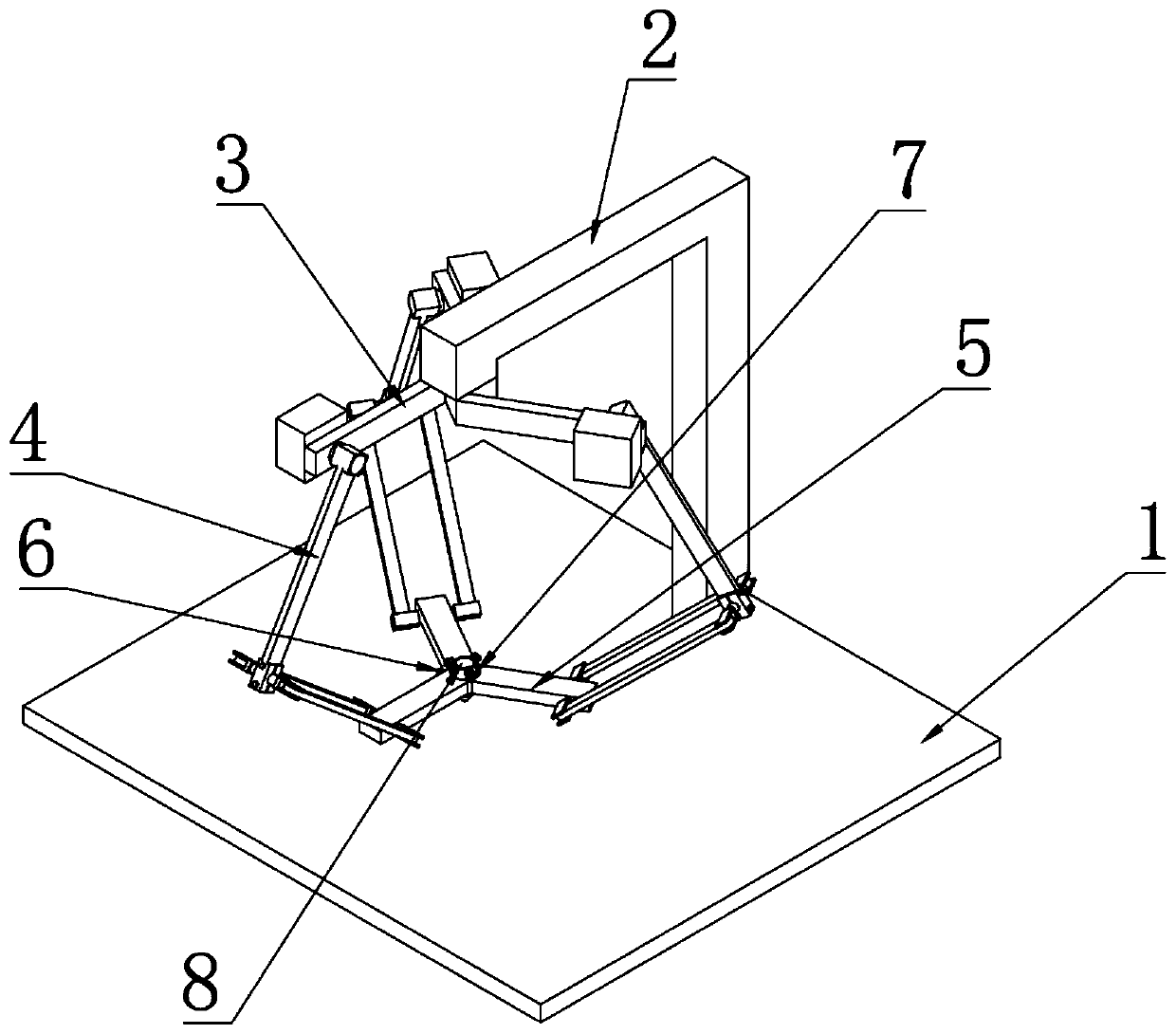

Reactive 3D printer

A 3D printer, reactive technology, applied in the field of 3D printing, can solve the problem of single, unable to splicing and printing multiple materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

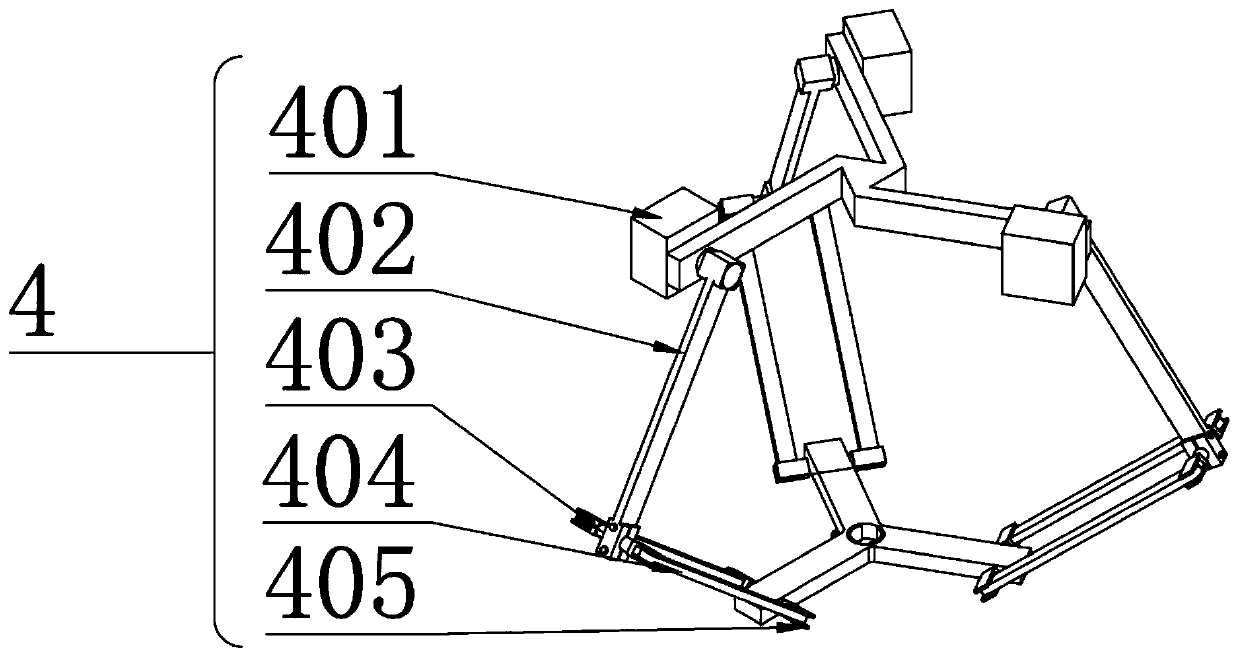

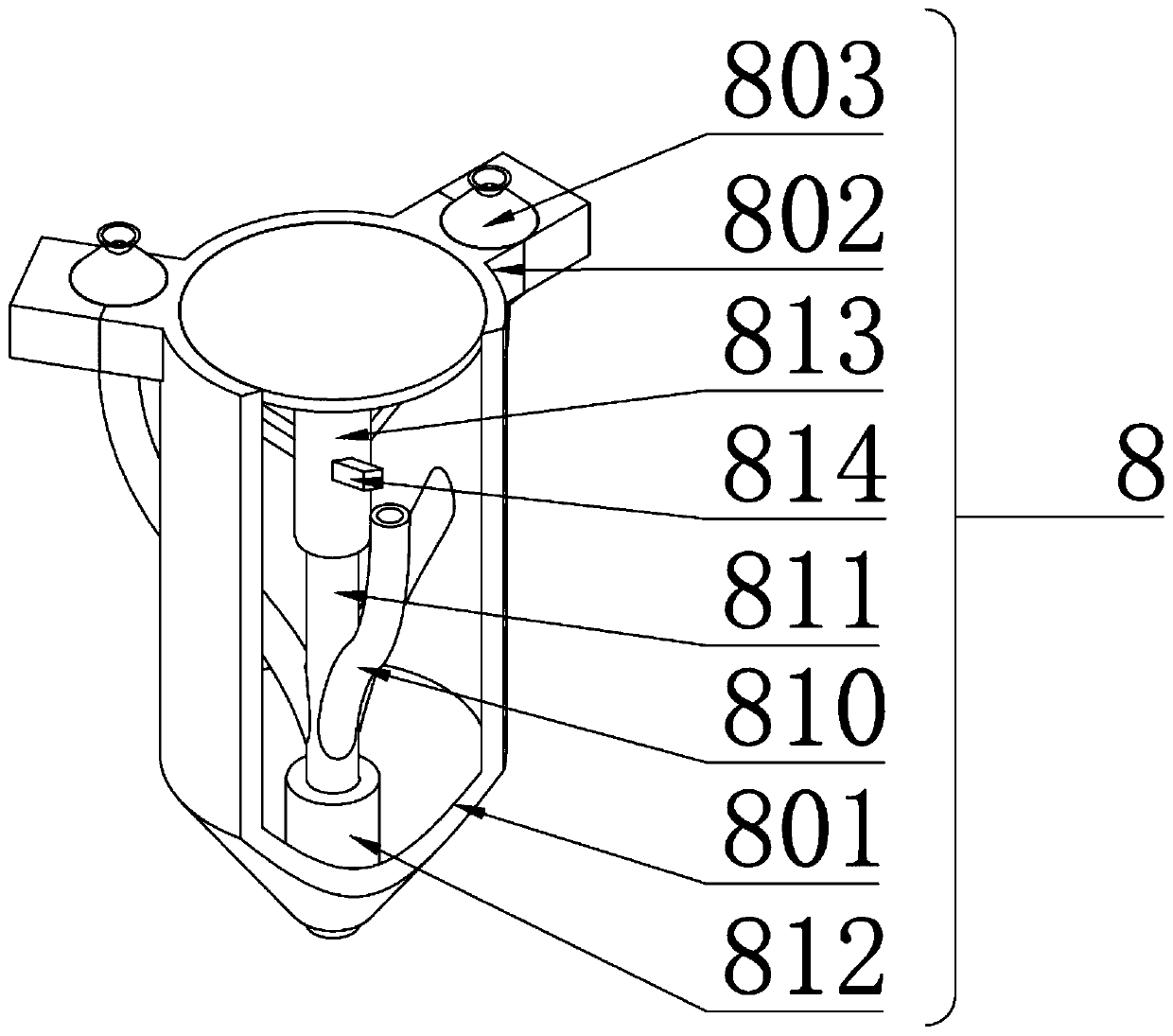

[0030]Embodiment: first place the printing device 8 in the through hole provided on the upper wall of the fixing frame 5, and at the same time rotate the adjusting bolt 6 to fix it, then insert the required consumables into the feeding ports of the printing device 8, and simultaneously turn on the motor 2 808, and control the motor to drive shaft three 805 through the belt 809 to drive the gear 804 to rotate, so that the consumables can move, and then turn on the power supply of the heating ring 812 to make it heated, and separately control the motor two 808 at different positions to carry out Consumables of different materials are loaded, and motor 1 401 at different positions is controlled at the same time, and the movement of the connecting rod 1 402 and connecting rod 2 404 in different directions can be controlled to control the printing device 8 to perform continuous printing. When the consumables need to be replaced, Turn off the power supply of the heating ring 812, wai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com