Automatic detection type ink supply system for printer

An automatic detection and printing machine technology, applied in the direction of printing machines, printing, general parts of printing machinery, etc., can solve problems such as waste, working environment impact, ink fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

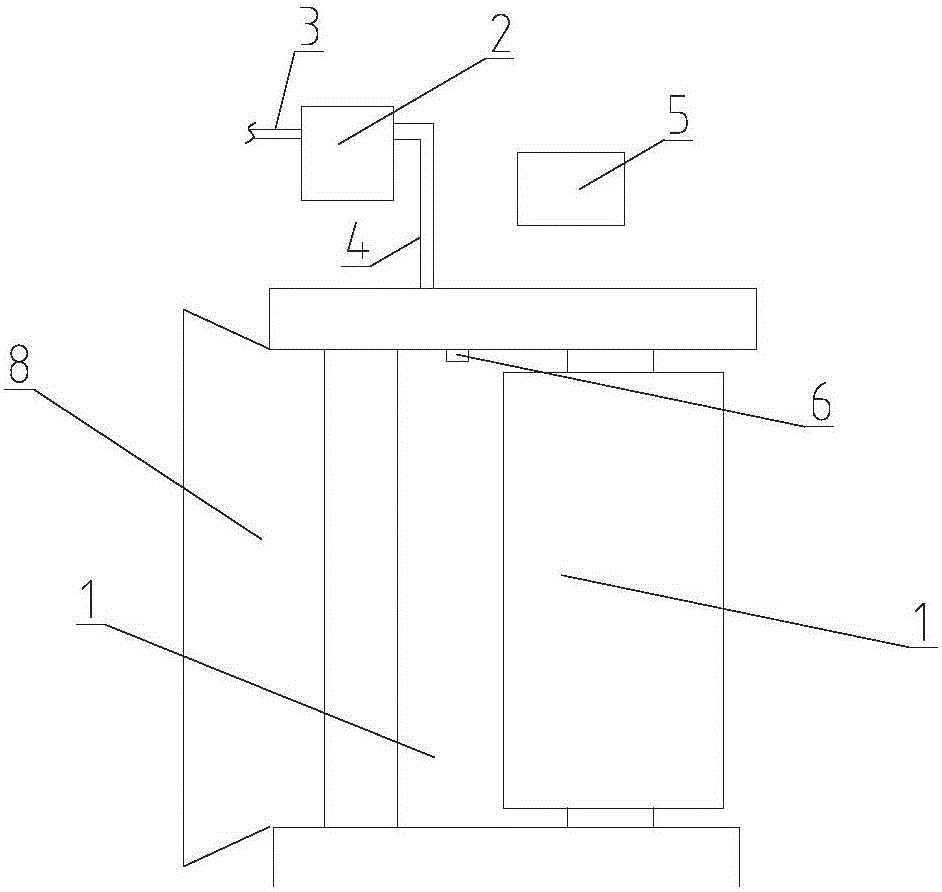

[0010] Such as figure 1 As shown: the printing machine automatically detects the ink supply system, including the printing roller set, the ink cartridge 1 and the ink supply pump 2. The ink supply pump 2 is connected with the ink inlet pipe 3 and the ink outlet pipe 4 respectively. A controller 5 and a flow sensor 6 are installed in the ink cartridge 1, and the controller is connected with the flow sensor 6 and the ink supply pump 2 respectively; Corresponding roller set. The return pipe 7 is a hose structure. The connecting end between the nozzle 8 and the ink cartridge 1 is a flexible structure.

[0011] During work, utilize the controller 5 to control the flow sensor 6, and when the ink exceeds its set flow value, the controller 5 controls the ink supply pump 2 to stop the ink supply, so as to prevent the ink in the ink cartridge 1 from exceeding a certain liquid level. Under the influence of the force generated when the printing roller group rotates, the ink in the ink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com