Multi-freedom-degree motion automobile welding robot

A technology of welding robot and degree of freedom, applied in the field of robotics, can solve the problems of poor mechanism dynamics, inconvenient welding of automobiles, small working space, etc., and achieve the effect of reducing active moment, small mechanism inertia, and improving working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

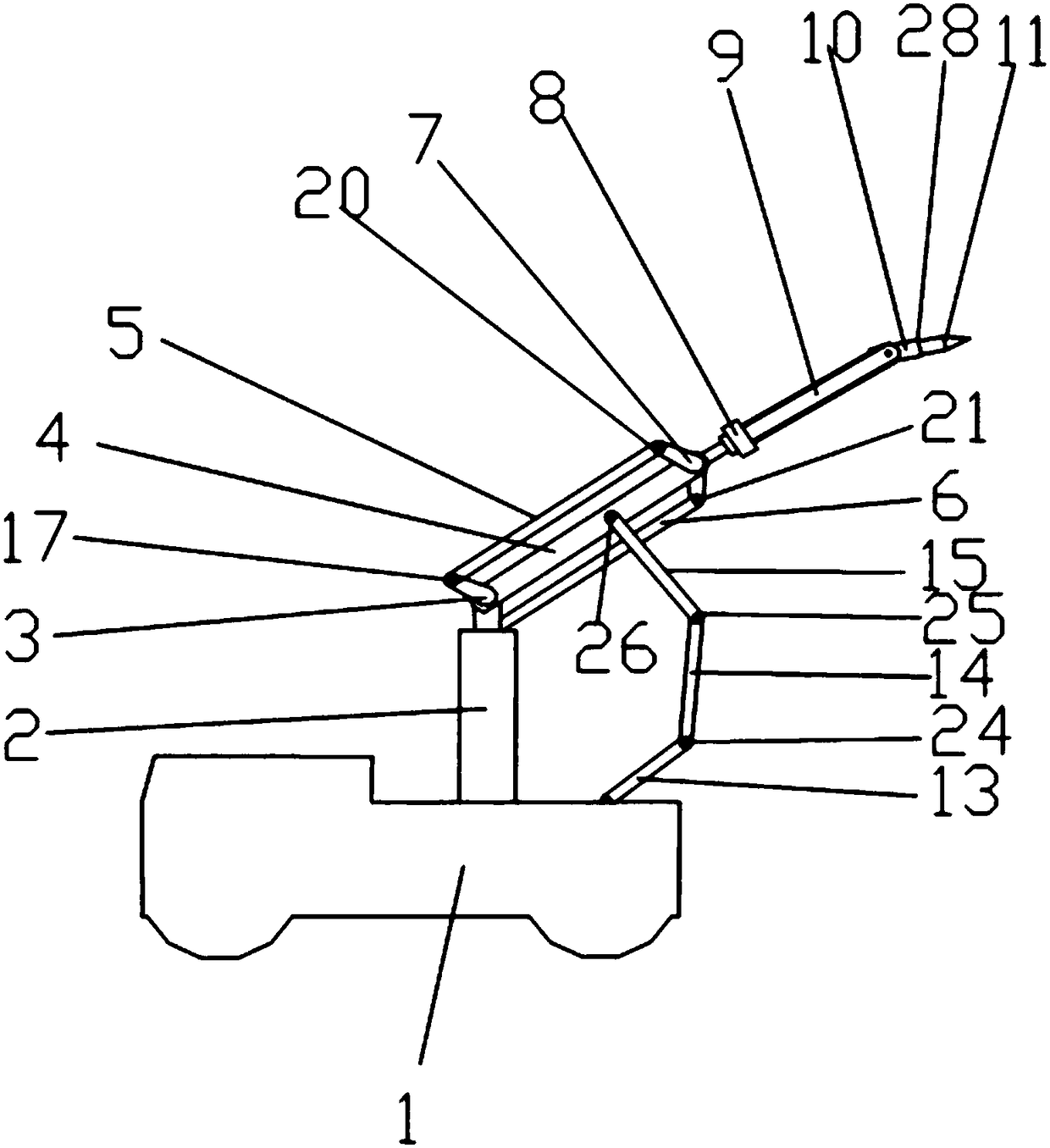

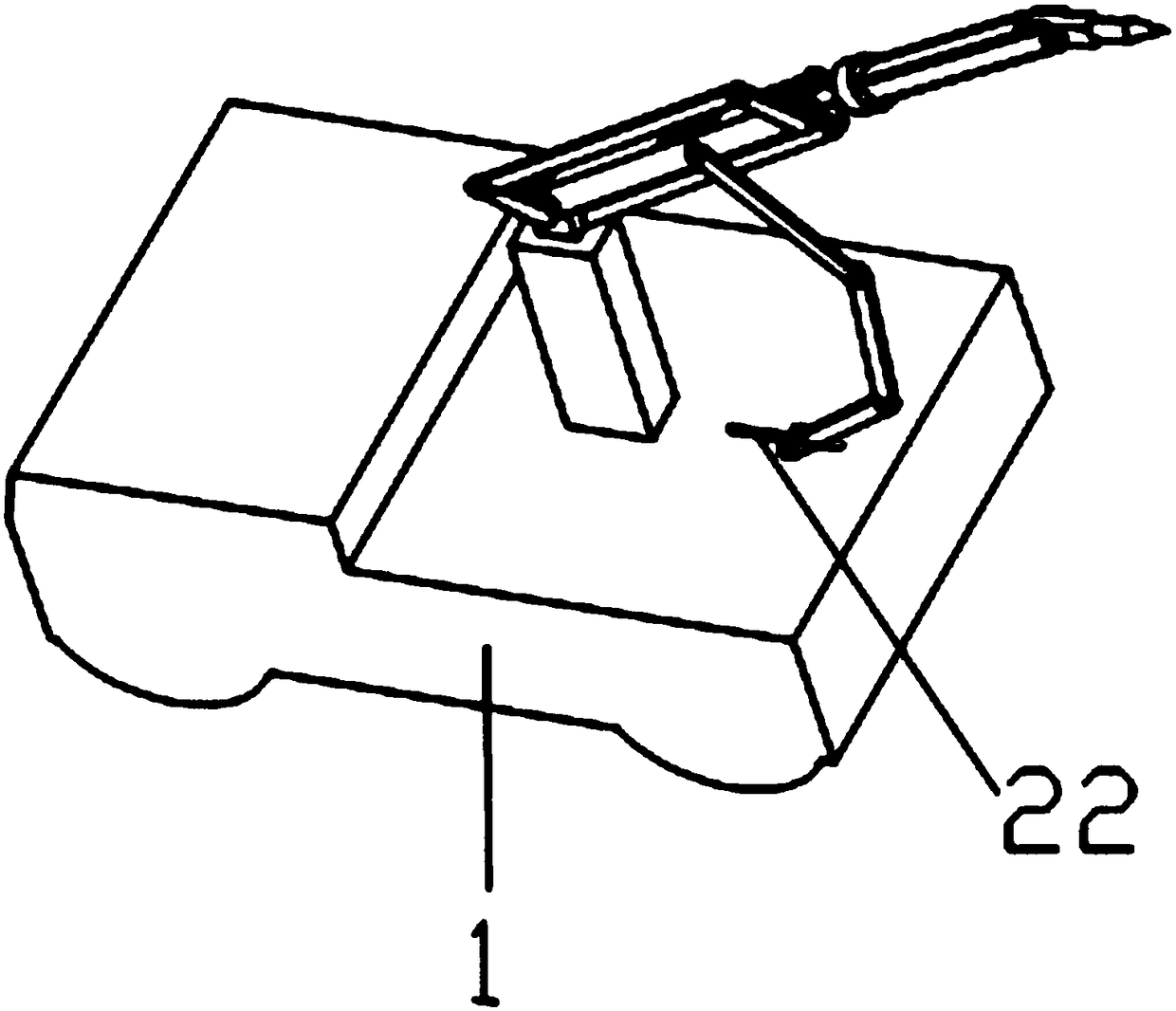

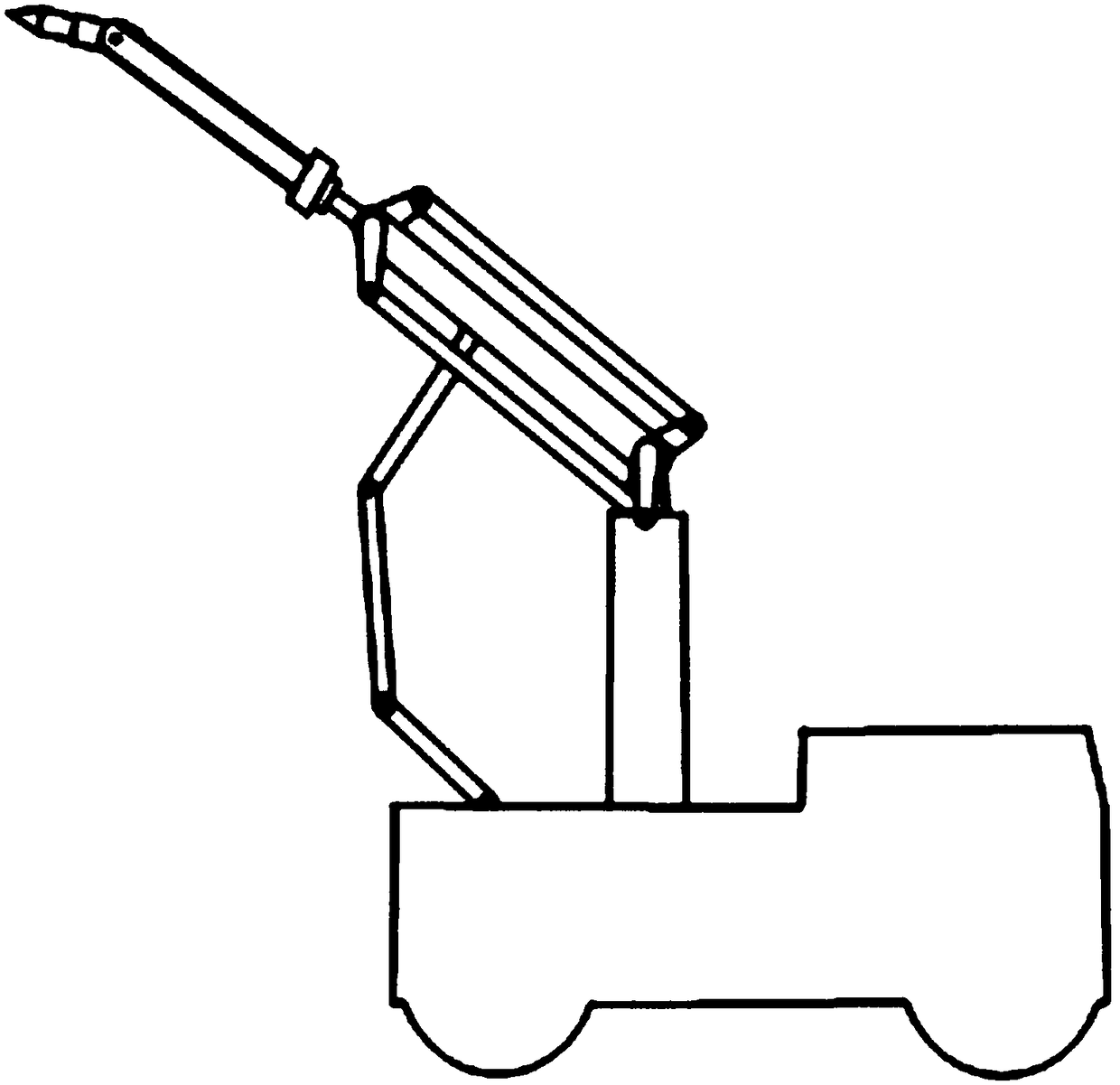

[0031] control figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 , a multi-degree-of-freedom mobile automobile welding robot, its structure and connection method are:

[0032] The main chain of the actuator consists of a car body 1, a column 2, a main arm 4, a first rocker arm 3, a second rocker arm 7, a first connecting rod 5, a second connecting rod 6, a rotating disc 8, a rotating arm 9, The third connecting rod 10 and the end welding actuator 11 are composed, the first connection end of the column 2 is connected with the car body 1 through the fixed pair, and the second connection end of the column 2 is first connected with the main arm 4 through the first rotating pair 16 end is connected to the first connecting en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com