A redundant drive parallel machine tool dead point avoidance system and method

A dead point and redundant technology, applied in the field of redundant drive parallel machine tool dead point avoidance system, to achieve the effect of accurate judgment of dead point approach, fast calculation speed and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

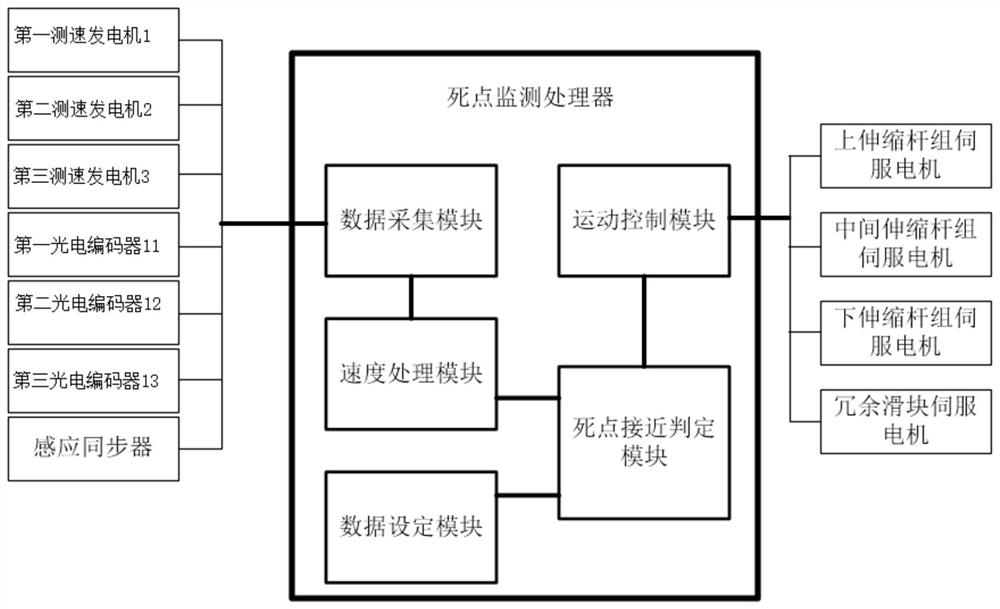

AI Technical Summary

Problems solved by technology

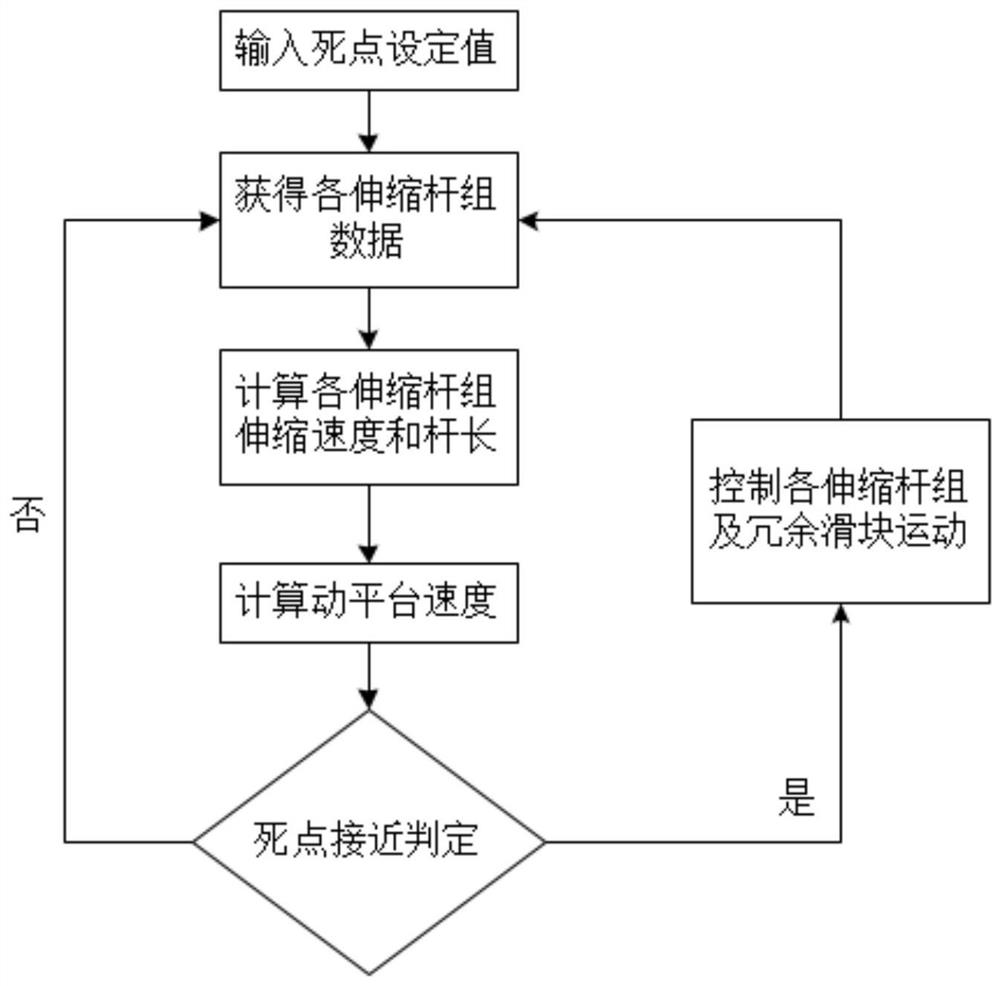

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

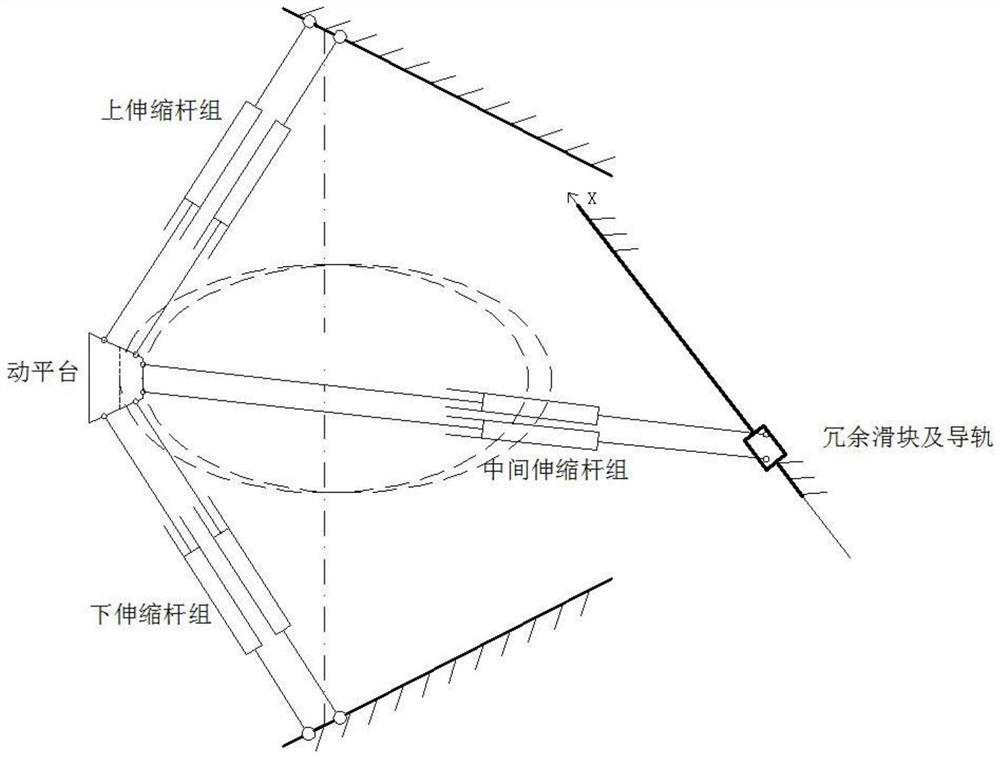

[0023] combine figure 2 , a parallel mechanism in a redundantly driven parallel machine tool, including an upper telescopic rod group, a lower telescopic rod group, a middle telescopic rod group, redundant sliders and guide rails, and four servo motors; one end of the upper telescopic rod group adopts a ball joint fixed, the other end is connected to the top of the moving platform by a ball joint; one end of the lower telescopic rod group is fixed by a ball joint, and the other end is connected to the bottom of the moving platform by a ball joint; one end of the middle telescopic rod group is connected by a ball joint and a redundant slide The blocks are connected, and the other end is connected to the rear of the moving platform by a ball joint; each telescopic rod group is connected to a servo motor, and the servo motor synchronously drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com