Paper feeding system used for printing machine

A printing machine and frame technology, applied in the field of paper loading system, can solve the problems of particles falling on the cardboard and affecting the printing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

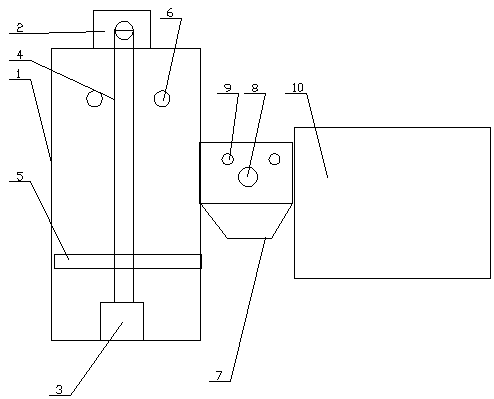

[0025] As shown in the figure, the present invention includes a paper loading device and a dust cleaning device,

[0026] The paper loading device includes a frame 1, a double-axis motor 2, a pair of chain boxes 3, a pair of chains 4, a stacking plate 5 and one or a group of pickup wheels 6,

[0027] One section of the frame 1 is provided with a material inlet, and the other end is provided with a material outlet,

[0028] The double-axis motor 2 is fixedly installed on the top of the frame 1,

[0029] A pair of chain boxes 3 are installed on both sides of the bottom of the frame 1 respectively,

[0030] A pair of chains 4 are respectively connected to the power output end of the biaxial motor 2 and the sprocket wheels in the pair of chain boxes 3,

[0031] Both sides of the stacking plate 5 are fixedly connected on a pair of chains 4, and move up and down with the chains,

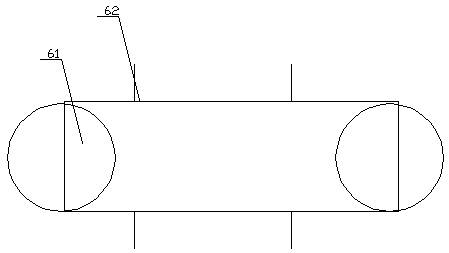

[0032] One or a group of shafts at both ends of the pick-up roller 6 are mounted on the inner top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com