3D printing bone platform

A technology for printing bone and printing table, which is applied in medical science, tissue regeneration, prosthesis, etc., and can solve the problem of poor biocompatibility of artificial bone, low printing accuracy, accuracy, pore uniformity, spatial structure complexity, and individualization of scaffolds Unsatisfactory problems, to achieve good biocompatibility, avoid printing overflow, high printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

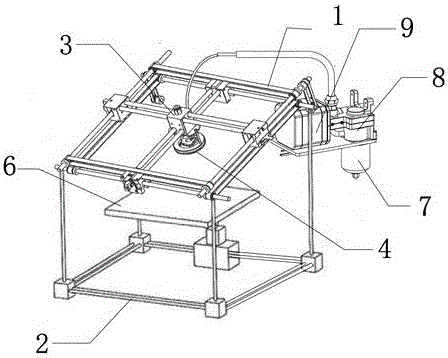

[0035] Such as figure 1As shown, a 3D printing bone platform includes an upper bracket 1 and a lower bracket 2 that are flexibly connected. The upper bracket 1 is square, and the bottom surface of the lower bracket 2 is square. The lower bracket 2 includes four vertical support rods. The vertex of 1 is connected to the vertex of the bottom surface of the lower support 2 through the support rod, and the support rod is movably connected with the upper support 1. The upper support 1 can be turned over with the connection point as the midpoint. The upper support 1 is provided with a print head 4, and the upper support 2 A melt-out device is fixedly installed, and the melt-out device is connected with the print head 4 through a sampling tube. The melting device includes a sample reservoir 8, the lower surface of the sample reservoir 8 is provided with a heating device 7, the sample reservoir 8 is connected to the nozzle through a vacuum pump 9, and the nozzle is connected to the pr...

Embodiment 2

[0040] Nano-hydroxy calcium phosphate / polycaprolactone / polylactic acid is prepared by the following method: through the reaction formula Ca(NO 3 )·4H 2 O+(NH 4 ) 2 HPO 4 → Ca 10 (PO 4 ) 6 (OH) 2 To prepare nano-hydroxycalcium phosphate, configure nano-calcium hydroxyphosphate into a slurry with a mass fraction of 5%, add the slurry to a three-necked bottle with a water separator, a stirring device and a condensation device, and add 150mL solvent DMAC and an appropriate amount of polyethylene glycol at the same time. For diol, the temperature is gradually increased to 100°C, dehydrated at 100-120°C, then polycaprolactone and polylactic acid are added in proportion, stirred and compounded for 4 hours at 120-130°C, taken out, and washed with hot deionized water for 4 hours times, washed with ethanol twice, and dried at 50-60°C for 48 hours to obtain a composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com