An Automatic Inking Mechanism of Printing Machine Based on Floating Ball Seal

A technology for automatic inking and printing presses, applied in printing presses, general parts of printing machinery, printing, etc., can solve the problems of working environment impact, waste, poor printing quality, etc., to avoid the effect of fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

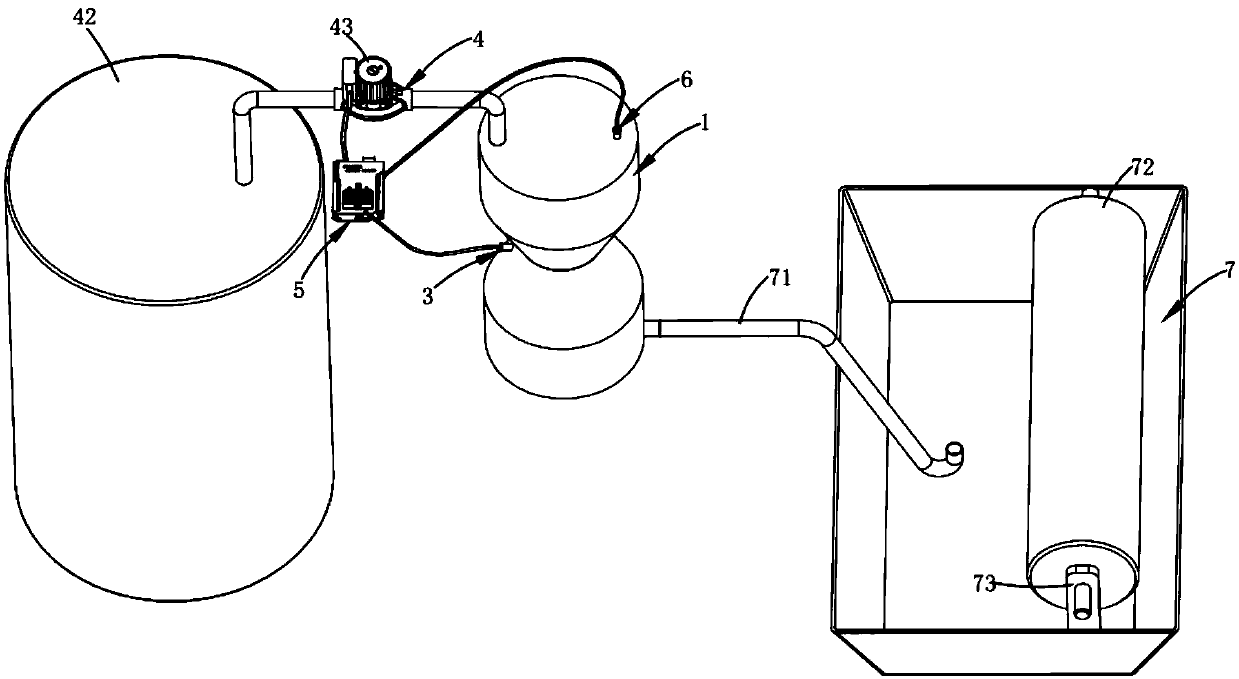

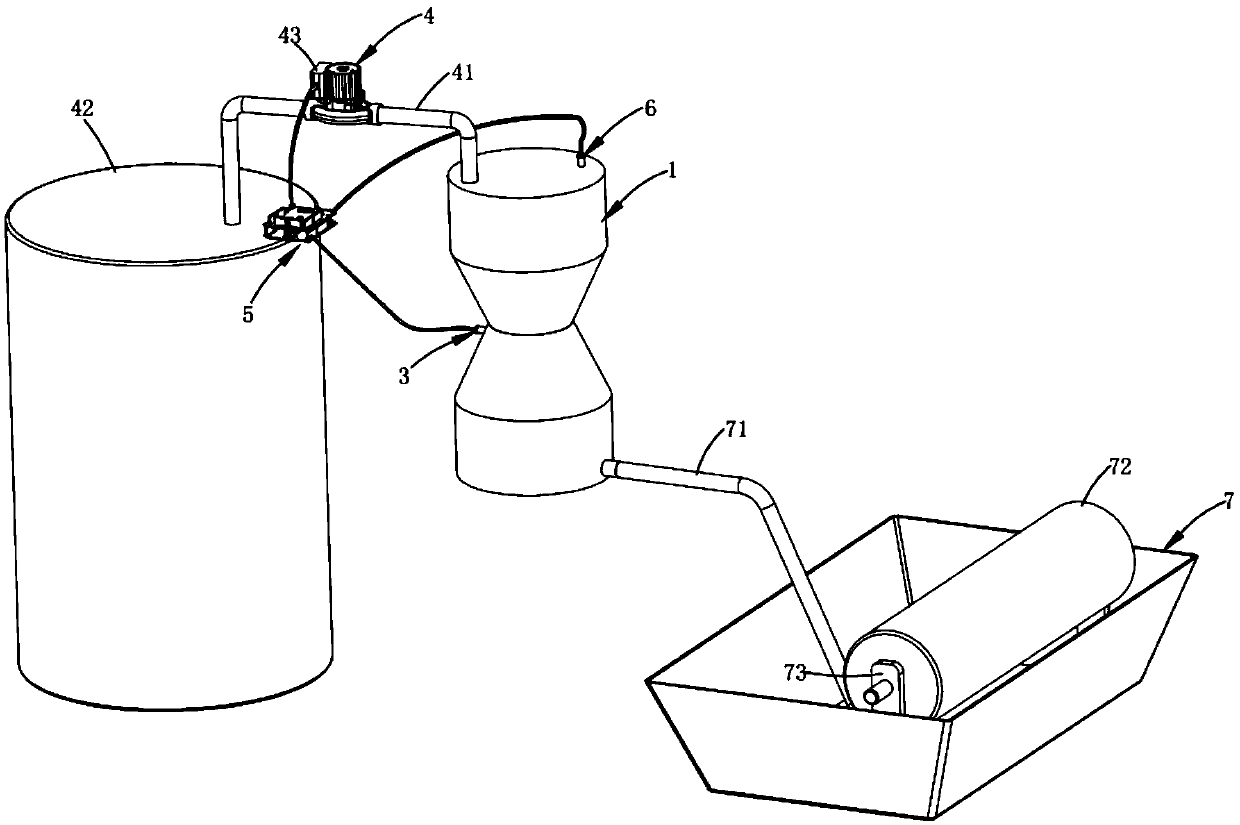

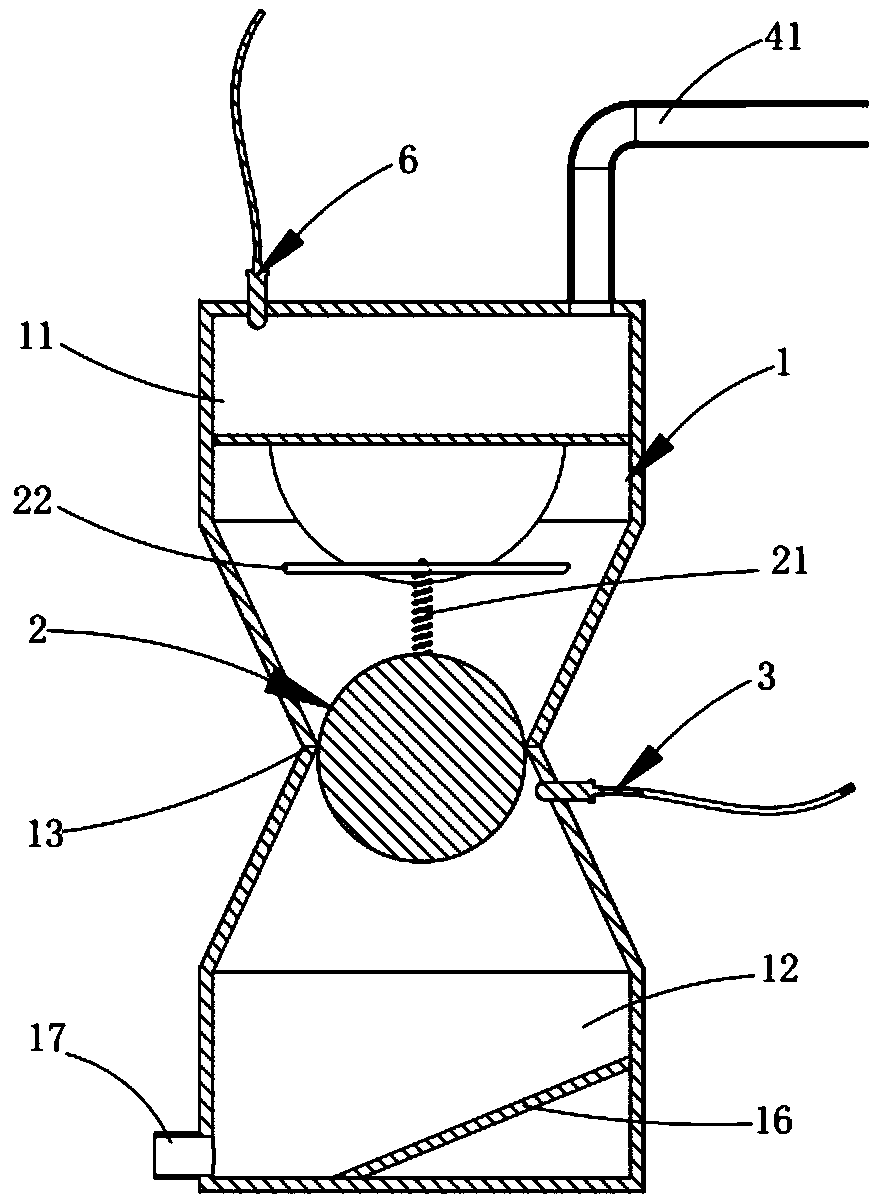

[0031] Such as figure 1 , figure 2 and image 3 As shown, an automatic ink filling mechanism for a printing machine based on a floating ball seal includes an ink bucket 1, a floating ball 2, a position sensor 3, an ink filling mechanism 4, a circuit control board 5 and a liquid level sensor 6, and is characterized in that the The ink barrel 1 is divided into a feeding chamber 11 located on the upper floor and a safety ink volume chamber 12 located on the lower floor, and a neck 13 for limiting the floating ball 2 is arranged between the feeding chamber 11 and the safety ink volume chamber 12; The float 2 is located in the safety ink volume chamber 12, and is connected to the fixed shaft 22 located in the feeding chamber 11 through a pull cord 21. The position sensor 3 is arranged in the safety ink volume chamber 12, and is located in the safety ink volume chamber 12. On the top of the measuring chamber 12, the liquid level sensor 6 is arranged on the top of the feeding cham...

Embodiment 2

[0046] Figure 5 It is a structural schematic diagram of Embodiment 2 of a pruning angle adjustable pruning device of the present invention; Figure 5 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0047] Such as Figure 5 As shown, a buffer plate 14 is also provided in the charging chamber, and a plurality of through holes 141 distributed in a fan shape are symmetrically provided on the buffer plate 14 .

[0048] As an improved technical solution, arc-shaped deflectors 15 corresponding to the plurality of through-holes 141 are fixedly arranged below the plurality of through-holes 141, and the arc-shaped surfaces of the arc-shaped deflectors 15 completely cover the Several through holes 141 .

[0049] It shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com