Combined pressure hole equipment

A combination and equipment technology, applied in the direction of metal processing, etc., can solve the problems of complex structure of the punching device and poor punching effect, and achieve the effect of simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

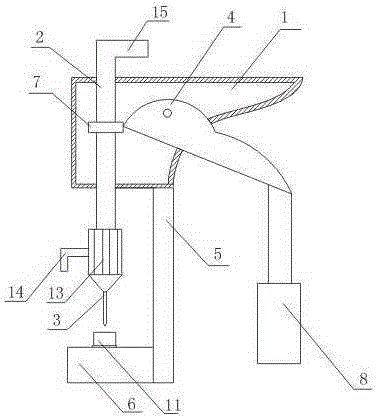

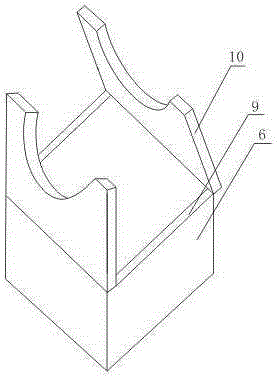

[0022] Such as figure 1 , figure 2 As shown, a combined punching device includes a fixed handle 1 with a cavity structure, a sliding rod 2 slidingly arranged in the fixed handle 1 through the upper and lower end faces of the fixed handle 1 , and a drill needle arranged at the bottom of the sliding rod 2 3. The movable handle 4 hinged on the fixed handle 1, the support rod 5 fixed on the lower end of the fixed handle 1 and the adjustment seat 6 connected with the support rod 5; one side of the fixed handle 1 is completely open, and also includes a The chuck 7 on the 2, one end of the movable handle 4 is connected with the chuck 7, and the other end runs through the side opening of the fixed handle 1 and is located outside the fixed handle 1; it also includes a hydraulic device 8 fixed on the other end of the movable handle 4; The adjusting seat 6 includes a base 9 and a cover 10 respectively hinged on both sides of the upper surface of the base 9. The side of the cover 10 has...

Embodiment 2

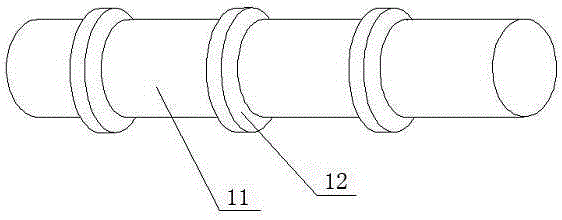

[0025] This embodiment is on the basis of embodiment 1, as image 3 As shown, retaining rings 12 are evenly distributed on the bottom rod 11 from bottom to top along the axis direction of the bottom rod 11 , and the diameter of the retaining rings 12 is larger than that of the bottom rod 11 .

[0026] When it is necessary to adjust the distance between the material to be punched and the drill pin 3, the cover 10 hinged on both sides of the upper surface of the base 9 is opened, and the bottom rod 11 is placed in the base 9. When the bottom rod 11 reaches the When in place, the two side shields 10 are covered. Since the diameter of the retaining ring 12 is larger than that of the bottom rod 11, the position of the bottom rod 11 will be fixed.

Embodiment 3

[0028] On the basis of embodiment 1 or embodiment 2, this embodiment further includes a cone head 13 fixed on the lower end of the slide rod 2 through threaded connection, and the drill needle 3 is fixed on the bottom of the cone head 13 . It also includes a handle 14 fixed on the side surface of the cone head 13 .

[0029] When the material to be punched is thicker or the strength of the hand is difficult to complete the hole, while the above operation, rotate the handle 14 with the other hand, the drill needle 3 will move up and down and act on the material to be punched again, thereby assisting Finish punching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com