Tooth knife punching die structure for knife bending machine and knife bending machine

A punching die and machete machine technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of punching precision impact, frequent mold adjustment, etc., and achieve the effect of height adjustment guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

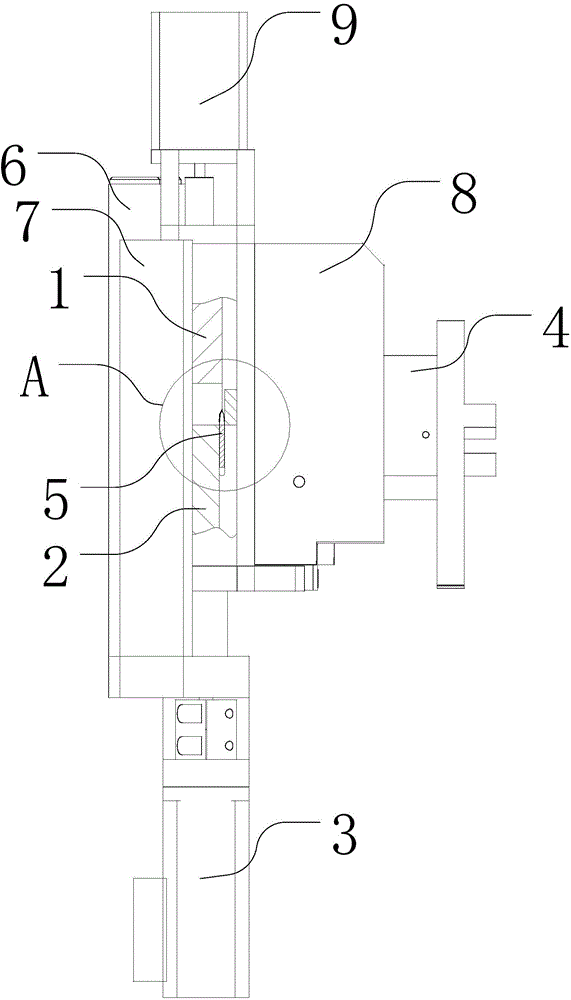

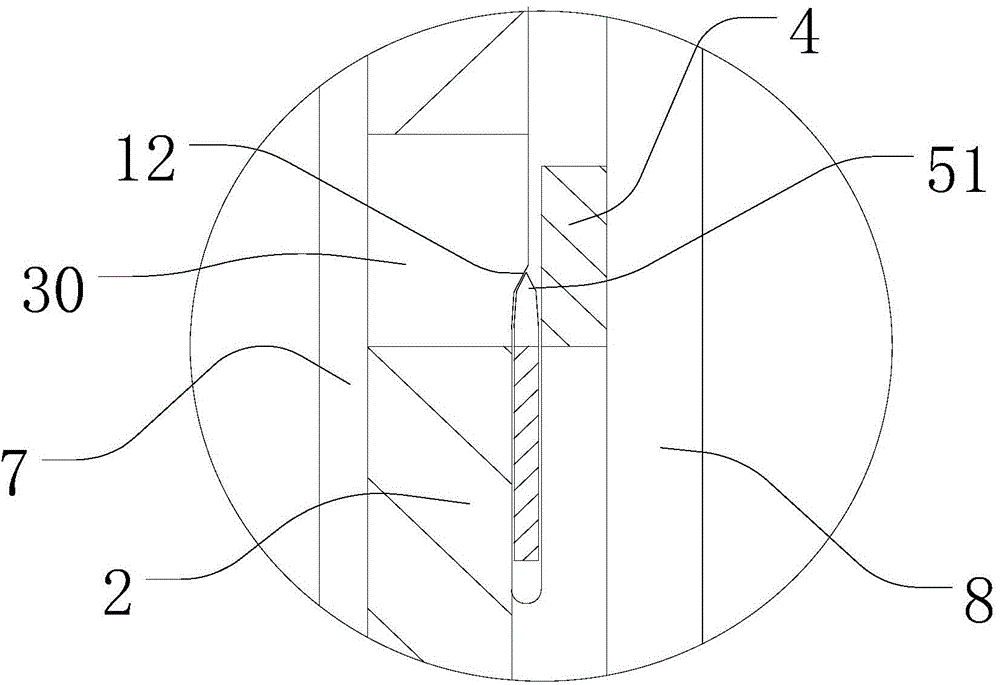

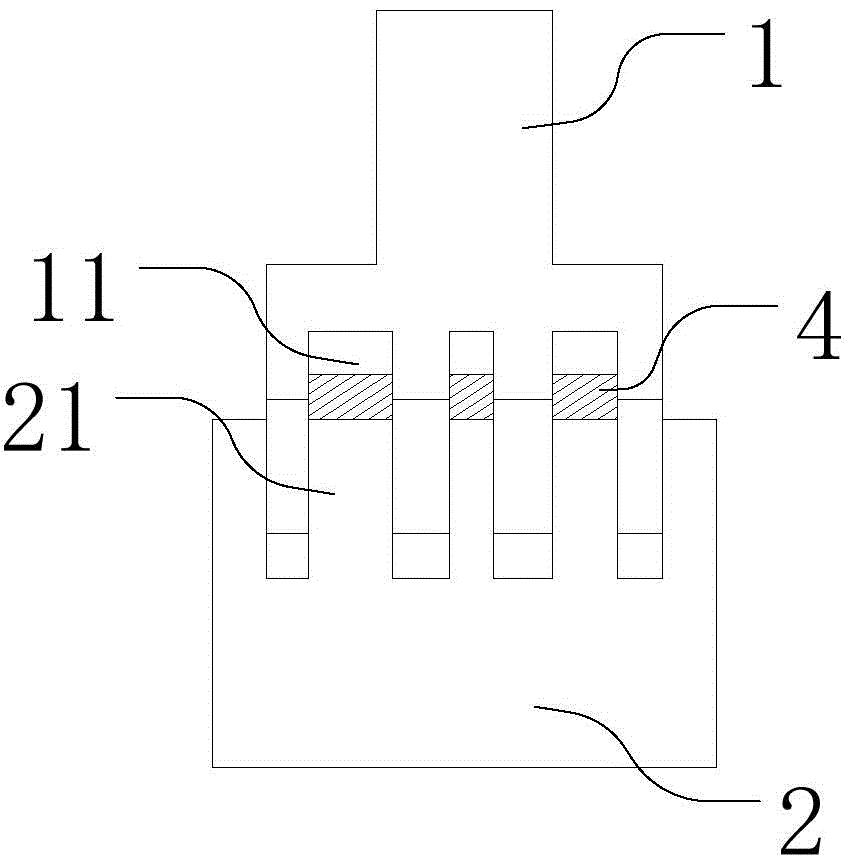

[0021] The embodiment of the present invention provides a punching die structure with a gear knife for a machete machine, combining Figure 1 to Figure 3 As shown, it includes: pillow mold 1, bottom mold 2, bottom mold driving mechanism 3, punching male mold 4, pillow mold 1 and bottom mold 2 are located on the same side, punching male mold 4 is located on the opposite side, pillow mold 1 1. Between the bottom mold 2 and the punching male mold 4, a blade channel for the passage of the blade is formed. The lower end surface of the pillow mold 1 is provided with a groove 11 that runs through the front and back and matches the width of the punching male mold. The upper end surface of the bottom mold 2 is provided with The bump 21 matching the width of the groove 11, the pillow mold 1 and the bottom mold 2 are set up and down oppositely, and the groove 11 is matched with the bump 21 to form a die matching the width of the punching die 3 hole 30, the bottom mold 2 is driven by the ...

Embodiment 2

[0030] A machete machine is provided in this embodiment, which includes a toothed knife punching die, a blade grinding device and a machete device, wherein the blade grinding device and the machete device all adopt the structure of the prior art. Needless to repeat, the gear knife punching die adopts the structure of the gear knife punching die for a machete machine in the above-mentioned embodiment 1. For the specific structure and working principle, reference may be made to the description in Embodiment 1 above in detail, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com