Method for integrating sludge dewatering and sludge damp drying

A sludge dehydration and integrated method technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problem that sewage treatment plants should not adopt sewage treatment processes with high sludge output, sewage treatment processes should not adopt treatment processes, sewage treatment The plant should not adopt low load and other issues to achieve the effects of easy optimal control, energy saving, and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

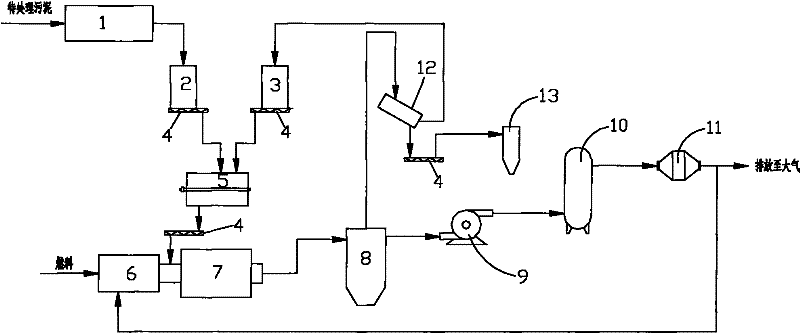

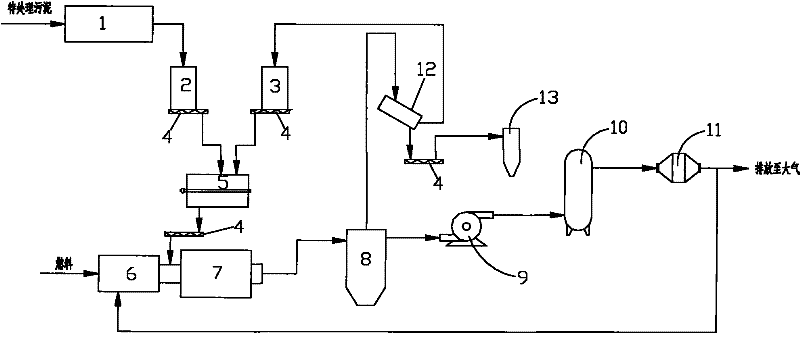

[0020] The present invention will be further described below in conjunction with accompanying drawing.

[0021] Such as figure 1 As shown, a kind of sludge dewatering and sludge semi-drying integrated method of the present invention comprises the following steps:

[0022] (1) Dewater the wet sludge with a water content of 99.3% to 98.5% to be treated in the sewage treatment plant. The specific operation method is: add a flocculant to the wet sludge, the flocculant is preferably polyacrylamide. The dosing rate of the agent by weight is less than 5‰, and the sludge is dehydrated by a screw press dehydrator 1. The moisture content of the dehydrated sludge is 75% to 80%, and the dehydrated sludge is collected by a screw conveying device. In wet sludge silo 2;

[0023] (2) The wet sludge collected in the wet sludge silo 2 and the semi-dried sludge collected in the circulating sludge silo 3 are sent to the mixer 5 through the screw conveying device 4 respectively. Two kinds of sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com