a printer

A technology for printers and machine cores, applied in typewriters, printing devices, printing and other directions, can solve the problems of printing can not be centered, easy to lose, inconvenient to operate, etc., to achieve the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

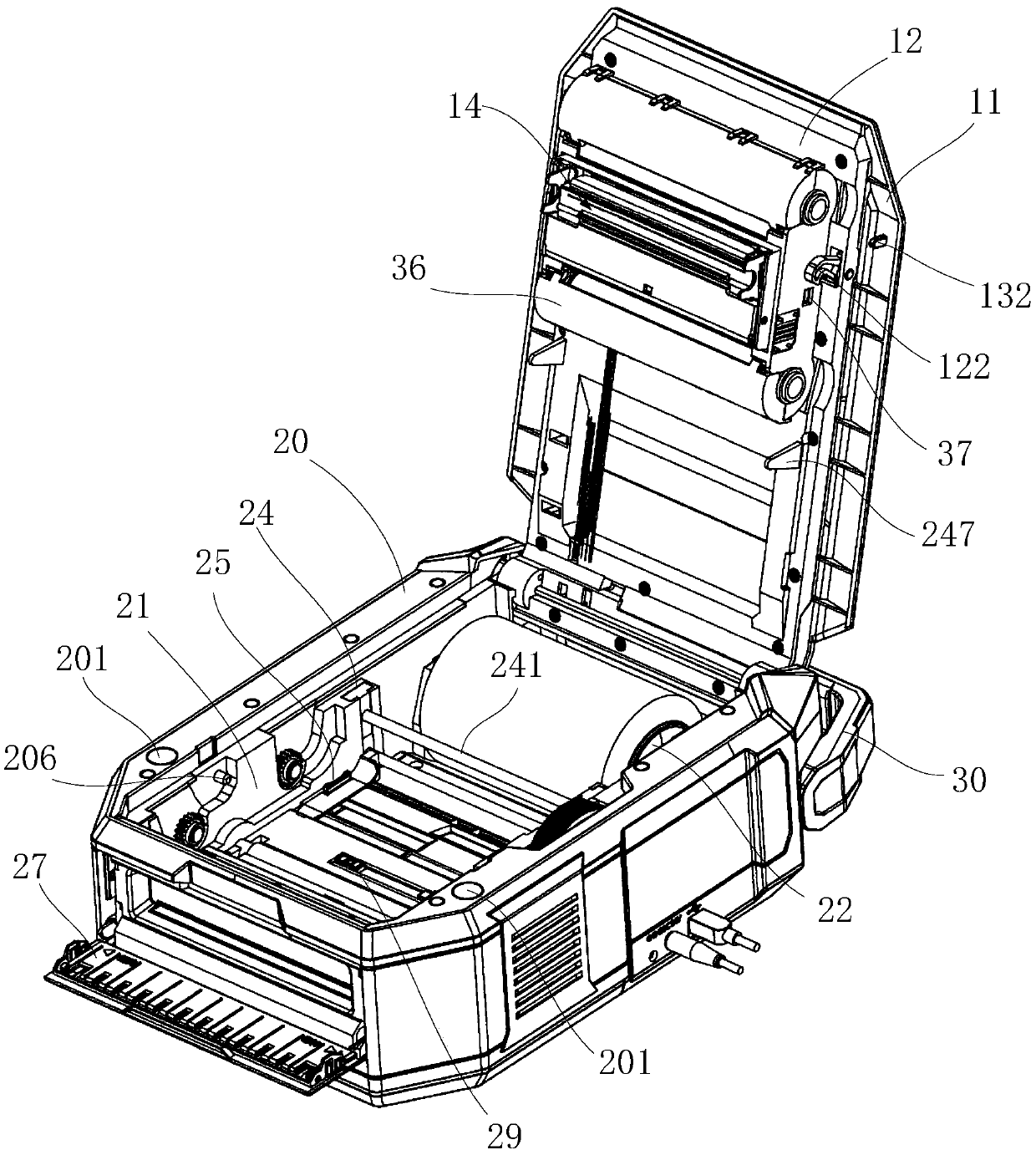

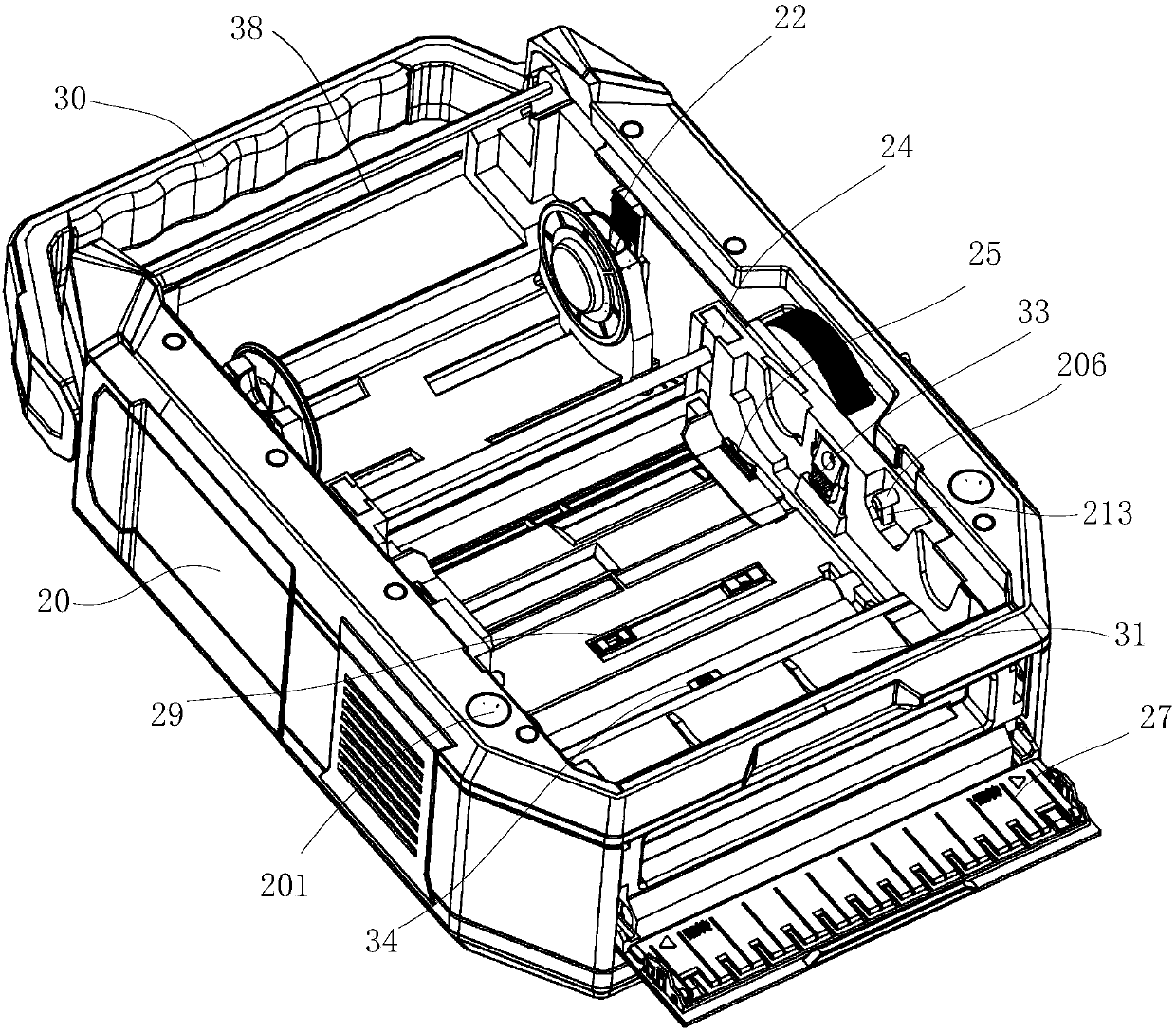

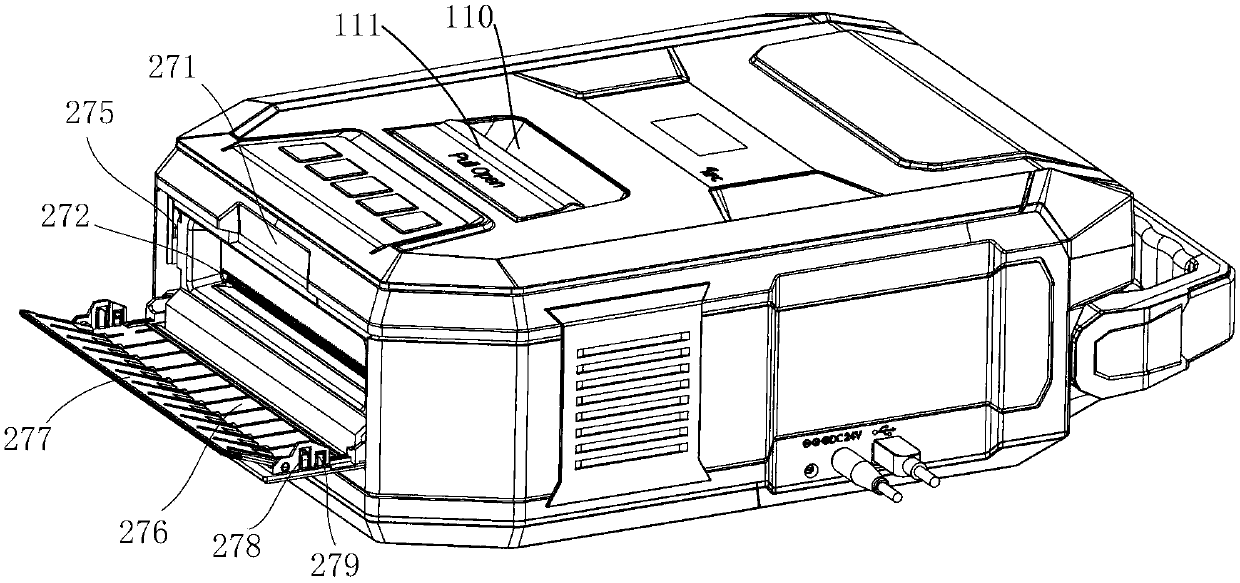

[0210] Such as Figure 1 to Figure 3 as well as Figure 11 As shown, a printer includes an upper case assembly and a lower case assembly, the rear ends of the upper case assembly and the lower case assembly are rotatably connected by a torsion spring 208 and a rotating shaft 207, and a locking cover is provided between the upper case assembly and the lower case assembly mechanism, an auxiliary ejection mechanism is provided between the upper case assembly and the lower case assembly. When the cover is opened, after the cover locking mechanism is unlocked, the auxiliary ejection mechanism pushes the upper case assembly out so that it is in contact with the lower case assembly. There is a gap between them, which is convenient for fingers to reach in and open the upper shell assembly. A paper support mechanism 27 is provided on the paper output side of the front end of the lower shell assembly. The paper support mechanism 27 includes a tray 276 and a supporting plate 277. The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com