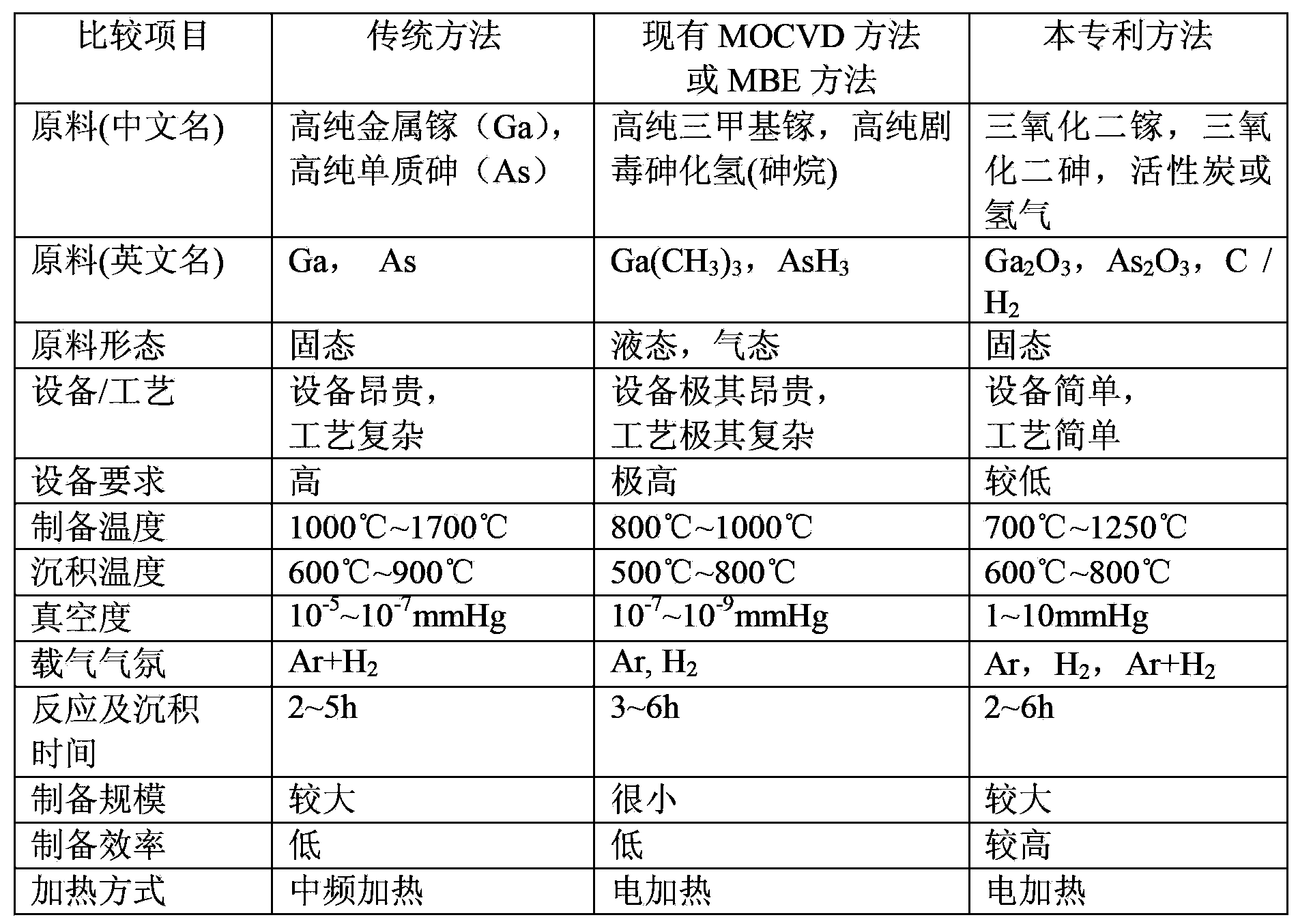

A kind of method for preparing GAAS film material

A thin-film material and thin-film technology, applied in the field of preparing GaAs thin-film materials, can solve problems such as the difficulty of using the Czochralski method, and achieve the effects of short preparation cycle, simple raw materials, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Accurately weigh Ga with one ten thousandth electronic balance 2 o 3 , As 2 o 3 , activated carbon C, uniformly mixed and ground according to the ratio of molar ratio Ga / As / C=1.0 / 1.2 / 6.0, because As is easy to sublimate, the proportion of As is slightly excessive, add absolute ethanol equivalent to 50% of the mass of solid raw materials, and grind carefully After uniformity, use a pressure of 10MPa to press it into a disc with a thickness of 3mm, then place it in the corundum crucible of the reactor, and use high-purity nitrogen to evacuate and replace the oxygen concentration to the ppm level, and then use Ar+H 2 Mixed gas (including H 2 The volume percentage is 10%) vacuum replacement once, the substrate required for deposition is pre-placed in the designated position in the reactor after treatment, and then vacuumed to 7Pa, the temperature rise rate is controlled at 5°C / min, and the temperature is raised to the reaction zone 1200°C, 600°C in the deposition area, ...

Embodiment 2

[0033] Accurately weigh Ga with one ten thousandth electronic balance 2 o 3 , As 2 o 3 , activated carbon C, uniformly mixed and ground according to the ratio of molar ratio Ga / As / C=1.0 / 1.0 / 6.0, adding absolute ethanol equivalent to 100% of the solid raw material mass, after careful grinding, press it into Thickness is 10mm square piece, then place it in the reactor, use high-purity nitrogen to evacuate to replace the oxygen concentration to the ppm level, and then use Ar+H 2 Mixed gas (including H 2 The volume percentage is 30%) and replaced twice by vacuuming, and the substrate required for deposition is processed and placed in a designated position in the reactor in advance. Then evacuate to about 1mmHg, control the temperature rise rate at 5-10°C / min, start electric heating and heat up to 1300°C in the reaction zone, and 800°C in the deposition area. When the temperature in the reaction zone reaches the predetermined temperature, turn on the substrate rotation device u...

Embodiment 3

[0036] Accurately Weighing Ga with 1 / 10000 Electronic Analytical Balance 2 o 3 , As 2 o 3 or As 2 o 5 , activated carbon C, uniformly mixed and ground according to the ratio of molar ratio Ga / As / C=1.0 / 1.2 / 8.0, adding absolute ethanol equivalent to 65% of the solid raw material mass, carefully ground it evenly, and pressed it with a pressure of 12MPa A disc with a thickness of 8mm is then placed in the reactor, evacuated with high-purity nitrogen to replace the oxygen concentration at the ppm level, and then filled with Ar+H 2 Mixed gas (including H 2 The volume percentage is 25%) and replaced twice by vacuuming. After the substrate required for deposition is processed, it is pre-placed in the designated position in the reactor, and then vacuumed to about 7Pa. The temperature rise rate is controlled at 8°C / min, and the heating is started until the reaction The zone is 1210°C, and the temperature of the deposition zone is controlled at 700°C. When the temperature of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com