Sewage purification device with dry-wet separation mechanism

A technology of dry and wet separation and sewage purification, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Improve water purification capacity and ensure the effect of effective purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

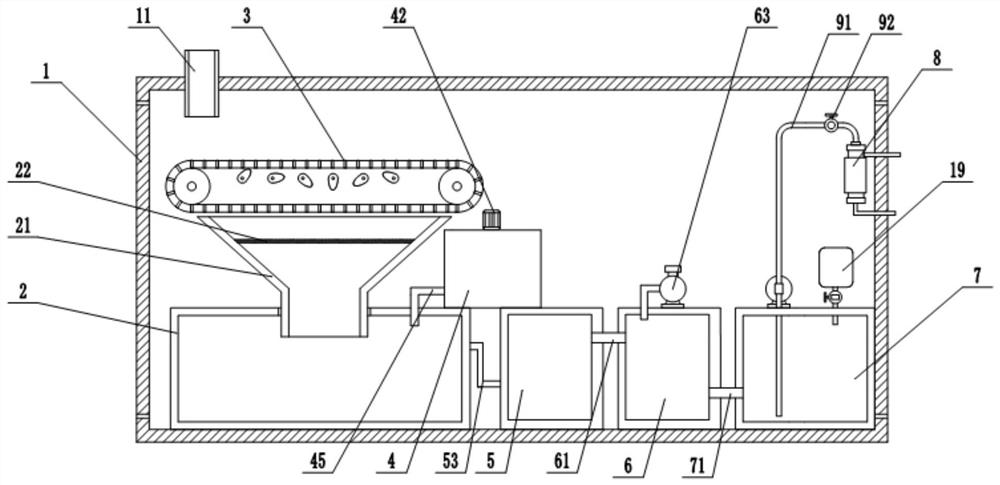

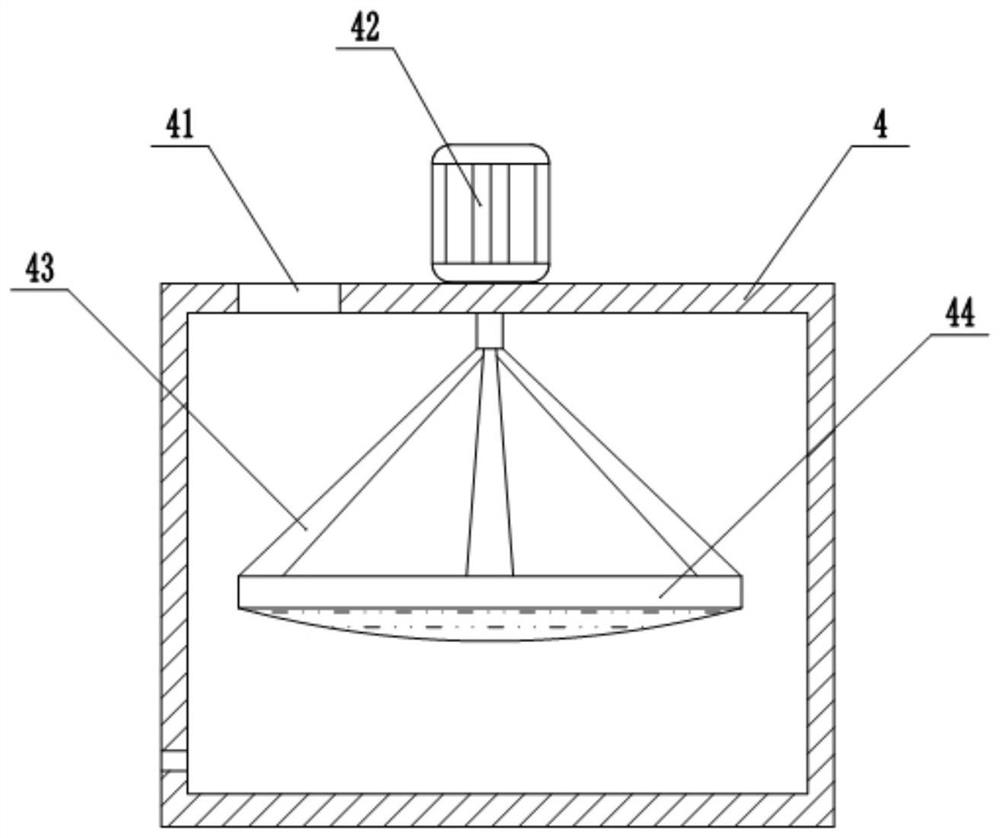

[0033] Such as Figures 1 to 6 As shown, a sewage purification device with a dry-wet separation mechanism includes a purification chamber 1, a water inlet 11 is provided on the top of the purification chamber 1, a water storage tank 2 is provided below the water inlet 11, and a water storage tank 2 is arranged between the water inlet 11. There is a dry-wet separation mechanism. The dry-wet separation mechanism includes a first-level dry-wet separation component and a second-level dry-wet separation component. The sewage with solid impurities is separated by the first-level dry-wet separation component and the second-level dry-wet separation component and then flows into the water storage tank. 2 within.

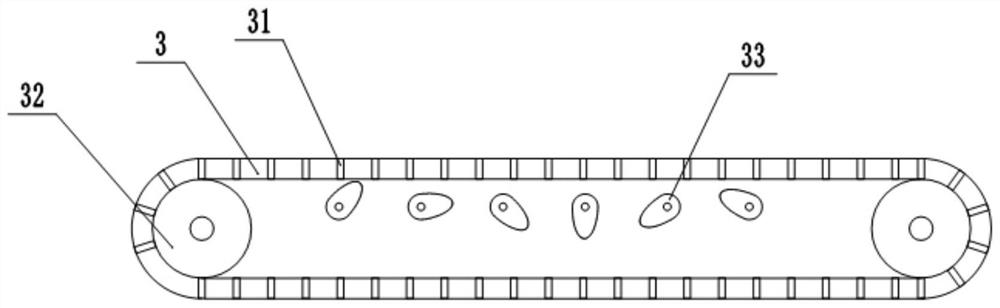

[0034] Such as Figures 1 to 2As shown, the first-stage dry-wet separation assembly includes a group of drive rollers 32 that are rotatably installed in the clean room 1, and the outside of the clean room 1 is equipped with a first servo motor (not shown in the figure) that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com