One-way valve and manufacturing method thereof as well as ink box and manufacturing method thereof

A manufacturing method and technology of a one-way valve, applied in the printing field, can solve problems affecting printing quality, high production cost, and low work efficiency, and achieve the effects of avoiding printing quality, simple manufacturing process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

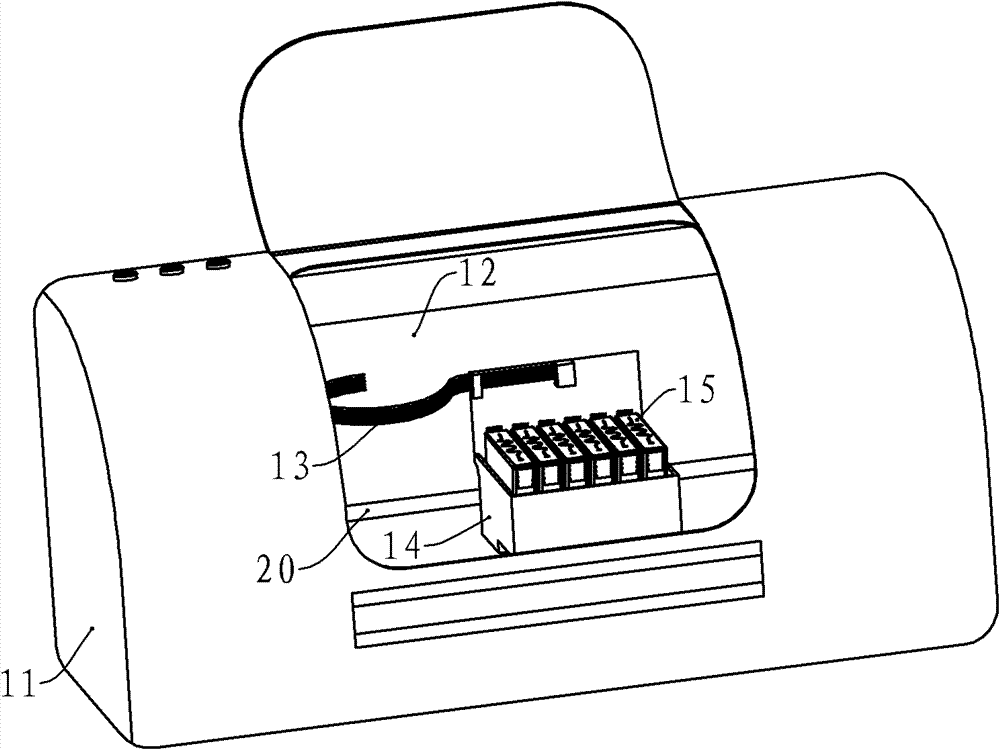

[0036] The ink cartridge of this embodiment is detachably installed in the inkjet printer, the inkjet printer has a casing, the casing is provided with a movement, the movement is provided with a circuit board, and the circuit board is provided with a main control circuit of the inkjet printer, Used to control the work of inkjet printers. Moreover, a slide bar is also provided in the casing of the printer, and the printing carriage can reciprocate in the casing along the slide bar under the drive of the motor.

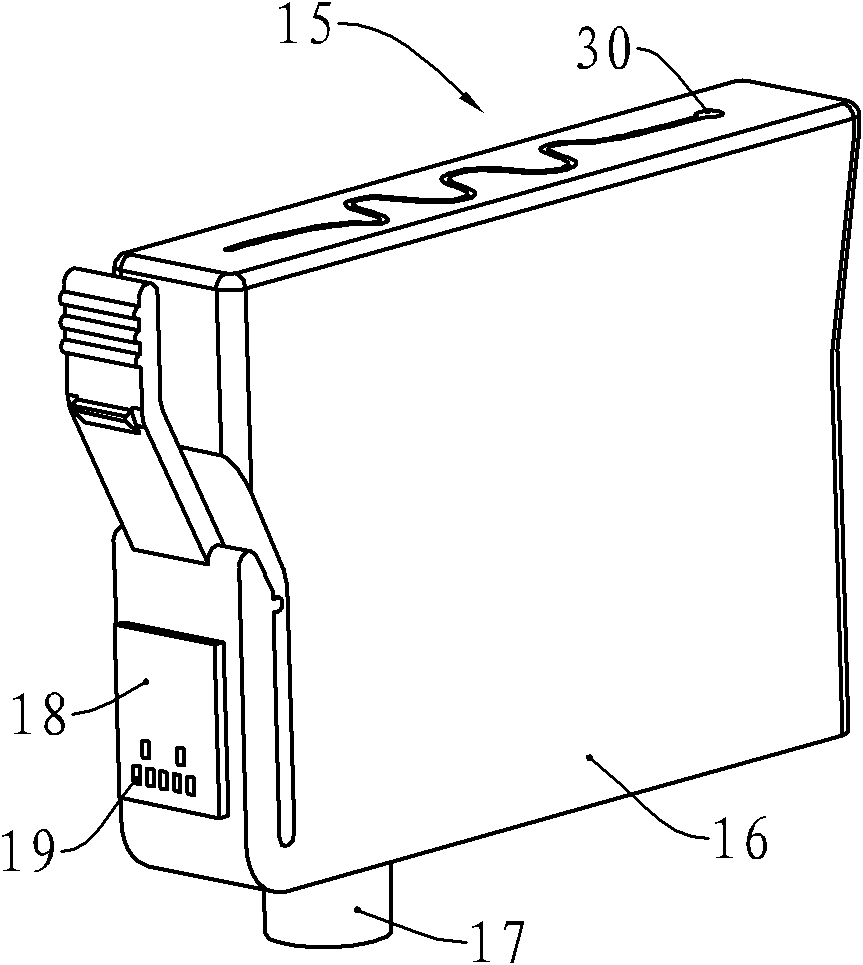

[0037] The printing carriage has a cavity into which a plurality of ink cartridges are detachably installed. Each ink cartridge has a shell, and the shell forms a cavity for containing ink. The lower end of the cavity is provided with an ink outlet through which the ink in the cavity flows out.

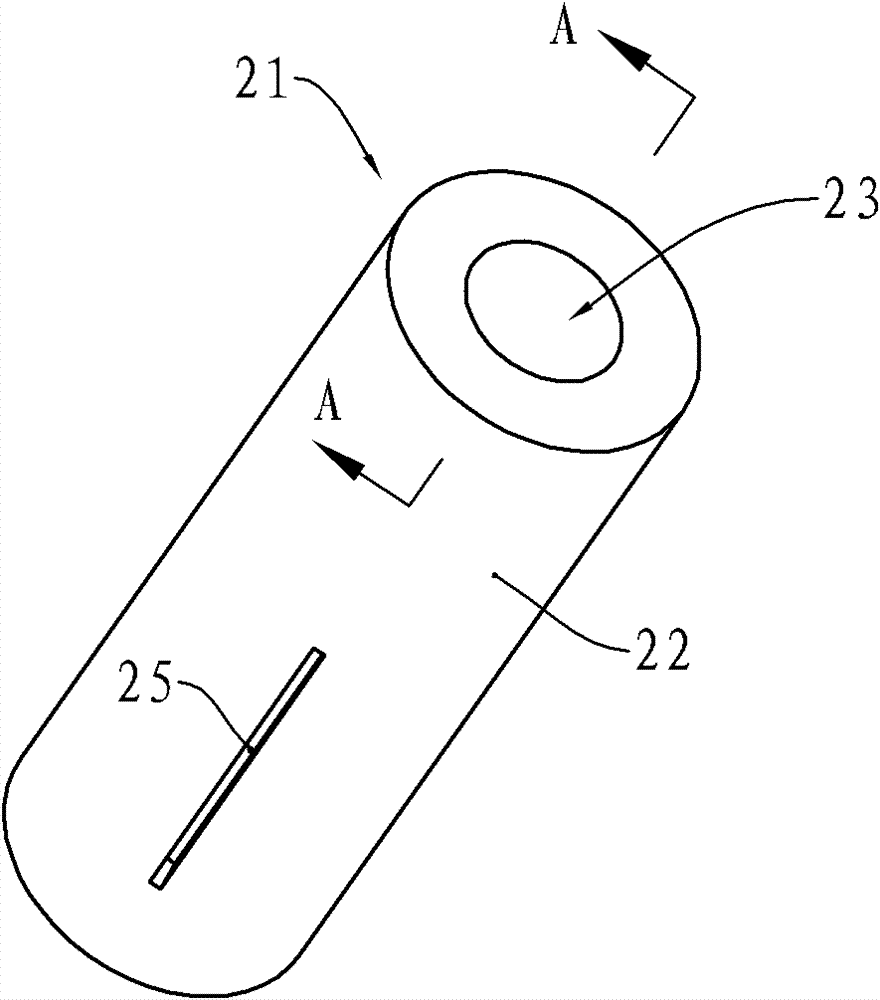

[0038] The chamber of the ink cartridge is divided into an ink storage chamber and an ink supply chamber, the ink storage chamber is connected to the ink outlet, and a check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com