Device and method for measuring collision process in laser shock high-speed forming of plate

A technology of laser shock and laser forming, which is applied in the field of measurement, can solve problems such as measuring the contact time and the number of collisions that cannot be measured, measuring the speed of sheet metal movement and deformation, blocking and measuring laser pulses, etc., to achieve simple debugging, The effect of fast response and simple measurement equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

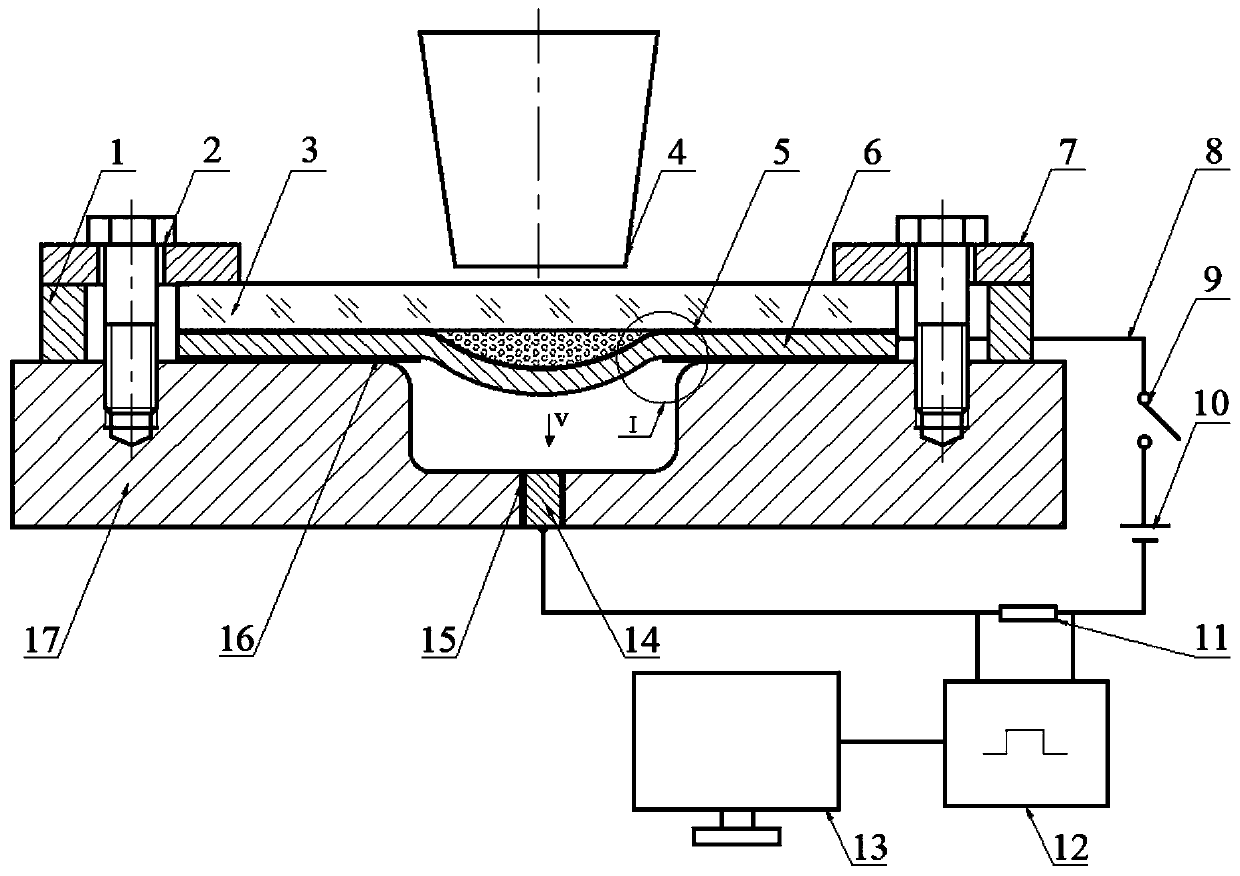

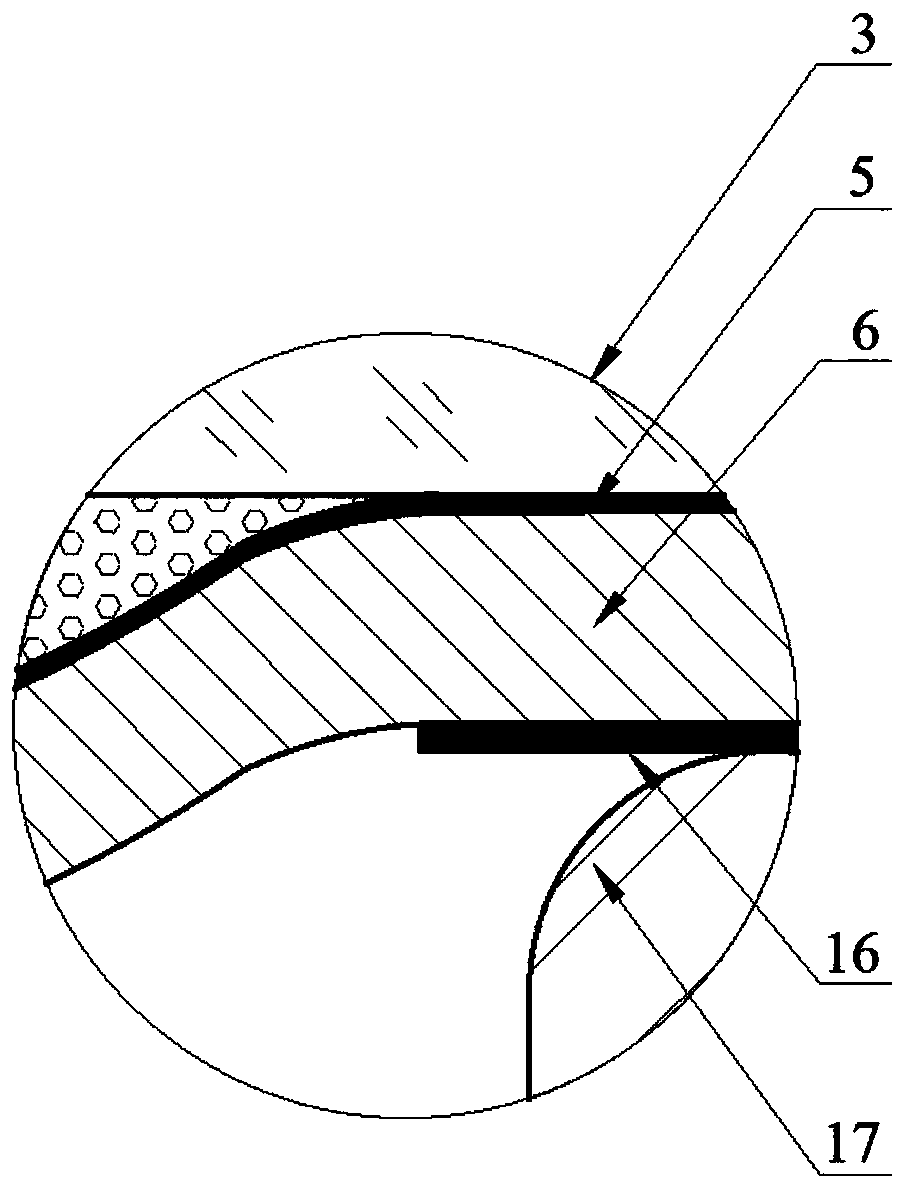

[0017] The invention provides a device and method for measuring the collision process in the laser shock high-speed forming of a sheet material. The device includes a laser forming system and a measuring system. The laser forming system includes a spacer block 1, a bolt 2, an optical glass 3, a laser 4, an absorption layer 5, a metal sheet 6, a pressing plate 7, a metal round bar 14, a barrier film 15, an insulating paper 16, and a concave mold 17. The measurement system includes a thin metal plate 6, a wire 8, a switch 9, a power supply 10, a fixed value resistor 11, a data acquisition recorder 12 and a computer (13). The wire 8 in the measurement system sequentially connects the metal sheet 6, the switch 9, the power supply 10, the fixed-value resistor 11 and the metal round bar 14 in series, and the two ends of the fixed-value resistor 11 are connected in parallel with the data acquisition recorder 12 through the wires. The recorder 12 is connected to the computer 13 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com