Intelligent profile rolling assembly line

An intelligent, assembly-line technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of single profile product, limited application scope of profile rolling line, and high production cost, to ensure punching effect, profile products Rich, simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

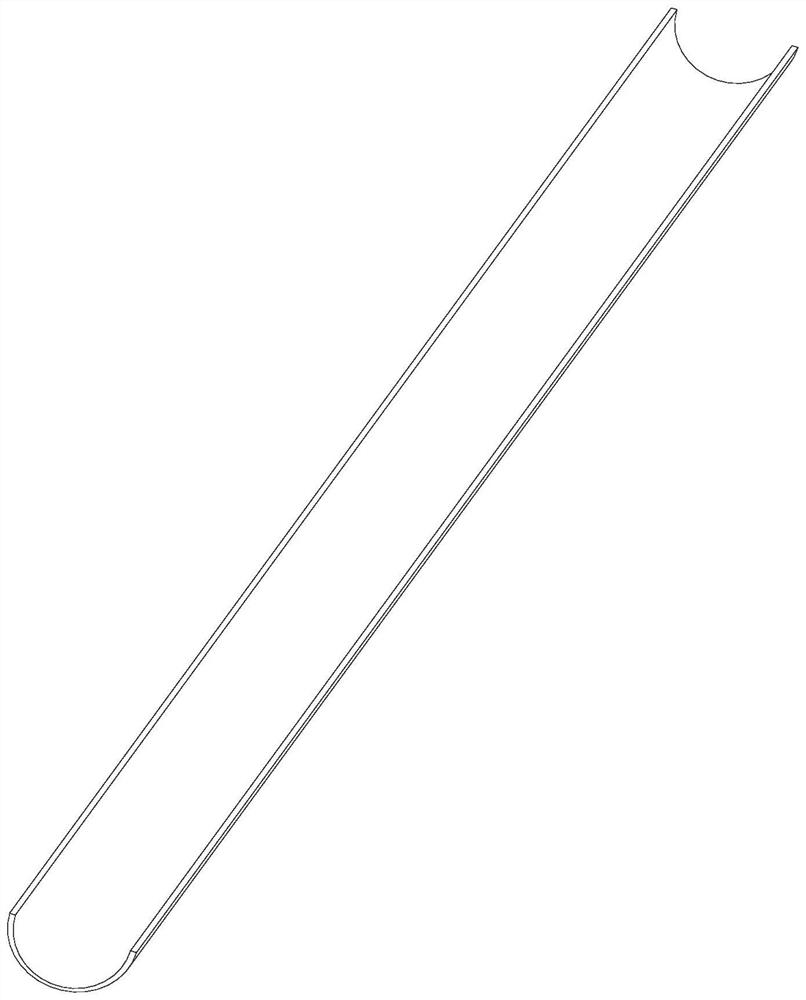

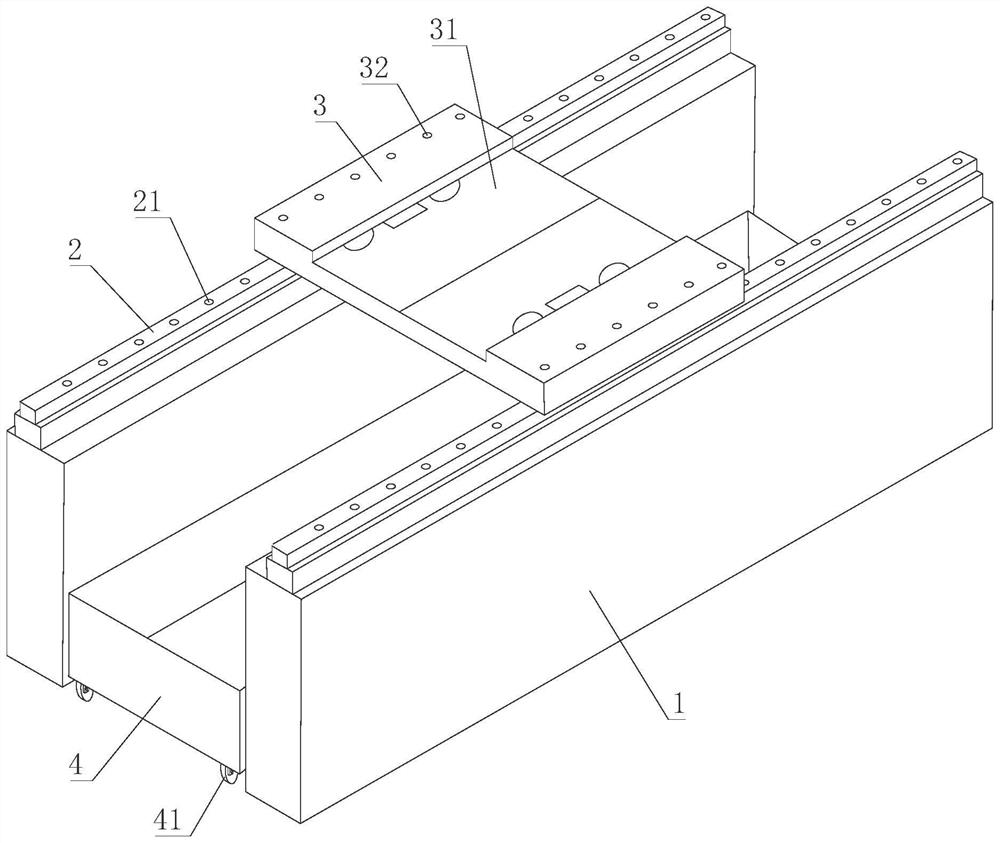

[0025] refer to Figure 3-4 , an intelligent profile rolling assembly line, including a control system and an unwinding mechanism, a straightening mechanism, a punching system, a roll forming mechanism and a cutting mechanism arranged sequentially along the conveying direction of the metal strip, the unwinding mechanism, the straightening mechanism , punching system, roll forming mechanism and cutting mechanism are all connected and controlled by the control system. During operation, the metal coil is released by the unwinding mechanism, adjusted to a straight metal strip by the straightening mechanism, and then passed through the punching system. The metal strip is blanked out to the required shape intermittently, then the Rongguang roll forming mechanism rolls it into the required profile, and finally cuts it into sections according to the required length by the cutting mechanism.

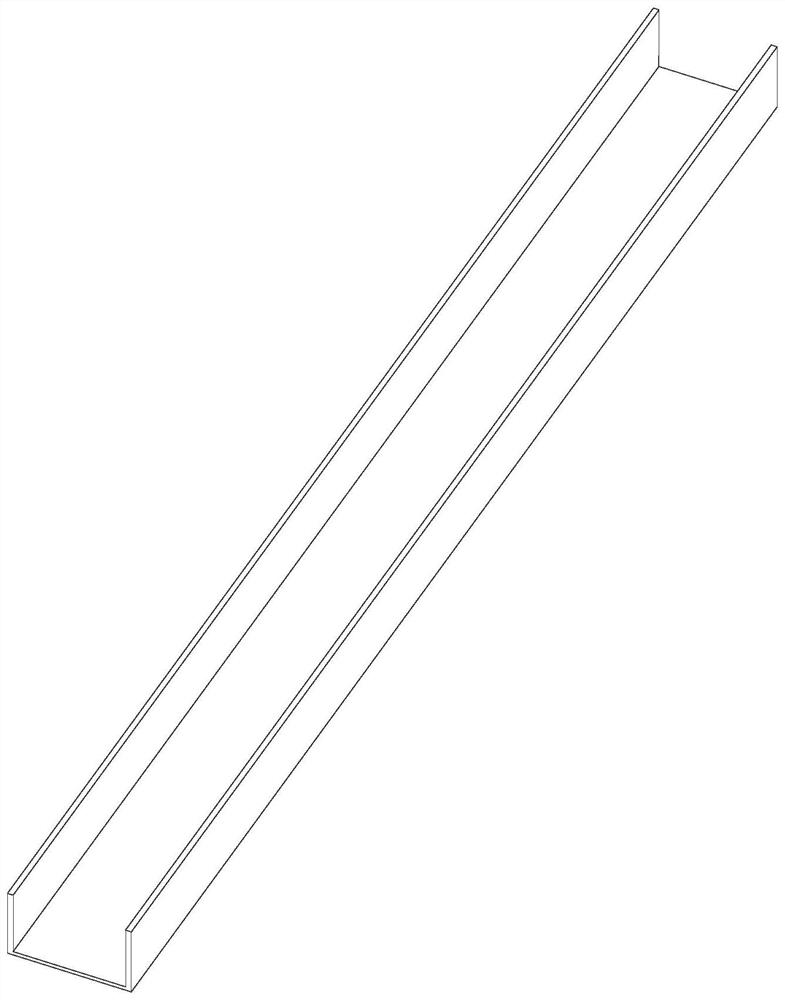

[0026] In this embodiment, the blanking system includes two supporting bases 1 arranged in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com