Passive high-temperature heat pipe fast reactor core heat transfer system and method

A high-temperature heat pipe and heat transfer system technology, applied in the field of passive high-temperature heat pipe fast reactor core heat transfer system, can solve problems such as corrosion of structural component materials, increased safety hazards of fast reactor nuclear power plants, threats to reactor safety operation, etc., to improve safety Performance, small charge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

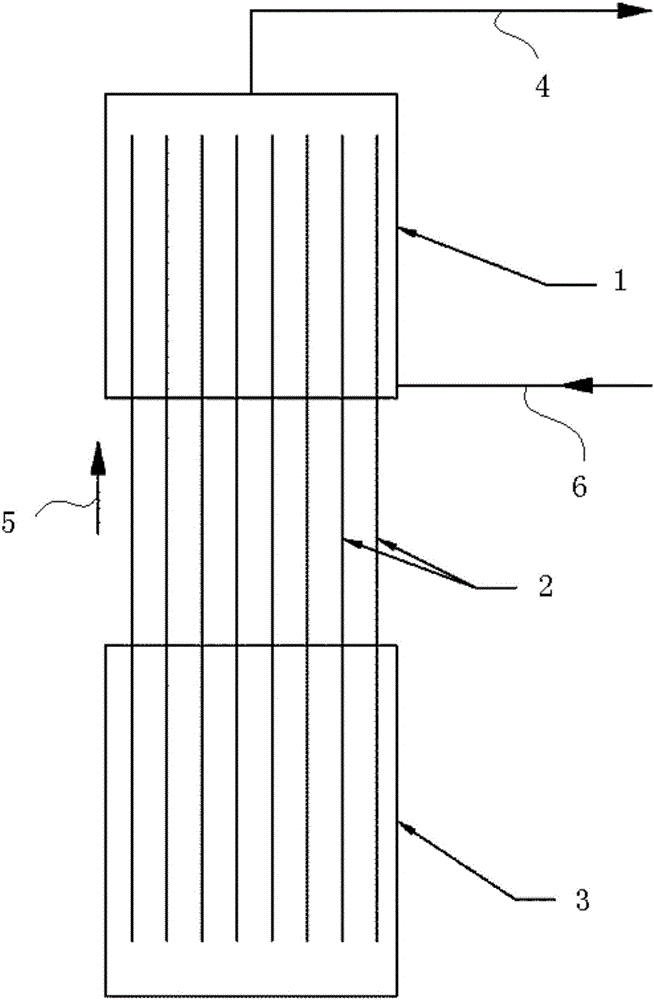

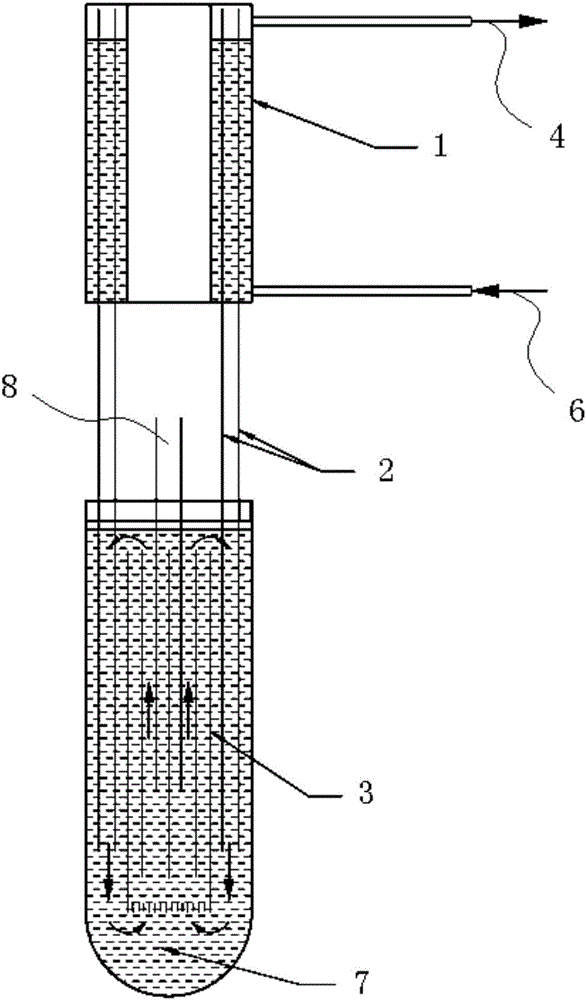

[0020] Such as figure 1 , 2 shown. The invention discloses a passive high-temperature heat pipe fast reactor core heat transfer system, which includes a fast reactor coolant pool 7 filled with sodium liquid, a heat pipe 2 and a steam generator 1; the lower end of the heat pipe 2 is placed in the fast reactor for cooling In the sodium liquid of the agent pool 7, the upper end of the heat pipe 2 is placed in the water of the steam generator 1.

[0021] The reactor fuel assembly 3 is placed in the fast reactor coolant pool 7, and the reactor fuel assembly 3 is submerged under the liquid surface of the sodium liquid.

[0022] The heat pipe 2 is a plurality of vertical heat pipe arrays arranged parallel to each other at intervals; the steam generator 1 is located above the fast reactor coolant pool 7 .

[0023] The bottom side wall of the steam generator is provided with a high-pressure water inlet 6, and the top is provided with a steam outlet 4; the reactor fuel assembly 3 emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com