Method of preparing GaAs thin-film material

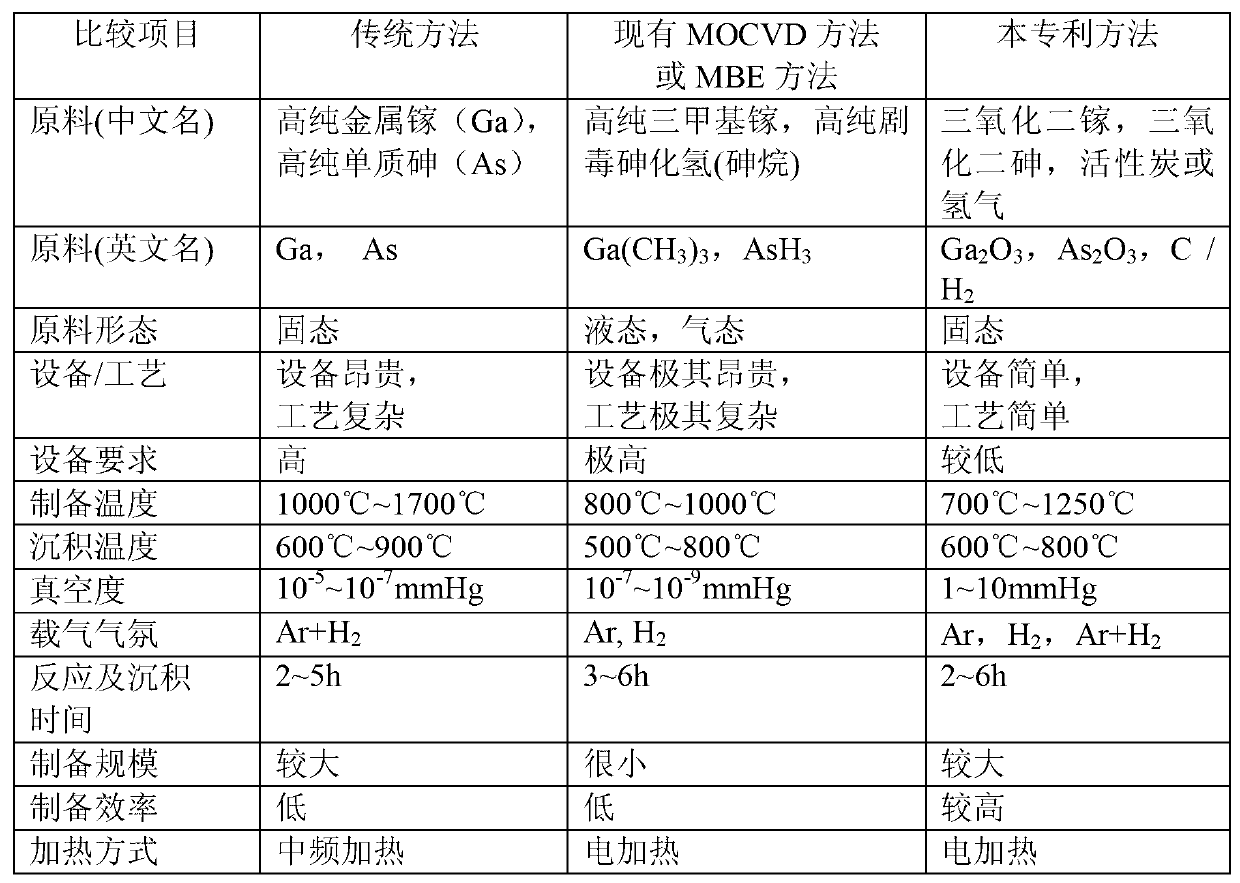

A thin film material, as2o3 technology, applied in the field of thin film material manufacturing, can solve the problems such as the difficult application of the Czochralski method, and achieve the effects of short preparation cycle, simple raw materials and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

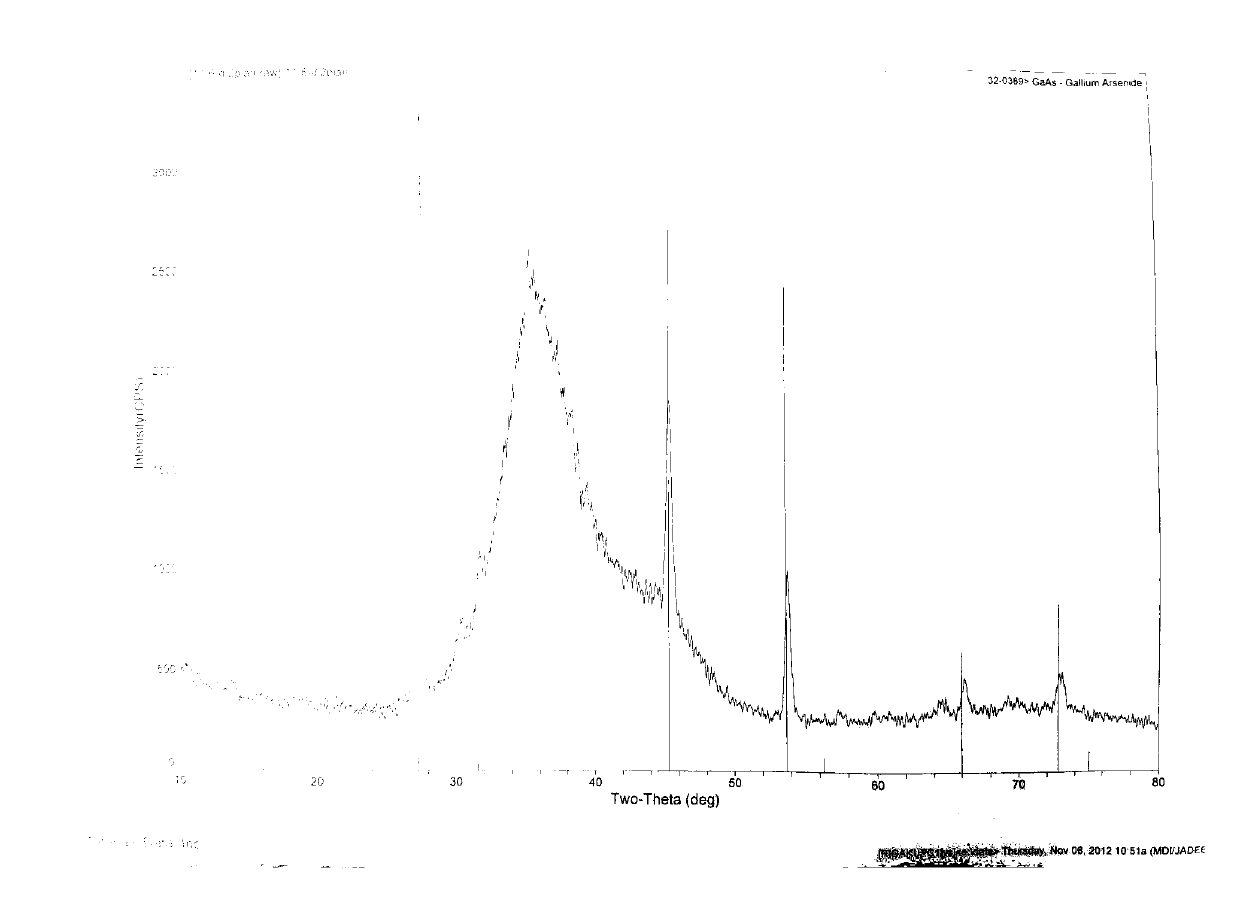

Embodiment 1

[0030] Accurately weigh Ga with one ten thousandth electronic balance 2 o 3 , As 2 o 3 , activated carbon C, uniformly mixed and ground according to the ratio of molar ratio Ga / As / C=1.0 / 1.2 / 6.0, because As is easy to sublimate, the proportion of As is slightly excessive, add absolute ethanol equivalent to 50% of the mass of solid raw materials, and grind carefully After uniformity, use a pressure of 10MPa to press it into a disc with a thickness of 3mm, and then place it in the corundum crucible of the reactor, and use high-purity nitrogen to evacuate it to an oxygen concentration of ppm level, and then use Ar+H 2 Mixed gas (including H 2 The volume percentage is 10%) vacuum replacement once, the substrate required for deposition is pre-placed in the designated position in the reactor after treatment, and then vacuumed to 7Pa, the temperature rise rate is controlled at 5°C / min, and the heating is started to heat up to the reaction zone 1200°C, 600°C in the deposition area,...

Embodiment 2

[0033] Accurately weigh Ga with one ten thousandth electronic balance 2 o 3 , As 2 o 3 , activated carbon C, uniformly mixed and ground according to the ratio of molar ratio Ga / As / C=1.0 / 1.0 / 6.0, adding absolute ethanol equivalent to 100% of the solid raw material mass, after careful grinding, press it into Thickness is 10mm square piece, then place it in the reactor, use high-purity nitrogen to evacuate to replace the oxygen concentration to the ppm level, and then use Ar+H 2 Mixed gas (including H 2 The volume percentage is 30%) and replaced twice by vacuuming, and the substrate required for deposition is processed and placed in a designated position in the reactor in advance. Then evacuate to about 1mmHg, control the temperature rise rate at 5-10°C / min, start electric heating and heat up to 1300°C in the reaction zone, and 800°C in the deposition area. When the temperature in the reaction zone reaches the predetermined temperature, turn on the substrate rotation device u...

Embodiment 3

[0036] Accurately Weighing Ga with 1 / 10000 Electronic Analytical Balance 2 o 3 , As 2 o 3 or As 2 o 5 , activated carbon C, uniformly mixed and ground according to the ratio of molar ratio Ga / As / C=1.0 / 1.2 / 8.0, adding absolute ethanol equivalent to 65% of the solid raw material mass, carefully ground it evenly, and pressed it with a pressure of 12MPa A disc with a thickness of 8mm is then placed in the reactor, evacuated with high-purity nitrogen to replace the oxygen concentration at the ppm level, and then filled with Ar+H 2 Mixed gas (including H 2 The volume percentage is 25%) and replaced twice by vacuuming. After the substrate required for deposition is processed, it is pre-placed in the designated position in the reactor, and then vacuumed to about 7Pa. The temperature rise rate is controlled at 8°C / min, and the heating is started until the reaction The zone is 1210°C, and the temperature of the deposition zone is controlled at 700°C. When the temperature of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com