Automatic cloth paving device for screen printing and cloth paving method thereof

A screen printing and automatic technology, applied in screen printing, screen printing machines, printing, etc., can solve problems such as poor laying flatness, low recognition limit, wrinkles, etc., and achieve the effect of ensuring coverage and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

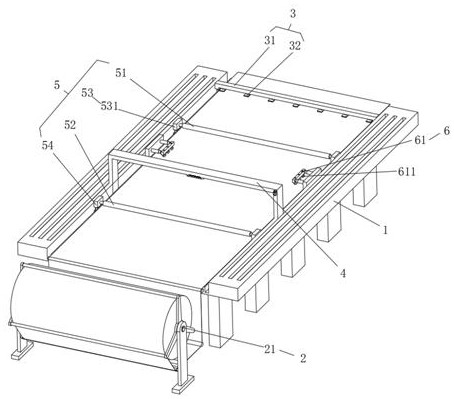

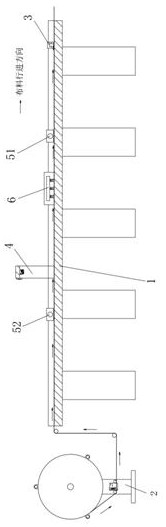

[0040] see Figure 1-2 , an automatic cloth spreading device for screen printing, comprising a printing platform 1 and a quantitative feeder 2, the printing platform 1 is provided with a spreading mechanism 3, a flatness measuring mechanism 4, a longitudinal flattening mechanism 5, a horizontal flattening mechanism 6 and Controller; printing platform 1 is used to provide a flat surface for printing, quantitative feeder 2 is used to intermittently release a fixed length of cloth; spreading mechanism 3 can be disassembled from printing platform 1, and spreading mechanism 3 is used for the first feeding Pull the cloth at the same time, and spread the cloth on the flat surface; the flatness measuring mechanism 4 can slide along the direction of the cloth on the printing platform 1, and the flatness measuring mechanism 4 includes a scanner and a positioner, and the scanner is used to scan the cloth , to identify the flatness of the cloth, the locator is used to locate and calculate...

Embodiment 2

[0063] Further, please refer to figure 1 , the spreading mechanism 3 includes a spreading slide 31 and some movable clips 32, and some movable clips 32 are installed on the lower surface of the spreading slide 31, and the movable clips 32 can slide on the lower surface of the spreading slide 31, and several movable clips 32 are used for common When the cloth is clamped, the spreading slide 31 together with a plurality of movable folders 32 can move along the direction of cloth travel.

[0064] Therefore, the cloth can be evenly clamped by the plurality of movable clamps 32 , and the cloth can be spread relatively smoothly on the upper surface of the printing platform 1 through the sliding of the spreading slide 31 , reducing the workload of subsequent leveling.

Embodiment 3

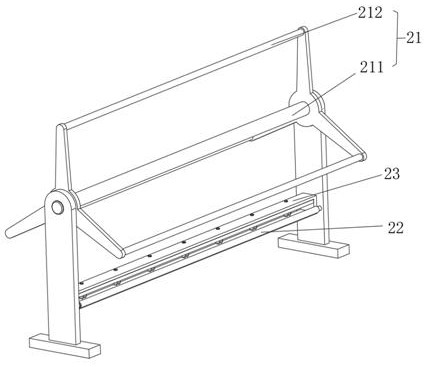

[0066] Further, please refer to Figure 3-4 , The raw material support 21 also includes a plurality of positioning shafts 212, the distance between the positioning shafts 212 and the central installation roller shaft 211 can be adjusted, and the plurality of positioning shafts 212 are used to prevent the cloth from getting loose from the raw material support 21 together.

[0067] Thereby make through the adjustment of the distance of the positioning shaft 212, the cloth roll is relatively fixed on the raw material support 21, prevent the spontaneous expansion of the cloth roll, and affect the judgment of the quantitative feeder 2 on the output of the cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com