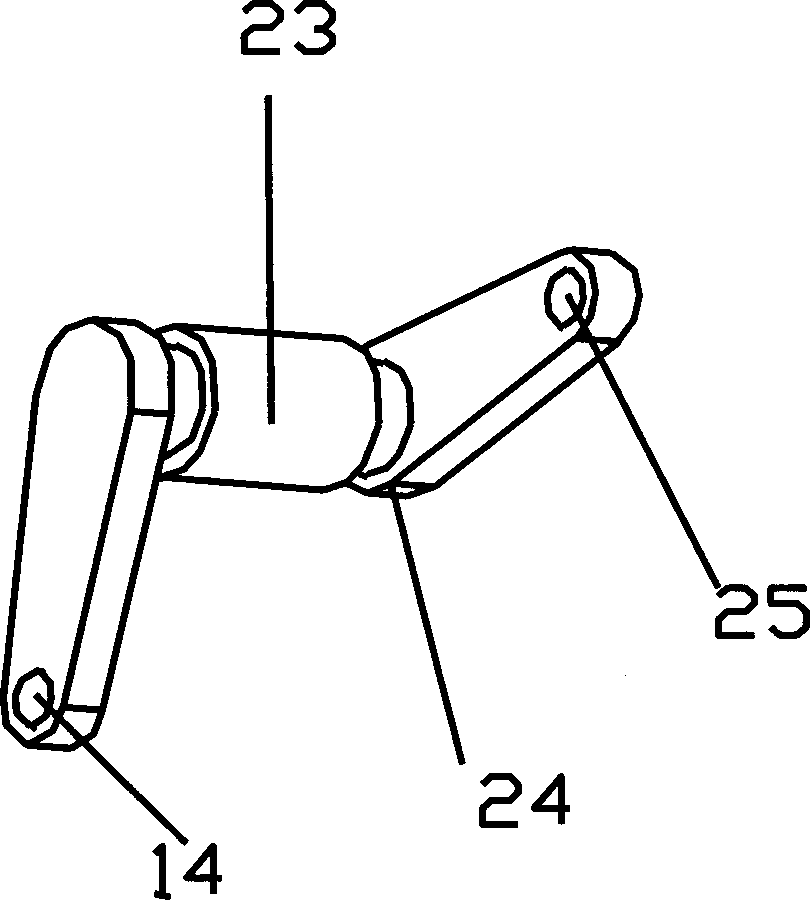

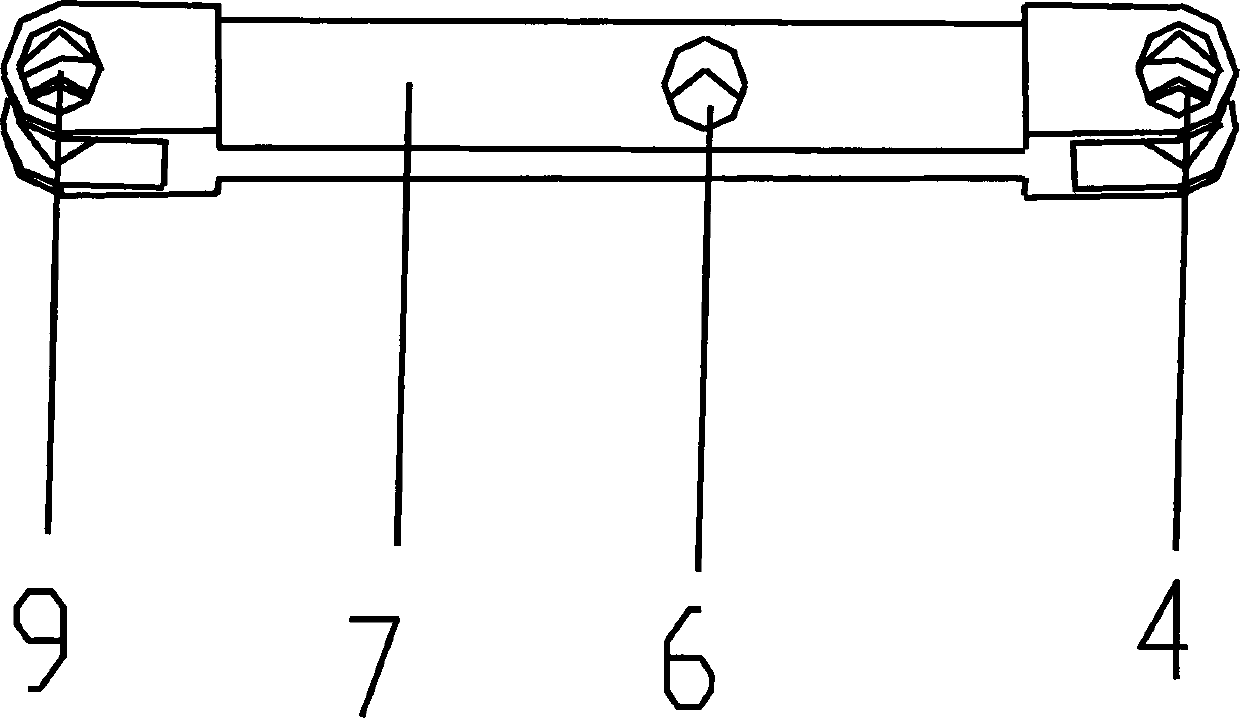

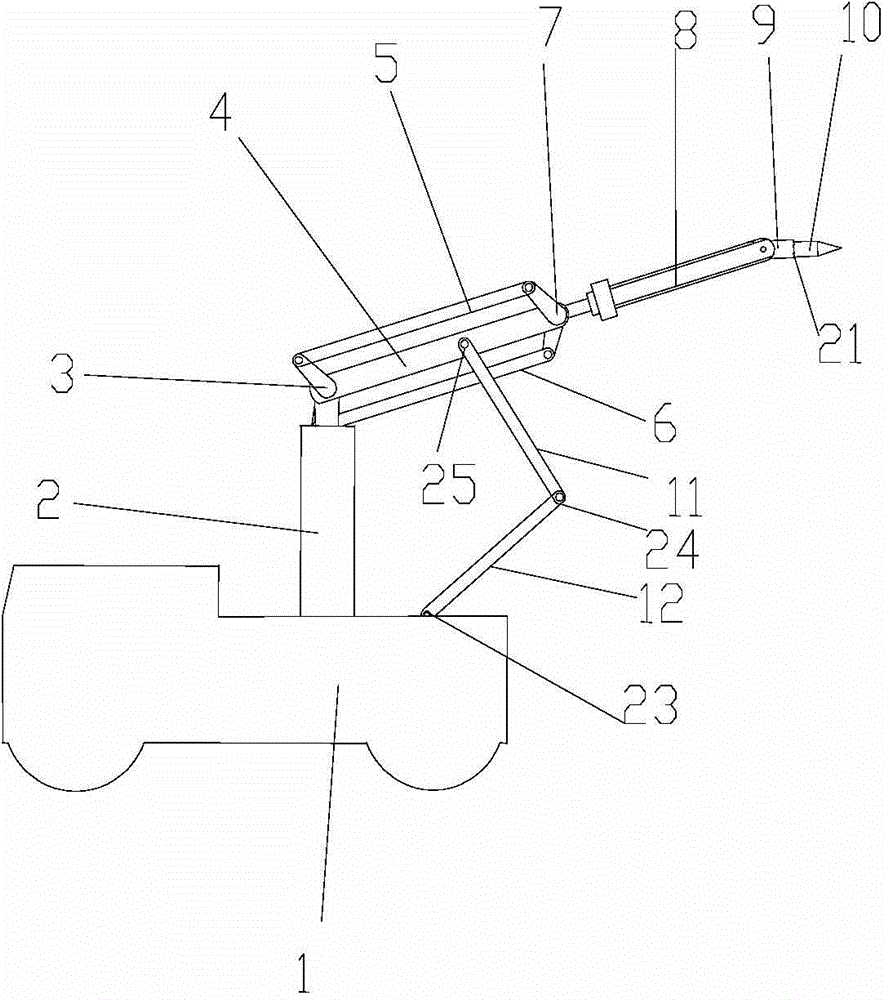

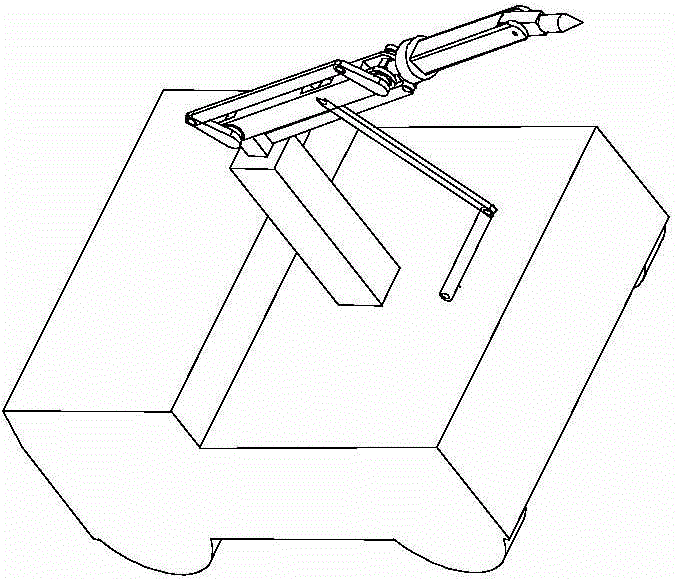

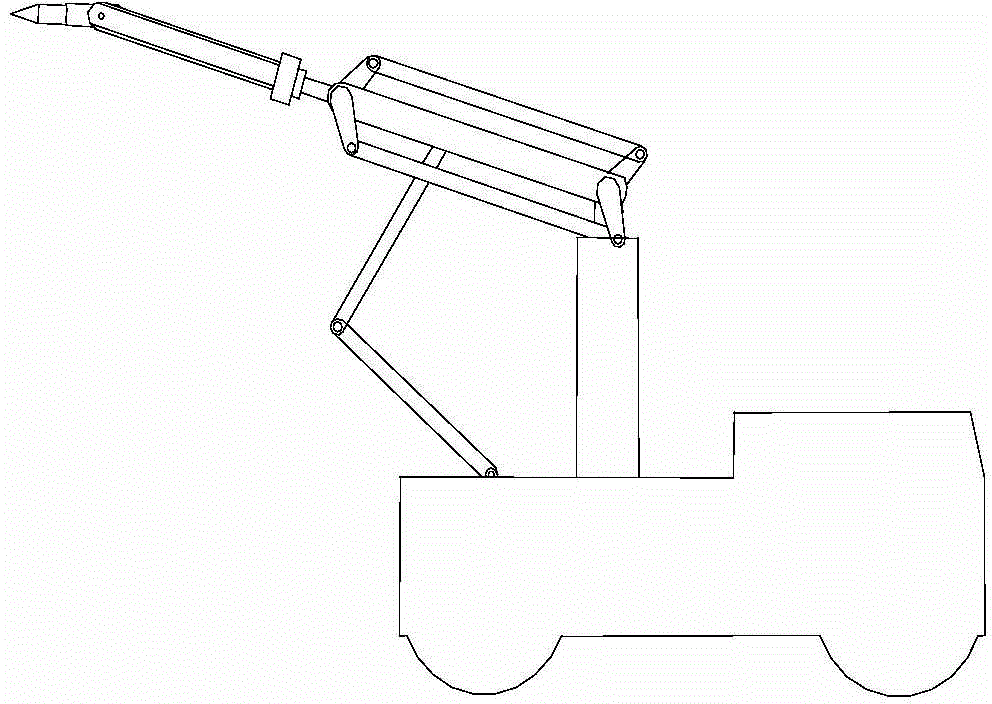

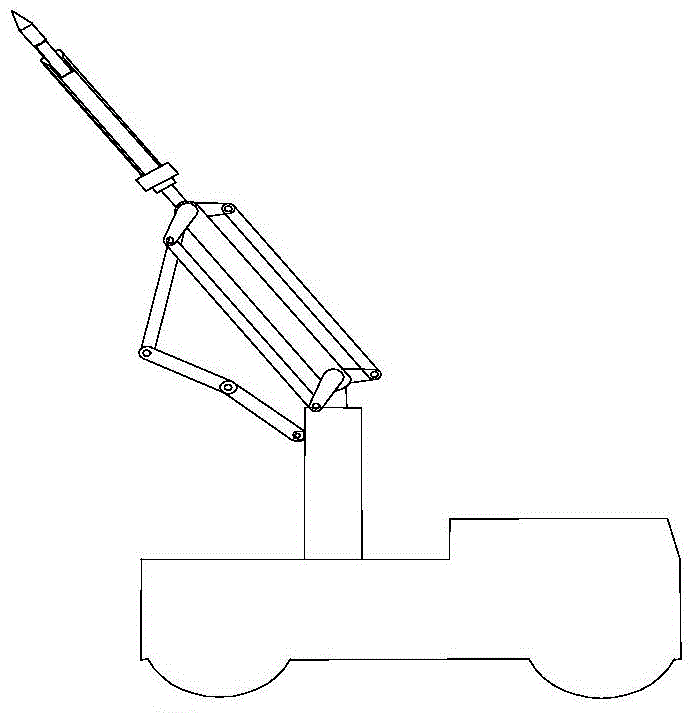

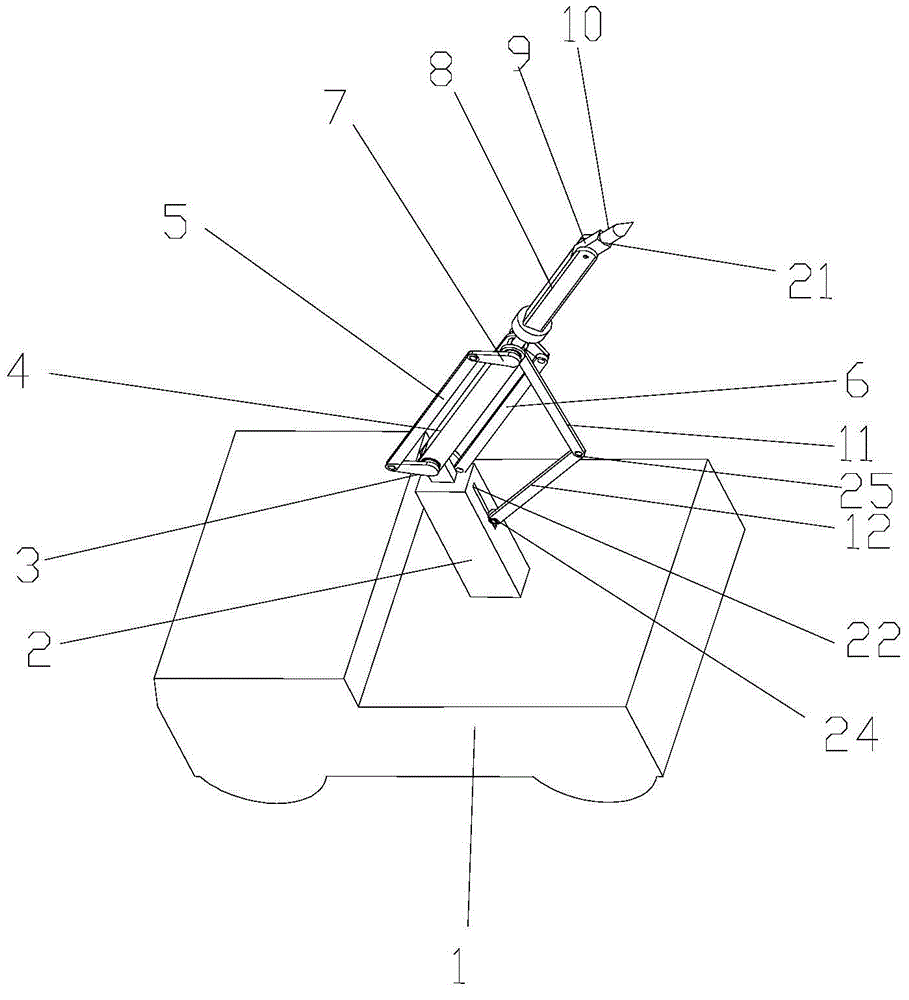

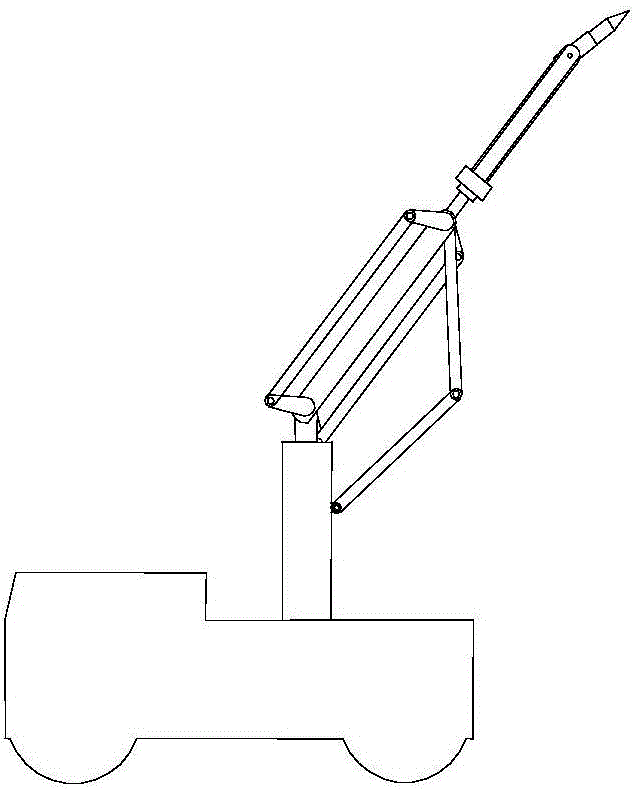

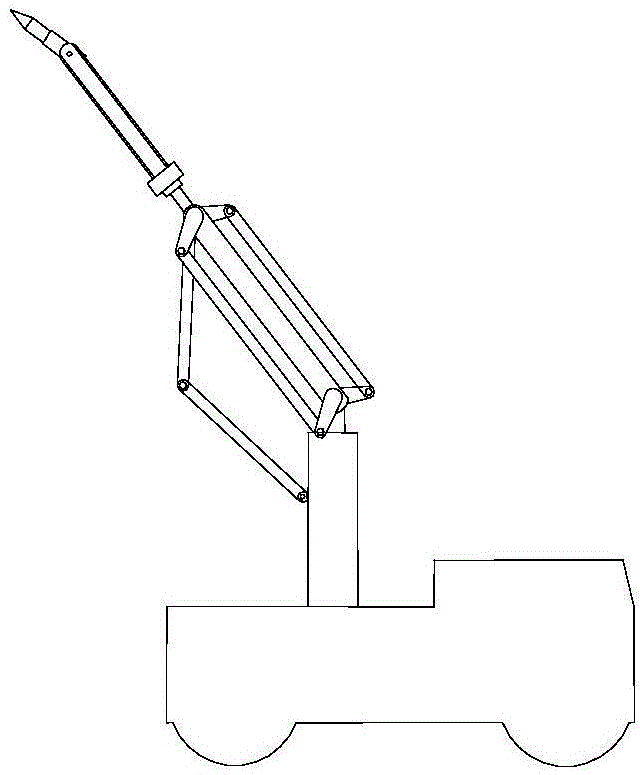

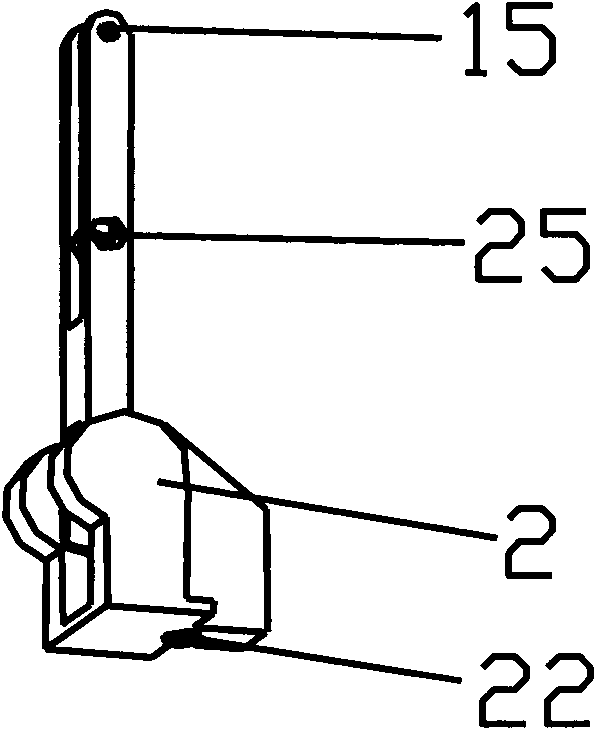

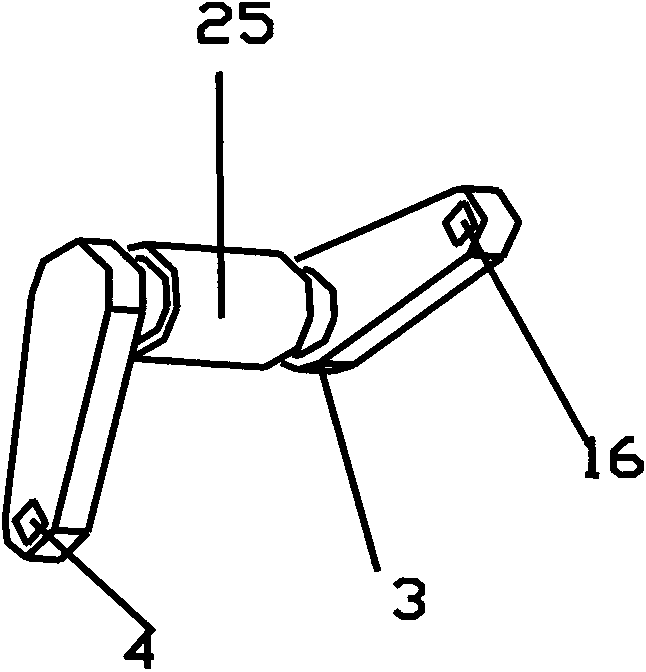

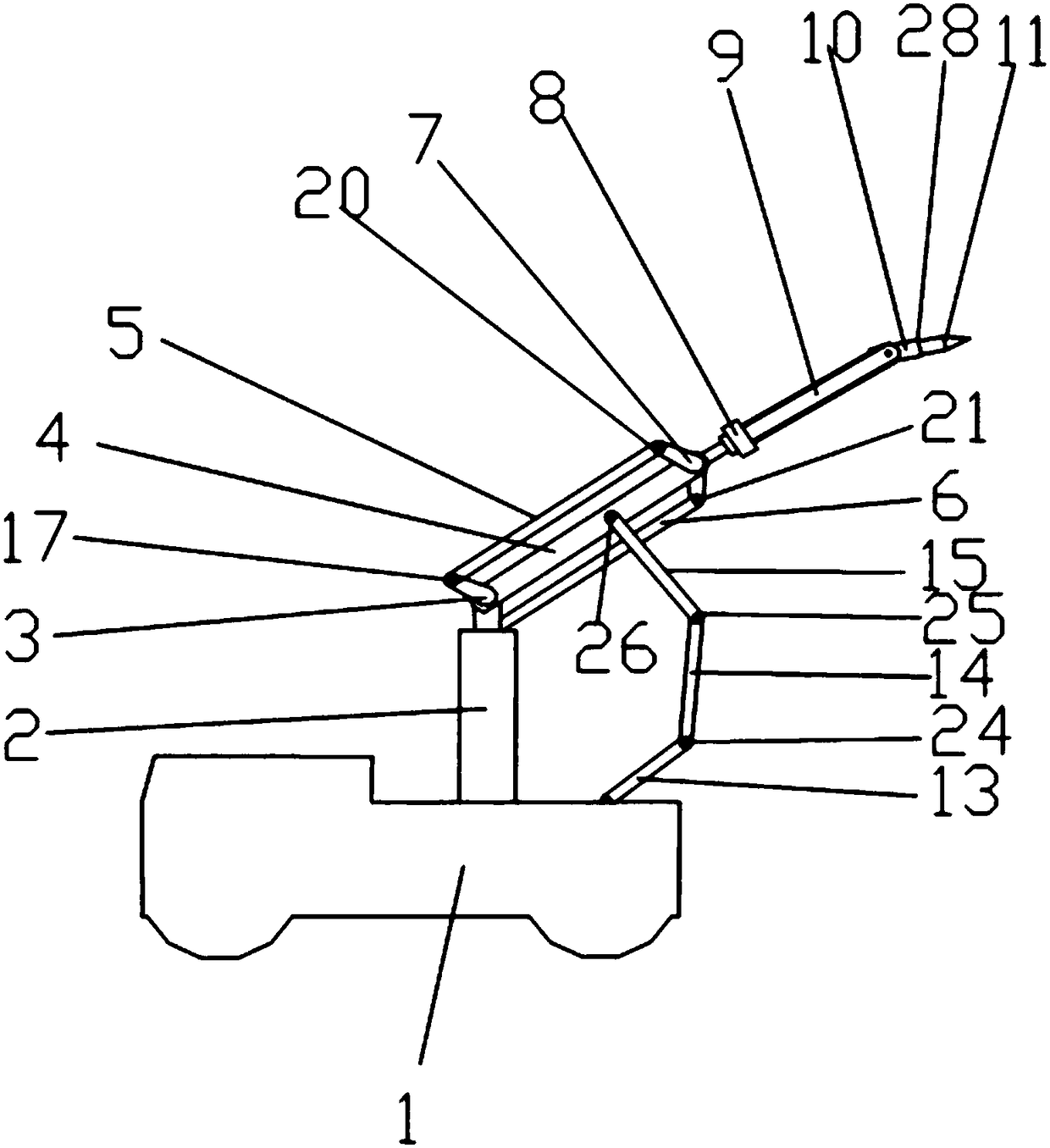

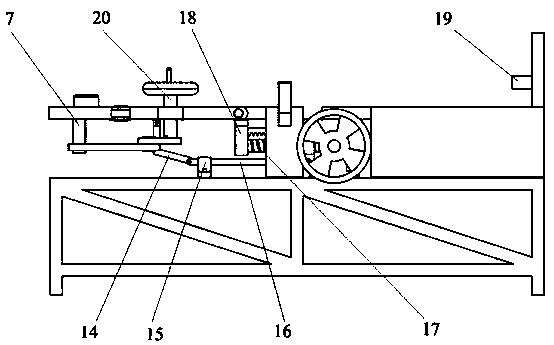

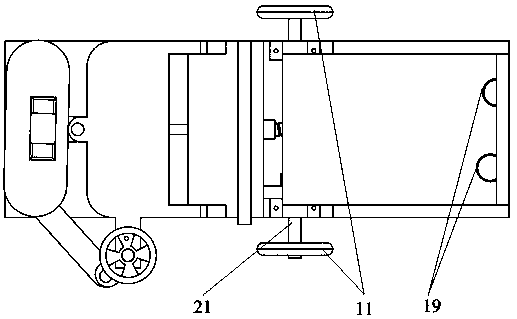

The invention discloses a multi-degree-of-freedom controllable mechanism type moving welding robot. One end of a stand column is connected with a vehicle body; the other end of the stand column is respectively connected with one end of a main arm and the first connection end of a first rocker arm; the second connection end of the first rocker arm is connected with one end of a first connecting rod; the other end of the first connecting rod is connected with the second connection end of a second rocker arm; the first connection end of the second rocker arm is connected with the other end of the main arm; the third connection end of the second rocker arm is connected with one end of a second connecting rod; the other end of the second connecting rod is connected with the third connection end of the first rocker arm; one end of a third connecting rod is connected with the fourth connection end of the second rocker arm; the other end of the third connecting rod is connected with one end of a fourth connecting rod; the other end of the fourth connecting rod is connected with a tail end welding executor; one end of a sliding block is connected with the stand column via a moving pair; the other end of the sliding block is connected with a fifth connecting rod; the fifth connecting rod, a sixth connecting rod, a seventh connecting rod and the third connection end of the main arm are successively connected. The multi-degree-of-freedom controllable mechanism type moving welding robot has the advantages of large working space, high rigidity, high bearing capability and high execution precision.

Owner:GUANGXI UNIV

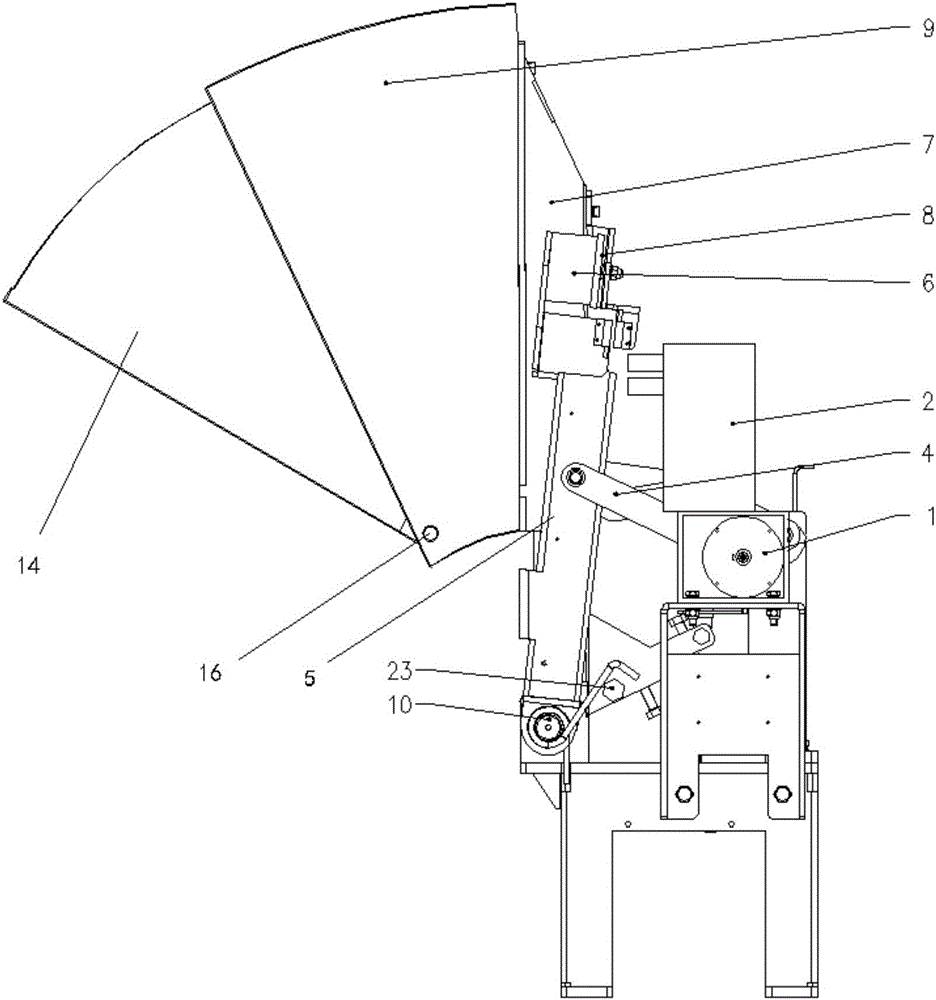

Scissor type door

ActiveCN105113440ASimple structureImprove transmission efficiencyDoors/windowsTraffic restrictionsForeign matterRocker arm

The invention relates to a scissor type door. The scissor type door comprises a rack, a power device, a crank, a first connecting rod, a main rocker arm, an auxiliary rocker arm, a sector-shaped door body and an inner door body. The sector-shaped door body is fixedly arranged on the auxiliary rocker arm so that the sector-shaped door body and the auxiliary rocker arm can jointly swing. The sector-shaped door body is hollow and is provided with a lateral opening. The inner door body is connected with the auxiliary rocker arm through a connecting rod mechanism arranged on the rack. When the auxiliary rocker arm swings around a rotating shaft, the auxiliary rocker arm drives the inner door body through the connecting rod mechanism to stretch out from or draw back into the lateral opening of the sector-shaped door body so that the sector-shaped door body and the inner door body can be switched between the stopping state and the releasing state. According to the scissor type door, the inner door body is driven by the connecting rod mechanism to stretch out or draw back; and compared with a sliding mechanism and a gear mechanism, the scissor type door has the beneficial effects of being low in friction and free of influences of foreign matter.

Owner:EASYWAY SUZHOU ELECTRONICS TECH

Multi-degree-of-freedom parallel-mechanism type controllable welding robot

ActiveCN103722553AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopMulti degree of freedom

A multi-degree-of-freedom parallel-mechanism type controllable welding robot comprises multiple parallel-mechanism closed-loop actuator subchains and a serially-connected main actuator chain, the mechanism closed-loop subchains can control main chain connecting bars to move in a plane of the four-bar mechanism closed-loop subchains, and spatial movement of a moving platform can be realized by movement of multiple parallel connecting bar subchains and a body. Control is realized through resultant movement of the four closed-loop subchains and the body, spatial movement of an end actuator is realized through connection of multiple connecting bars and the body, the end actuator is small in movement inertia, good in dynamics performance and high in reliability, the robot has the advantages of compact structure and simplicity in control, the bars can be made to light bars, the robot is large in working space, center of gravity of the robot shifts backwards to keep the robot in balance, and the robot can act to more situations.

Owner:GUANGXI UNIV

Method for performing welding construction by use of multi-DOF (Degree Of Freedom) controllable rocking arm type connecting rod mechanism

InactiveCN104646881AAvoid dead center positionIncrease stiffnessProgramme-controlled manipulatorWelding/cutting auxillary devicesEngineeringMulti degree of freedom

The invention relates to a method for performing welding construction by use of a multi-DOF (Degree Of Degree) controllable rocking arm type connecting rod mechanism. The method comprises the following steps of: constructing an execution main chain by use of an upright column, a main arm, a first rocking arm, a second rocking arm, a first connecting rod, a second connecting rod, a third connecting rod and a fourth connecting rod; constructing an execution sub-chain by use of a fifth connecting rod, a sixth connecting rod, an upright column and a main arm; during a welding operation, driving the main arm by use of a motor so as to enable the main arm to perform rotating motion, supporting the main arm by use of the fifth connecting rod and the sixth connecting rod, and performing motion synthesizing on the fifth and sixth connecting rods and the main arm; driving the second rocking arm by use of the motor so as to enable the second rocking arm to perform rocking arm type control on the third connecting rod; driving the third connecting rod and the fourth connecting rod to perform rotating motion by use of the motor so as to enable the connecting rod mechanism to finish the welding operation. The method has the advantages of large operating space, high rigidity, high bearing capacity and high execution accuracy.

Owner:GUANGXI UNIV

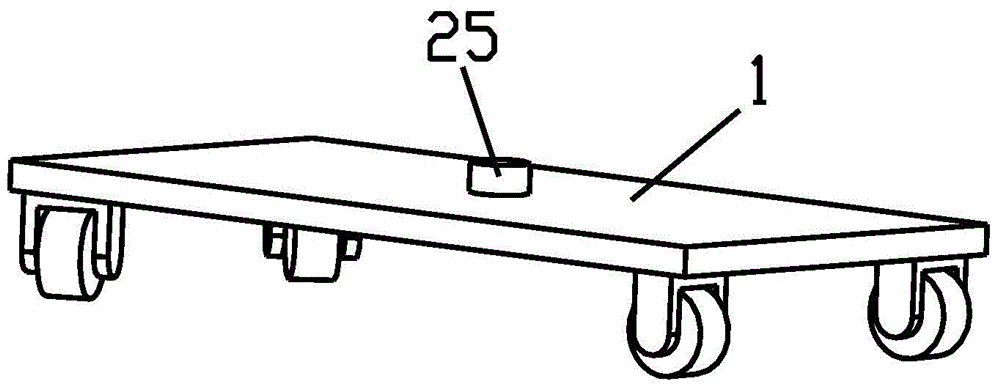

Wheeled mobile welding robot with plurality of closed-loop sub-chains

InactiveCN104552245ALarge working spaceHigh Motion RedundancyProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopEngineering

The invention provides a wheeled movable welding robot with a plurality of closed-loop sub-chains. The wheeled mobile welding robot comprises a plurality of parallel mechanism closed-loop executing mechanism sub-chains, a serial executing mechanism main chain and a moveable platform, wherein the mechanism closed-loop sub-chains are used for controlling a connecting rod of the main chain to move in a plane of a four-rod mechanism closed-loop sub-chain, and the space movement of the movable platform is realized by the movement of parallel connecting rod sub-chains, a robot body and the movable platform. The wheeled mobile welding robot has the advantages that the control is realized by the synthesis movement of the four closed-loop sub-chains and the robot body, and the space movement of a tail executer is realized by the connecting of the connecting rods, the robot body and the movable platform, the movement inertia of the tail executer is small, the dynamic property is good, and the reliability is high; the movement and operation functions of the mechanism are realized, and the robot has maximum working space and good movement redundancy, and can be applied to multiple occasions.

Owner:GUANGXI UNIV

Multi-degree-of-freedom controllable parallel type mobile robot

InactiveCN104476536ALarge working spaceHigh Motion RedundancyProgramme-controlled manipulatorClosed loopMulti degree of freedom

The invention relates to a multi-degree-of-freedom controllable parallel type movable spot welding robot. The multi-degree-of-freedom controllable parallel type movable spot welding robot comprises a movable platform, four parallel controllable four-bar mechanism closed-loop actuator subchains and a serial actuator main chain. The controllable four-bar mechanism closed-loop actuator subchains controls main-chained connecting bars to move within a plane where the four-bar mechanism closed-loop subchains are located, and spatial motion of the movable platform can be realized through motions of a first connecting bar, a machine body and the movable platform. A moving function is realized through the movable platform; the robot is controlled through the synthetic motion of the four four-bar mechanism closed-loop actuator subchains and the machine body; the spatial motion of an end actuator is realized through a plurality of connecting bars and the machine body; the end actuator is small in movement inertia, good in dynamics performance and high in precision. Through the structure, the robot has motion redundancy of almost infinite work space and height, has moving and operating functions at the same time, and can act on more occasions.

Owner:GUANGXI UNIV

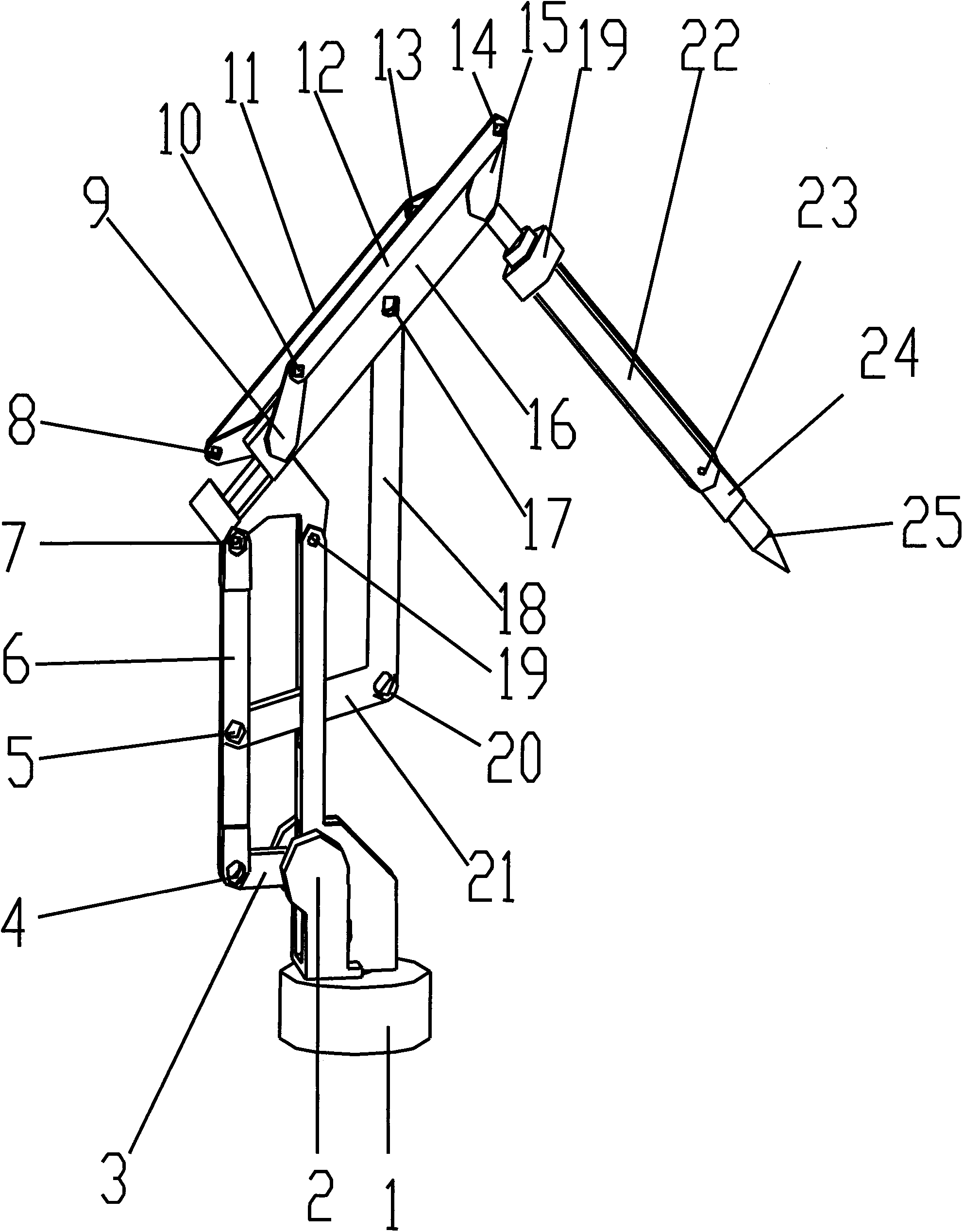

Welding construction method using multi-degree-of-freedom rocker arm type movable connecting rod mechanism

InactiveCN104625506AAvoid dead center positionIncrease stiffnessProgramme-controlled manipulatorWelding/cutting auxillary devicesArchitectural engineeringMulti degree of freedom

The invention relates to a welding construction method using a multi-degree-of-freedom rocker arm type movable connecting rod mechanism. A vertical pillar, a main arm, a first rocker arm, a second rocker arm, a first connecting rod, a second connecting rod, a third connecting rod and a fourth connecting rod form an execution main chain. A fifth connecting rod, a sixth connecting rod, the vertical pillar and the main arm form an execution sub-chain. In the welding work process, the main arm is driven through a motor to rotate, and the fifth connecting rod and the sixth connecting rod support the main arm and carry out movement synthesis along with the main arm. The second rocker arm is driven through the motor, and therefore the second rocker arm can carry out rocker arm type control over the third connecting rod. The third connecting rod and the fourth connecting rod are driven through the motor to rotate, and therefore the connecting rod mechanism can finish welding work. The welding construction method using the multi-degree-of-freedom rocker arm type movable connecting rod mechanism has the advantages of being large in work space, high in rigidity, high in bearing capacity and high in execution accuracy.

Owner:GUANGXI UNIV

Space-controllable multi-rod six-degree-of-freedom welding robot with parallel closed-loop sub-chains

InactiveCN103737581BIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopEngineering

A multi-bar six-freedom-degree welding robot containing parallel closed loop sub chains and provided with controllable space comprises two controllable fine adjustment four-bar mechanism closed loop sub chains connected in parallel and an executing mechanism sub chain connected in series. The four-bar mechanism closed loop sub chains can control a first connecting bar to move in a plane where the four-bar mechanism closed loop sub chains are located. Spatial motion of a movable platform can be achieved through motion of the first connecting bar and a robot body. Control is achieved through resultant motion of the two closed loop sub chains and the first connecting bar and the first connecting bar and a second connecting bar are connected with the robot body, so that spatial motion of an executor at the tail end is achieved. The multi-bar six-freedom-degree welding robot containing the parallel closed loop sub chains and provided with the controllable space has the advantages that the structure is compact, control is simple, control is achieved through the first connecting bar connected to the robot body, the bars can be manufactured into light bars, mechanism motion inertia is small, the dynamics performance is good, the reliability is high, and the work space of a mechanism is large.

Owner:GUANGXI UNIV

Mechanism type mobile mechanical hand with multiple degrees of freedom

InactiveCN104526690ALarge working spaceHigh Motion RedundancyProgramme-controlled manipulatorArmsClosed loopPalletizer

A mechanism type mobile mechanical hand with multiple degrees of freedom comprises multiple parallel mechanism closed-loop executing mechanism sub chains, a series executing mechanism main chain and a mobile platform. The mechanism closed-loop sub chains can control a main chain connecting rod to move in a plane where the four-rod mechanism closed-loop sub chains are located. Space movement of the mobile platform can be achieved through movement of the multiple parallel connecting rod sub chains, a robot palletizer body and the mobile platform. According to the mechanism type mobile mechanical hand, control is achieved through resultant movement of the four closed-loop sub chains and the robot palletizer body, space movement of an end executor is achieved through connection of multiple connecting rods, the robot palletizer body and the mobile platform, the end executor is small in movement inertia, good in dynamics performance and high in reliability, the mechanism has the advantages of being compact in structure, easy to control and capable of moving and being operated at the same time, the rods can be light, and the mechanism is large in working space so as to act on more occasions.

Owner:GUANGXI UNIV

Multi-freedom degree wheeled mobile stacking robot

InactiveCN104552234AWith mobile capabilitiesImprove mobilityProgramme-controlled manipulatorStacking articlesClosed loopMulti degree of freedom

The invention discloses a multi-freedom degree wheeled mobile stacking robot. The stacking robot comprises a plurality of parallel mechanism closed-loop actuating mechanism sub chains, a serial actuating mechanism main chain and a moveable platform, wherein the mechanism closed-loop sub chains can control a main chain connecting rod to move in the plane where a four-rod mechanism closed-loop sub chain is; the movement of a plurality of parallel connecting rod sub chains, a machine body and the moveable platform can realize the space movement of the moveable platform. The multi-freedom degree wheeled mobile stacking robot provided by the invention is controlled through the resultant movement of four closed-loop sub chains and the machine body; the space movement of a tail end executor is realized through the connection among a plurality of connecting rods, the machine body and the moveable platform; the tail end executor is low in movement inertia, good in dynamic performance and high in reliability; the mechanism has the advantages of compact structure and simple control; the functions of movement and operation can be simultaneously realized; the mechanism can be applied in more places and has great market development potential.

Owner:GUANGXI UNIV

Six-freedom-degree five-rod movable welding robot

InactiveCN104552249AAvoid dead center positionImprove balanceProgramme-controlled manipulatorWelding/cutting auxillary devicesAgricultural engineeringDegrees of freedom

The invention discloses a six-freedom-degree five-rod movable welding robot. One end of a stand column is connected with a vehicle body; the other end of the stand column is connected with one end of a main arm and a first connection end of a first rocker arm; a second connection end of the first rocker arm is connected with one end of a first connection rod; the other end of the first connection rod is connected with a second connection end of a second rocker arm; a first connection end of the second rocker arm is connected with the other end of the main arm; a third connection end of the second rocker arm is connected with one end of a second connection rod; the other end of the second connection rod is connected with a third connection end of the first rocker arm; one end of a third connection rod is connected with a fourth connection end of the second rocker arm; the other end of the third connection rod is connected with one end of a fourth connection rod; the other end of the fourth connection rod is connected with a tail end welding actuator; one end of a connection block is connected with the stand column through a fixed pair; the other end of the connection block is connected with a fifth connection rod; the fifth connection rod, a sixth connection rod, a seventh connection rod and the second connection end of the main arm are sequentially connected with one another. The six-freedom-degree five-rod movable welding robot has the advantages of large working space, high rigidity, high bearing capability and high execution accuracy.

Owner:GUANGXI UNIV

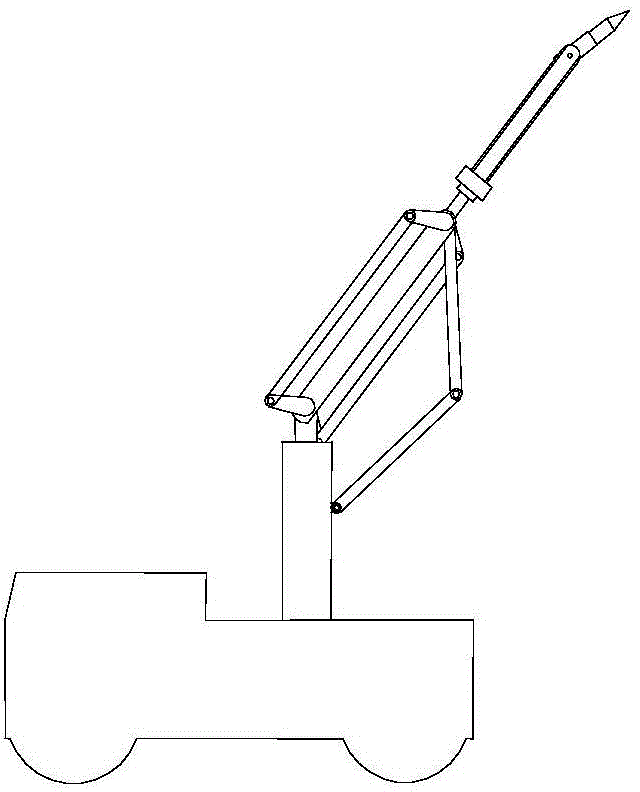

Six-freedom-degree rocker arm type movable welding robot

InactiveCN104552258AAvoid dead center positionIncrease stiffnessProgramme-controlled manipulatorWelding/cutting auxillary devicesEngineeringActuator

The invention discloses a six-freedom-degree rocker arm type movable welding robot. One end of a stand column is connected with a vehicle body; the other end of the stand column is connected with one end of a main arm and a first connection end of a first rocker arm; a second connection end of the first rocker arm is connected with one end of a first connection rod; the other end of the first connection rod is connected with a second connection end of a second rocker arm; a first connection end of the second rocker arm is connected with the other end of the main arm; a third connection end of the second rocker arm is connected with one end of a second connection rod; the other end of the second connection rod is connected with a third connection end of the first rocker arm; one end of a third connection rod is connected with a fourth connection end of the second rocker arm; the other end of the third connection rod is connected with one end of a fourth connection rod; the other end of the fourth connection rod is connected with a tail end welding actuator; one end of a sliding block is connected with the stand column through a movable pair; the other end of the sliding block is connected with a fifth connection rod; the other end of the fifth connection rod is connected with one end of a sixth connection rod; the other end of the sixth connection rod is connected with the other arm of the main arm. The six-freedom-degree rocker arm type movable welding robot has the advantages of large working space, high rigidity, high bearing capability and high execution accuracy.

Owner:GUANGXI UNIV

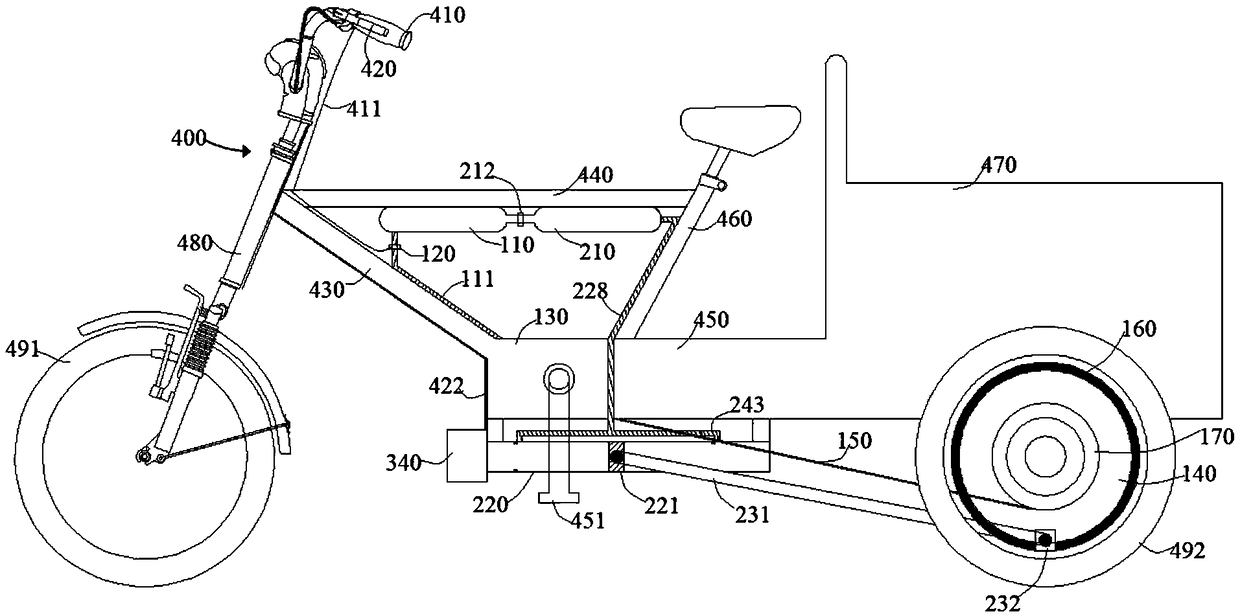

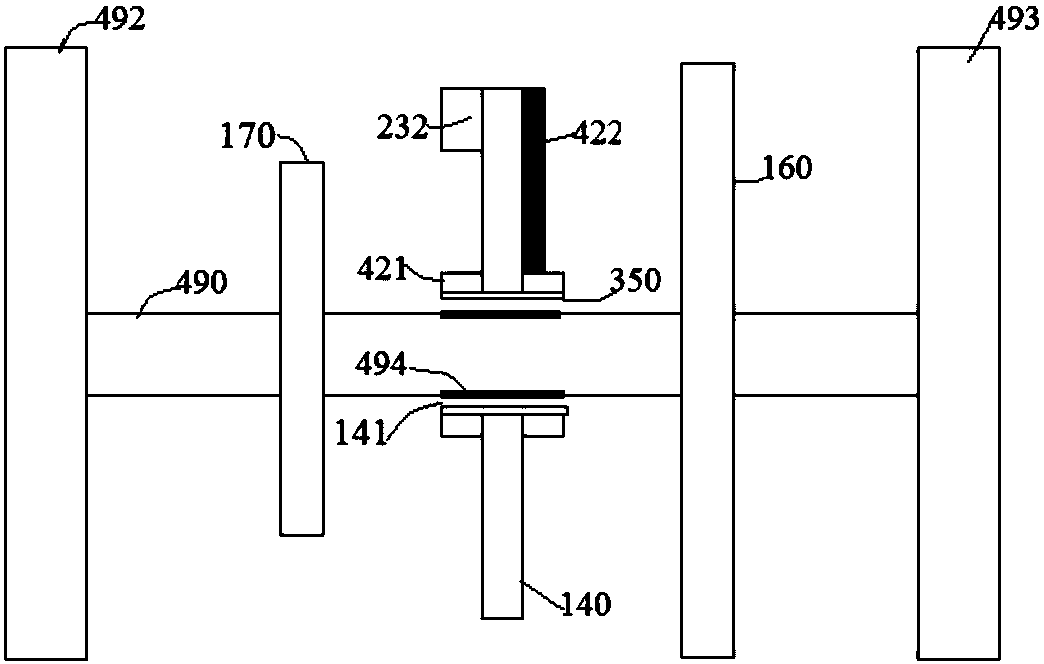

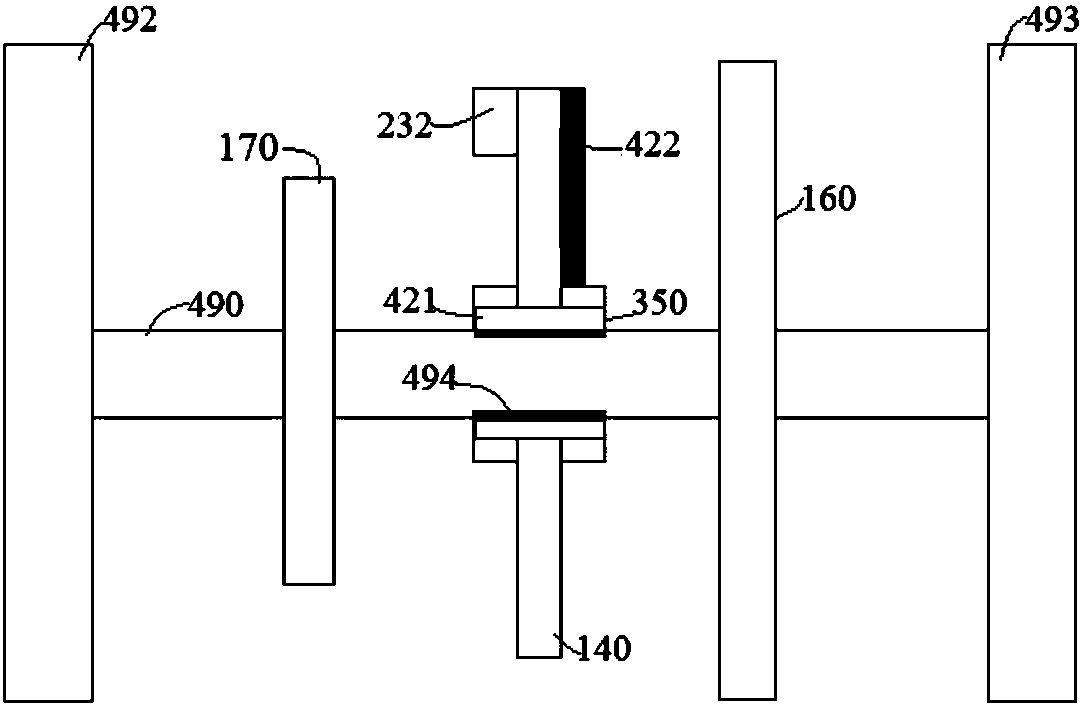

Self inflation pneumatic tricycle and use method thereof

ActiveCN108515814AImprove compression efficiencyImprove braking effectNon-mechanical gearing transmissionTyre measurementsDrive shaftEnergy supply

The invention relates to a self inflation pneumatic tricycle and a use method thereof, and belongs to the field of a pneumatic tricycle. The self inflation pneumatic tricycle comprises a power assistance unit, an inflation unit and a tricycle body, wherein the inflation unit comprises a gas storage tank and a compression cylinder; the tricycle body comprises a speed regulating rod, a brake mechanism and a transmission shaft; the speed regulating rod is used for regulating the gas supply quantity of an energy supply gas tank; the brake mechanism is used for regulating the work efficiency of thecompression cylinder; the brake execution end of the brake mechanism is matched with the transmission shaft; the brake execution end is close to the transmission shaft and is fixed with the transmission shaft. At the moment, the inflation unit works; the gas storage tank is used for storing air compressed by the compression cylinder; the compression cylinder is connected with the gas storage tankthrough a pipeline; the compressed gas is conveyed into the gas storage tank through a pipeline; inflation is performed; the kinetic energy during braking is used for completing the self inflation; more energy can be saved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

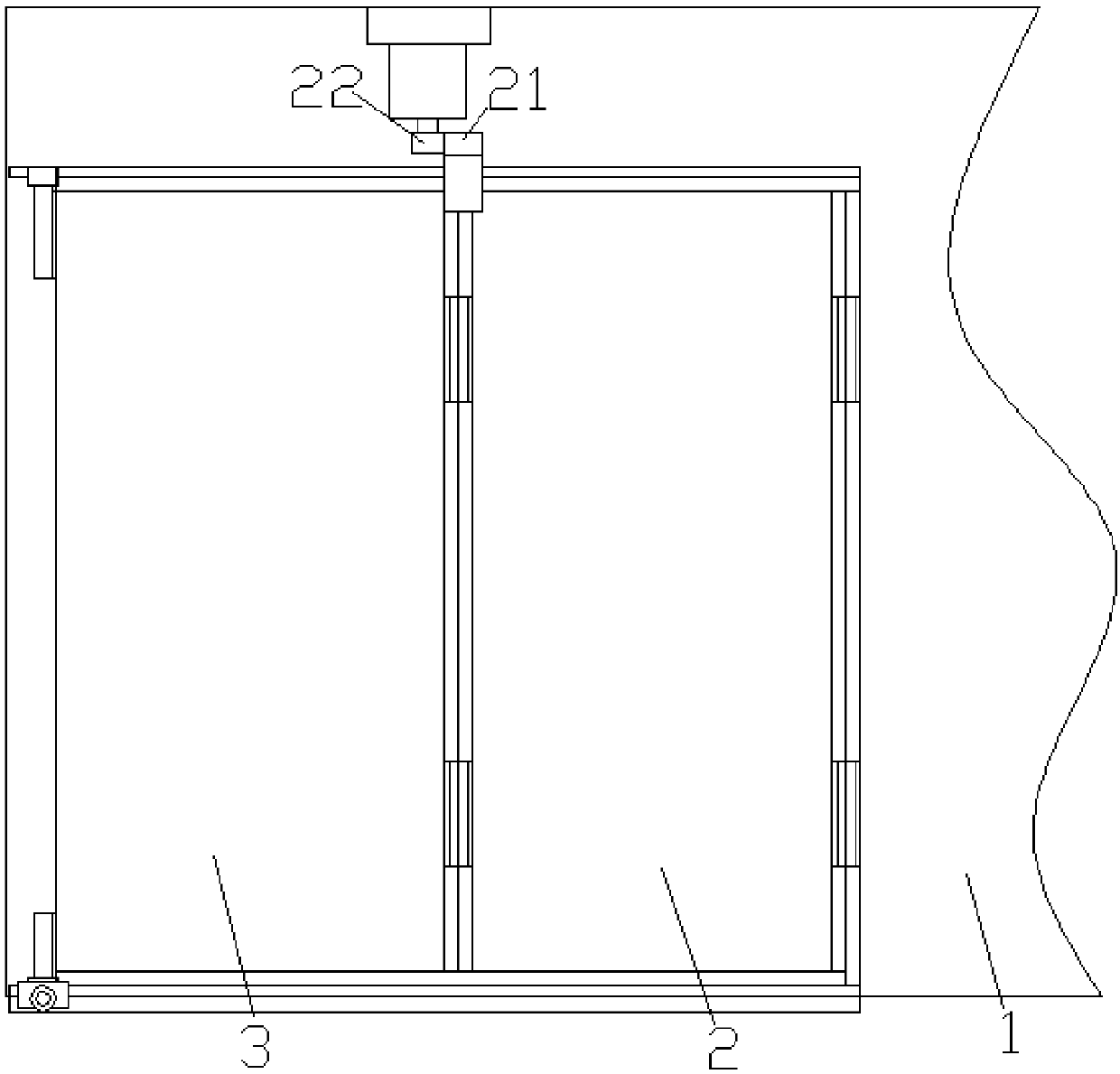

Foldable door device and using method thereof

InactiveCN107630637ASmall sizeSmall footprint for installationPower-operated mechanismWing arrangementsDrive motorEngineering

Owner:华若延

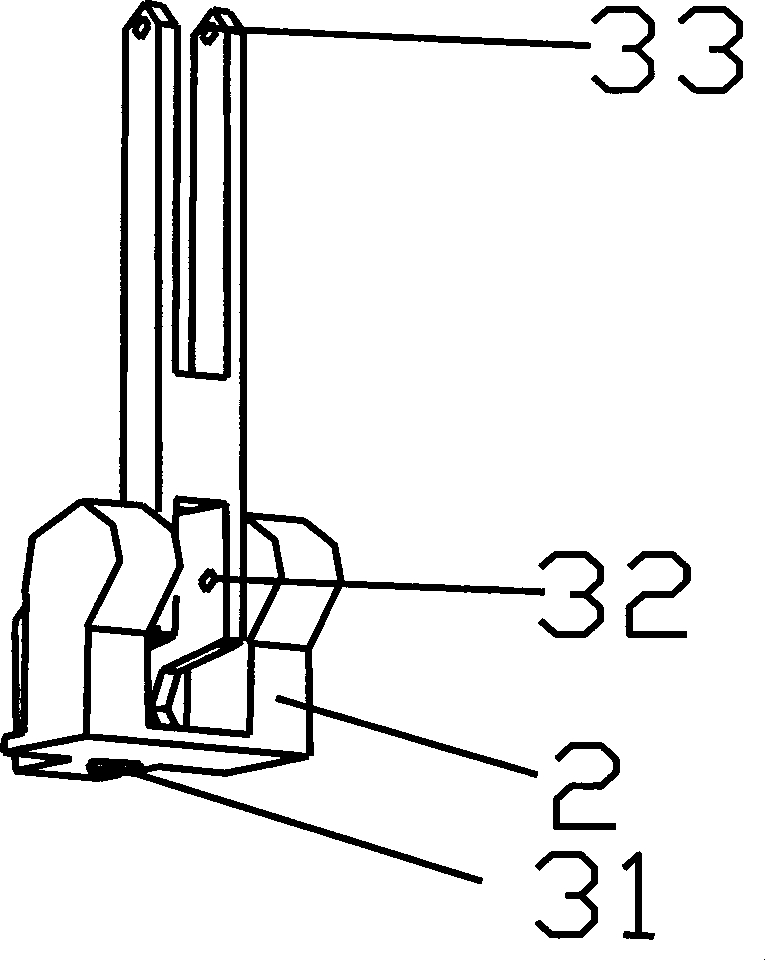

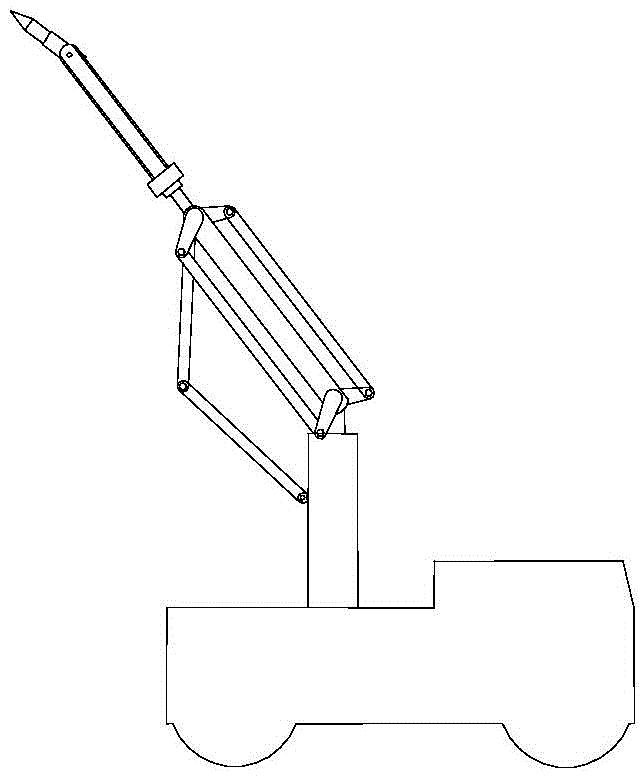

Mobile welding robot

InactiveCN104552257AAvoid dead center positionIncrease stiffnessProgramme-controlled manipulatorWelding/cutting auxillary devicesEngineeringActuator

The invention relates to a mobile welding robot. One end of a vertical column is connected with a vehicle body; the other end of the vertical column is respectively connected with one end of a main arm and a first connecting end of a first rocker arm; a second connecting end of the first rocker arm is connected with one end of a first connecting rod; the other end of the first connecting rod is connected with a second connecting end of a second rocker arm; a first connecting end of the second rocker arm is connected with the other end of the main arm; a third connecting end of the second rocker arm is connected with one end of a second connecting rod; the other end of the second connecting rod is connected with a third connecting end of the first rocker arm; one end of a third connecting rod is connected with a fourth connecting end of the second rocker arm; the other end of the third connecting rod is connected with one end of a fourth connecting rod; the other end of the fourth connecting rod is connected with a tail-end welding executor; one end of a connection block is connected with the vertical column through a fixing pair; the other end of the connection block is connected with one end of a fifth connecting rod; the other end of the fifth connecting rod is connected with one end of a sixth connecting rod; the other end of the sixth connecting rod is connected with the middle part of the main arm. The mobile welding robot has the advantages of large working space, high rigidity, strong bearing capacity and high executing precision.

Owner:GUANGXI UNIV

Method for carrying out welding construction by utilizing six-degree of freedom rocker arm type movable connecting rod mechanism

InactiveCN104551471AAvoid dead center positionIncrease stiffnessProgramme-controlled manipulatorWelding/cutting auxillary devicesCarrying capacityArchitectural engineering

The invention relates to a method for carrying out welding construction by utilizing a six-degree of freedom rocker arm type movable connecting rod mechanism. An execution main chain is formed by a stand column, a main arm, a first rocker arm, a second rocker arm, a first connecting rod, a second connecting rod, a third connecting rod and a fourth connecting rod; an execution sub chain is formed by a fifth connecting rod, a sixth connecting rod, a stand column and a main arm; when welding operation is carried out, the main arm is driven through a motor so as to rotate, and the fifth connecting rod and the sixth connecting rod support the main arm and are in movement combination with the main arm; the second rocker arm is driven through the motor, so that the second rocker arm carries out rocker arm type control on the third connecting rod; the third connecting rod and the fourth connecting rod are driven through the motor to rotate, so that the connecting rod mechanism can finish welding operation. The method provided by the invention has the advantages of large working space, high rigidity, strong carrying capacity and high execution precision.

Owner:GUANGXI UNIV

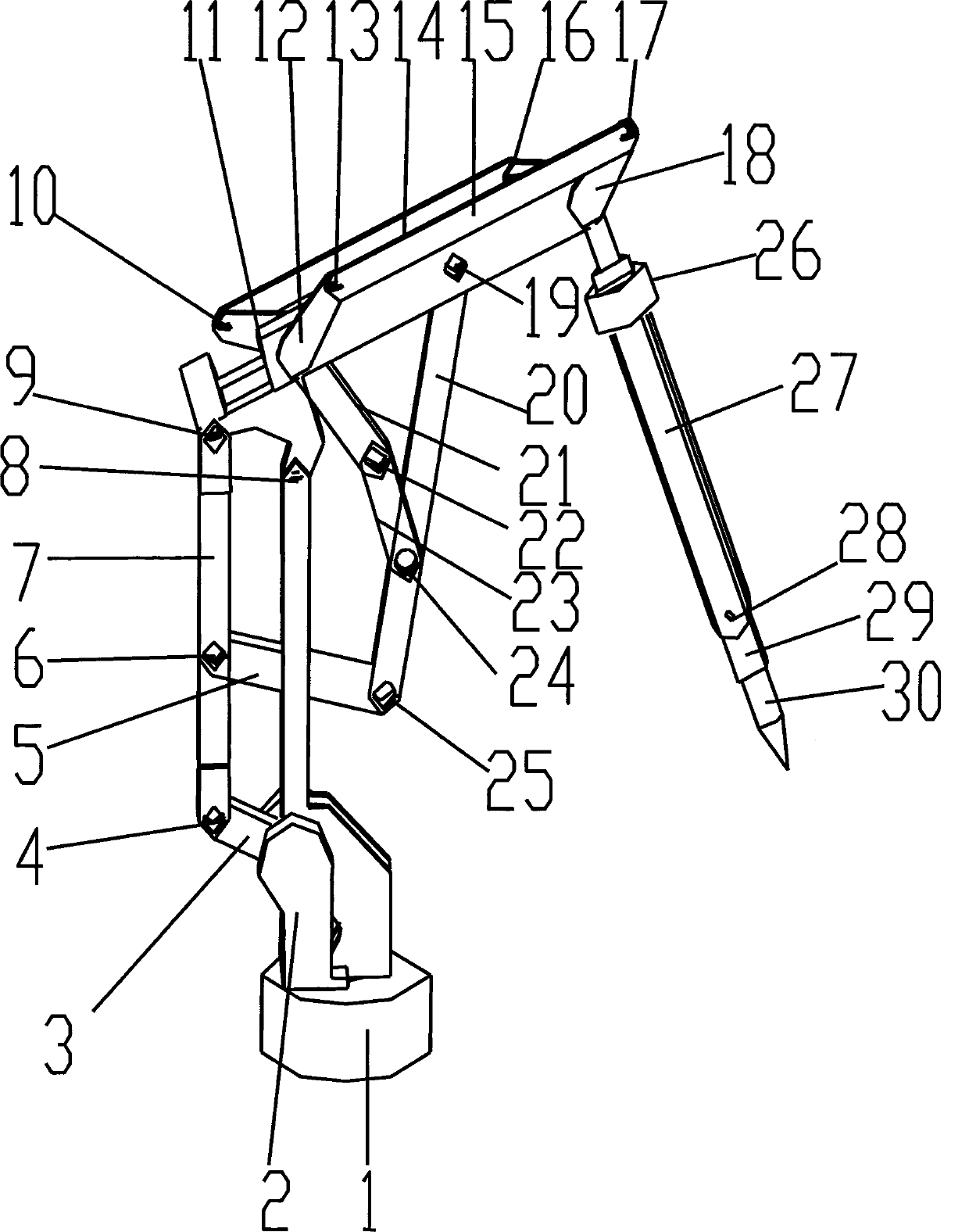

Multi-degree-of-freedom controllable mechanism type connecting rod mechanism

InactiveCN104552272AAvoid dead center positionImprove balanceProgramme-controlled manipulatorMulti degree of freedomEngineering

The invention discloses a multi-degree-of-freedom controllable mechanism type connecting rod mechanism. A stand column and one end of a main arm are connected with a first connection end of a first rocker arm; the second connection end of the first rocker arm is connected with one end of a first connecting rod; the other end of the first connecting rod is connected with the second connection end of a second rocker arm; the first connection end of the second rocker arm is connected with the other end of the main arm; the third connection end of the second rocker arm is connected with one end of a second connecting rod; the other end of the second connecting rod is connected with the third connection end of the first rocker arm; one end of a third connecting rod is connected with the fourth connection end of the second rocker arm; the other end of the third connecting rod is connected with a fourth connecting rod; one end of a sliding block is connected with the stand column via a moving pair; the other end of the sliding block is connected with a fifth connecting rod; the fifth connecting rod, a sixth connecting rod, a seventh connecting rod and the third connection end of the main arm are successively connected. The multi-degree-of-freedom controllable mechanism type connecting rod mechanism has the advantages of large working space, high rigidity, high bearing capability and high execution precision.

Owner:GUANGXI UNIV

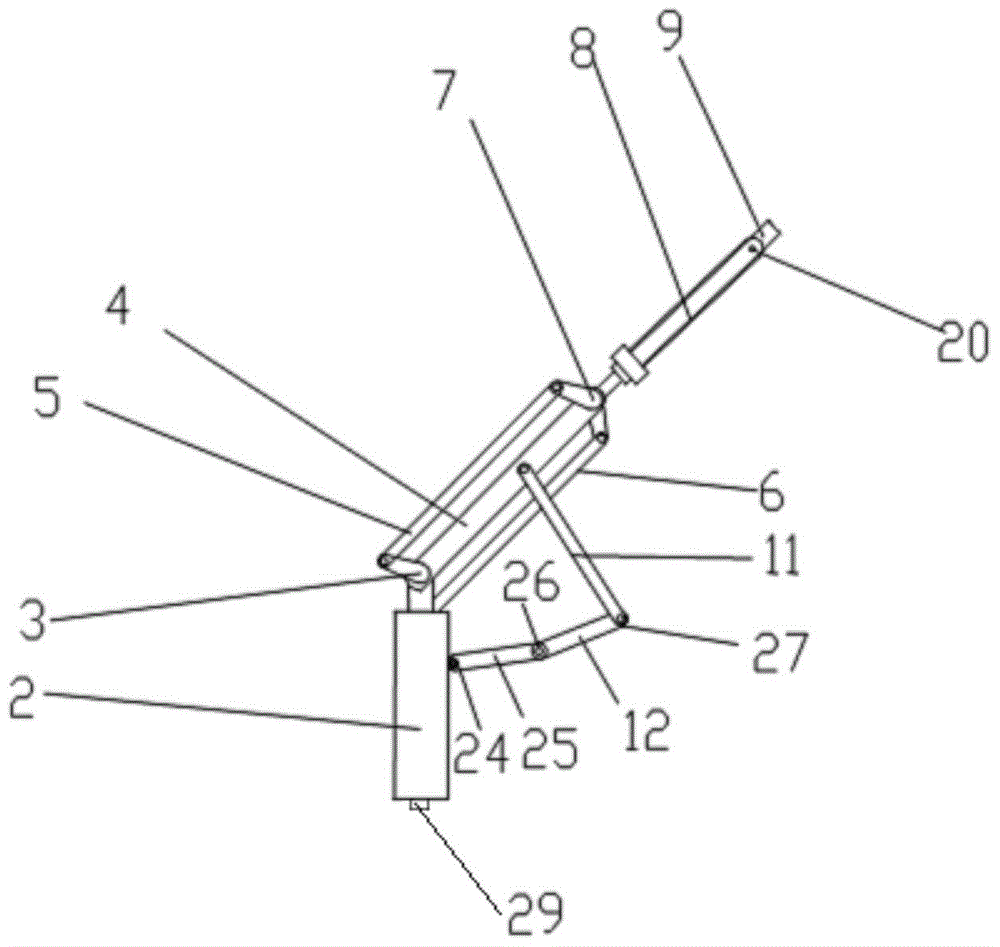

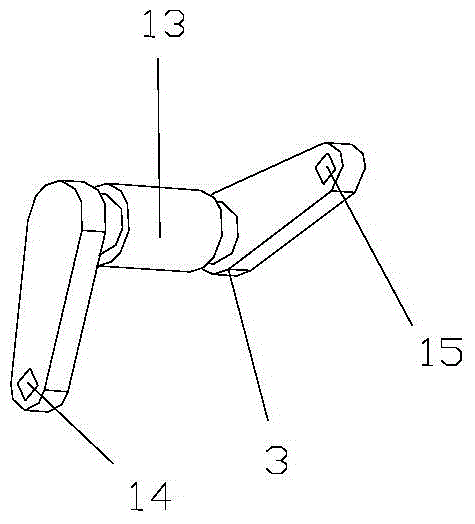

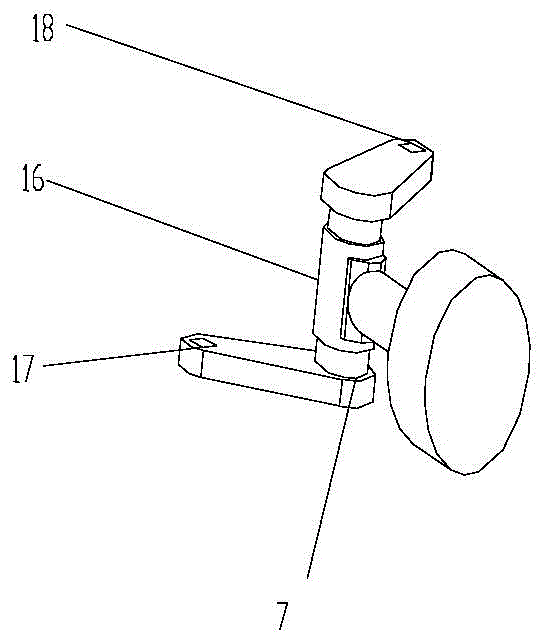

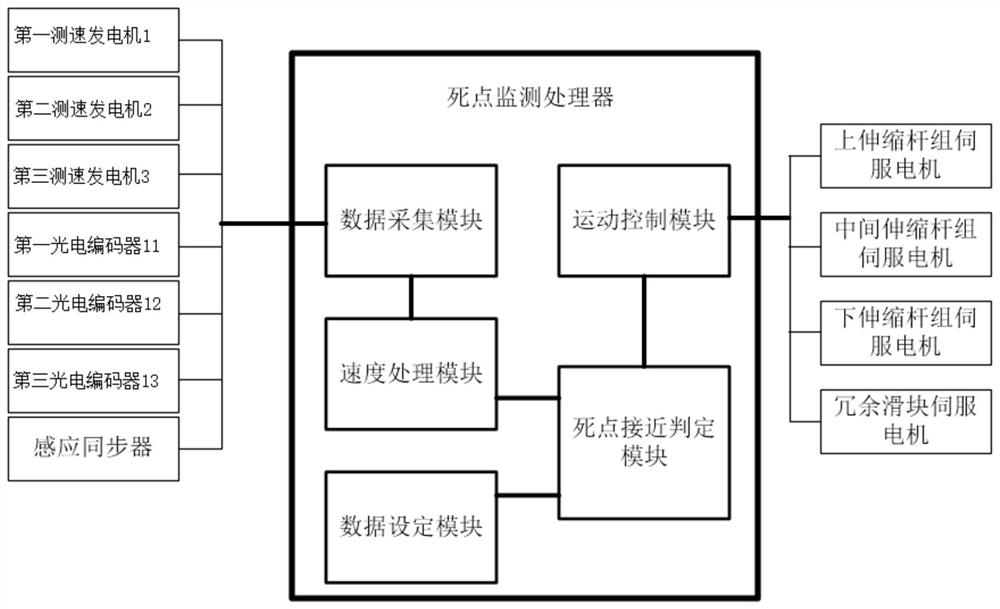

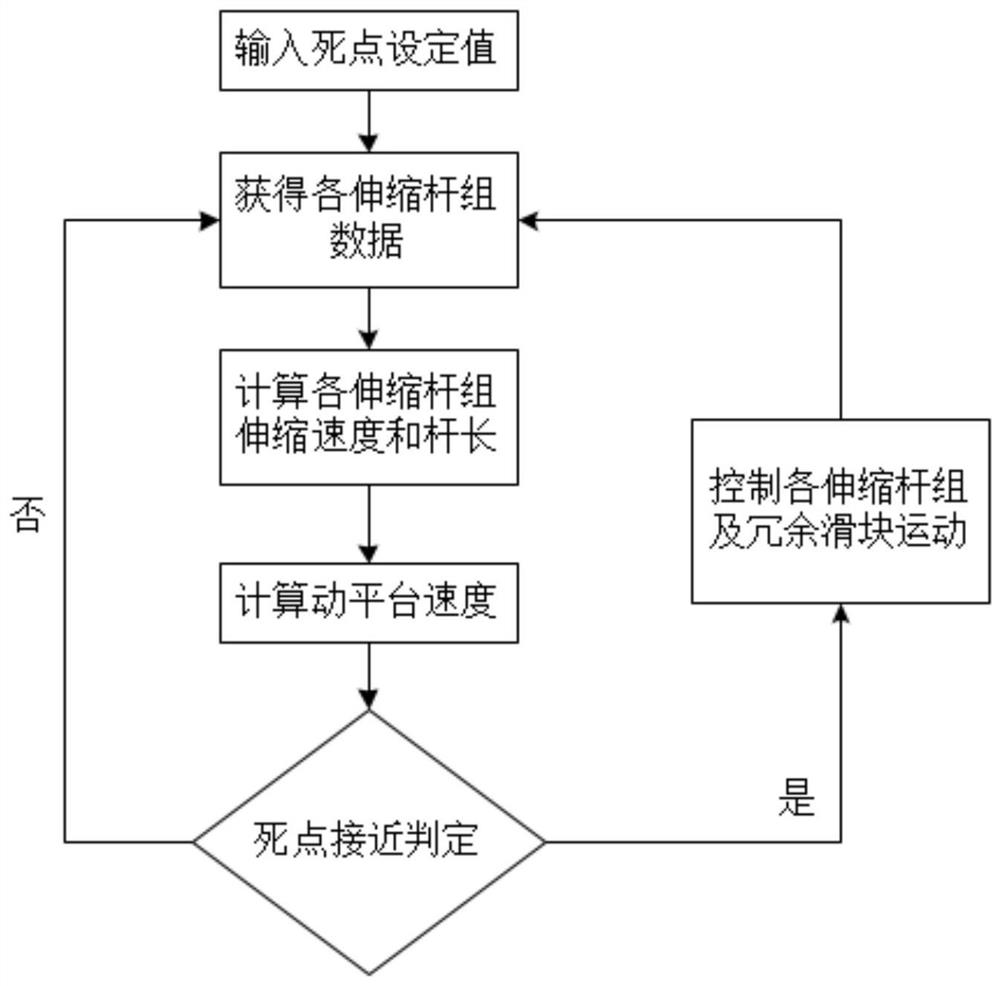

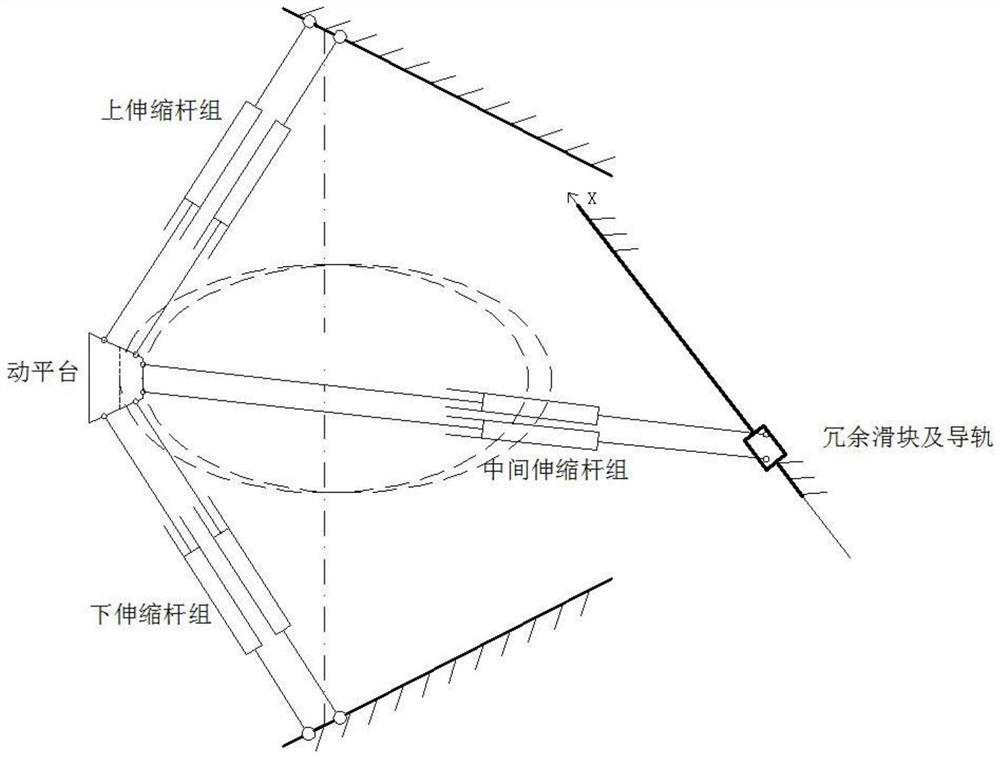

A redundant drive parallel machine tool dead point avoidance system and method

ActiveCN109894906BCalculation speedImprove real-time performanceMetal working apparatusControl engineeringServo

The invention discloses a dead point avoiding system and method of a redundant drive parallel machine tool. The system comprises speed measuring generators, photoelectric encoders, a linear sensing synthesizer and a dead point monitoring processor, wherein the speed measuring generators and the photoelectric encoders are connected to servo motors of three telescoping rod groups; the linear sensingsynthesizer is connected to a redundant sliding block; the speed measuring generators are used for acquiring output rotating speed of the servo motors of the three telescoping rod groups; the photoelectric encoders are used for acquiring the rotating circle number of lead screws of the three telescoping rod groups; the linear sensing synthesizer is used for acquiring the position of the redundantsliding block on a guide rail; and the dead point monitoring processor is used for determining whether a parallel mechanism is close to the position of a dead point or not and controlling the telescoping rod groups to telescope as well as controlling the moving direction of the redundant sliding block so as to avoid the position of the dead point. The method comprises the steps of acquiring the output rotating speed of the three telescoping rod groups, the rotating circle number of the lead screws, and the coordinates of the redundant sliding block on the guide rail; calculating the speed ofa movable platform; determining whether the parallel mechanism is close to the position of the dead point or not; and controlling each telescoping rod group and the redundant sliding block to move toavoid the position of the dead point. With the adoption of the system and the method, the dead point can be predicated and avoided.

Owner:NANJING UNIV OF SCI & TECH

Method for carrying out welding construction by utilizing six-degree of freedom mechanism type movable connecting rod mechanism

InactiveCN104551470AAvoid dead center positionIncrease stiffnessProgramme-controlled manipulatorWelding/cutting auxillary devicesCarrying capacityArchitectural engineering

The invention relates to a method for carrying out welding construction by utilizing a six-degree of freedom mechanism type movable connecting rod mechanism. An execution main chain is formed by a stand column, a main arm, a first rocker arm, a second rocker arm, a first connecting rod, a second connecting rod, a third connecting rod and a fourth connecting rod; an execution sub chain is formed by a fifth connecting rod, a sixth connecting rod, a stand column and a main arm; when welding operation is carried out, the main arm is driven through a motor so as to rotate, and the fifth connecting rod and the sixth connecting rod support the main arm and are in movement combination with the main arm; the second rocker arm is driven through the motor, so that the second rocker arm carries out rocker arm type control on the third connecting rod; the third connecting rod and the fourth connecting rod are driven through the motor to rotate, so that the connecting rod mechanism can finish welding operation. The method provided by the invention has the advantages of large working space, high rigidity, strong carrying capacity and high execution precision.

Owner:GUANGXI UNIV

A space multi-degree-of-freedom controllable mechanism fine-tuning welding robot

ActiveCN103737578BIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorWelding/cutting auxillary devicesClosed loopEngineering

A controllable mechanism type fine-adjusting welding robot with multiple degrees of spatial freedom comprises three controllable fine-adjusting four-rod mechanism closed-loop subchains connected in parallel and an execution mechanism subchain in series connection. The four-rod mechanism closed-loop subchains can control a first connecting rod to move in the plane where the four-rod mechanism closed-loop subchains are located, and the spatial movement of a platform can be achieved through the movement of parallel connecting rods and a machine body. The spatial movement of a tail end executor can be controlled through the resultant movement of the three closed-loop subchains and the machine body, the movement inertia of the tail end executor is small, dynamics performance is good, reliability is high, the mechanism has the advantages of being compact in structure and easy to control, the connecting rods are used for control, rod pieces can be made into light rods, the work space of the mechanism is large, the gravity of the mechanism moves backwards, the mechanism is kept balanced, and the mechanism can act on more occasions.

Owner:GUANGXI UNIV

Mechanical arm with symmetrical mechanisms

InactiveCN103737583AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorClosed loopEngineering

The invention discloses a mechanical arm with symmetrical mechanisms. The mechanical arm comprises a plurality of parallel mechanism closed loop execution mechanism sub-chains and a series execution mechanism main chain. A main chain connecting rod can be controlled by the mechanism closed loop sub-chains to move in the plane where a four-rod mechanism closed loop sub-chain is located, and spatial motion of a movable platform can be achieved through motion of a plurality of parallel connecting rod sub-chains and a machine body. Control is achieved through resultant movement of four closed-loop sub-chains and the machine body; spatial motion of a tail end executor is achieved through connection of a plurality of connecting rods and the machine body; the tail end executor is small in motion inertia, good in dynamics performance and high in reliability; the mechanisms have the advantages of being compact in structure and easy to control; light rods can be produced; because the mechanisms are large in work space, the gravity of the mechanisms moves backwards, and the mechanisms are kept balanced and can be applied to more occasions.

Owner:GUANGXI UNIV

Multi-freedom-degree motion automobile welding robot

InactiveCN108284437AIncrease workspaceAvoid dead center positionProgramme-controlled manipulatorWelding/cutting auxillary devicesEngineeringGravity center

The invention provides a multi-freedom-degree motion automobile welding robot composed of an executing mechanism auxiliary chain and an executing mechanism main chain. The executing mechanism main chain can move in a plane through a main arm control mechanism, and the space movement of a movable platform can be achieved through supporting of the executing mechanism auxiliary chain and the movementof a machine body. Control is achieved through the synthesized movement of the executing mechanism auxiliary chain and the machine body, and the space movement of a tail end welding executer is achieved through connection of two rockers of a main arm. The motion inertia of the tail end welding executer is small, the dynamics performance is good, and reliability is high. The mechanism has the beneficial effects of being compact in structure and simple in control. The work space is large, the gravity center of the mechanism moves backwards, and the multi-freedom-degree motion automobile weldingrobot can be applied to more occasions.

Owner:CHENGDU ZHENGGUANG ELECTRONICS TECH CO LTD

Multi-degree-of-freedom controllable moving type welding robot

InactiveCN104552252AAvoid dead center positionImprove balanceProgramme-controlled manipulatorWelding/cutting auxillary devicesMulti degree of freedomEngineering

The invention discloses a multi-degree-of-freedom controllable moving type welding robot. One end of a stand column is connected with a vehicle body; the other end of the stand column is respectively connected with one end of a main arm and the first connection end of a first rocker arm; the second connection end of the first rocker arm is connected with one end of a first connecting rod; the other end of the first connecting rod is connected with the second connection end of a second rocker arm; the first connection end of the second rocker arm is connected with the other end of the main arm; the third connection end of the second rocker arm is connected with one end of a second connecting rod; the other end of the second connecting rod is connected with the third connection end of the first rocker arm; one end of a third connecting rod is connected with the fourth connection end of the second rocker arm; the other end of the third connecting rod is connected with one end of a fourth connecting rod; the other end of the fourth connecting rod is connected with a tail end welding executor; one end of a connecting block is connected with the stand column via a fixing pair; the other end of the connecting block is connected with a fifth connecting rod; the fifth connecting rod, a sixth connecting rod, a seventh connecting rod and the third connection end of the main arm are successively connected. The multi-degree-of-freedom controllable moving type welding robot has the advantages of large working space, high rigidity, high bearing capability and high execution precision.

Owner:GUANGXI UNIV

Twenty-degree-of-mobility and six-degree-of-freedom vehicle welding robot

InactiveCN108044275AEasy to controlFlexible drive modeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDegrees of freedom

The invention provides a twenty-degree-of-mobility and six-degree-of-freedom vehicle welding robot. The twenty-degree-of-mobility and six-degree-of-freedom vehicle welding robot comprises a serial connection welding main chain, a rocking arm fine adjustment control sub chain and an actuation mechanism sub chain. The serial connection welding main chain can control the vehicle robot to perform a six-degree-of-freedom motion in space; the rocking arm fine adjustment control sub chain is a four-rod mechanism formed by two rocking arms and two connecting rods, and is mounted on a large arm for fine adjustment control over the main chain through the four-rod mechanism; and the actuation mechanism sub chain supports and the adjusts the large arm. Through connection between multiple mechanical arms and a machine body, six-degree-of-freedom output of a terminal trajectory is realized; and the mechanism has the advantages of quick actions, high precision, low motion inertia, excellent power performances, compact structure, large working space, high bearing capacity, multiple motion trajectory output and simple control, and can be applied to multiple welding fields.

Owner:CHENGDU ZHENGGUANG ELECTRONICS TECH CO LTD

Wheel type mobile robot palletizer with multiple closed-loop sub chains

InactiveCN104526676AIncrease stiffnessIncrease workspaceProgramme-controlled manipulatorJointsPalletizerClosed loop

The invention discloses a wheel type mobile robot palletizer with multiple closed-loop sub chains. The wheel type mobile robot palletizer comprises the multiple parallel mechanism closed-loop executing mechanism sub chains, a series executing mechanism main chain and a mobile platform. The mechanism closed-loop sub chains can control a main chain connecting rod to move in a plane where the four-rod mechanism closed-loop sub chains are located. Space movement of the mobile platform can be achieved through movement of the multiple parallel connecting rod sub chains, a robot palletizer body and the mobile platform. According to the wheel type mobile robot palletizer with the multiple closed-loop sub chains, control is achieved through resultant movement of the four closed-loop sub chains and the robot palletizer body, space movement of an end executor is achieved through connection of multiple connecting rods, the robot palletizer body and the mobile platform, the end executor is small in movement inertia, good in dynamics performance and high in reliability, and the mechanism has the moving and operating functions at the same time, so that the robot palletizer has the almost infinitely large working space and the high movement redundancy, and can act on more occasions.

Owner:GUANGXI UNIV

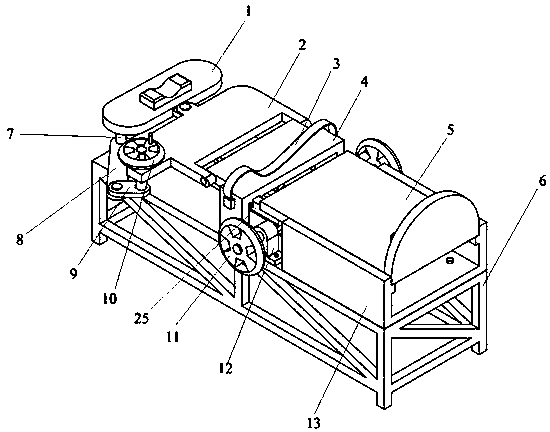

Actively operated manual traction bed

InactiveCN108478320BReal-time adjustment of tractionWith snap back featureFractureMedical equipmentEngineering

The invention relates to the field of medical equipment, in particular to an initiative control type hand-cranking traction bed and aims to solve problems of low user friendliness in a treatment process and poor treatment effects caused by the fact that patients can only passively accept traction treatment instead of initiative control in use of existing traction medical equipment. The initiativecontrol type hand-cranking traction bed comprises a headrest platform, an upper body platform, a hip plate, a lower limb platform, a frame and a bed body guide rail. The headrest platform is hinged tothe upper body platform, the upper body platform is movably connected with the hip plate through rotating shafts on two sides of the hip plate, the hip plate is fixedly mounted on the frame, and thelower limb platform is arranged on the bed body guide rail. The headrest platform has a horizontal bilateral swing degree of freedom relative to the upper body platform, the upper body platform has avertical turning degree of freedom relative to the hip plate, and the lower limb platform has a longitudinal moving degree of freedom relative to the lower limb platform. By the initiative control type hand-cranking traction bed, initiative cervical vertebra, lumbar vertebra and vertebral column traction treatment of patients can be realized.

Owner:青岛市黄岛区中心医院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com