Patents

Literature

30results about How to "No security threat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

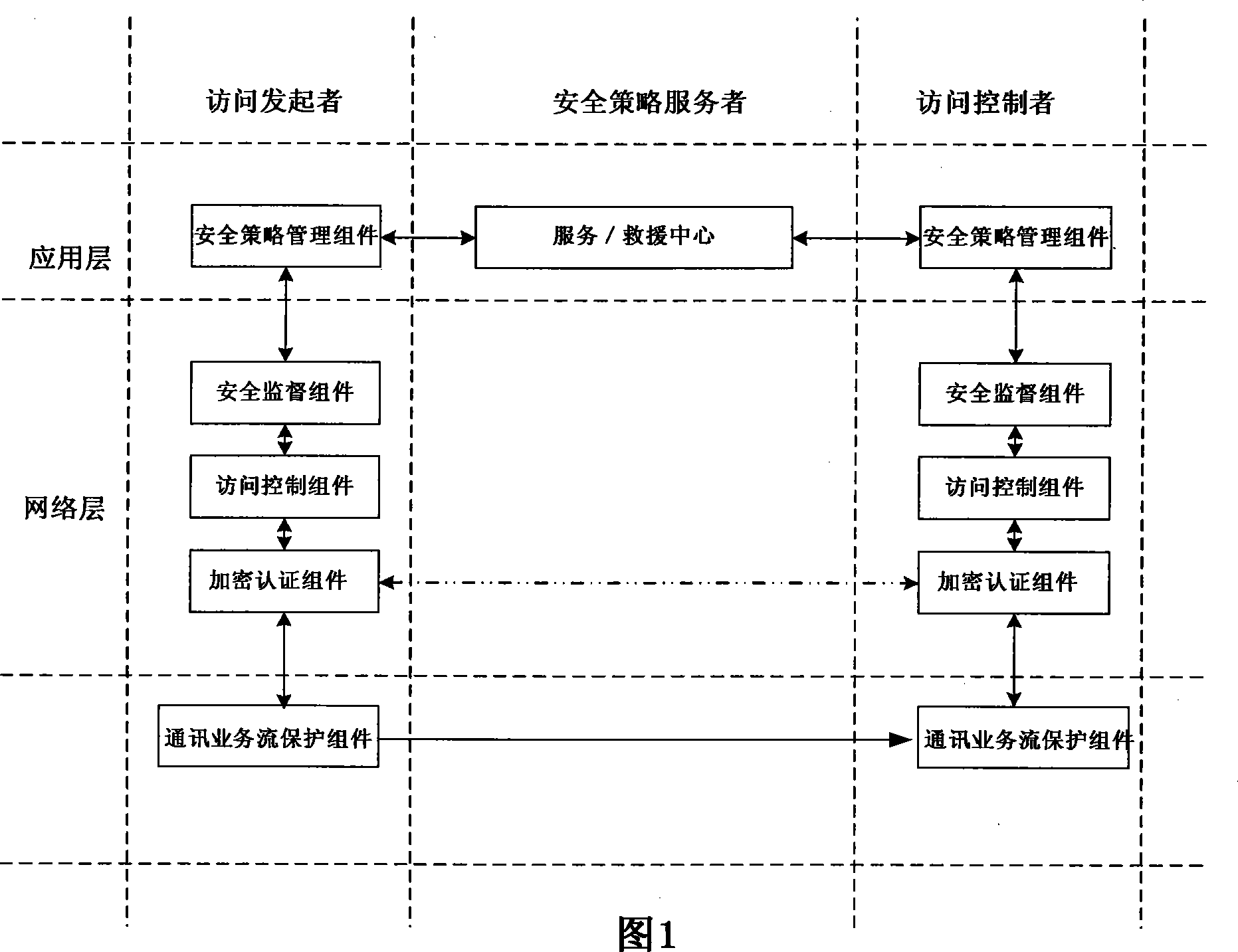

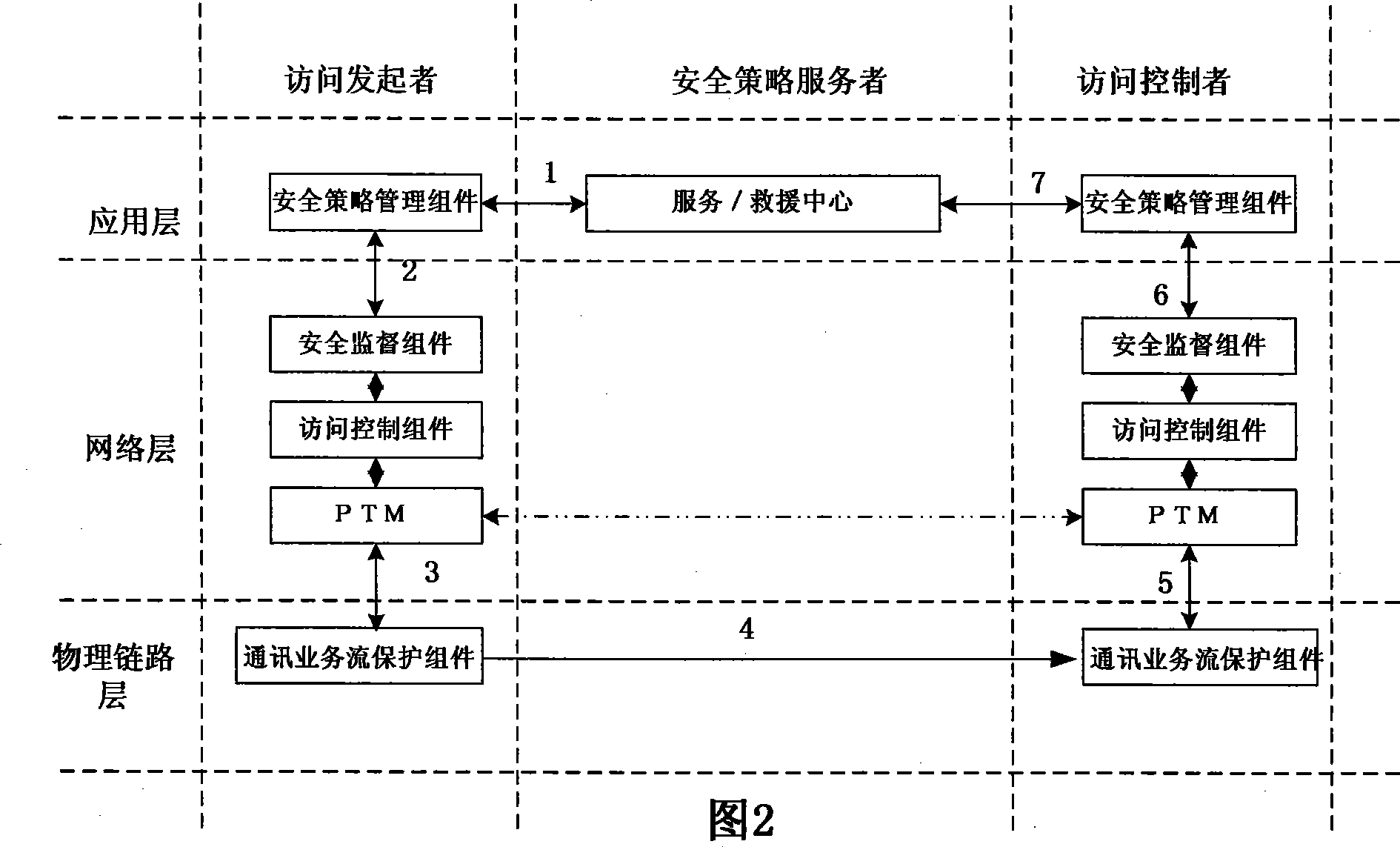

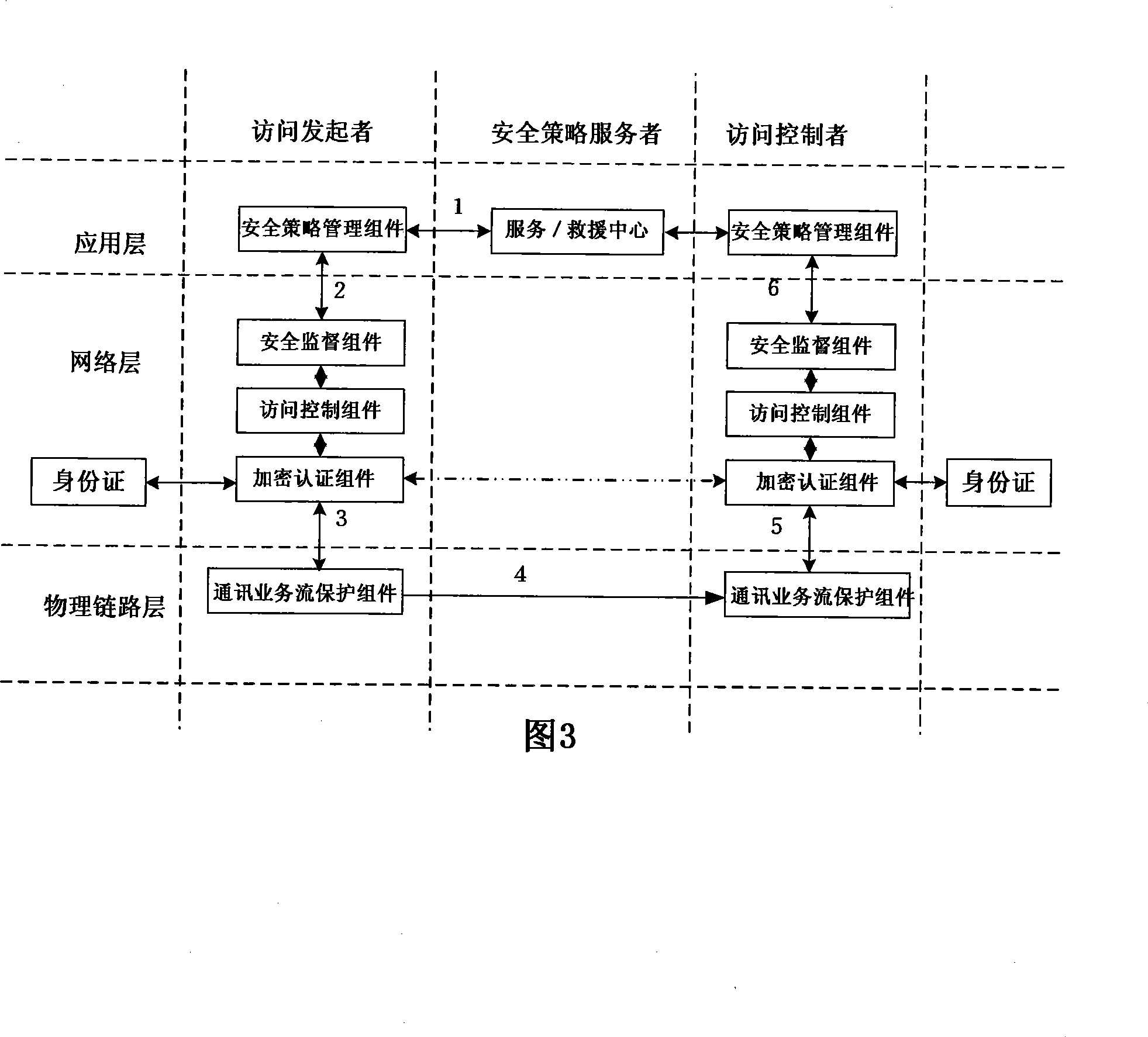

Trusted network architecture based on identity

InactiveCN101425903ASimple technical implementationSimple and efficient structureUser identity/authority verificationData switching networksData streamNetwork architecture

A credibility network framework based on identities belongs to the technical field of information security, which comprises three layers and three entities, wherein the three layers are a physical transmission layer, a network layer and an application program layer; and the three entities are a network access sponsor, a network access controller and a safety tactics server. The credibility network framework adopts a vector quantity encryption authentication mechanism based on the identifies of accessors, and guarantees that the requirements of all network accessors are the encryption data streams bound with accessor entities, as long as access controllers use personal identify labels and identify information of access requesting labels to obtain accurate proof test value through decrypting requesting data, bidirectional equipotent identify authentication is realized, then authority and content are evaluated and detected by access control assemblies and safety monitoring assemblies so as to guarantee that all access requirements are safe, and unsafe access requirements are refused, thereby the credibility network framework is realized.

Owner:冯振周

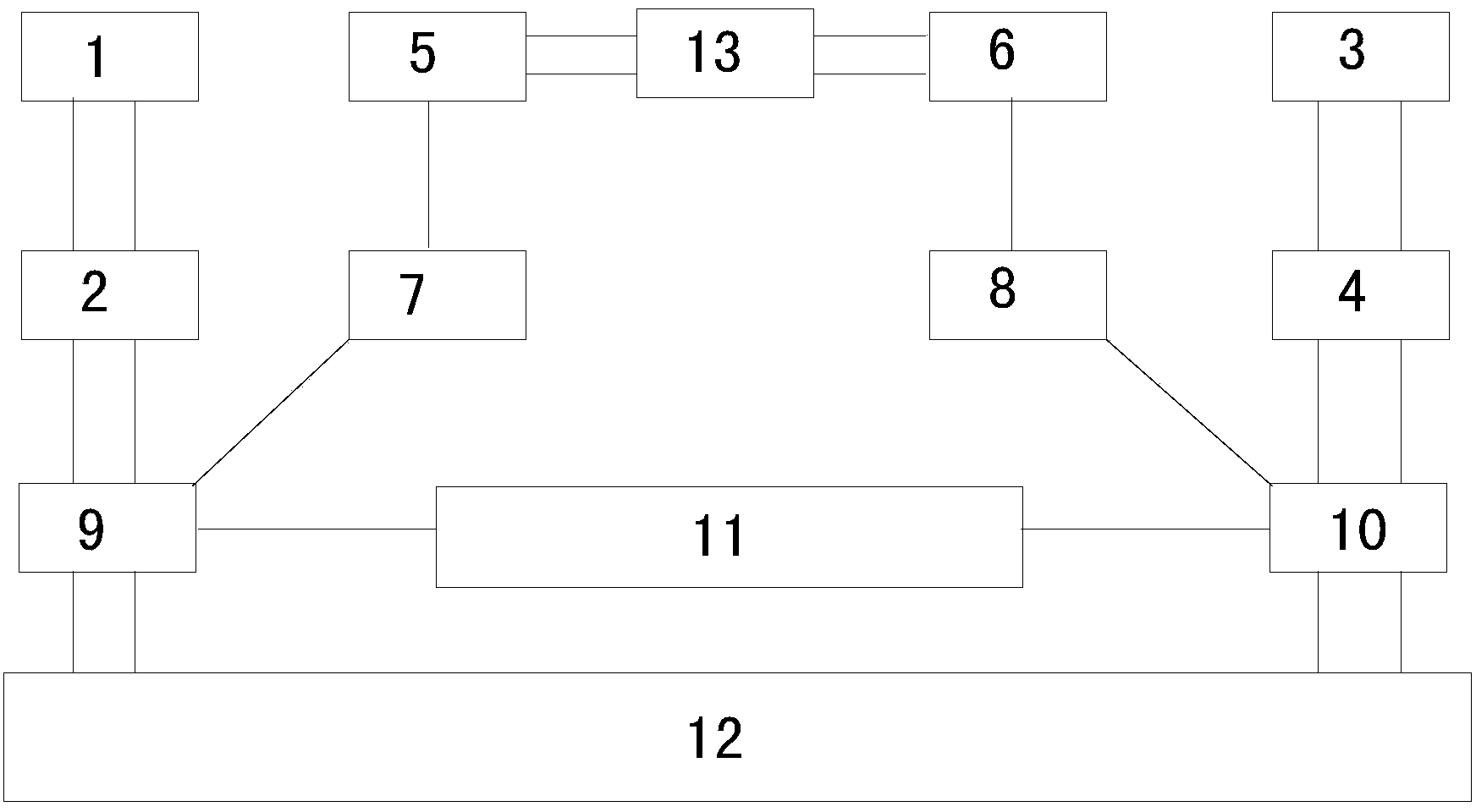

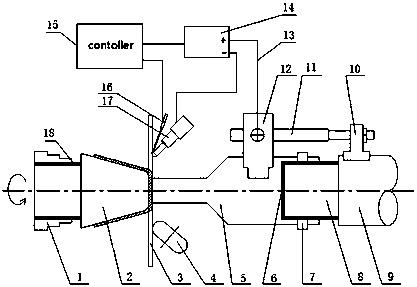

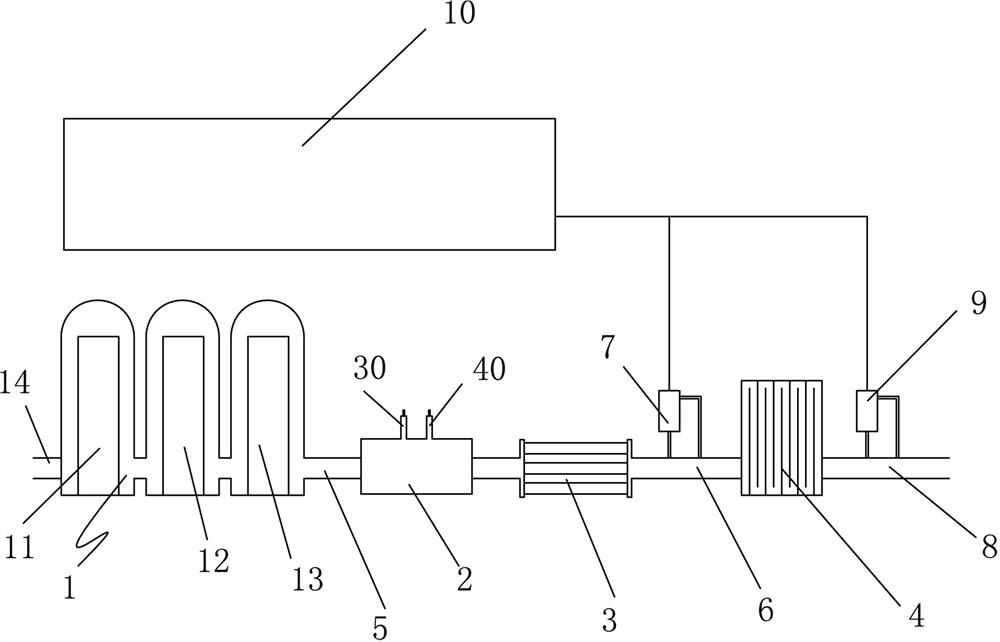

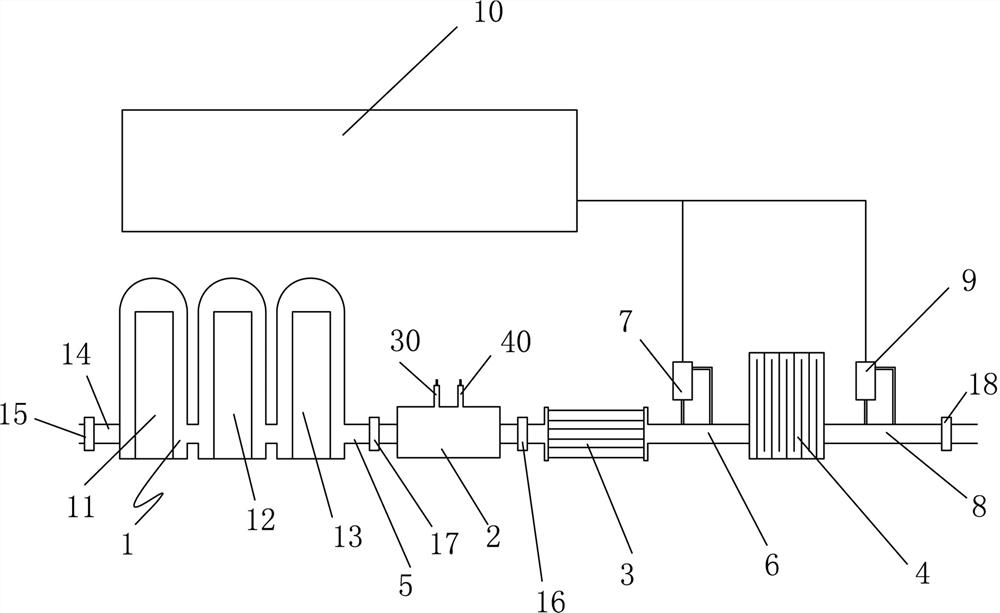

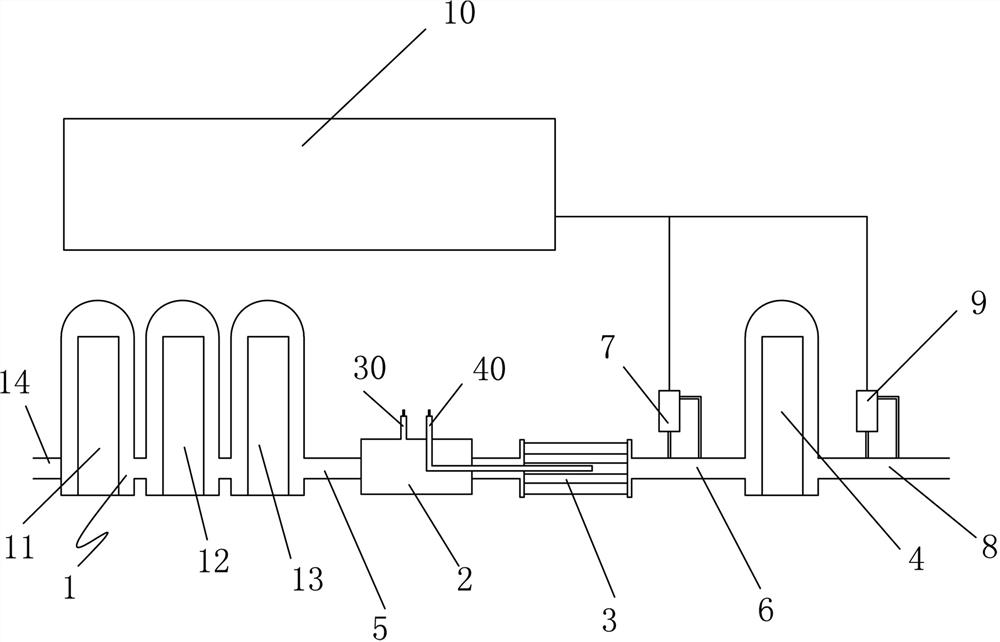

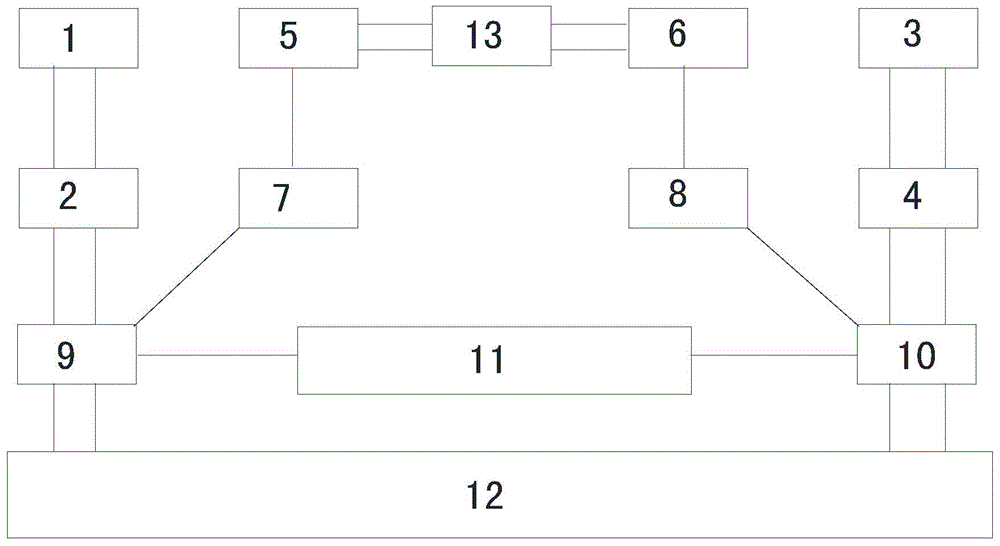

Coordinated control system and method of train door and platform door

ActiveCN103895655ALow costReduce secondary development costsSignal operation from vehicleRailway stationControl systemMonitoring system

The invention provides a coordinated control system and method of a train door and a platform door. The coordinated control system comprises an RFID system, a ZigBee wireless two-way transmission system, a PSL platform door local control system and a PSA platform door state monitoring system; the RFID system provides an enabling switching signal of in-place stable stop of a train; the ZigBee wireless two-way transmission system completes wireless two-way transmission of instruction sending of the train door and the platform door and state feedback receiving of the platform door; the PSL platform door local control system completes data collection and transmission of the RFID system and ZigBee wireless two-way transmission system, and control over the platform door; the PSA platform door state monitoring system completes operation recording of all events, failure state alerting, and monitoring and control of on-line parameter adjustment. The coordinated control system and method of the train door and the platform door have the advantages that cost is low, the construction period is short, the interface integration level is high, higher reliability and safety are achieved, and operation is convenient.

Owner:SHANGHAI JIACHENG RAILWAY TRANSPORTATION SAFETY SYST

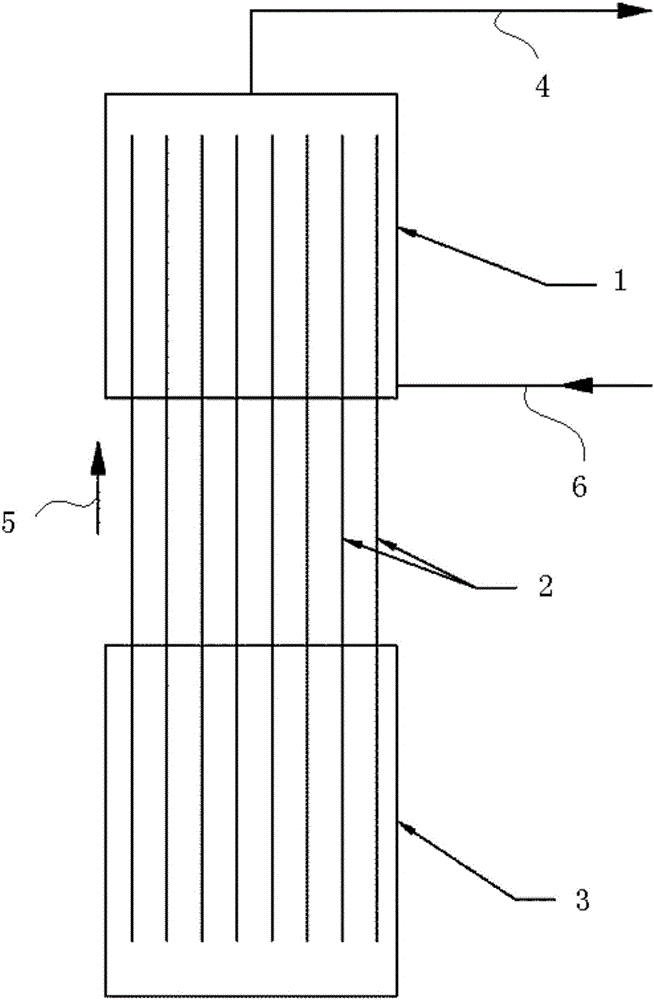

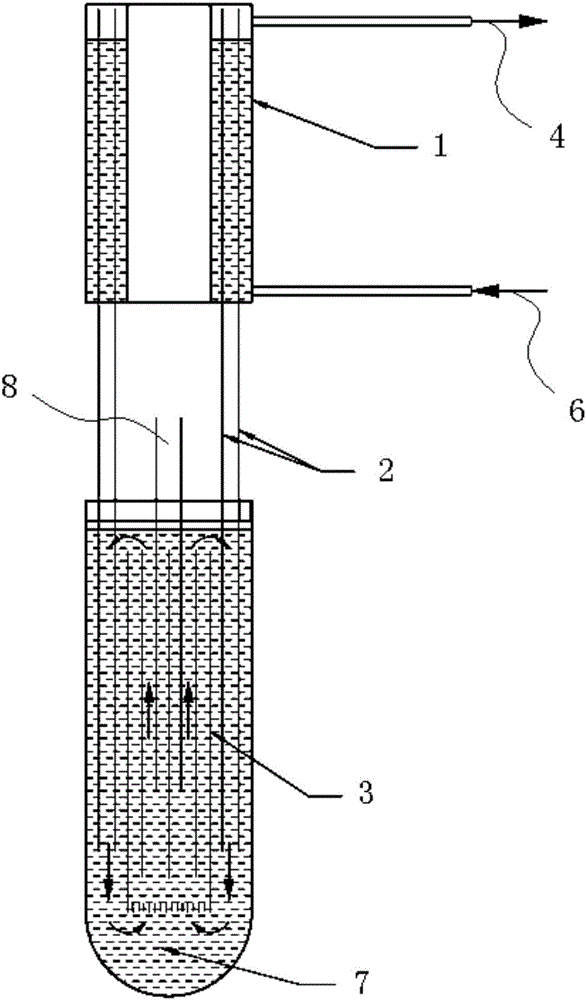

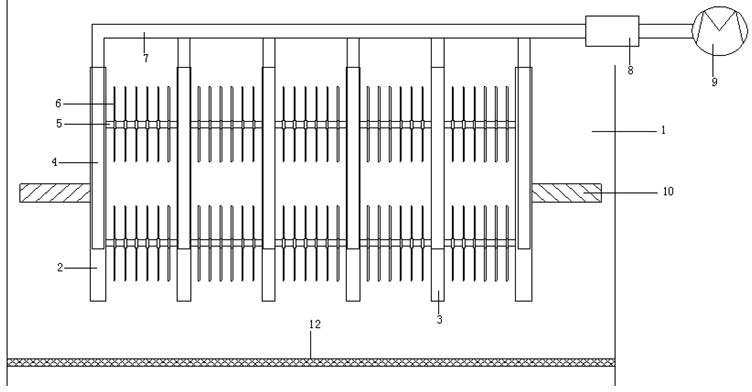

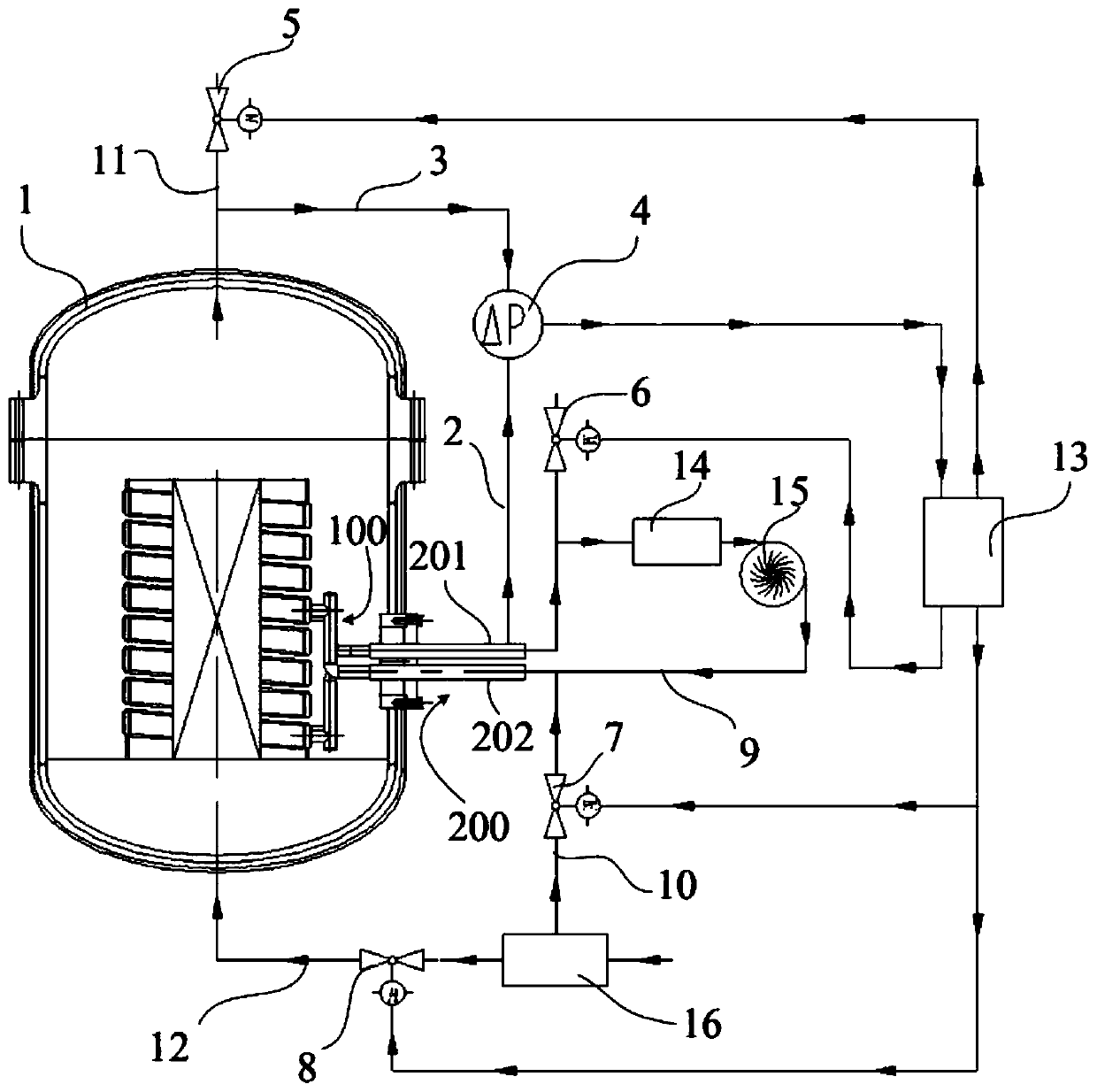

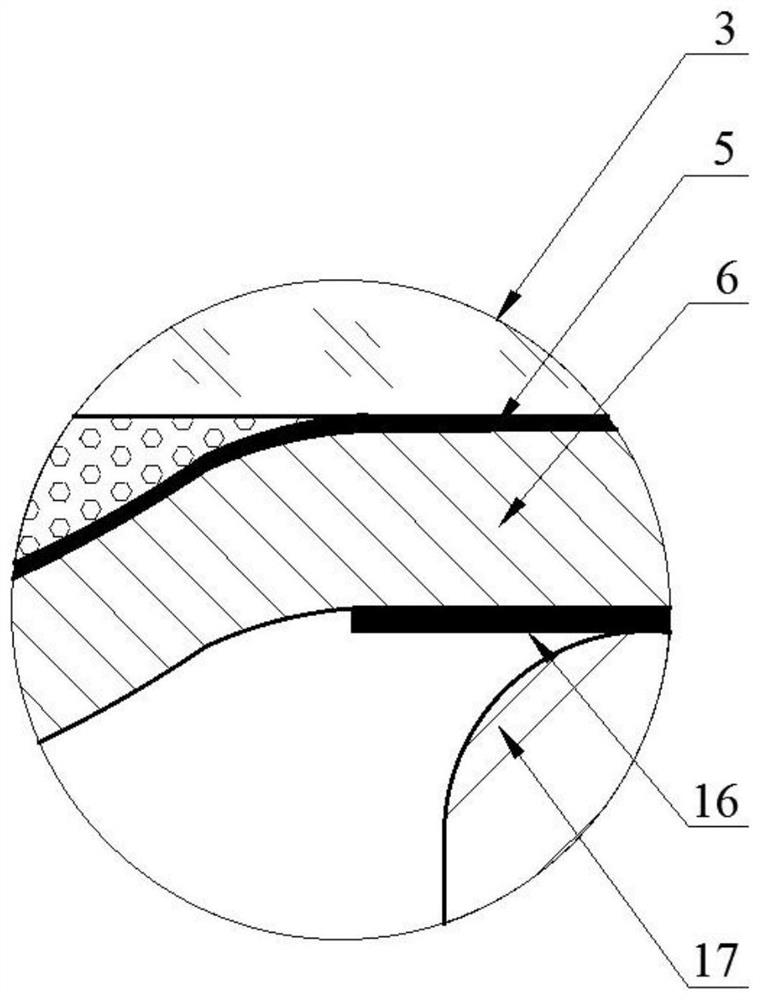

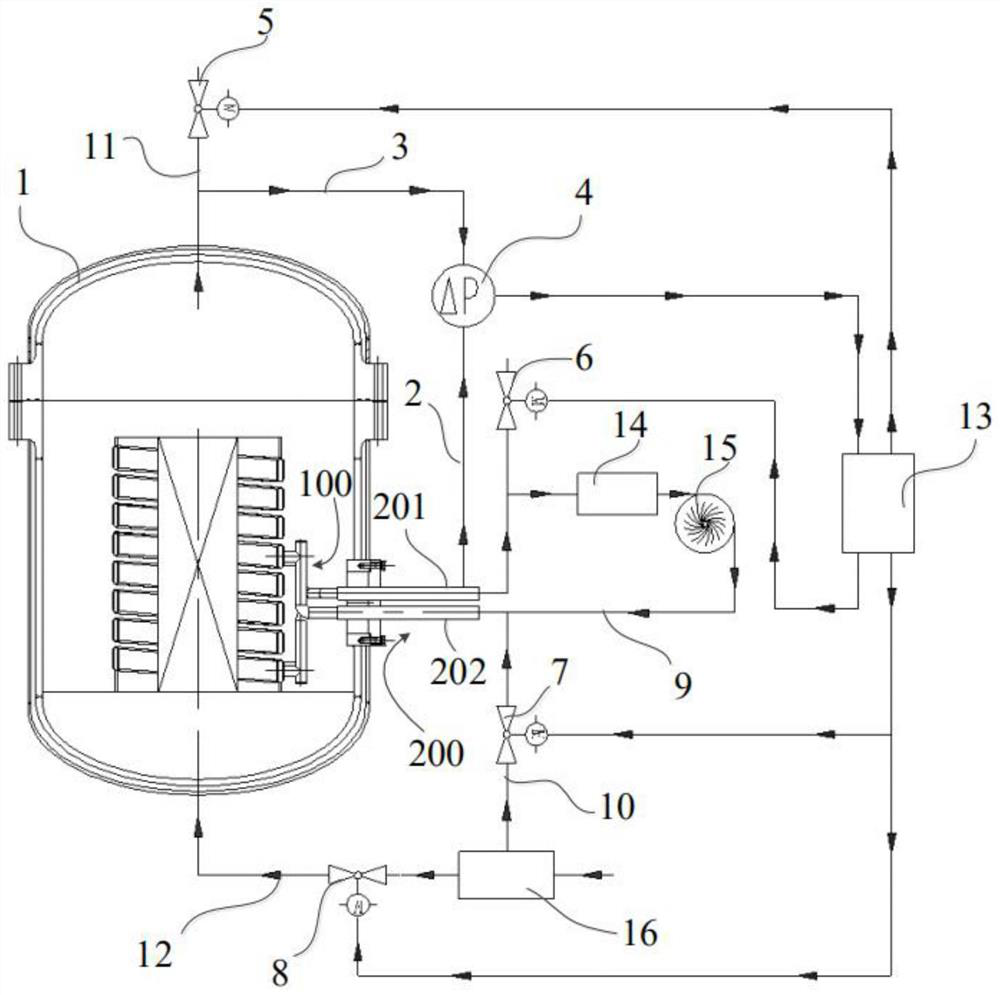

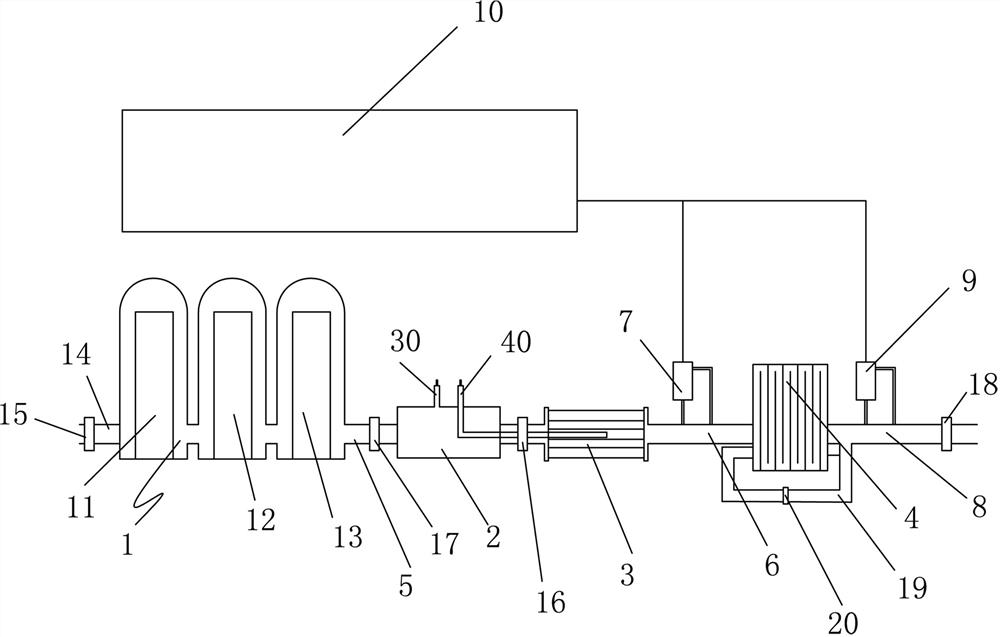

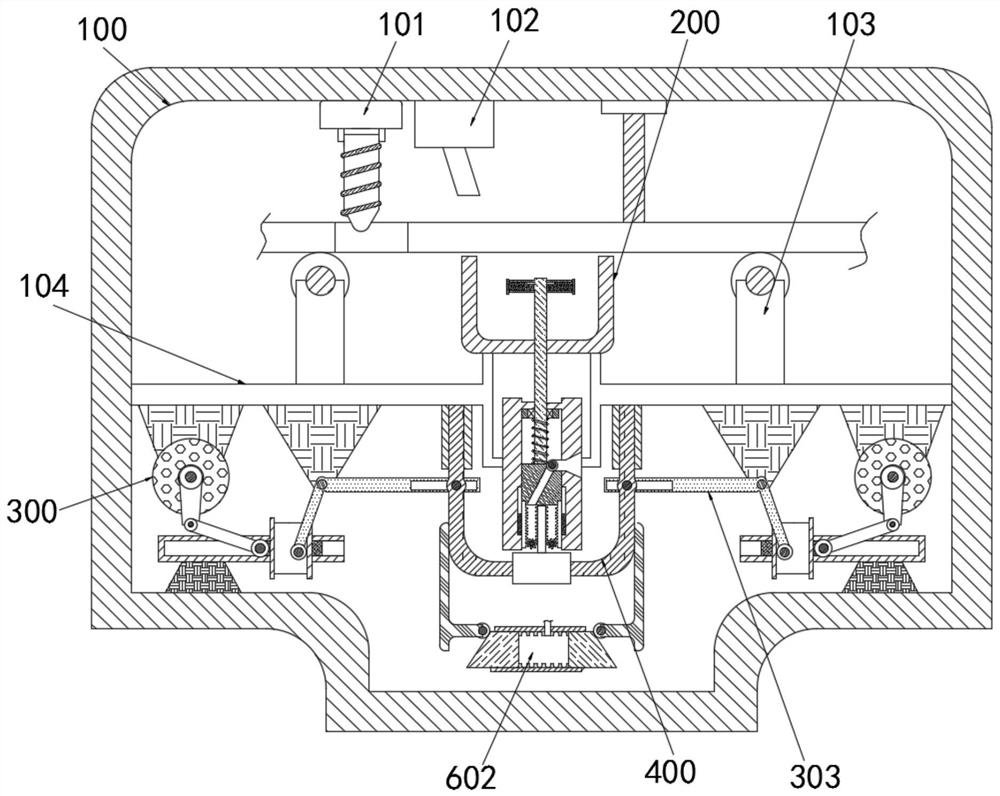

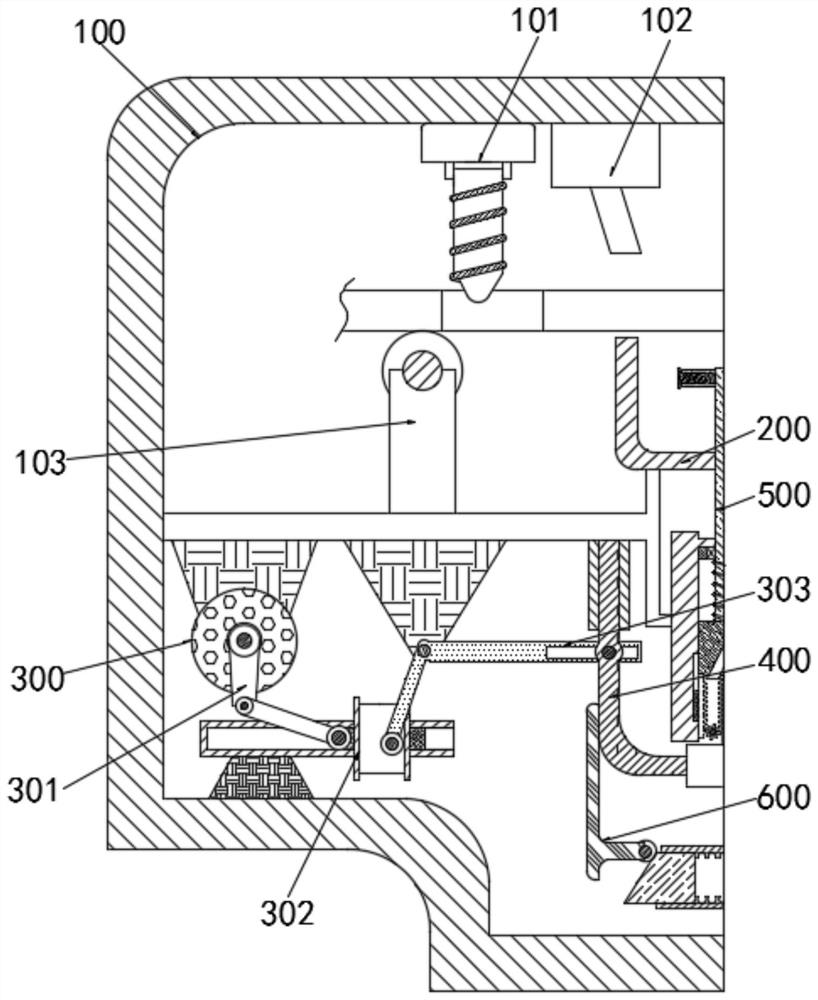

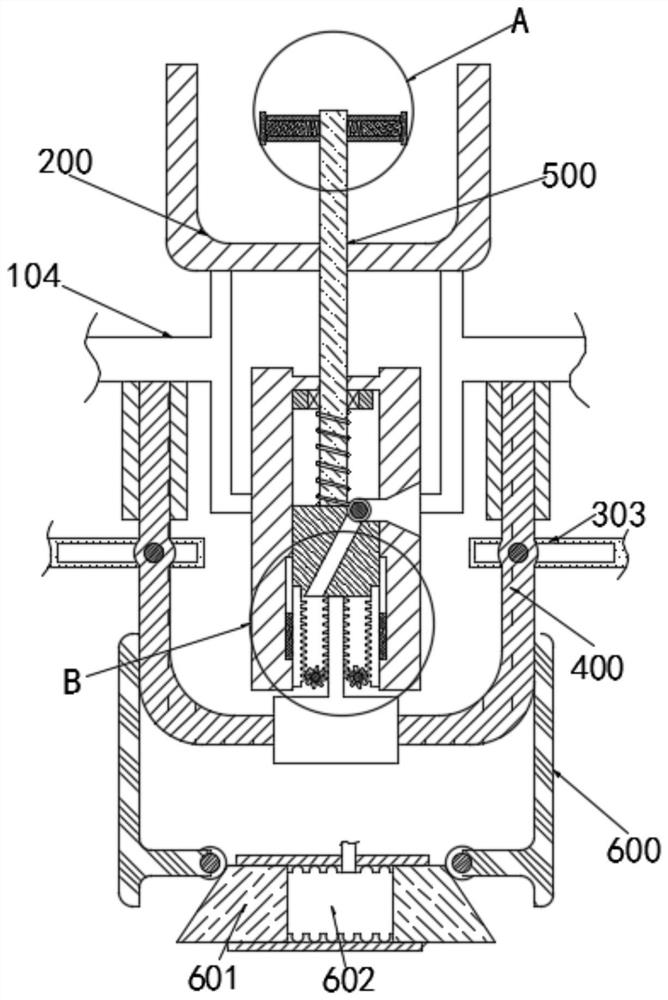

Passive high-temperature heat pipe fast reactor core heat transfer system and method

InactiveCN106297914AImprove securityNo security threatNuclear energy generationCooling arrangementChemical reactionNuclear engineering

The invention discloses a passive high-temperature heat pipe fast reactor core heat transfer system and method. The system comprises a fast reactor cooling agent pond containing sodium liquid, heat tubes and a steam evaporator. The lower ends of the heat tubes are placed in the sodium liquid of the fast reactor cooling agent pond, and the upper ends of the heat tubes are placed in water of the steam generator. A reactor fuel assembly is placed in the fast reactor cooling agent pond and immersed under the liquid surface of the sodium liquid. A sodium cooling agent and a reactor core fuel assembly are sealed, heat transfer is conducted on the steam evaporator through the heat tubes, the heat tubes can be filled with mercury, lead, bismuth, tin and other alloy which can not chemically react with water easily and serve as working media, the sodium cooling agent cannot transfer heat directly with water, and safety is greatly improved. Mercury serves as the working medium of the heat tubes, and due to the fact that the charging amount of single heat tubes is small, direct security threats are not caused even if the heat tubes leak.

Owner:SOUTH CHINA UNIV OF TECH

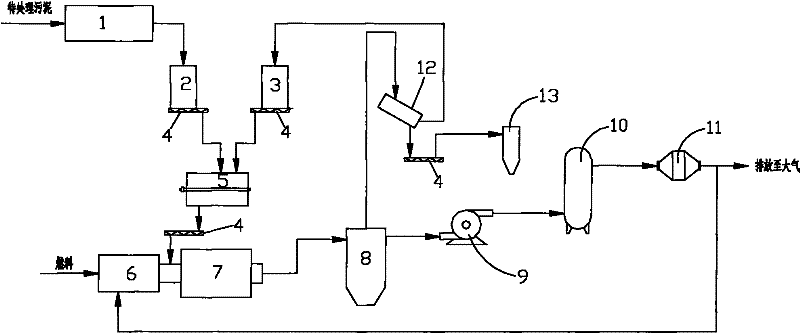

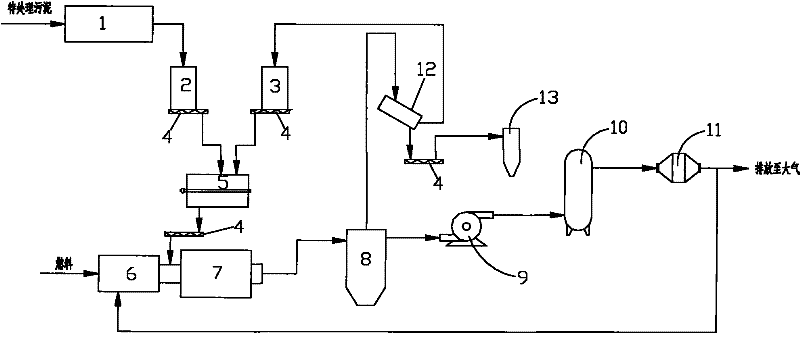

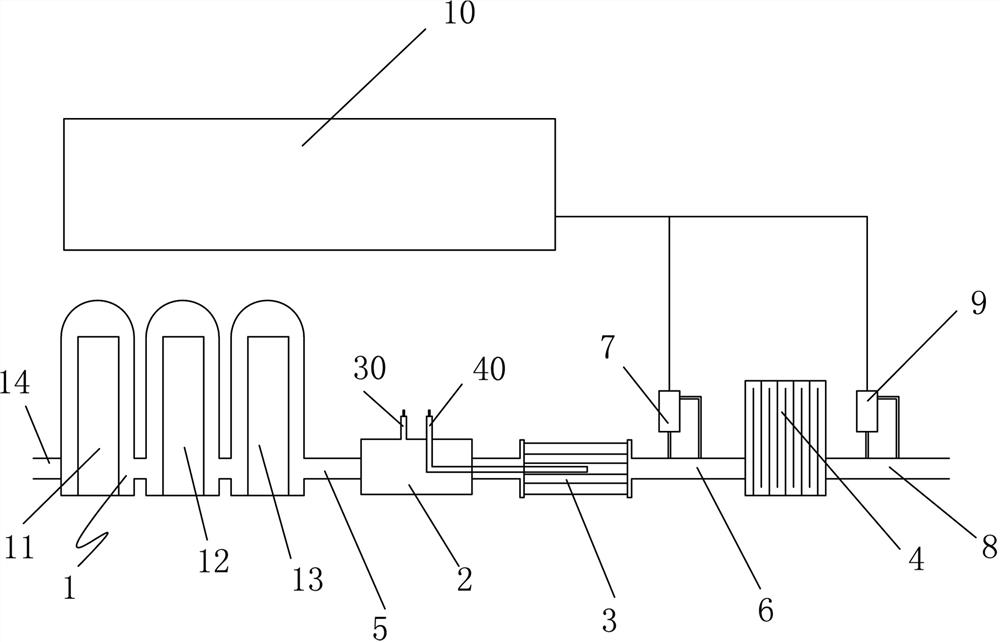

Method for integrating sludge dewatering and sludge damp drying

InactiveCN102206030AReduce moisture contentFlexible adjustment of back-mixing ratioSludge treatment by de-watering/drying/thickeningGas phaseDewatered sludge

The invention discloses a method for integrating sludge dewatering and sludge damp drying, which comprises the following steps: dewatering sludge from sewage treatment plants; mixing; mixing dewatered sludge and sludge treated by a damp drying treatment for forming mixed sludge; drying the mixed sludge in a drying device by a direct heat exchange mode with outer heat source for forming damp drying sludge with 40 to 45% of the water content; gas-solid separating and screening the damp dried sludge, wherein sludge particle with 1 to 2mm of particle size is circularly used as damp drying sludge in the step. The present invention has the advantages that the method is simple, operation is easy, time of damp drying is short, drying, heat energy efficiency is high, gas phase products through gas-solid separation are sent to a rotary drum drier for a heat exchanging with the mixed sludge, recycle usage of energy is realized, tail gas processing burden can be minimized and the energy consumption is reduced.

Owner:BEIJING BIOTECHINA ENVIRONMENT CORP

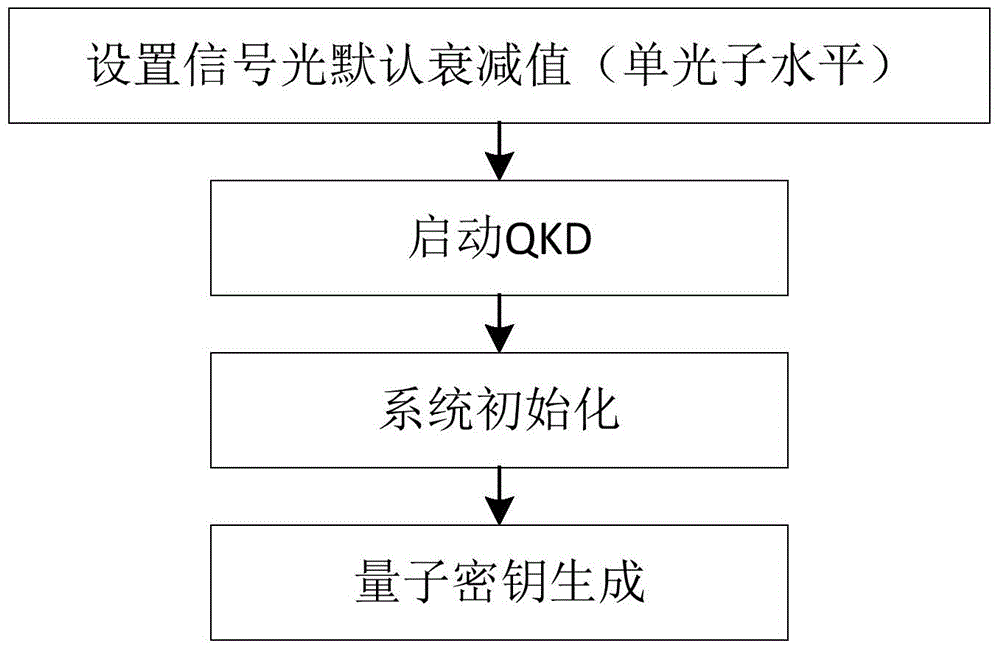

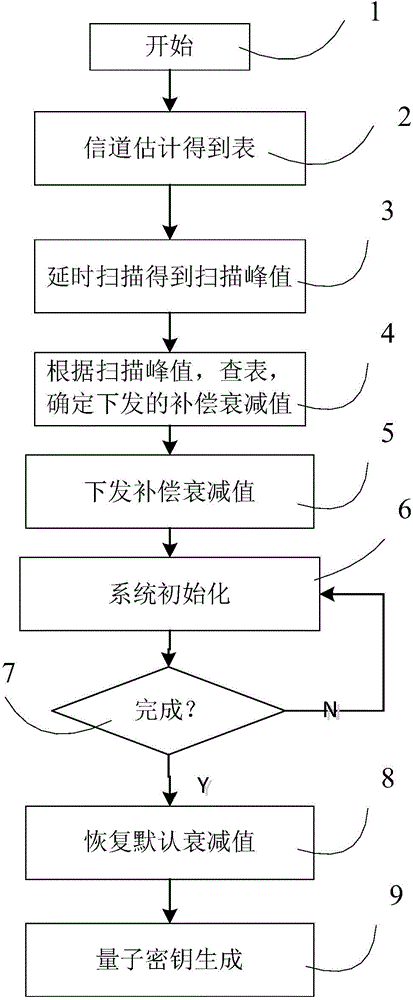

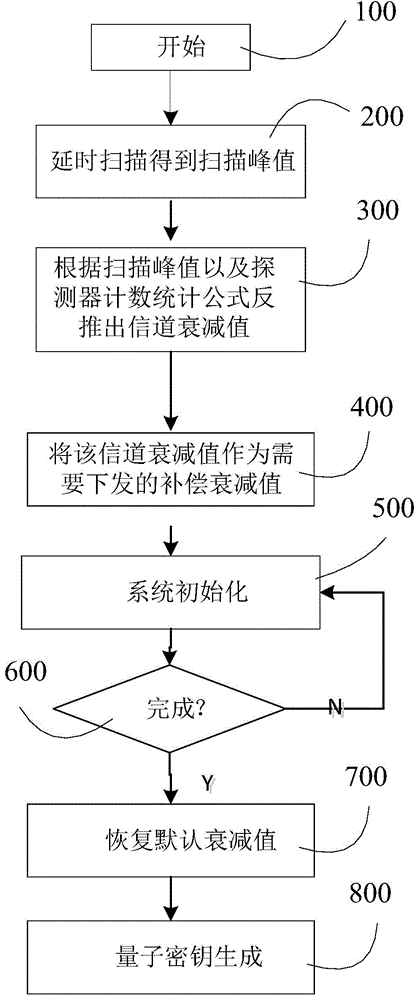

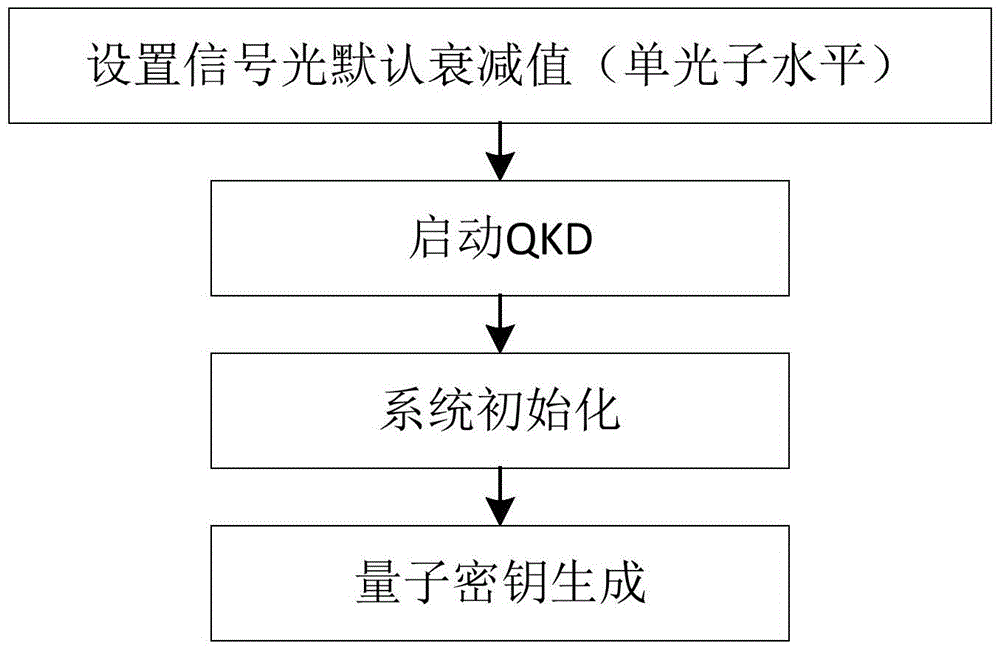

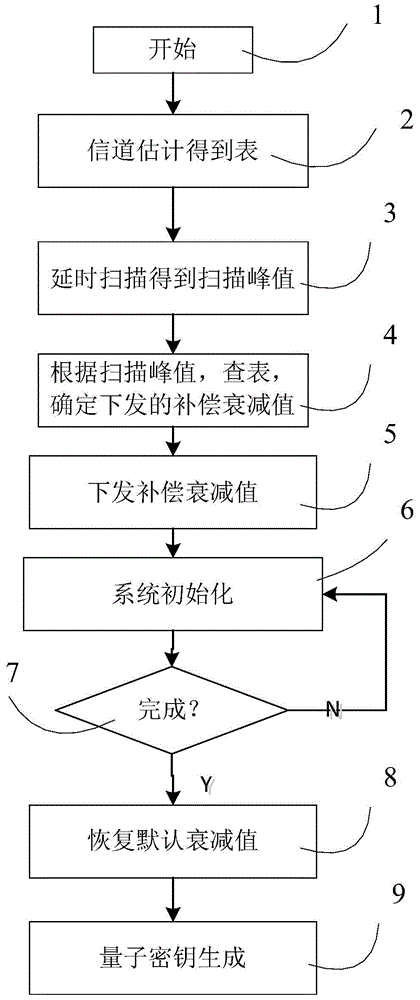

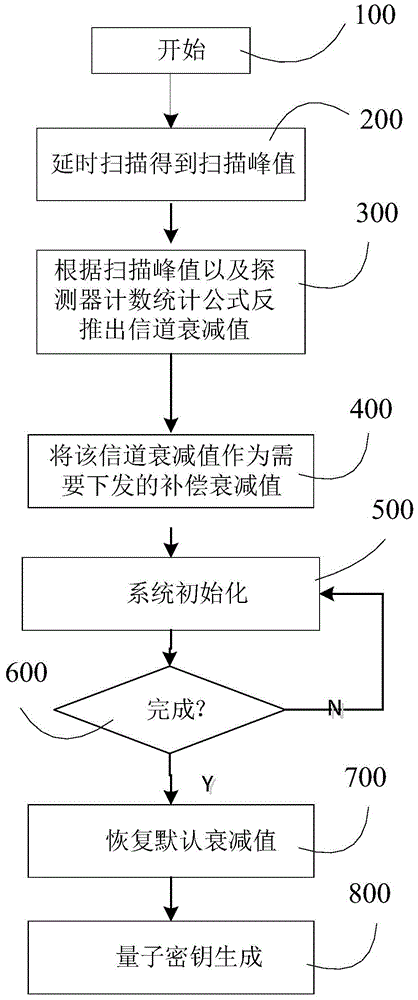

Channel self-adaptive method of quantum key distribution system and QKD (quantum key distribution) system based on channel self-adaptive method

ActiveCN104639316AHigh strengthNo security threatKey distribution for secure communicationSelf adaptiveKey generation

The invention provides a channel self-adaptive method of a quantum key distribution system. The channel self-adaptive method comprises the following steps: at an initialization stage of the system, reducing attenuation, caused by a sending end, to signal light; increasing exit light intensity of the signal light; starting a system initialization process comprising delaying scanning and polarization feedback, so that the system initialization process is finished; after the system initialization process is finished, recovering the attenuation to the signal light to a single photon level corresponding to a default attenuation value; starting a quantum key generation process. The invention further provides a QKD (quantum key distribution) system based on the channel self-adaptive method of the quantum key distribution system. The channel self-adaptive method of the quantum key distribution system has the advantages that automatic estimation and channel attenuation compensation are carried out at the system initialization stage,, so that a method for properly increasing the signal light intensity is realized, the system initialization process can be smoothly finished, and the QKD process can be rapidly and effectively established. The method is good for networking operation of the QKD system, the working efficiency of the QKD system is improved, the operation stability and reliability are improved, and the whole performance of a QKD network is improved.

Owner:QUANTUMCTEK

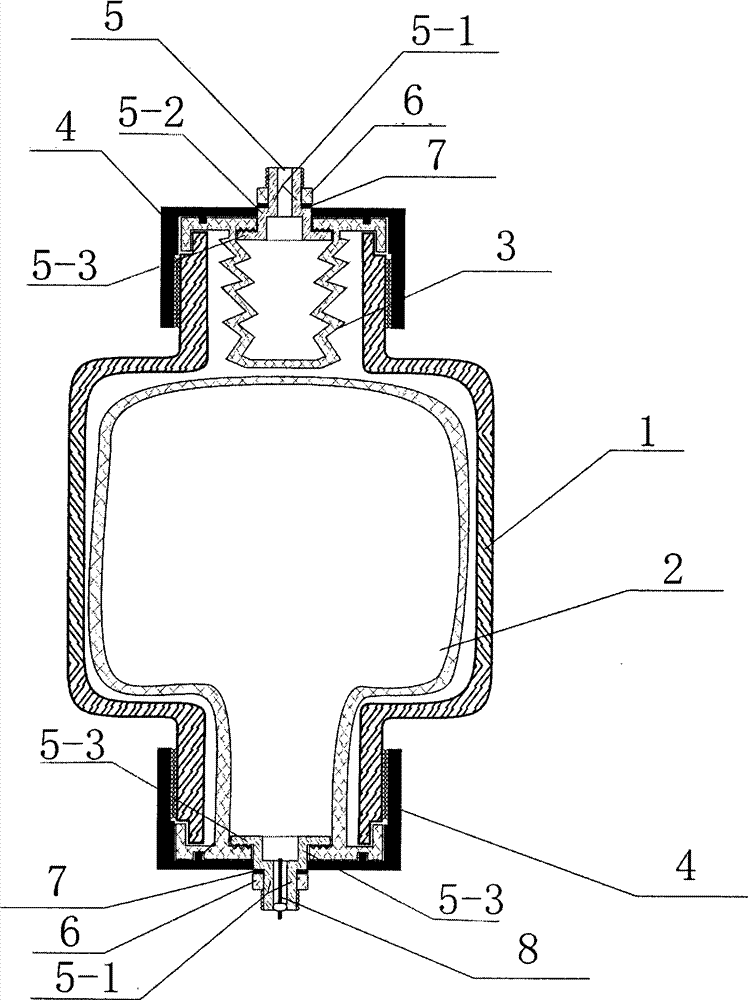

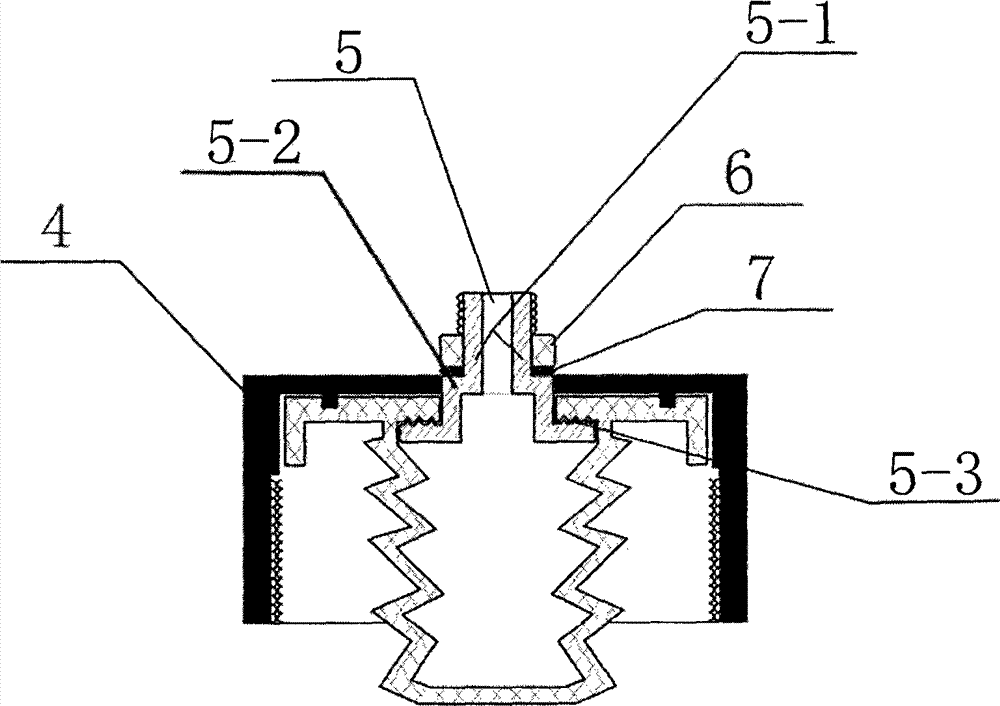

Pressure water storage barrel

InactiveCN104265879AReduce operating proceduresShorten the timePressure vesselsWater storageReservoir bag

The invention relates to the field of a water storage device about a water purifier, medical fire fighting, bathing, solar energy, a water pump, radiant floor heating, a boiler or a household appliance, and especially relates to a pressure water storage barrel, wherein the storage barrel comprises a pressure barrel body, and a reservoir bag and a water storage bag both which are arranged in the pressure barrel body, the top of the pressure barrel body and the bottom thereof are provided with a connecting nozzle, the water storage bag opening and the reservoir bag opening are respectively connected with upper and lower connecting nozzles, the connecting nozzle connected with the water storage bag opening is the water inlet and outlet, the connecting nozzle connected with the reservoir bag opening is the air inlet and outlet on which a valve core is arranged. When the device is disassembled for cleaning, the reservoir bag isn't affected, when the device is reassembled, air pressure cannot be again injected into the reservoir bag, thereby reducing operating processes, saving time and manpower and material resource, and greatly improving safety factor.

Owner:宁波重八净水科技有限公司

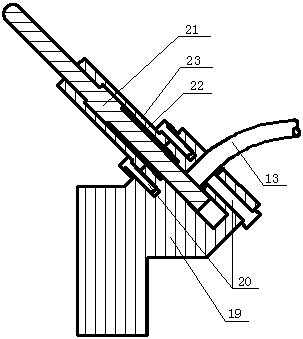

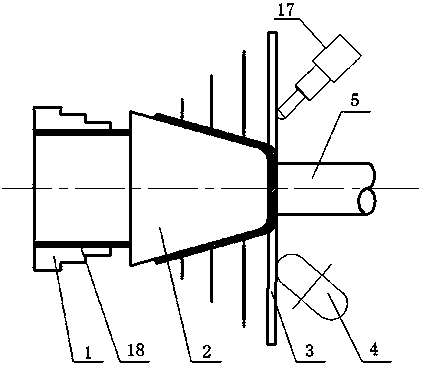

Synergistic self-resistance electric heating type plate auto-increment spinning forming device and method

The invention provides a synergistic self-resistance electric heating type plate auto-increment spinning forming device and method. The synergistic self-resistance electric heating type plate auto-increment spinning forming device comprises a spinning wheel, a high-frequency low-voltage power source, a high-temperature insulated spacer, a cable, a resistor rod, an infrared thermometer, a plate, acarbon brush and a fixing frame of the carbon brush. The spinning wheel and the resistor rod are located on the same arc surface of the plate and are symmetrically distributed (the spinning wheel andthe resistor rod are separated by 180 degrees), the spinning wheel and the resistor rod synergistically act to complete the heating and forming process. The synergistic self-resistance electric heating type plate auto-increment spinning forming device is compact in structure, the synergistic self-resistance electric heating type plate auto-increment spinning forming method is simple, the heating and formation problems of the material which is high in strength at normal temperature, large in forming force and difficult to deform are solved, and the synergistic self-resistance electric heating type plate auto-increment spinning forming method is suitable for auto-increment spinning formation of pure titanium plate materials, titanium alloy plate materials, magnesium alloy plate materials andthe like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

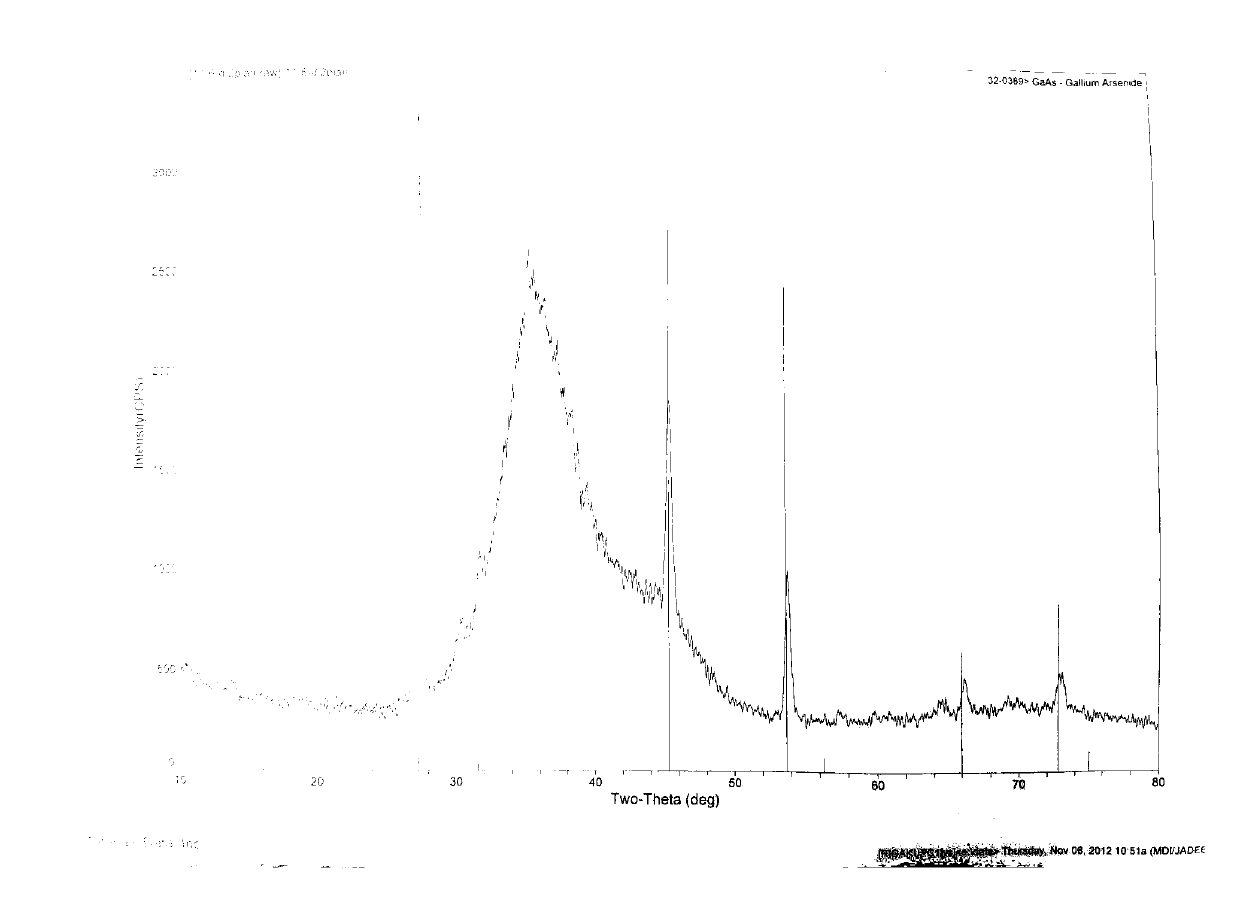

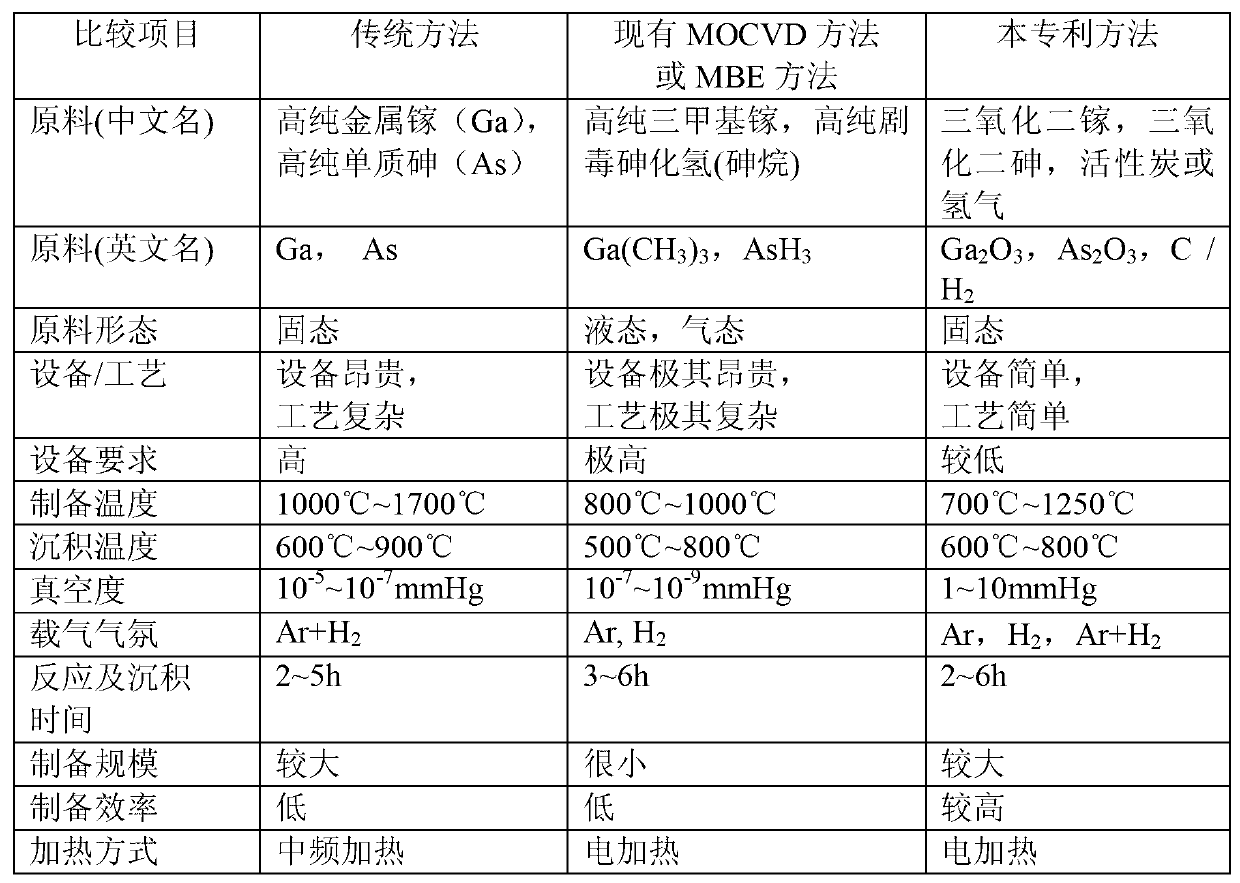

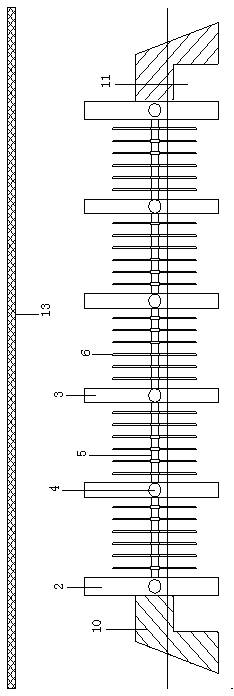

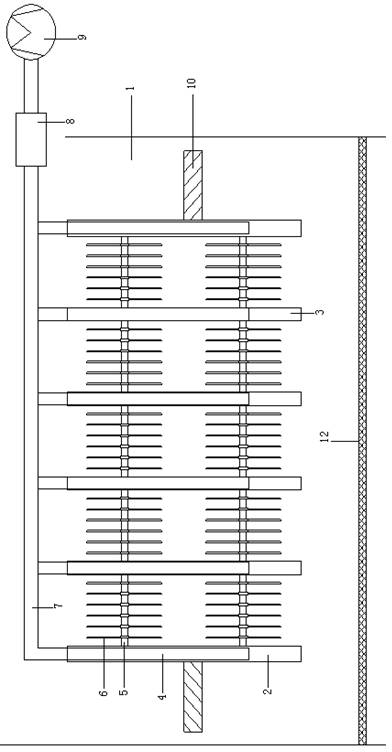

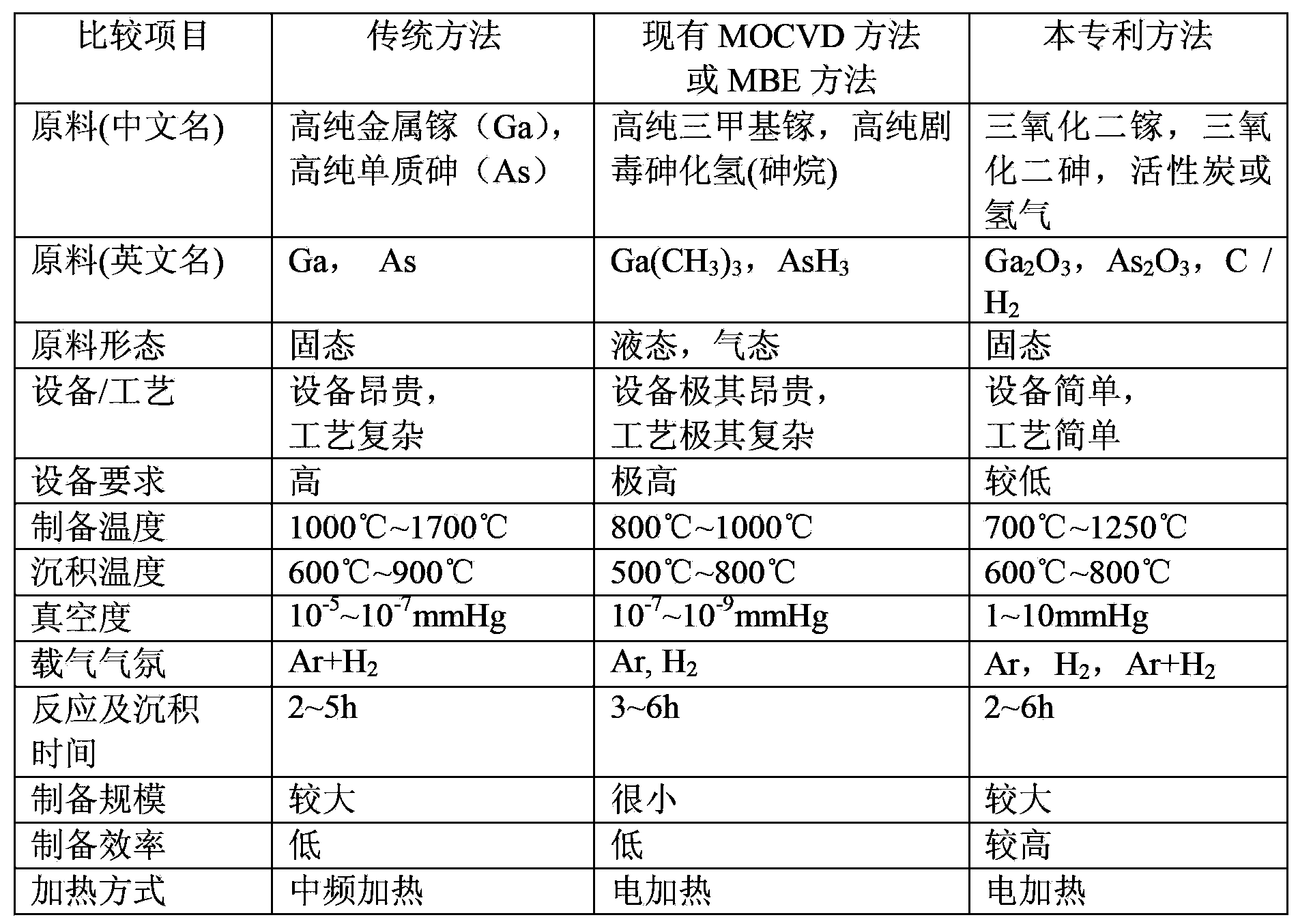

Method of preparing GaAs thin-film material

ActiveCN103147038AAdaptableShort preparation cyclePolycrystalline material growthVacuum evaporation coatingToxic gasActivated carbon

The invention discloses a method of preparing a GaAs thin-film material. The method comprises steps as follows: using Ga 203, As 203 and activated carbon C as raw materials; adding absolute ethyl alcohol corresponding to 50-100% of solid raw materials in weight; after grinding the materials uniformly, using 10-15 MPa of pressure to press the materials into a sheet with thickness of 1-10 mm; then placing the sheet in a reactor corundum crucible; vacuumizing with high-purity nitrogen; permuting the reactor corundum crucible until oxygen concentration reaches a ppm level; then using mixed gas to vacuumize and permute the reactor corundum crucible once or twice; vacuumizing to 7-13 Pa; controlling a rate of temperature increase to be within a range of 5-10 DEG C per minute; heating a reaction zone until the temperature of the reaction zone rises to a range of 1200-1250 DEG C; heating a sediment zone until the temperature of the sediment zone rises to a range of 600-800 DEG C; keeping the temperature constant for 3-4 hours when vacuum degree is kept no less than minus 0.08 MPa; cooling naturally until the temperature drops to the room temperature after the temperature of the reaction zone reaches a predetermined temperature; and obtaining a grey black GaAs thin film after filling the reactor corundum crucible with the mixed gas. According to the method of preparing the GaAs thin-film material, used raw materials are simple, low in price, and easy to obtain, and the raw materials are either solid or non-toxic gas, are free from polluting the environment, and do not threat the safety of an operator.

Owner:CHANGZHOUSR SEA ELECTRONICS

River channel connected power station

InactiveCN102587336AStable positionLow costWater-power plantsMachines/enginesPower stationWater flow

The invention belongs to the field of water-power engineering, in particular to a river channel connected power station, which comprises two parallel side walls disposed on two sides of a river channel in the waterflow direction. The river channel connected power station is characterized in that a plurality of support walls parallel to the side walls are evenly disposed between the two side walls. A link shaft is disposed in each of the support walls and the side walls. A plurality of transverse rotating shafts connected with the link shafts are disposed between each adjacent twos of the support walls and the side walls respectively. A plurality of evenly distributed in-water blades are disposed on each rotating shaft. The link shafts are all connected with a spindle for mounting a gearbox, and the gearbox is connected with a motor. The river channel connected power station is simple in structure and low in manufacturing cost, has no limitation on landform selection, is high in river flow utilization rate, has no safety threat to the downstream, and is high in power generating capacity and suitable for wide application.

Owner:张新轩

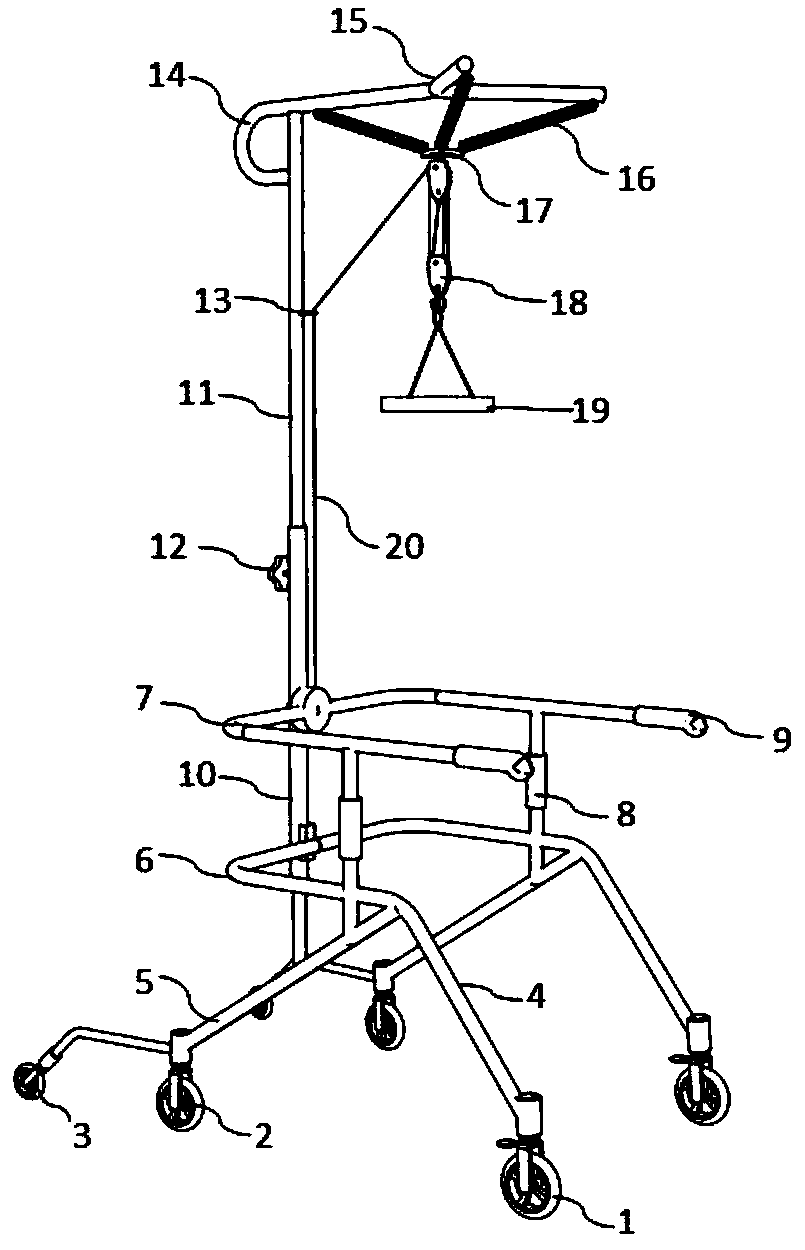

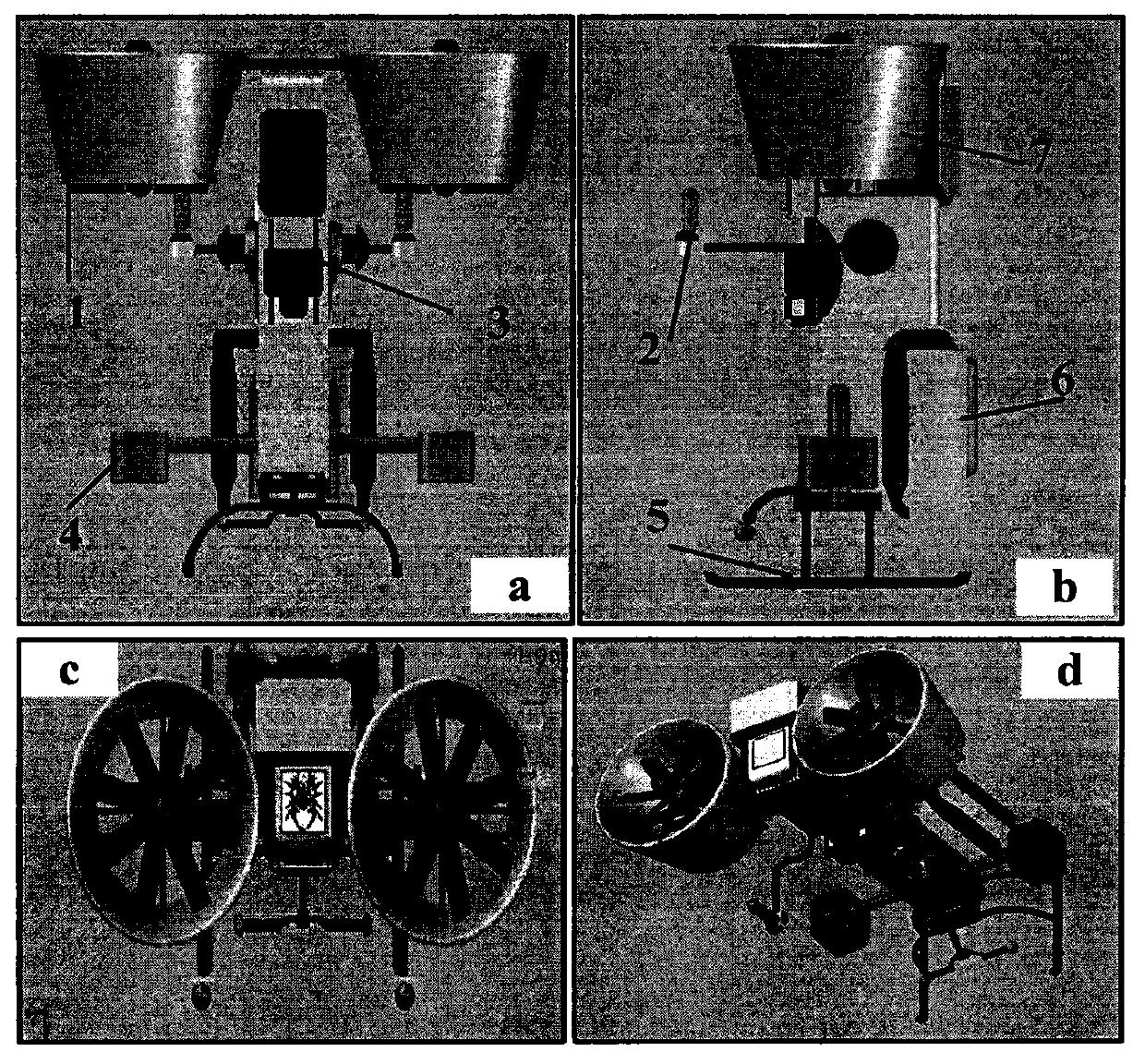

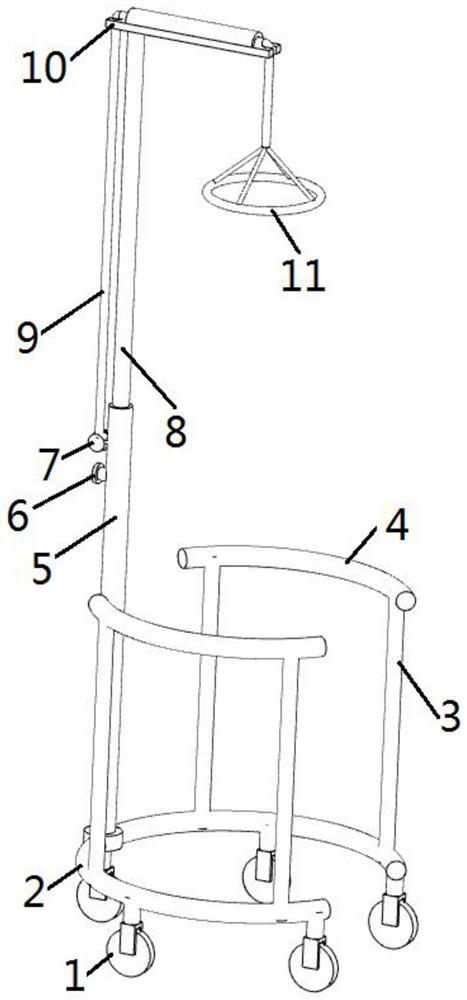

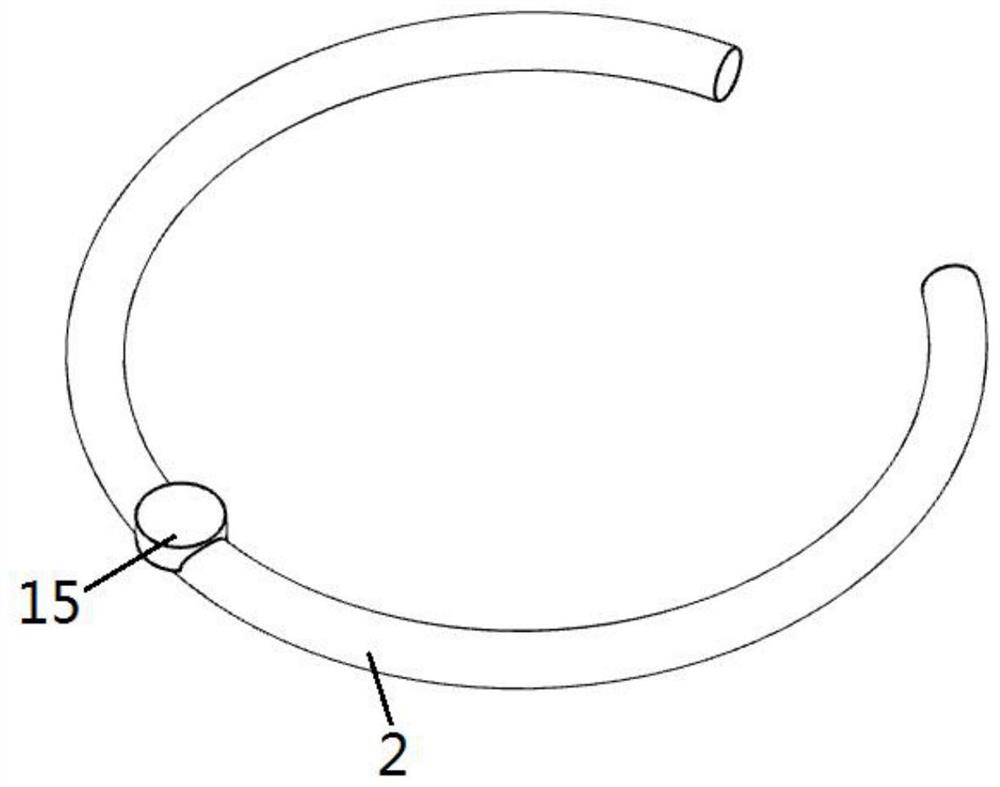

Walking type scoliosis traction device

PendingCN111035495AImprove life freedomNo security threatOperating tablesWalking aidsPhysical medicine and rehabilitationTraction cord

The invention relates to a walking type scoliosis traction device. A traction support is composed of a hand guided walking support, an adjustable supporting frame and a spring type gravity traction device. The hand guided walking support is composed of front wheels, rear wheels, rear protection wheels, a front wheel rod, a rear wheel rod, a bottom U-shaped rod, an upper U-shaped rod, a screwing type height adjusting rod and a handle. The adjustable supporting frame is composed of a bottom rod, an upper rod, a height adjusting nut, a ferrule, a top bent rod and a front fork. According to the device, a dragged person can also be subjected to traction treatment in an upright walking state, so that the large living freedom degree is kept, weights, sandbags and other heavy objects are not needed in the traction process, self gravity is used as traction force, the equilateral three-fork type high-precision spring combination enables the traction force to be flexible and stable, and a pulleyblock and a traction rope are convenient for a patient to self-adjust and remove the traction force, so that the simplicity, convenience and safety of traction operation are greatly improved.

Owner:NANJING CHILDRENS HOSPITAL

Facility vegetable cryoprotective agent

InactiveCN101595873AFew componentsReduce manufacturing costBiocidePlant growth regulatorsNutrientChemistry

A facility vegetable cryoprotective agent is composed of glucose, choline chloride, naphthylacetic acid, chlormequat chloride, alcohol and water. The invention relates to a facility vegetable cryoprotective agent prepared by taking glucose, choline chloride, naphthylacetic acid and chlormequat chloride as active ingredients and has the characteristics of less components, low production cost and good freeze-proofing effect. Through field test, influence of low temperature of minus 3 to 5 DEG C can be effectively prevented. The invention has simple preparation, convenient use, labour and time saving and obvious effect, raw material components are not only cryoprotective agent but also vegetable nutrient substances, and the cryoprotective agent has no toxic hard on vegetables or safety threat on human body, thus being applicable to facility vegetable production in northern China.

Owner:VEGETABELE INST AGRI SCI ACAD SHANXI PROV

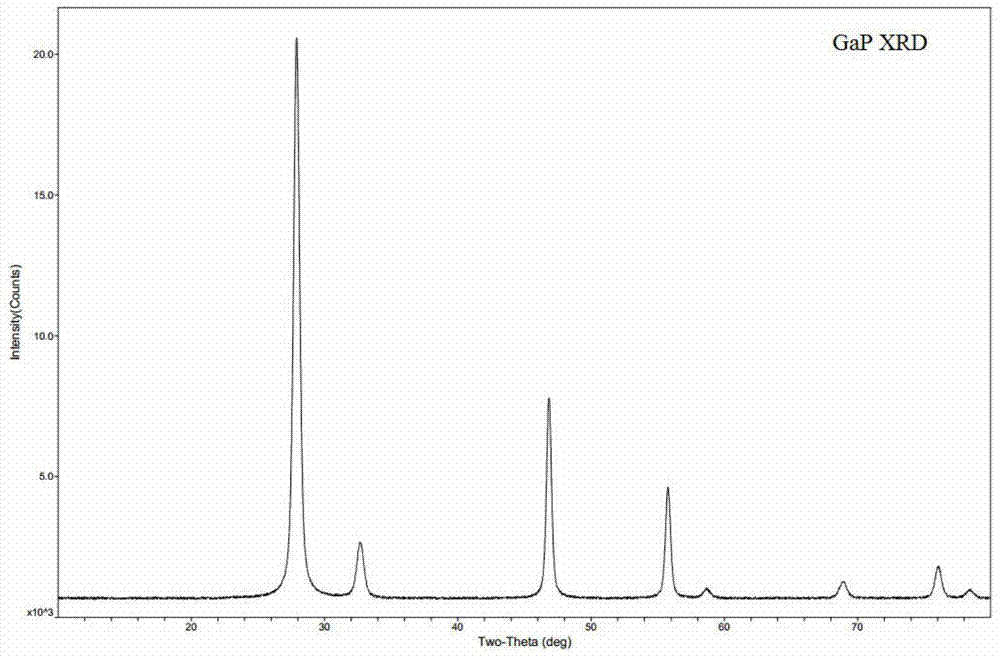

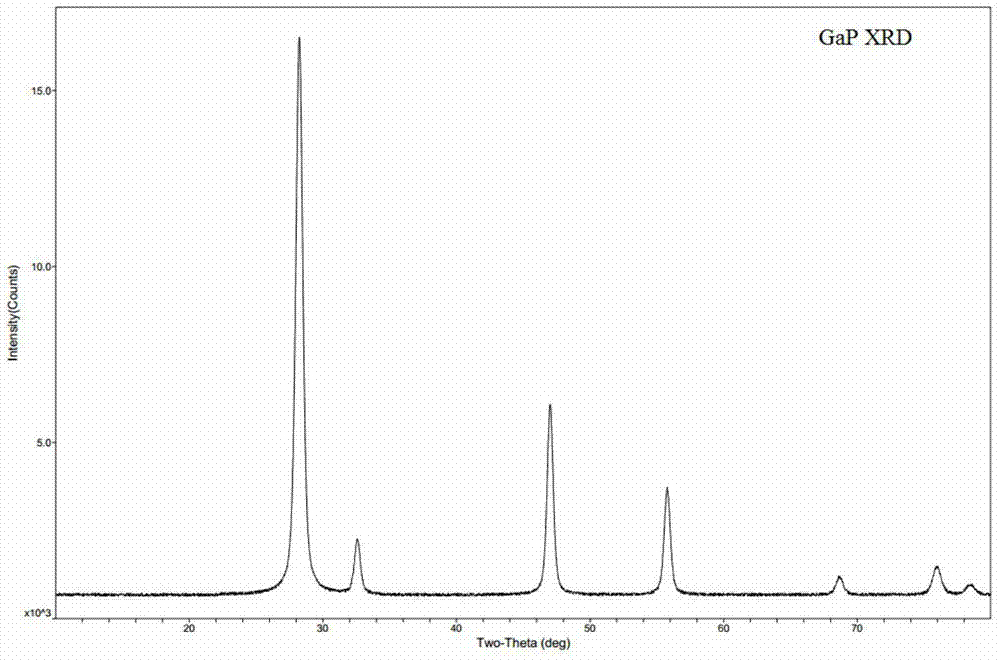

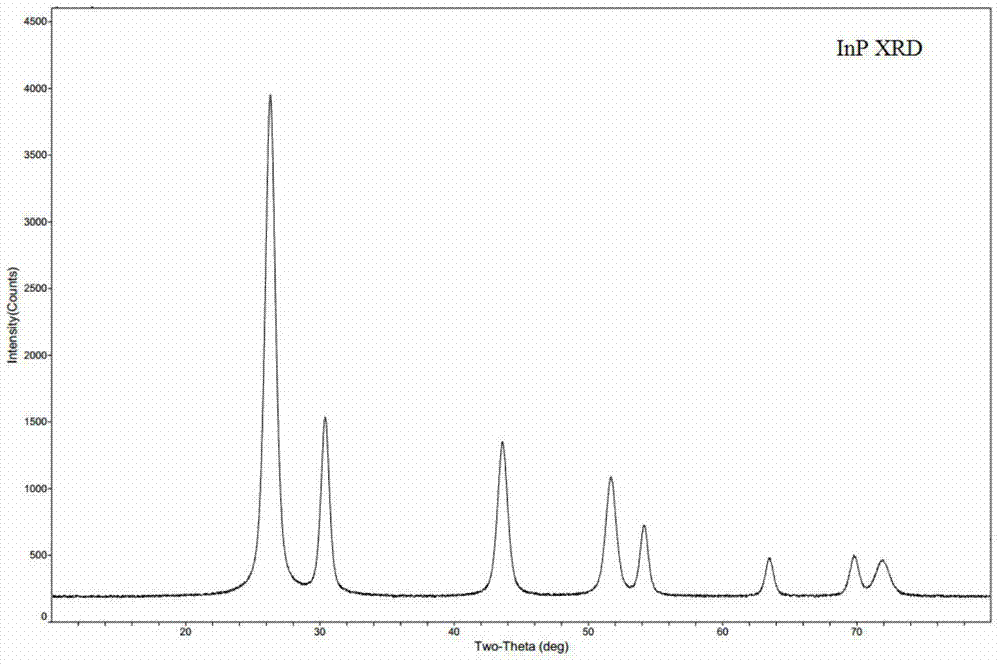

Preparation method of film material for compound semiconductor

InactiveCN104498896ANo pollution in the processNo security threatVacuum evaporation coatingSputtering coatingPolymer scienceChemical compound

The invention relates to a preparation method of a film material for a compound semiconductor. A target film material for the compound semiconductor can be prepared by a one-step method disclosed by the invention on a large scale. A plurality of films can be prepared one time; the preparation method is short in preparation cycle, high in preparation efficiency, and high in adaptability on a substrate (chip) material; the substrate (chip) does not need to be particularly treated, so that the preparation cost is low; the film material for the compound semiconductor prepared by a two-step method is high in purity and good in crystallinity; a sealing system is adopted in the preparation process, so that loss of raw materials caused by sublimation is avoided; the method is high in controllability; and the preparation temperature is relatively low, so that the energy consumption is reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

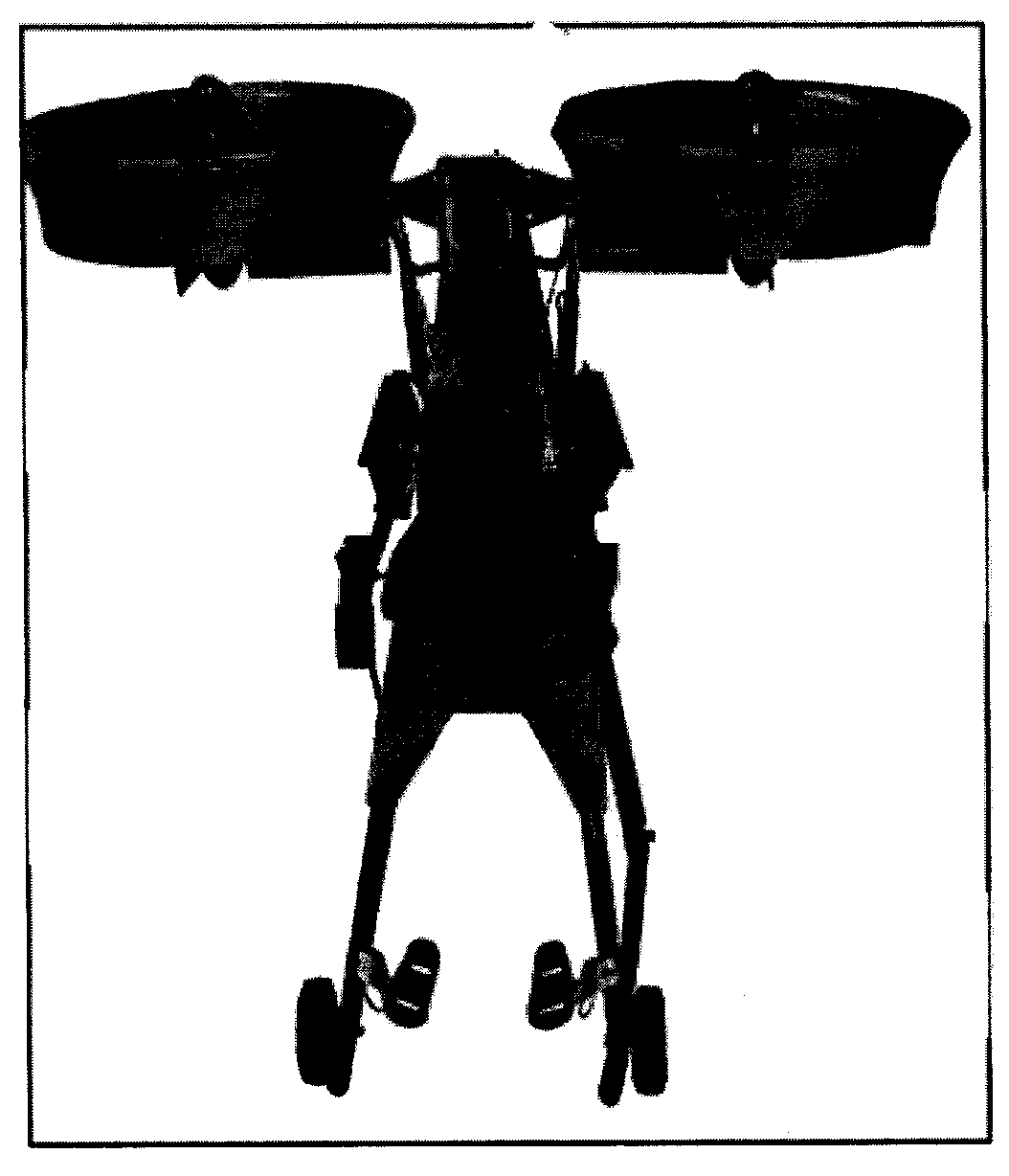

Double-main-duct ultra-light type vertical take-off and landing solo aircraft

InactiveCN103224024AAbundant air trafficSimple and compact structure and manufacturing costRotocraftNacelleNet Weight

The invention relates to a double-main-duct ultra-light type vertical take-off and landing solo aircraft which comprises a cabin main body and main ducts symmetrically arranged at the upper parts of the left side and the right side of the cabin main body, wherein the lower part of the cabin main body is provided with an undercarriage; each main duct is internally provided with a screw propeller, and an engine drives and rotates the screw propeller through a centrifugal speed reducer; and the engine is arranged at the lower part of the axis inside each main duct, and a nozzle of each main duct is further provided with a flow guide plate. Due to the use of the double-main duct aircraft provided by the invention,, the net weight of the aircraft is less than 116 kilograms, the height and the length of the aircraft are less than 1.9m, and the volume of the aircraft is equal to be about a half of the weight of a common car, so that the requirement on take-off and landing site is extremely simple, the aircraft is suitable for take-off and landing in the crowed cities, and the aircraft can be conveniently controlled.

Owner:谷承露 +3

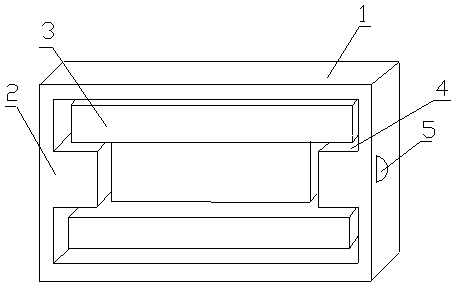

Induction coil cooling pressure-bearing system for induction heating equipment

The invention discloses an induction coil cooling pressure-bearing system for induction heating equipment, comprising a pressure vessel and a heating induction coil. The heating induction coil penetrates through the pressure vessel, and comprises an inner coil section located in the pressure vessel and an outer coil section located outside the pressure vessel. The outer coil section comprises an exhaust coil section and an intake coil section. A cooling medium is arranged in the heating induction coil, and the cooling medium is a gas which is the same with or similar to the pressurized gas ofthe pressure vessel. The induction coil cooling pressure-bearing system for induction heating equipment further comprises a first air pressure detection pipeline connected with the exhaust coil section and a second air pressure detection pipeline connected with the pressure vessel, and the first air pressure detection pipeline is connected with the second air pressure detection pipeline through adifferential pressure gauge. The induction coil cooling pressure-bearing system for induction heating equipment is disclosed in order to solve the technical problem that the induction heating in the prior art can be hardly applied to high-pressure and ultrahigh-pressure equipment and is of poor safety.

Owner:BEIJING POWER MACHINERY INST +2

Low-cost transparent thermal-insulation high-elasticity self-cleaning refrigerator door seal

InactiveCN110511495AImprove toughnessLow transparencyAdhesive processesLighting and heating apparatusIndiumThermal insulation

The invention discloses a low-cost transparent thermal-insulation high-elasticity self-cleaning refrigerator door seal, which is prepared from the following raw materials: poly 4-methyl-1-pentene, polybutadiene, SEEPS rubber, indium oxide, a vinyl ester resin, poly 1-butene, animal and plant derived oil, EBS, a regulator, a stabilizer, polycarbosilane, polybornene, zinc borate, alpha-methylstyrene, nanometer silicon dioxide, konjac glucomannan and magnesium chloride. According to the present invention, the prepared self-cleaning refrigerator door seal has characteristics of high elasticity, good thermal insulation property, transparency, low cost, no folding, high elasticity, high welding strength, low-temperature resistance, no toxicity, no harm, high transparency, self-cleaning function,weather resistance and heat resistance.

Owner:蚌埠创特新材料科技有限公司

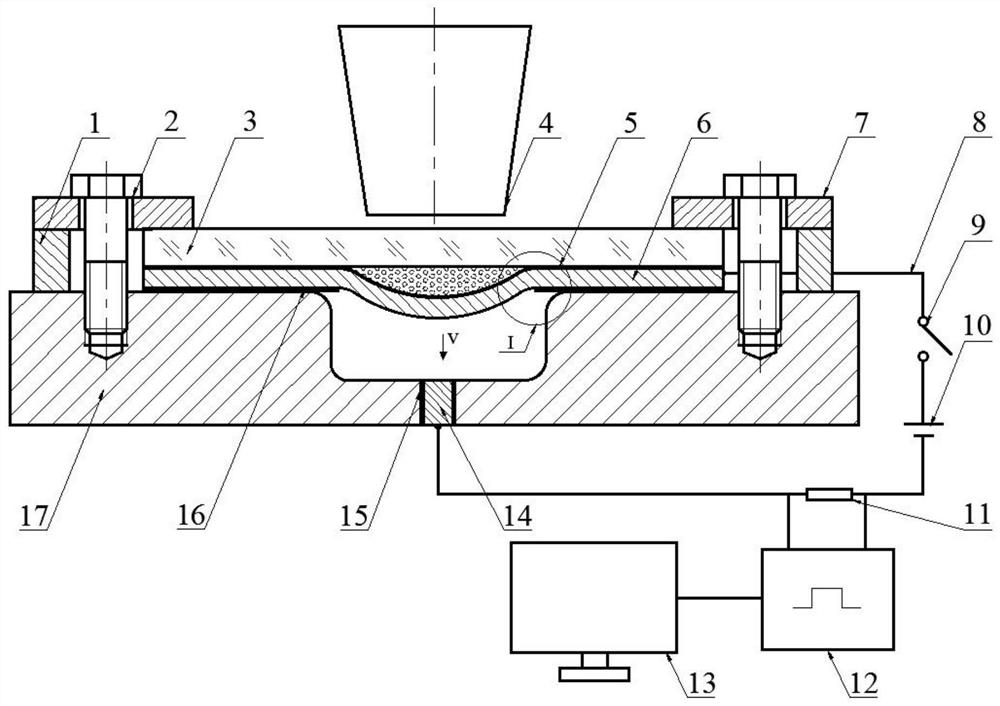

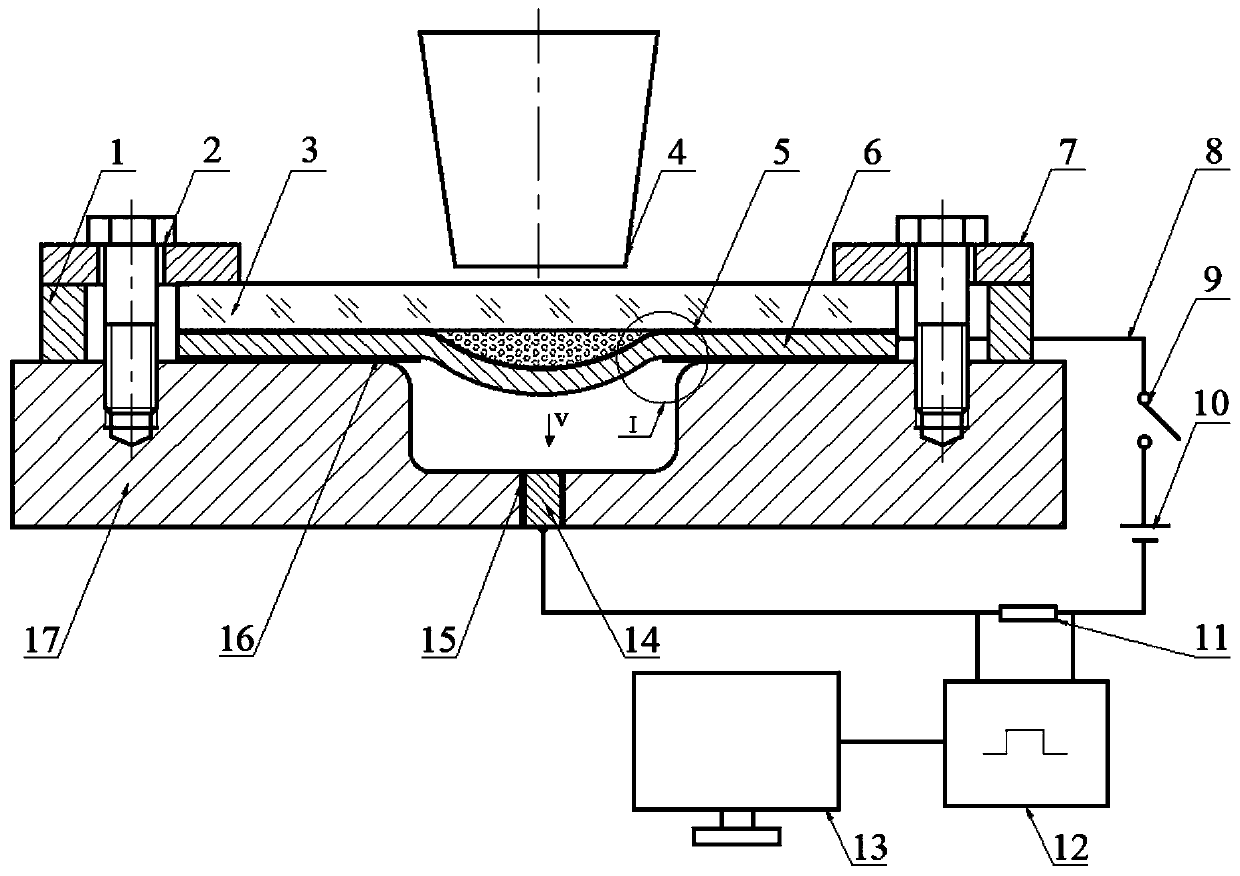

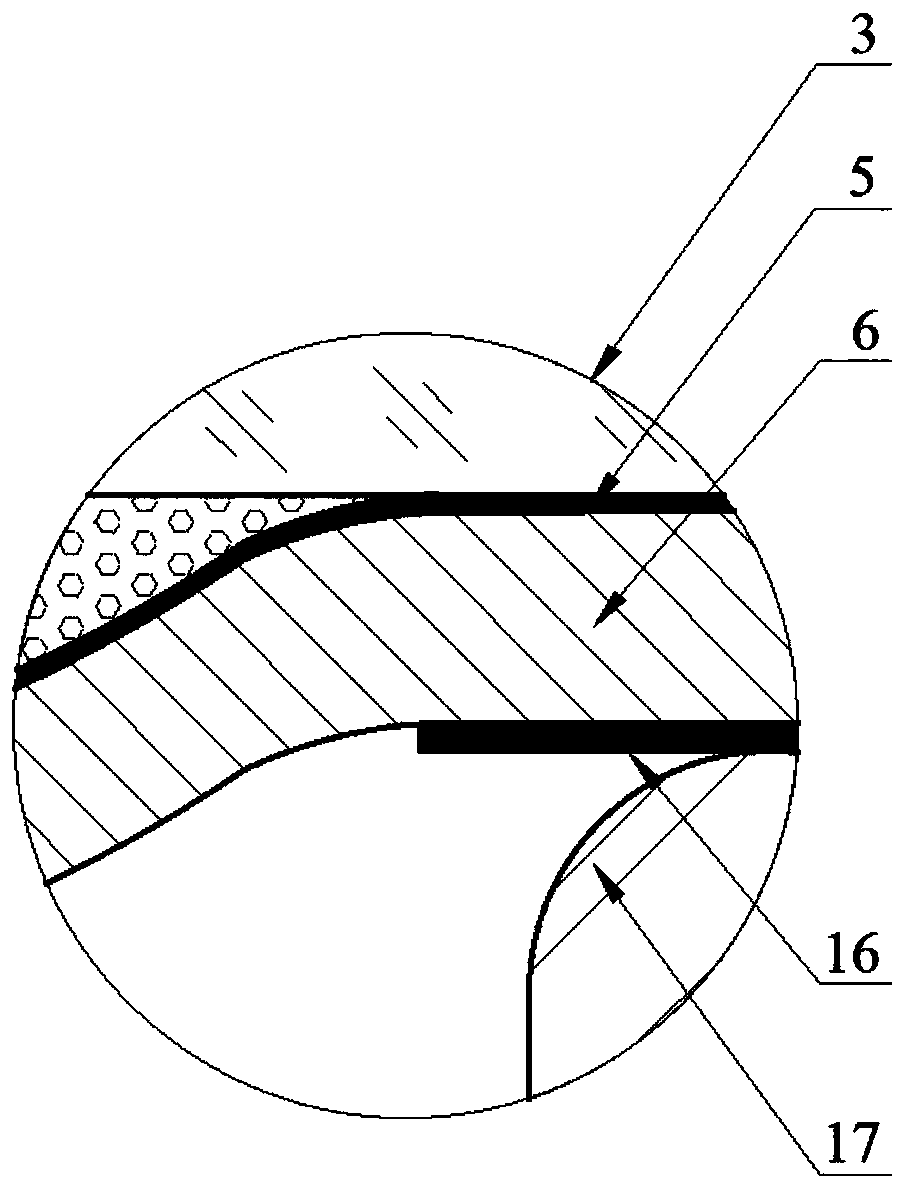

A device and method for measuring the collision process in high-speed laser shock forming of plates

ActiveCN111331026BEasy to measureCollisions cannot be observedMetal working apparatusVoltage pulseThin membrane

The invention discloses a device and method for measuring the collision process in laser shock high-speed forming of plates, belonging to the field of measurement technology. The device includes a laser forming system and a measuring system. The laser forming system includes optical glass, laser, absorbing layer, metal sheet, metal round rod, barrier film, insulating paper and die; The thin plate and the metal round rod are not in direct contact. The metal sheet and the metal round rod are respectively connected to the positive and negative poles of the power supply. After the metal sheet is deformed by the laser shock and touches the metal round rod, the measurement circuit is turned on. The number of times the high-speed moving metal sheet collides with the metal mold, and the width of the voltage pulse is the time of collision contact. The method and device can accurately measure the collision process in the high-speed laser shock forming of the plate. The device of the invention has potential market application prospects.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Process and equipment for preparing hypochlorous acid by combining two-liquid method with electrolytic method

PendingCN112501638AImprove stabilityImprove performanceCellsPhotography auxillary processesChlorate ionHypochlorite

The invention discloses a process and equipment for preparing hypochlorous acid by combining a two-liquid method with an electrolytic method. The hypochlorous acid preparation process comprises the following steps: S1, treating tap water by adopting a pre-filter to obtain purified water; S2, adding a hypochlorite solution and the purified water in the step S1 into a hypochlorite solution dilutingdevice to obtain a hypochlorite diluted solution; S3, adding the hypochlorite solution and an acidic solution in the step S2 into a mixer for mixing reaction to obtain a hypochlorous acid mixed solution; and S4, electrolyzing the hypochlorous acid mixed solution obtained in the step S3 through an electrolysis device to convert chloride ions in the solution into hypochlorous acid molecules, reducethe content of the chlorine ions in the solution, and remove heavy metal ions to obtain a subacid hypochlorous acid product.

Owner:中山市原域企业投资有限公司

Box used for containing cutters on construction site

InactiveCN103508038AEasy to placeNo security threatInternal fittingsArchitectural engineeringBuilding construction

The invention discloses a box used for containing cutters on a construction site. The box comprises a box body; the box body mainly comprises a peripheral body, a supporting body and a cavity, wherein a layer of flexible glue is arranged inside the cavity. The box used for containing the cutters on the construction site has the advantages that the box enables the cutters to be stored conveniently and be in a state relatively safe to people; the layer of flexible glue is arranged in the cavity, and therefore the sharpness of the cutters can be effectively protected against damage; the box is easy to manufacture and convenient to use.

Owner:SICHUAN KAIMING INVESTMENT

Channel adaptive method of quantum key distribution system and qkd system based on it

ActiveCN104639316BHigh strengthNo security threatKey distribution for secure communicationUltrasound attenuationSignal light

The invention provides a channel self-adaptive method of a quantum key distribution system. The channel self-adaptive method comprises the following steps: at an initialization stage of the system, reducing attenuation, caused by a sending end, to signal light; increasing exit light intensity of the signal light; starting a system initialization process comprising delaying scanning and polarization feedback, so that the system initialization process is finished; after the system initialization process is finished, recovering the attenuation to the signal light to a single photon level corresponding to a default attenuation value; starting a quantum key generation process. The invention further provides a QKD (quantum key distribution) system based on the channel self-adaptive method of the quantum key distribution system. The channel self-adaptive method of the quantum key distribution system has the advantages that automatic estimation and channel attenuation compensation are carried out at the system initialization stage,, so that a method for properly increasing the signal light intensity is realized, the system initialization process can be smoothly finished, and the QKD process can be rapidly and effectively established. The method is good for networking operation of the QKD system, the working efficiency of the QKD system is improved, the operation stability and reliability are improved, and the whole performance of a QKD network is improved.

Owner:QUANTUMCTEK

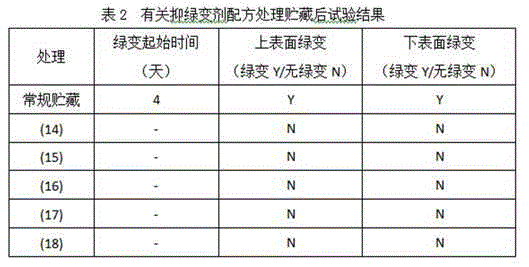

Potato greening inhibitor and preparation and application methods

InactiveCN105166029AEasy to makeEasy to useFruit and vegetables preservationSolanum tuberosumGuar gum

The invention discloses a potato greening inhibitor and a preparation method. The potato greening inhibitor comprises raw materials in parts by weight as follows: 20-40 parts of guar gum, 1-2.5 parts of norflurazon and 10,000 parts of clear water. The preparation method of the potato greening inhibitor comprises steps as follows: 1-2.5 parts of the norflurazon are dissolved in 10,000 parts of clear water and stirred uniformly, and then 20-40 parts of the guar gum are added and stirred uniformly. The application method of the potato greening inhibitor comprises steps as follows: the potato greening inhibitor is sprayed once after harvesting and before storage of potatoes, and the dosage standard is that the surfaces of the potatoes are wet through spraying. The potato greening inhibitor is simple to prepare and convenient to use, saves time and labor, has low cost and can completely inhibit the potatoes exposed to light from greening, and components of the raw materials do not have toxic effects on the potatoes and do not threaten the safety of a human body.

Owner:CROP SCI RES INST SHANXI ACADEMY OF AGRI SCI

Facility vegetable cryoprotective agent

InactiveCN101595873BLess componentsReduce manufacturing costBiocidePlant growth regulatorsAlcoholChloride

A facility vegetable cryoprotective agent is composed of glucose, choline chloride, naphthylacetic acid, chlormequat chloride, alcohol and water. The invention relates to a facility vegetable cryoprotective agent prepared by taking glucose, choline chloride, naphthylacetic acid and chlormequat chloride as active ingredients and has the characteristics of less components, low production cost and good freeze-proofing effect. Through field test, influence of low temperature of minus 3 to 5 DEG C can be effectively prevented. The invention has simple preparation, convenient use, labour and time saving and obvious effect, raw material components are not only cryoprotective agent but also vegetable nutrient substances, and the cryoprotective agent has no toxic hard on vegetables or safety threat on human body, thus being applicable to facility vegetable production in northern China.

Owner:VEGETABELE INST AGRI SCI ACAD SHANXI PROV

Method and equipment for preparing hypochlorous acid by combining gas-liquid synthesis with ion exchange method

PendingCN112499799AImprove stabilityStable performanceElectrolysis componentsSpecific water treatment objectivesIon exchangeCarbon dioxide

The invention discloses a method and equipment for preparing hypochlorous acid by combining gas-liquid synthesis with an ion exchange method, and the preparation method comprises the following steps:S1, treating tap water by adopting a pre-filter to obtain purified water; S2, adding a hypochlorite solution and the purified water in the step S1 into a hypochlorite solution diluting device to obtain a hypochlorite diluted solution; S3, adding the hypochlorite solution obtained in the step S2 into a mixer, and conveying carbon dioxide gas into the mixer through a pipeline for mixing reaction toobtain a hypochlorous acid mixed solution with the concentration of 10ppm to 5000 ppm and the pH value of 4.0-8.0; and S4, carrying out ion exchange on the hypochlorous acid mixed solution obtained inthe step S3 through an ion exchanger to remove heavy metal ions so as to obtain a slightly acidic hypochlorous acid product with the pH value of 4.0-6.8. The product disclosed by the invention is stable in performance, good in sterilization and disinfection effects, long in preservation time, non-toxic and odorless.

Owner:中山市原域企业投资有限公司

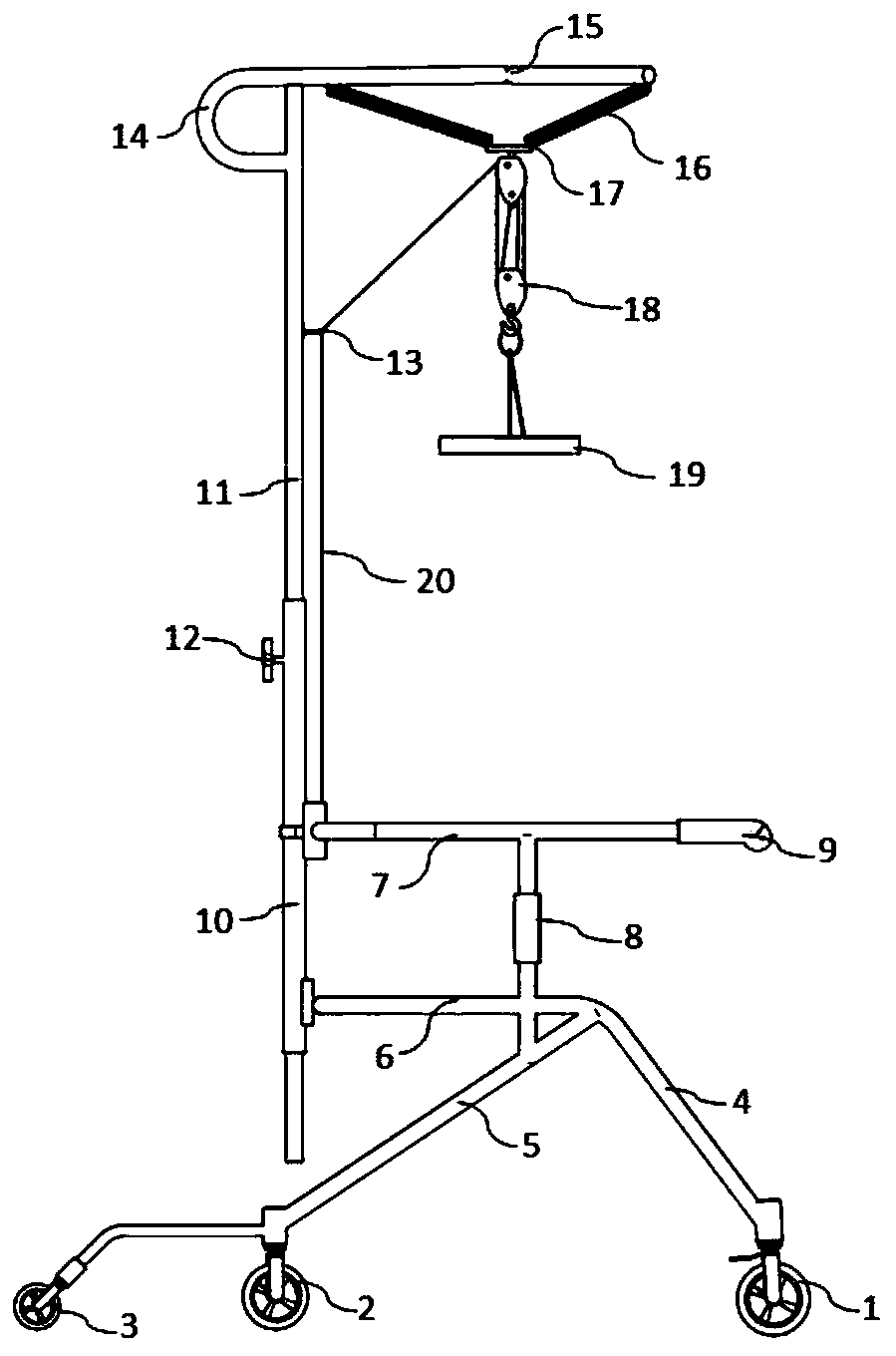

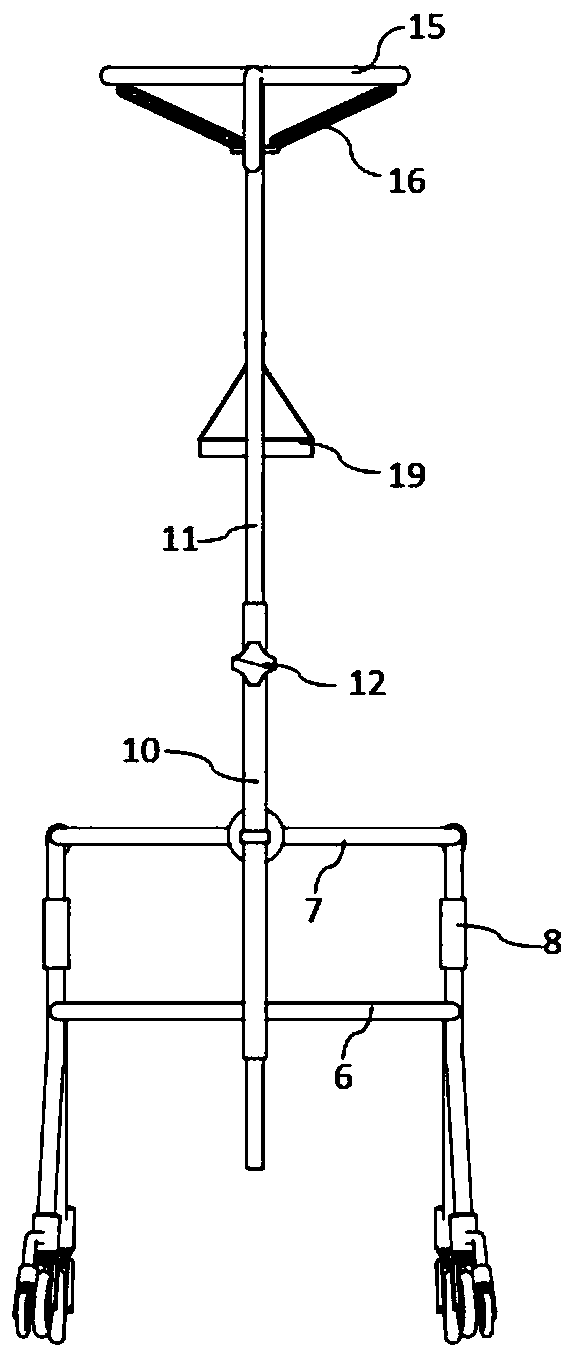

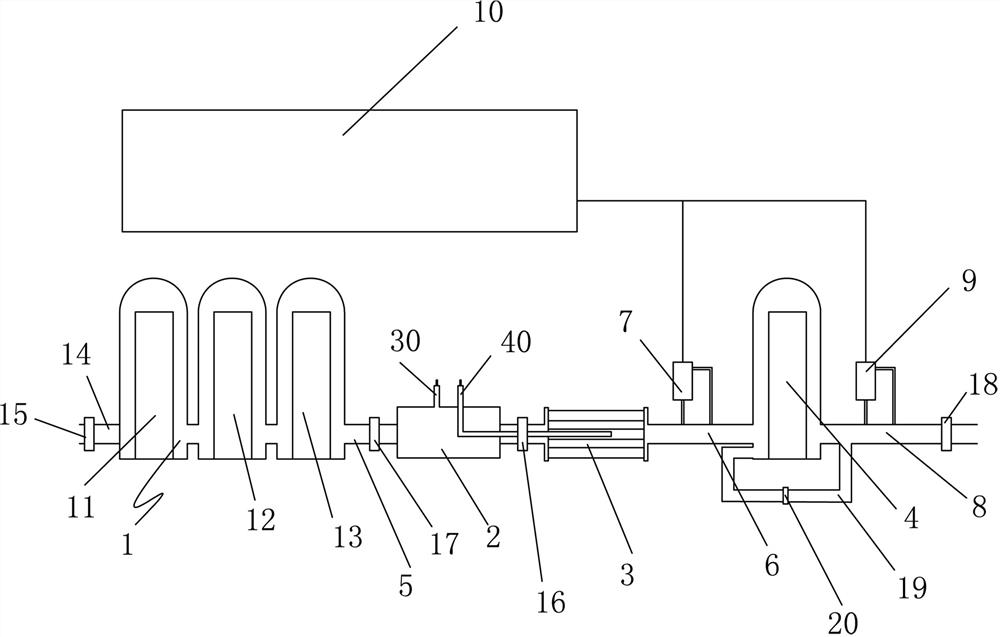

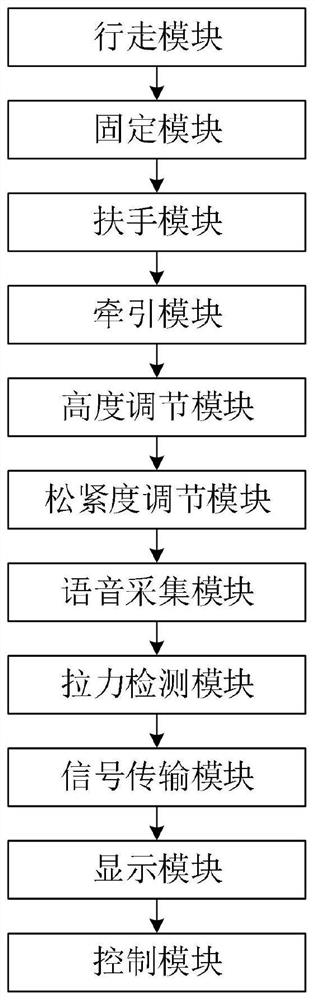

Adjustable scoliosis traction device

InactiveCN111803326AImprove comfortImplement voice controlChiropractic devicesPhysical medicine and rehabilitationScoliosis

The invention belongs to the technical field of traction devices, and discloses an adjustable scoliosis traction device. The adjustable scoliosis traction device comprises a walking module, a fixing module, an armrest module, a traction module, a height adjusting module, a tightness adjusting module, an audio acquisition module, a tensile force detection module, a signal transmission module, a display module and a control module, wherein acquired audio information can be processed and recognized through an external controller, detected junk information is processed, and through processing results and preset parameters, the height of armrest frames and tensile force of a traction rope are adjusted and controlled. By means of the adjustable scoliosis traction device, traction force can be intelligently adjusted through the tightness adjusting module, the adjustment speed is high, the traction force can be adjusted modestly, in the premise of guaranteeing a traction effect, comfort of a patient is improved, the height and the tensile force can be remotely adjusted through the control module, and the audio acquisition module can be in cooperation with the control module, so that audiocontrol of the traction device is achieved.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

Train door and platform door linkage control system and linkage control method

ActiveCN103895655BLow costReduce secondary development costsSignal operation from vehicleRailway stationData acquisitionEngineering

Owner:SHANGHAI JIACHENG RAILWAY TRANSPORTATION SAFETY SYST

An induction heating equipment induction coil cooling pressure bearing system

The invention discloses an induction heating equipment induction coil cooling pressure bearing system, which comprises a pressure vessel and a heating induction coil, the heating induction coil is arranged through the pressure vessel and includes an inner coil section located in the pressure vessel and an inner coil segment located in the pressure vessel The outer coil segment, the outer coil segment includes an exhaust coil segment and an intake coil segment, the heating induction coil has a cooling medium, the cooling medium is the same or similar gas as the pressurized gas of the pressure vessel, and the induction heating equipment induces The coil cooling pressure-bearing system also includes a first air pressure detection pipeline connected to the exhaust coil section and a second air pressure detection pipeline connected to the pressure vessel. The first air pressure detection pipeline and the second air pressure detection pipeline pass through the pressure Poor table connection. The induction coil cooling pressure bearing system for induction heating equipment aims to solve the technical problems that induction heating is difficult to apply to high-voltage and ultra-high-voltage equipment and has poor safety in the prior art.

Owner:BEIJING POWER MACHINERY INST +2

Method and equipment for preparing hypochlorous acid by combining gas-liquid synthesis with electrolytic method

PendingCN112093930AImprove stabilityStable performanceElectrolysis componentsSpecific water treatment objectivesEnvironmental chemistryHypochlorous acid

The invention discloses a method for preparing hypochlorous acid by combining gas-liquid synthesis with an electrolytic method, which is characterized by comprising the following steps: S1, treating tap water by using a pre-filter to obtain purified water; S2, adding ahypochlorite solution and purified water in the step S1 into a hypochlorite solution diluter to obtain a hypochlorite diluted solution; S3, adding the hypochlorite solution obtained in the step S2 into a mixer, and conveying carbon dioxide gas into the mixer through a pipeline for mixing reaction to obtain a hypochlorous acid mixed solution with the concentration of 10 ppm and the pH value of 4.0-8.0; and S4, electrolyzing the hypochlorous acid mixed solution obtained in the step S3 through an electrolysis device (4) to convert chloride ions in the solution into hypochlorous acid molecules, reducing the content of the chloride ions in the solution, and removing heavy metal ions to obtain a hypochlorous acid product. The product disclosed by the invention is stable in performance, good in sterilization and disinfection effects, long in preservation time, non-toxic and odorless.

Owner:中山市原域企业投资有限公司

Device for solving waste blockage on through hole in metal material drilling process

InactiveCN112517984APrevents clogged viasNo security threatBoring/drilling componentsMetallic materialsEngineering

The invention relates to the technical field of metal material machining, and discloses a device for solving waste blockage on a through hole in a metal material drilling process. The device for solving waste blockage on the through hole in the metal material drilling process comprises a device main body, wherein a collecting barrel is fixedly installed on a bottom plate, a friction plate is arranged in the collecting barrel, and fixedly connected with a telescopic column, and the telescopic column is fixedly connected with a first spring; a telescopic rod is arranged in the device main body,a cylinder is fixedly connected below the telescopic rod, and the upper portion of the telescopic rod is fixedly connected with the first spring on the telescopic column. According to the device, thetelescopic rod can rotate when moving upwards, when the friction plate at the upper end of the telescopic rod makes contact with crushed materials in the through hole, the friction plate extrudes anddrives the telescopic rod to contract towards the inner side, the telescopic rod compresses the first spring and drives the friction plate to move, and when the friction plate moves upwards and rotates, the crushed materials in the through hole are removed; and through the structure, the purpose of mechanically removing chippings from the machined through hole is realized, and compared with manualworking, higher mechanical removing efficiency and safety are achieved.

Owner:崔晶晶

Device and method for measuring collision process in laser shock high-speed forming of plate

ActiveCN111331026AEasy to measureCollisions cannot be observedMetal working apparatusVoltage pulseThin membrane

The invention discloses a device and a method for measuring a collision process in laser shock high-speed forming of a plate, and belongs to the technical field of measurement. The device comprises alaser forming system and a measuring system, wherein the laser forming system comprises optical glass, a laser, an absorption layer, a metal sheet, a metal round bar, a barrier film, insulating paperand a female die. The method comprises the following steps of: firstly, enabling a metal die not to be in direct contact with the metal sheet and the metal round bar by adopting the insulating paper and the barrier film; correspondingly connecting the metal sheet and the metal round bar with a positive electrode and a negative electrode of a power supply; enabling the metal sheet to be in contactwith the metal round bar after being subjected to laser shock deformation; and conducting a measuring loop, wherein the number of generated voltage pulse signals is the collision frequency of the metal sheet moving at a high speed and the metal die, and the width of voltage pulses is the collision contact time. According to the method and the device, the collision process in laser shock high-speedforming of the plate can be accurately measured. The device has potential market application prospects.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of method for preparing GAAS film material

ActiveCN103147038BAdaptableShort preparation cyclePolycrystalline material growthVacuum evaporation coatingOxygenNitrogen gas

The invention discloses a method of preparing a GaAs thin-film material. The method comprises steps as follows: using Ga 203, As 203 and activated carbon C as raw materials; adding absolute ethyl alcohol corresponding to 50-100% of solid raw materials in weight; after grinding the materials uniformly, using 10-15 MPa of pressure to press the materials into a sheet with thickness of 1-10 mm; then placing the sheet in a reactor corundum crucible; vacuumizing with high-purity nitrogen; permuting the reactor corundum crucible until oxygen concentration reaches a ppm level; then using mixed gas to vacuumize and permute the reactor corundum crucible once or twice; vacuumizing to 7-13 Pa; controlling a rate of temperature increase to be within a range of 5-10 DEG C per minute; heating a reaction zone until the temperature of the reaction zone rises to a range of 1200-1250 DEG C; heating a sediment zone until the temperature of the sediment zone rises to a range of 600-800 DEG C; keeping the temperature constant for 3-4 hours when vacuum degree is kept no less than minus 0.08 MPa; cooling naturally until the temperature drops to the room temperature after the temperature of the reaction zone reaches a predetermined temperature; and obtaining a grey black GaAs thin film after filling the reactor corundum crucible with the mixed gas. According to the method of preparing the GaAs thin-film material, used raw materials are simple, low in price, and easy to obtain, and the raw materials are either solid or non-toxic gas, are free from polluting the environment, and do not threat the safety of an operator.

Owner:CHANGZHOUSR SEA ELECTRONICS

Double main duct ultra-light vertical take-off and landing single-person aircraft

The invention relates to a double-main-duct ultra-light type vertical take-off and landing solo aircraft which comprises a cabin main body and main ducts symmetrically arranged at the upper parts of the left side and the right side of the cabin main body, wherein the lower part of the cabin main body is provided with an undercarriage; each main duct is internally provided with a screw propeller, and an engine drives and rotates the screw propeller through a centrifugal speed reducer; and the engine is arranged at the lower part of the axis inside each main duct, and a nozzle of each main duct is further provided with a flow guide plate. Due to the use of the double-main duct aircraft provided by the invention,, the net weight of the aircraft is less than 116 kilograms, the height and the length of the aircraft are less than 1.9m, and the volume of the aircraft is equal to be about a half of the weight of a common car, so that the requirement on take-off and landing site is extremely simple, the aircraft is suitable for take-off and landing in the crowed cities, and the aircraft can be conveniently controlled.

Owner:谷承露 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com