Automatic code spraying device and use method thereof

A technology of inkjet and inkjet printer, applied in printing devices, printing and other directions, can solve the problems of untimely ink monitoring, affecting printing quality, affecting printing progress, etc., to achieve the effect of sufficient ink, clean nozzles, and clean printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

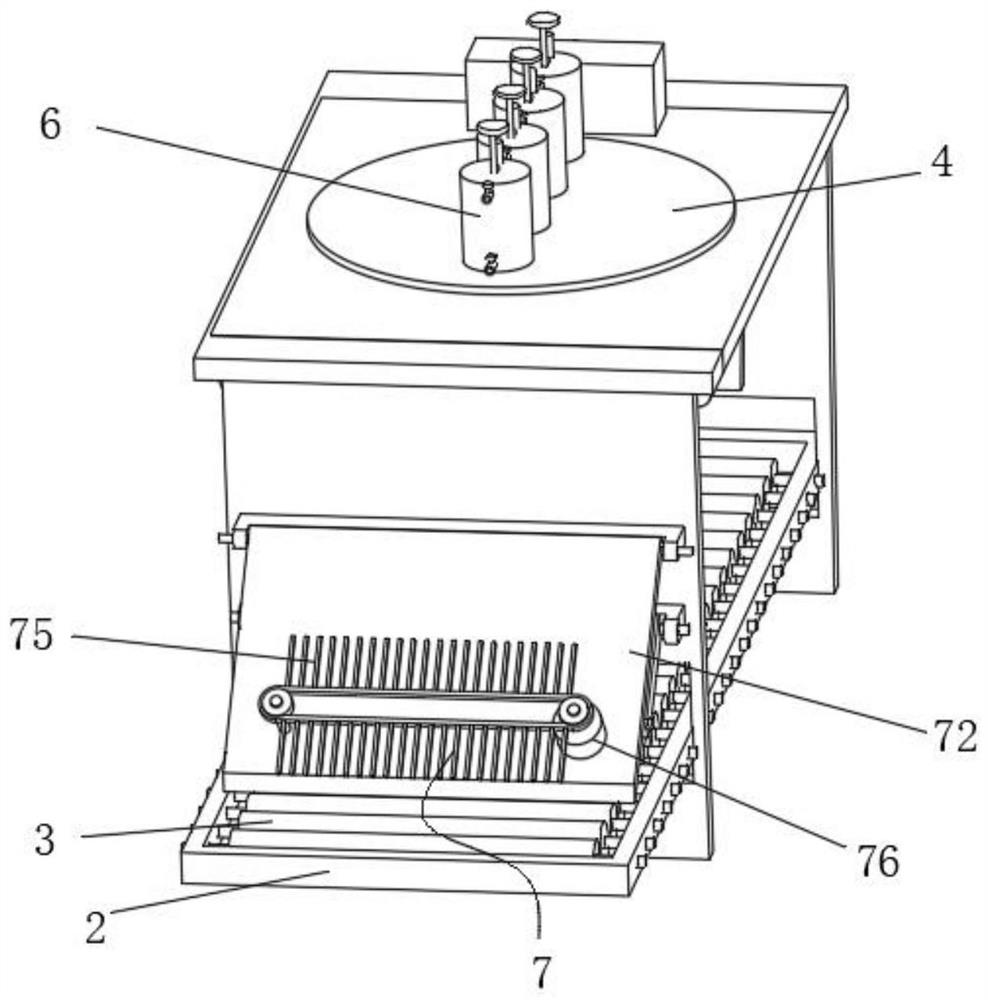

[0036] As an embodiment of the present invention, the conveying structure 7 includes a finishing structure 7 including a first mount 71, a second rubber scraper 72, a first contraction spring 73, a pulley 74, a brush 75, a cleaning motor 76, a second The mounting seat 77, the second retraction spring 78, the swing roller frame 79 and the swing roller 710, the first mounting seat 71 is fitted with a second rubber scraper 72 through a pin shaft, and one end of the top side of the second rubber scraper 72 is installed with Clean up motor 76, and the other end top side of the second rubber scraper 72 is equipped with cooperating shaft, is equipped with pulley 74 respectively on the rotating shaft of cleaning motor 76 and on the cooperating shaft, is fitted with rubber belt on two belt pulleys 74, and rubber belt A hairbrush 75 is installed on the top, and a swing roller frame 79 is mounted on the second mounting seat 77 through a pin shaft, and a swing roller 710 is mounted on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com