Process and equipment for preparing hypochlorous acid by combining two-liquid method with electrolytic method

A technology of hypochlorous acid and electrolysis, which is applied in hypochlorous acid, photographic technology, electrolysis process, etc., can solve problems such as potential safety hazards, and achieve the effects of good disinfection effect, stable performance and long storage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

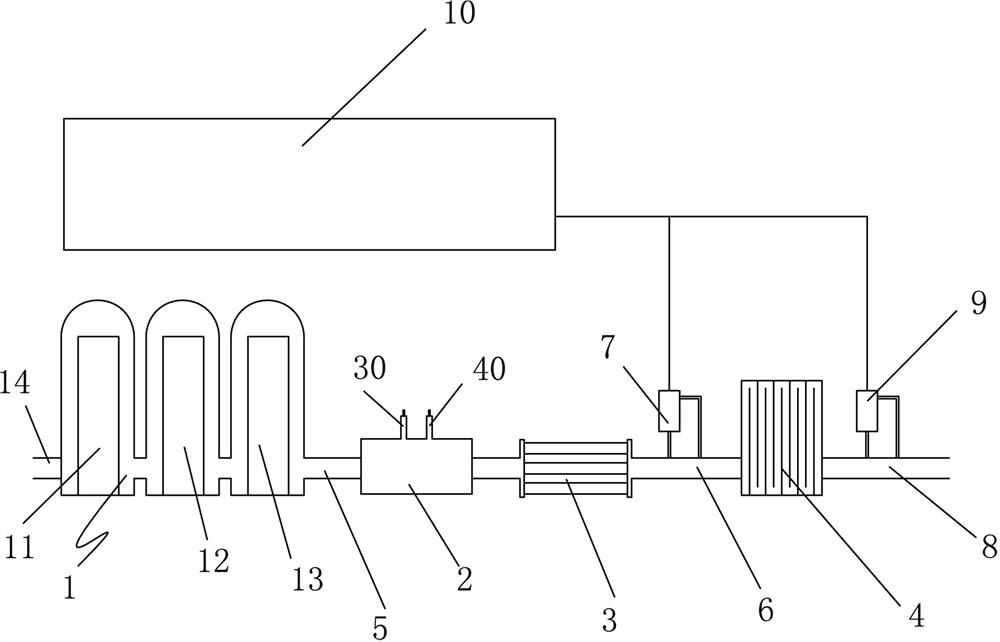

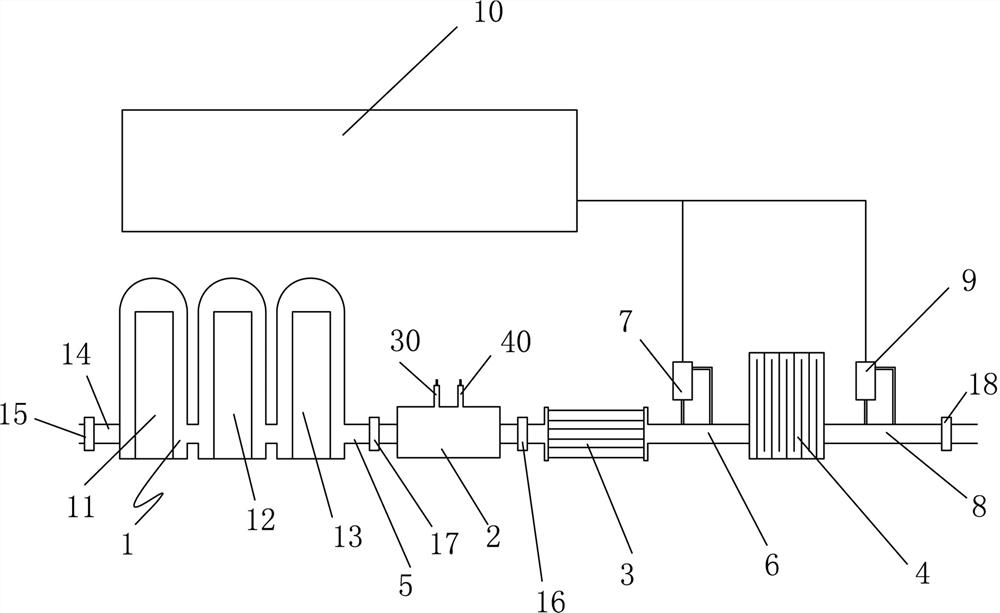

[0024] A kind of technology for preparing hypochlorous acid by a two-liquid method combined with an electrolysis method of the present invention comprises the following steps: S1, using a pre-filter 1 to process tap water to obtain purified water; wherein the water flow rate is adjusted to 5L / min, and the water pressure is 0.5 MPa. The pre-filter 1 is a three-stage filter device, and the three-stage filter device includes a 1 micron microporous PP cotton filter 11 connected in sequence, a second-stage activated carbon filter 12, and an acidic cation exchange resin filter 13. The micron microporous PP cotton filter 11 filters out large particle impurities in tap water; the second-stage activated carbon filter 12 absorbs organic matter and microbial impurities in tap water; the acidic cation exchange resin filter 13 filters out heavy metal impurities in tap water and cations. S2, in hypochlorite solution diluter 2, add hypochlorite solution and purified water in step S1, obtain...

Embodiment 2

[0026]A process for preparing hypochlorous acid by a two-liquid method combined with an electrolysis method of the present invention comprises the following steps: S1, using a pre-filter 1 to process tap water to obtain purified water; wherein the water flow rate is adjusted to 100 L / min, and the water pressure is 0.1 MPa. The pre-filter 1 is a three-stage filter device, and the three-stage filter device includes a 1 micron microporous PP cotton filter 11 connected in sequence, a second-stage activated carbon filter 12, and an acidic cation exchange resin filter 13. The micron microporous PP cotton filter 11 filters out large particle impurities in tap water; the second-stage activated carbon filter 12 absorbs organic matter and microbial impurities in tap water; the acidic cation exchange resin filter 13 filters out heavy metal impurities in tap water and cations. S2, add hypochlorite solution and purified water in step S1 in hypochlorite solution diluter 2, obtain hypochlor...

Embodiment 3

[0028] The present invention is a process for preparing hypochlorous acid by a two-liquid method combined with an electrolysis method, comprising the following steps: S1, using a pre-filter 1 to process tap water to obtain purified water; wherein the water flow rate is adjusted to 50 L / min, and the water pressure is 0.3 MPa. The pre-filter 1 is a three-stage filter device, and the three-stage filter device includes a 1 micron microporous PP cotton filter 11 connected in sequence, a second-stage activated carbon filter 12, and an acidic cation exchange resin filter 13. The micron microporous PP cotton filter 11 filters out large particle impurities in tap water; the second-stage activated carbon filter 12 absorbs organic matter and microbial impurities in tap water; the acidic cation exchange resin filter 13 filters out heavy metal impurities in tap water and cations. S2. Add the hypochlorite solution and the purified water in step S1 to the hypochlorite solution diluter 2 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com