Pressure water storage barrel

A technology of pressure barrels and water storage barrels, which is applied to pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc. It can solve problems such as cumbersome and impractical operations, non-detachable water storage barrels, and poor safety, so as to reduce operations Process, save time, manpower and material resources, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the invention is described in further detail:

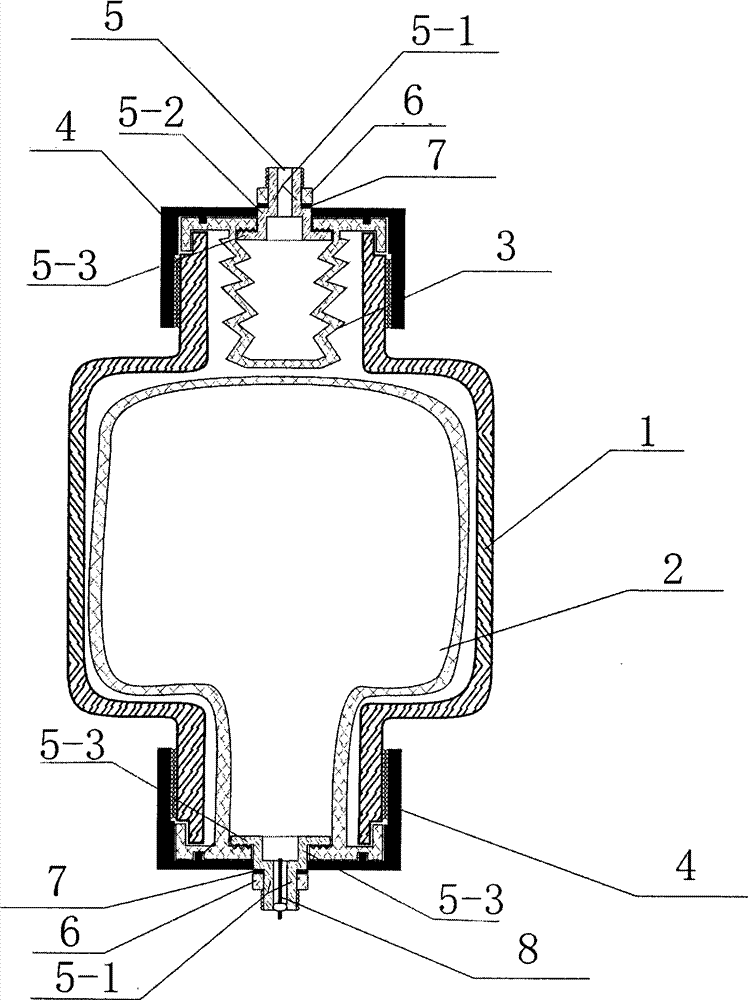

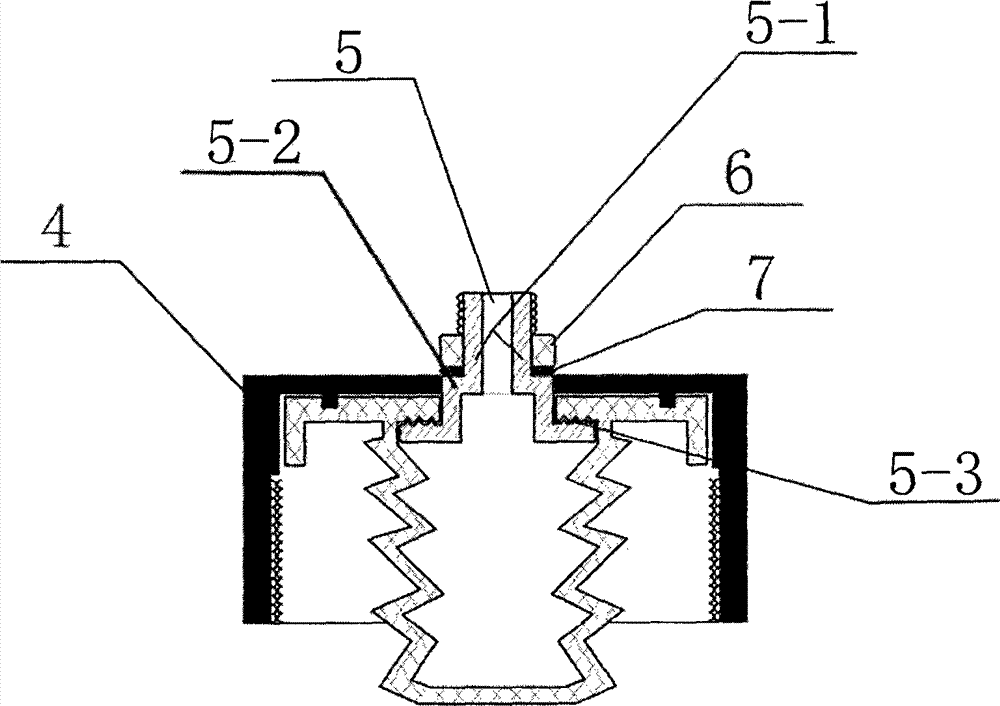

[0017] as attached figure 1 , 2 A pressure water storage barrel is shown, which includes a pressure barrel main body 1, an air storage bag 2 arranged inside the pressure barrel main body 1, and a water storage bag 3 arranged inside the pressure barrel main body 1, the top of the pressure barrel main body 1 and the The bottom is provided with a connecting nozzle 5, the pocket of the water storage bag 3 and the pocket of the air storage bag 2 communicate with the upper and lower connecting nozzles 5 respectively, and the connecting tube connected with the pocket of the water storage bag 3 The mouth 5 is the water inlet and outlet, and the connecting pipe mouth 5 communicated with the bag mouth of the air storage bag 2 is the air inlet and outlet, and the air valve core 8 is arranged on the air inlet and outlet. Valve core 8 plays the role of intake and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com