Ultra-thin glass jet-printing jig and process method thereof

A technology of ultra-thin glass and jigs, which is applied in the direction of copying/marking methods, printing, printing devices, etc., can solve the problems that affect the quality of printing, the quality of ink printing cannot be guaranteed, and the glass fixing effect is not ideal, so as to achieve precise thickness control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

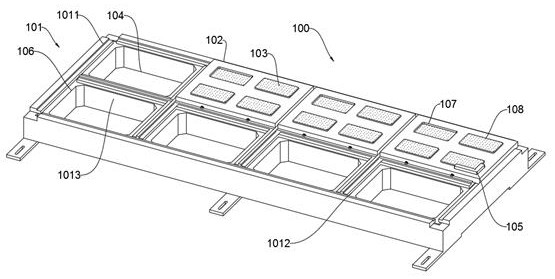

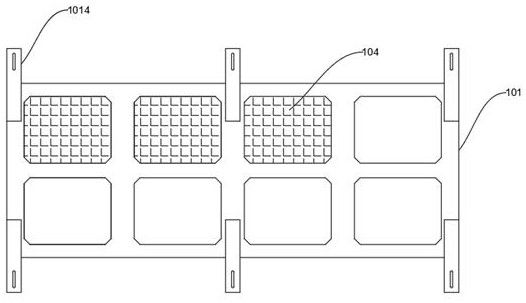

[0039]SeeFigure 1-4The present invention provides a technical solution: an ultra-thin glass printing fixture, including a jug body 100, and a fixture body 100 includes a positioning fixture 101, a fixture plate 102, a placed platform 103, a heating plate 104, and a positioning member. 105; The positioning fixture 101 includes an outer frame 1011, a plurality of vertical positioning columns 1012, the lateral positioning post 1013, and a plurality of mounting sheets 1014 mounted on both sides of the outer frame 1011, and the lateral positioning column 1013, respectively, and the inner wall of the outer frame 1011, respectively. The vertical positioning column 1012 is symmetrically distributed on both sides of the lateral positioning post 1013, and the vertical positioning column 1012 divides the outer frame 1011 lateral positioning column 1013 to several work area 106.

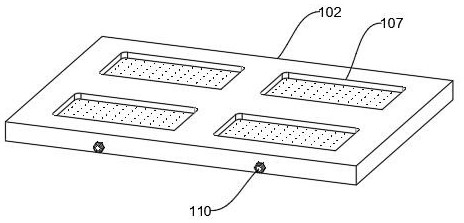

[0040]The fixture plate 102 is mounted on the upper portion of the work area 106, and the heating plate 104 is mounted...

Embodiment 2

[0058]SeeFigure 1-4The present invention provides a technical solution: an ultra-thin glass printing fixture, including a jug body 100, and a fixture body 100 includes a positioning fixture 101, a fixture plate 102, a placed platform 103, a heating plate 104, and a positioning member. 105; The positioning fixture 101 includes an outer frame 1011, a plurality of vertical positioning columns 1012, the lateral positioning post 1013, and a plurality of mounting sheets 1014 mounted on both sides of the outer frame 1011, and the lateral positioning column 1013, respectively, and the inner wall of the outer frame 1011, respectively. The vertical positioning column 1012 is symmetrically distributed on both sides of the lateral positioning post 1013, and the vertical positioning column 1012 divides the outer frame 1011 lateral positioning column 1013 to several work area 106.

[0059]The fixture plate 102 is mounted on the upper portion of the work area 106, and the heating plate 104 is mounted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com