Punching die mechanism with waste-falling protection sleeve

A technology of die mechanism and protective sleeve, applied in the field of punching die mechanism, can solve the problems of affecting the blanking effect, lack of protective parts, and waste stuck, and achieves the punching effect, the impact force is reduced, and the replacement and maintenance are convenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

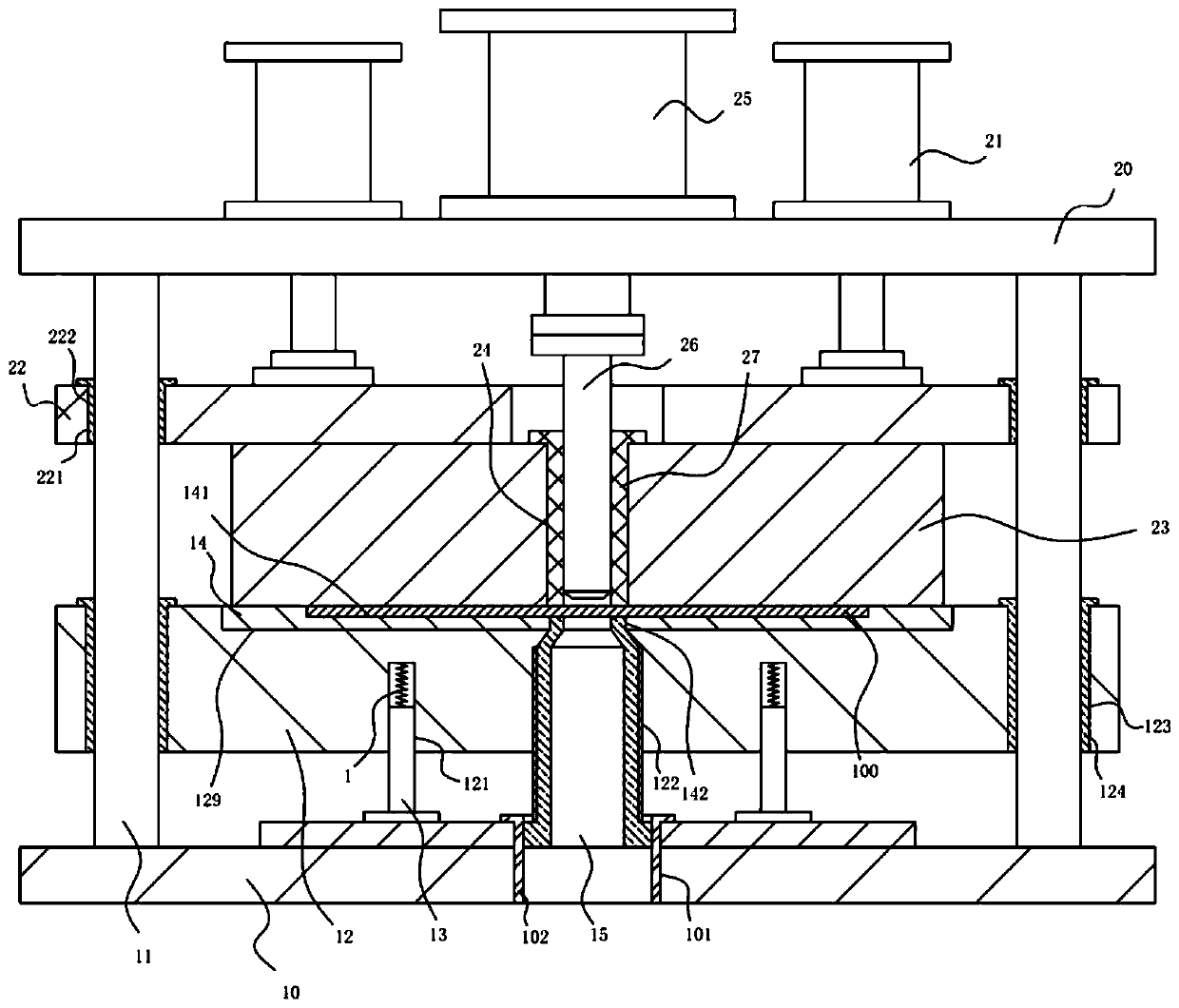

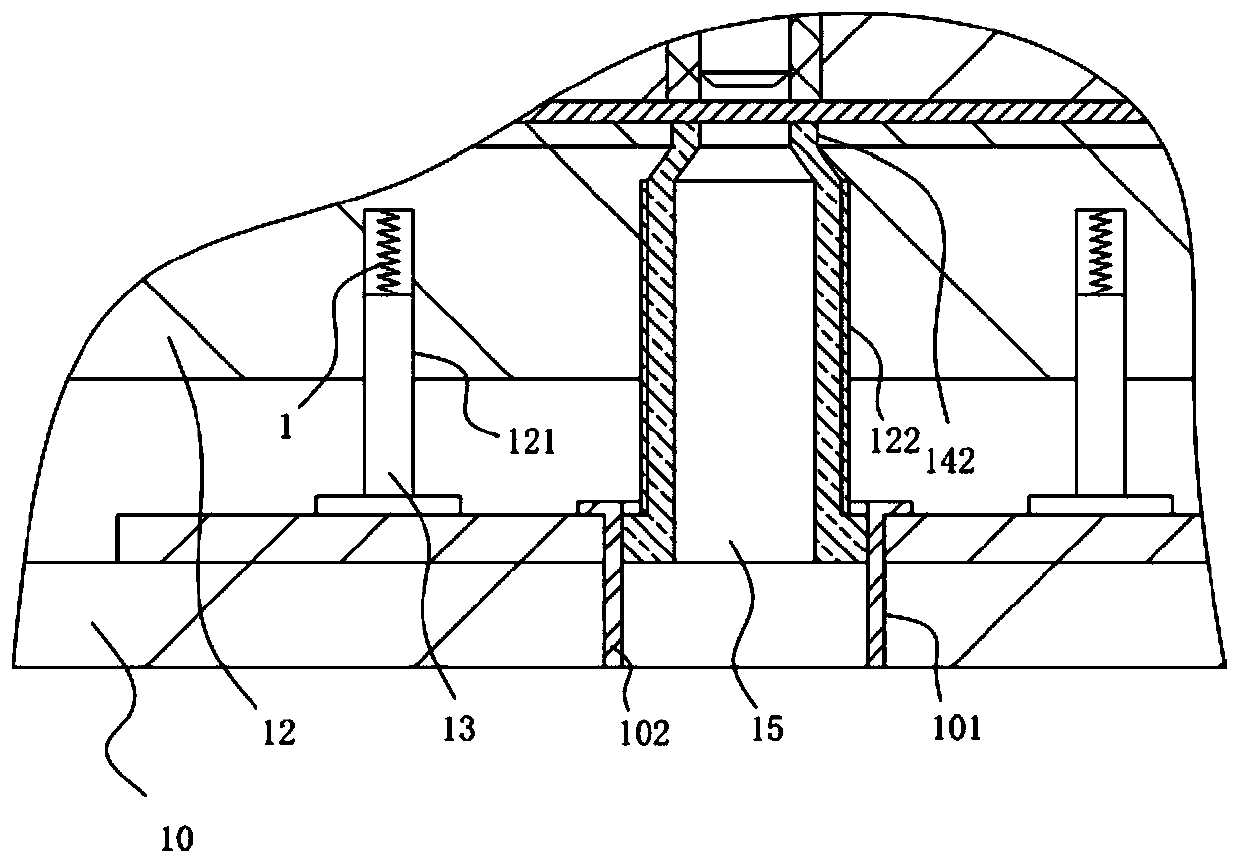

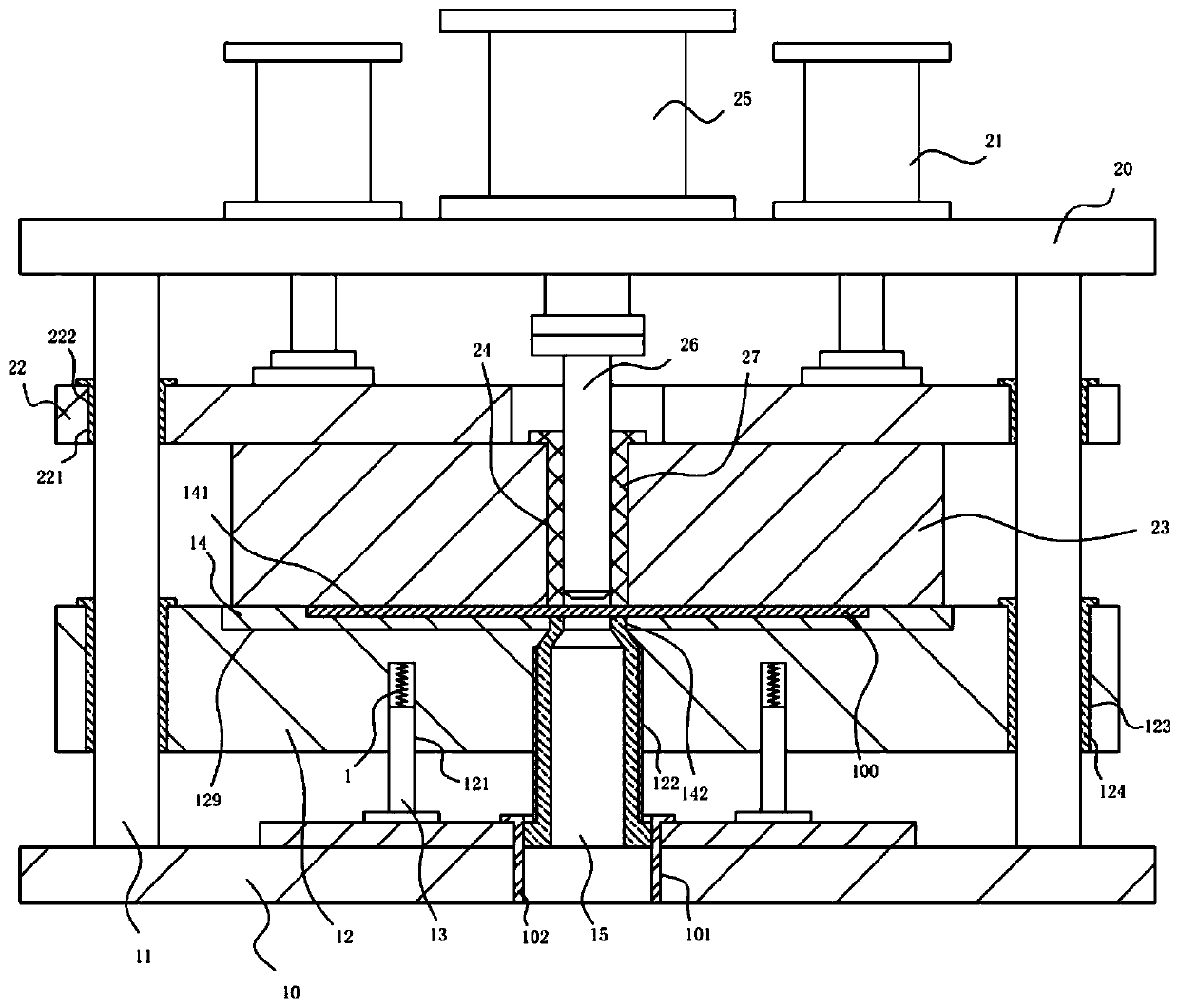

[0019] Example: see Figure 1 to Figure 2 As shown, a punching die mechanism with a blanking protective sleeve includes a lower mold fixed bottom plate 10, a plurality of vertical guide columns 11 are fixed on the top surface edge of the lower mold fixed bottom plate 10, and an upper fixed plate 20 is fixed on the top surfaces of all vertical guide posts 11;

[0020] A lower fixed plate 12 is provided above the fixed bottom plate 10 of the lower mold, and the lower fixed plate 12 is inserted into all vertical guide columns 11, and a plurality of vertical buffer columns 13 are fixed on the top surface of the fixed bottom plate 10 of the lower mold. , the vertical buffer column 13 is inserted into the guide socket 121 formed on the bottom surface of the lower fixing plate 12, the buffer spring 1 is inserted into the guide socket 121, and the bottom end of the buffer spring 1 focuses on the top of the vertical buffer column 13. On the surface, the top of the buffer spring 1 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com