Synergistic self-resistance electric heating type plate auto-increment spinning forming device and method

A spinning forming, electric heating technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult control, high cost of laser equipment, complex forming mechanism, etc., to reduce the output power requirements, simple structure , the effect of short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

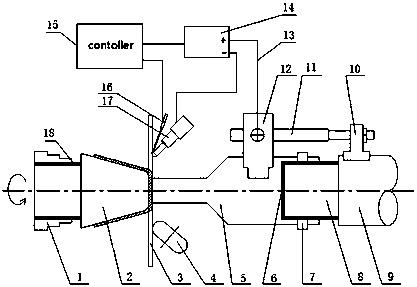

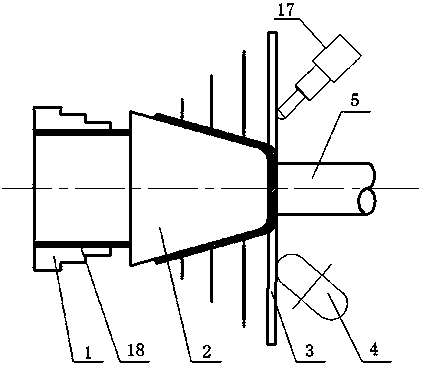

[0051] A kind of specific implementation mode of the present invention is as follows:

[0052] Calculate the size and thickness of the plate according to the principle of constant volume and elongation, and use the wire cutting machine to cut out a reasonable plate.

[0053] Build the mandrel and plate model in CAD, draw a reasonable spinning path; import the CAD graphics into Mastercam9.1, use its dynamic analysis function to determine the starting point and end point of the straight line and curve, and then manually write the spinning program, and The NC program is imported into the spinning machine tool.

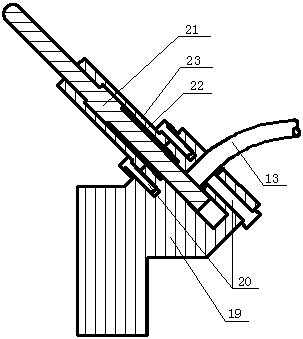

[0054] Installation tooling: first install the mandrel on the three-jaw chuck, and insulate and insulate the middle with high-temperature insulating materials; fix the tail top on the rotating top through M8 bolts, separate it with high-temperature insulating materials in the middle, and the tail top can rotate with it The top rotates together; the carbon brush holder as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com