Large-working-space multi-degree-of-freedom controllable mechanism-type shovel-loading integrated transport car

A technology with a working space and a degree of freedom, which is applied in the field of sanitation machinery, can solve the problems of high machining accuracy of hydraulic components, reduce the use of supporting facilities, and difficult maintenance, etc., and achieve convenient up and down turning, compact structure, and motion characteristics and good dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

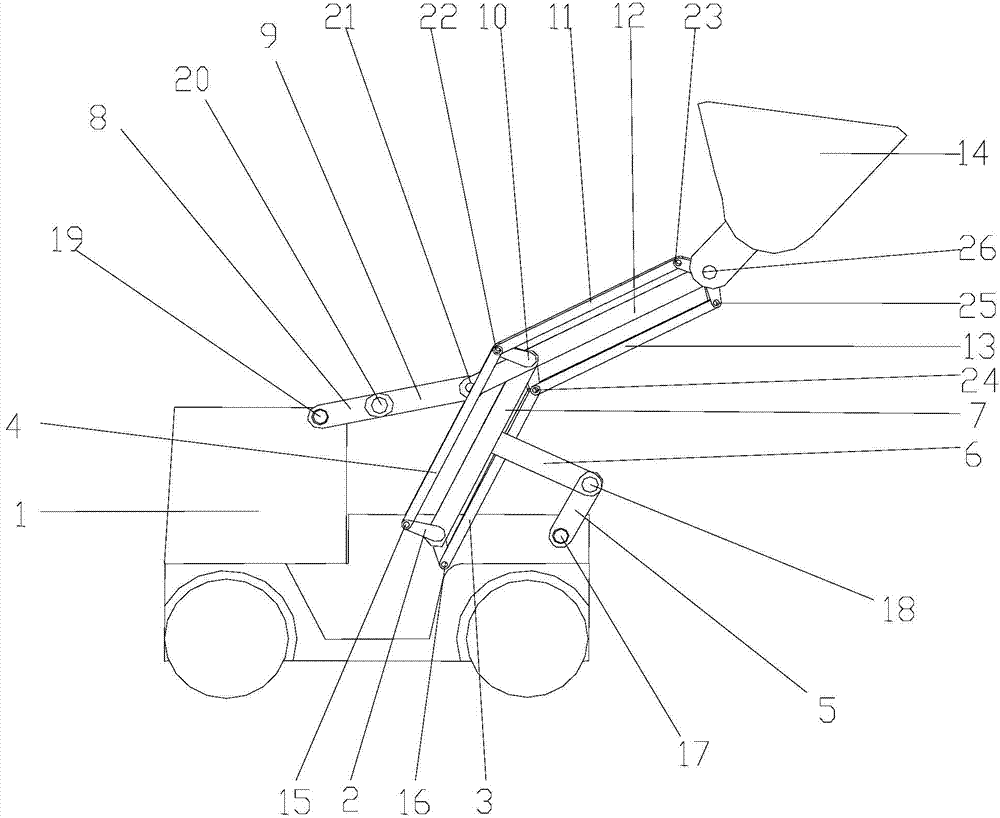

[0025] control figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , a large working space multi-degree-of-freedom controllable mechanism-type shovel-loading integrated transport vehicle, its structure and connection method are:

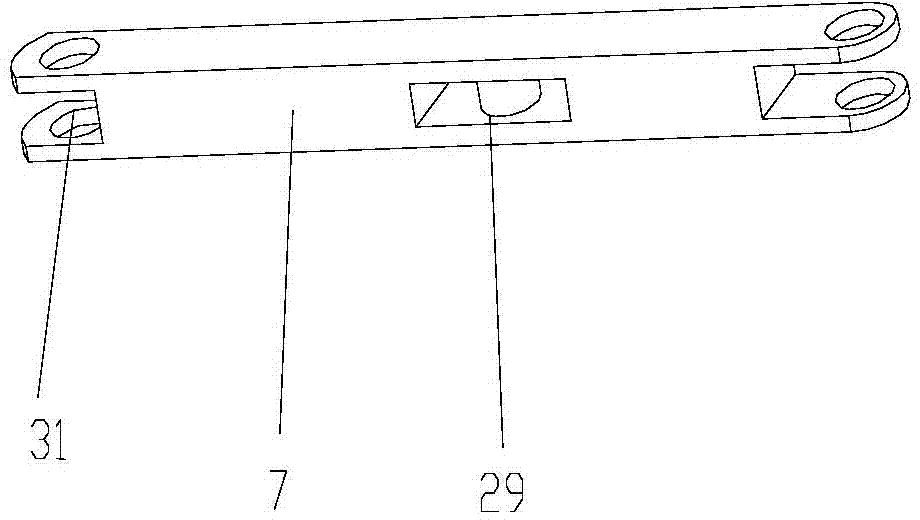

[0026] The parallel actuator sub-chain is composed of car body 1, first main arm lever 7, second main arm lever 12, first active lever 5, second active lever 8, first rocker arm lever 2, second rocker arm The rod 10, the first connecting rod 6, the second connecting rod 9, the third connecting rod 3, the fourth connecting rod 4, the fifth connecting rod 13, the sixth connecting rod 11 and the bucket 14 are connected, and the car body 1 passes through The first rotating pair 31 is connected with one end of the first main arm 7, one end of the first connecting rod 6 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com